EDT EX-RAY User manual

EX-RAY

VOLTAGE

USER’s MANUAL

SPEED | DISTANCE | TEMP | CLOCK | BATT VOLTAGE

“An Aftermarket solution

for Electric Vehicles used

on-road or off-road”

Digital Speedometer Panel With Voltage

Meter for Golf Carts, NEV, Conversions

Normal Mode:

= Activate backlight manually

= Switch between screens in normal mode

= Start or stop the stop watch

Data Setting Mode:

= Enter data setting mode

= Switch between screens in data setting mode

= Scroll through current data setting

= Move to next digit of current data setting

Data Reset:

= Reset single-ride data

Adjustable Trip Distance Edit:

= Enter/exit adjustable trip distance edit mode

= Scroll distance value

Rally Mode:

= Enter/exit rally mode

= Scroll distance value

Lap Timer Mode:

= Enter/exit lap timer mode

= Clear lap timer data

= Start/stop lap timer

= Signal new lap

= Enter/exit lap data review mode

= Scroll through lap information

Short Cuts

2

3

Table Of Contents

2 Short Cuts (Quick Set up guide)

3 Table Of Contents

4 Welcome to EDT llc

> Enter Dealer and warranty purchase information

5 Precautions

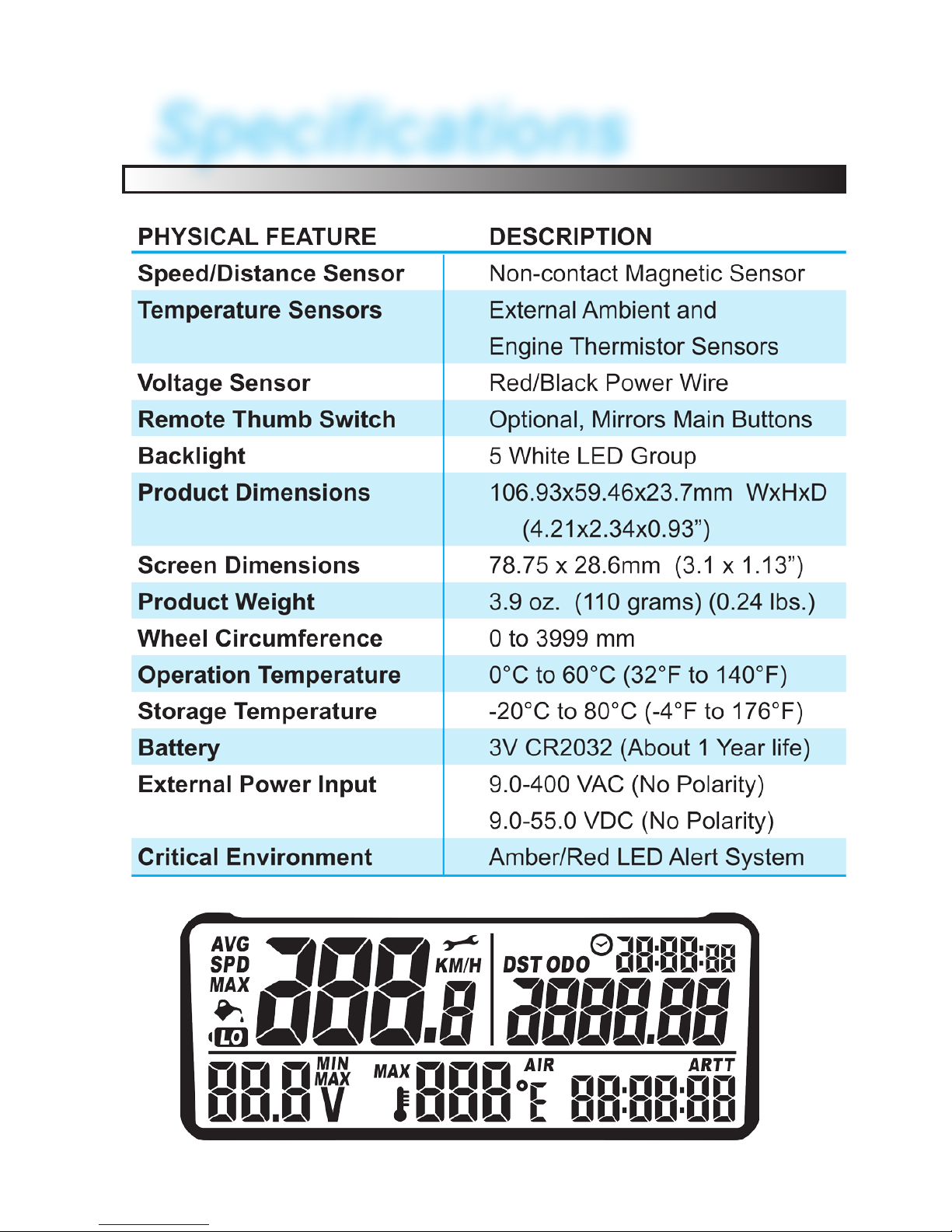

6 Specications

8 Overview

11 Installation

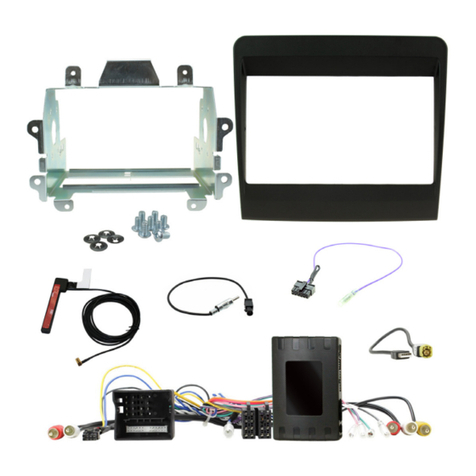

12 Parts Breakdown

13 Universal Bracket - Steering Column Mount

15 CNC Bracket - Steering Column Mount

18 Temp Sensor Mount

22 General Speed 10mm BOLT Sensor Installation

25-Short hub Mag, 28-31 Short-long axle,

32-Jakes Disc Brake, 34-ClubCar Lift

36 Speed TAB Sensor ClubCar XRT Installation

38 Power Cable Installation

39 Steering Column Wire Protector

40 Wheel Size Calculator

43 Data Setting Mode

> MPH/KPH, Temp limits, Time, DC Voltage

warnings, Maintenance,

52 Normal Screen Modes

> Screen 1-2-3, Sleep Mode, Reset data screens

54 EX-RAY Features

> Explanations of all screen data, settings, functions

63 Troubleshooting / FAQ’s

65 Inch to Metric Tire Size Conversion Chart

66 Glossary

68 EX-RAY Model Numbers, Kits, Replacement Parts

70 EX-RAY USER Setup notes and battery change dates

72 Warranty Statement

Thank you for purchasing an EDT.llc Product:

The EX-RAY™ is Digital Speedometer Display, the EX-RAY™

product line provides valuable information about your vehicle

for your gas or electric golf car or modied buggy, Neighbor-

hood Electric vehicle (NEV), or Small Task Oriented Vehicle.

Please read this manual carefully before installing your

EX-RAY™ Display. Note: This Manual intended as guide to

proper installation but cannot predict every possible applica-

tion. Some modications may be required.

EX-RAY™ is a trademark of the Energy Design Tek LLC

Company Oregon USA

Please Record Important Information:

For future reference and customer support, please record the

following information:

PURCHASE DATE: ______________________________

DEALER: ______________________________________

DEALER PHONE: _______________________________

EX-RAY MODEL (ON BOX): _______________________

Keep this manual, sales receipt, and original box for future

use. Serial Number TAG and WARRANTY last pages.

SAVE THESE INSTRUCTIONS

4

Welcome to EDT-Exray

Copyright ©2013

WARNING:

When using the EX-RAY™

follow basic precautions,

including the following:

• Read all instructions be-

fore using the EX-RAY™

• When installing the DC

Motor temperature Sensor,

be careful removing the

bolt and not to damage the

motors internal eld coil.

EDT llc is not responsible

for damage done during this

process.

• Use EX-RAY™ only for its

intended purpose.

• To reduce rick or injury, do

not disassemble EX-RAY™

or its accessories.

• EX-RAY™ can be used

in the rain but should not be

used under water.

• Do not leave the main unit

in direct sunlight when not

being used.

• Check magnetic sensor

gap and magnet mounting

periodically.

• Do not bend, twist, kink, or

otherwise abuse the sensor

cables. A damaged cable

may produce incorrect read-

ings.

• When installing EX-RAY™,

turn the vehicle power off

(or ignition switch off); the

wires carry power from the

vehicles battery.

• Avoid contact with gaso-

line, de-greasers or other

chemical cleaners as they

may damage the EX-RAY™.

• Do not exceed 60VDC at

any time as this may dam-

age the EX-RAY™.

Precautions

5

Copyright ©2013

Specications

6

7

Specications

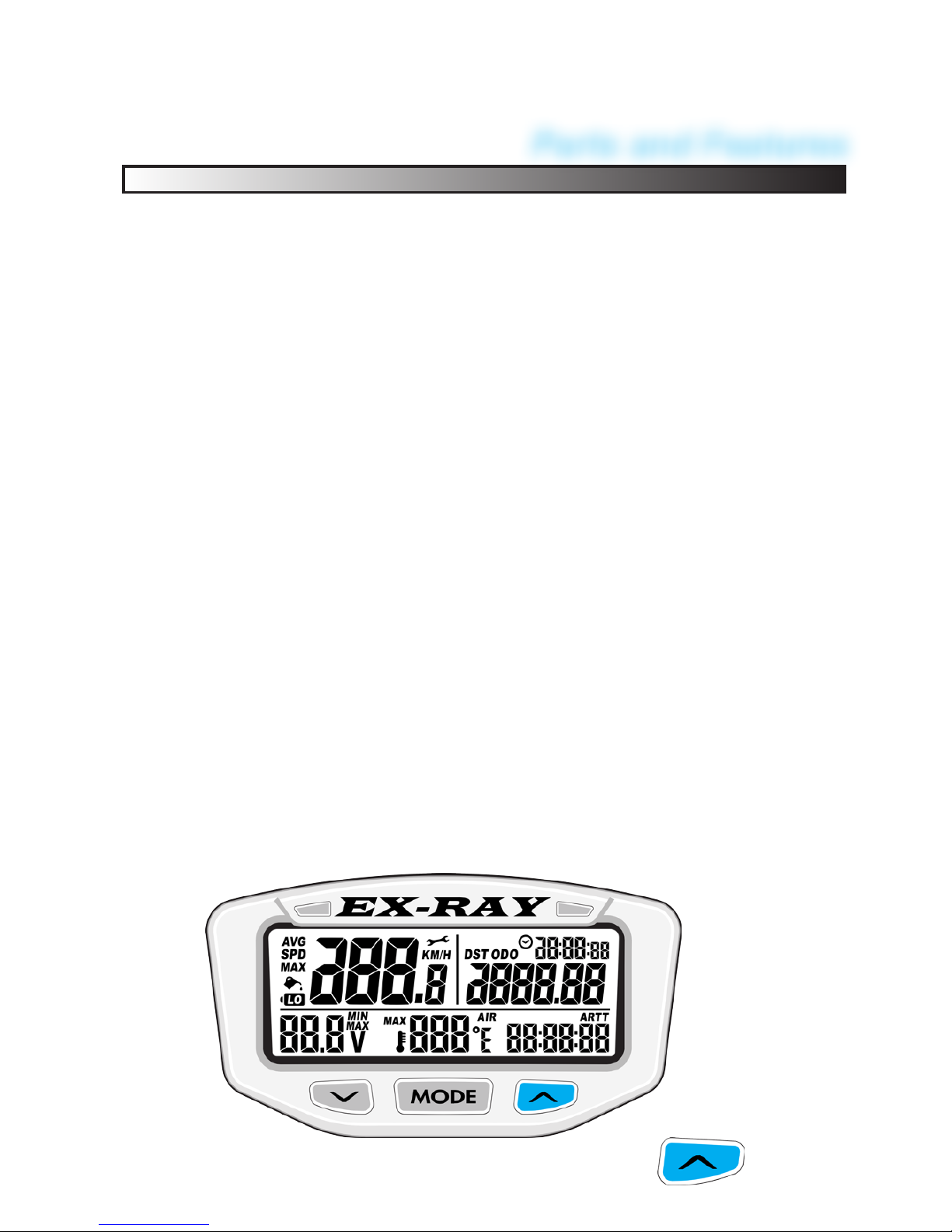

Overview

EX-RAY

™ Digital Speedometer:

Main Display:

• The display panel includes 3-user buttons, 2-warning

LED’s, and the LCD screen.

LED’s:

• Amber LED: Lights for temperature warning alert

(SOLID), Battery LOW Warning (FLASH).

• Red LED: Lights for over-temperature alert (SOLID)

and Battery LOW DANGER (FLASH).

Remote Switch (optional):

• The optional remote switch (sold separately) may be

required when access to the display buttons is not pos-

sible. Contact EDT llc for more information. (This is not a

standard option and special order only)

8

UP

MODE

DOWN

Small arrow

faces UP

Remote

Switch

Amber

LED

Red

LED

LCD

Screen

DOWN Left

Button

UP Right

Button

MODE Center

Button

Parts and Features

9

TO ACTIVATE BACKLIGHT MANUALLY PRESS

Display Backlight:

EX-RAY is equipped with a backlight for easy viewing during

night time operation.

Using External 12V Power:

• Display Backlight will light up with all ve backlight LED’s

• EX-RAY will remain lit as long as it senses wheel move-

ment. After 20 minute of inactivity, EX-RAY shuts off

the backlight. Press any button, roll the wheels, turn on

key switch (electric golf cars) or start the engine (gas golf

cars) and EX-RAY will light up again

• Amber and Red LED’s enabled (Shift or temperature)

Using Internal Batteries Only:

• EX-RAY will only stay lit for 3 seconds

• EX-RAY backlight will light up with 10% power to conserve

the internal battery power.

• If the LO symbol is present, the backlight will not turn

on. The LO symbol appears when battery voltage drops

below 2.45V

• If ambient temperature is cold (below -5°C, 23°F) the

backlight will not turn on.

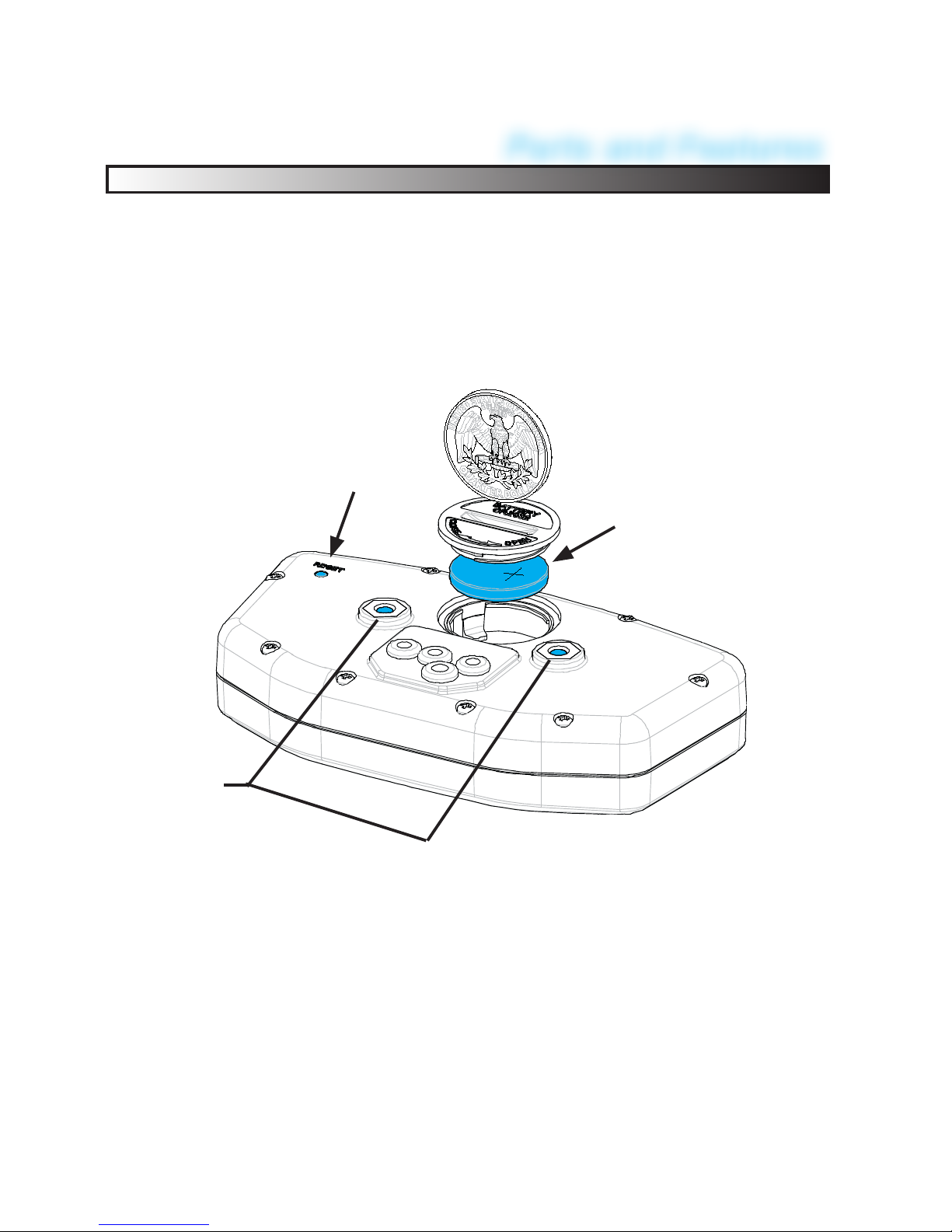

Battery

Reset

4mm

Mounting

Holes

Reset Button:

Use the Reset Button to erase data form the current ride includ-

ing clock and trip distance. Reset may also be required when

ever UNPLUGGING A SENSOR. (Forced computer to re-read

the sensor )

Internal Battery:

• EX-RAY has an internal non-rechargeable Lithium watch

type battery (#CR2032). The computer can be run from the

internal battery without external connection to vehicle power

source.

• To change the battery, unscrew the battery cap on the back oft

he computer with a coin. Make sure the POSITIVE SIDE of

the battery is FACING UP when replaced.

• REPLACE WITH BATTERY MODEL NUMBER CR2032

10

Parts and Features

Installation

11

Unpacking the Display:

Carefully remove the display from the packaging and verify all

the parts are included for your application.

Carefully remove the EX-RAY

cardboard TRAY from the box.

Be careful not to damage the rear

mounted connectors.

A sheet included will list the com-

ponents included in this kit.

Remove the bottom separator

and remove the display mounting

bracket (CNC Bracket Shown,

your application may vary). Color

options also available.

12

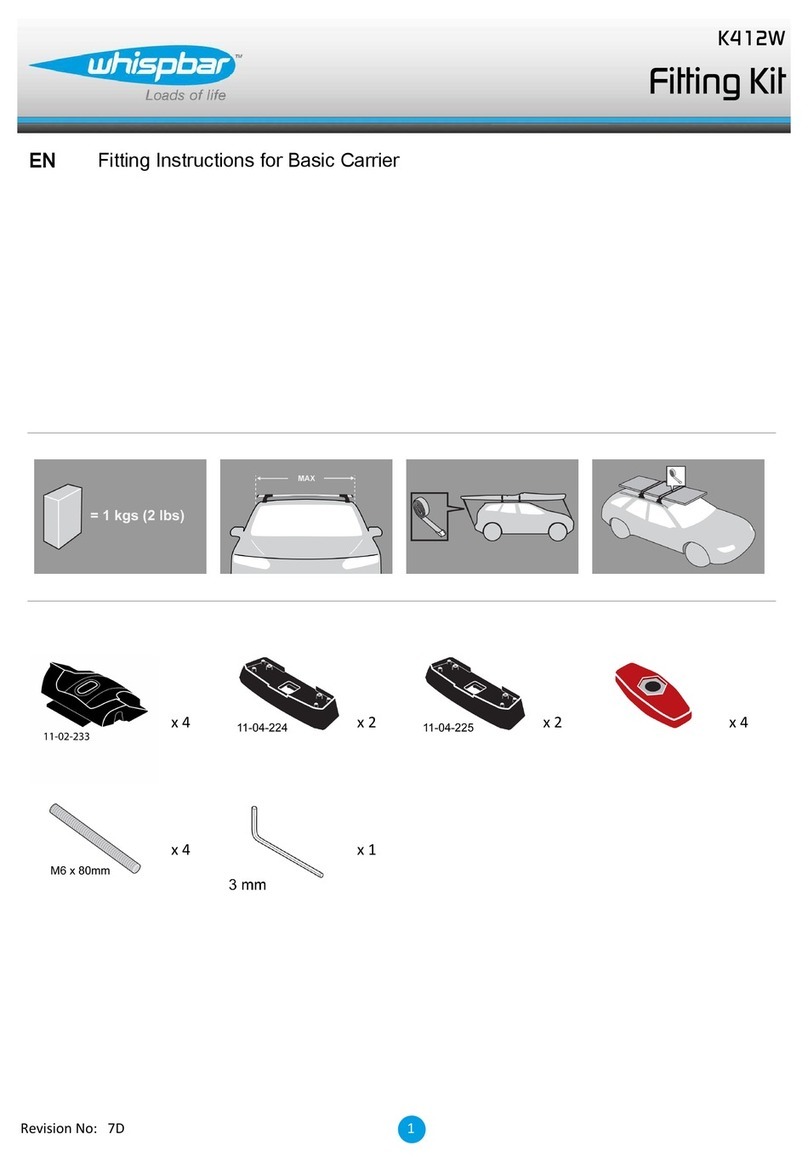

PARTS BREAKDOWN:

The kit includes the following:

1) 6MMx12MM Metric Magnetic bolt

mounts on the front DRIVERS side

wheel HUB with bracket and clamp. (In-

stall sheets may detail drilling the hub)

1) Speed Sensor that mounts on the

AXLE (either a 65” long 10MM BOLT or

or 65” long PLASTIC TAB speed

Sensor depending on your application.

1) Power Wires that connects to your

12Volt accessory system to provide

backlight and LED power. This cable

also used for Battery Voltage reading.

1) Temp Sensor mounting to the elec-

tric motor eld coil bolt or to a 10mm

bolt on a gas engine golf cart.

1) Temp Sensor Extension Cable

from the motor to display.

1) Bag Misc. Hardware

1) Display Mount Bracket, Hardware

*EXRAY-UBOLT Universal Bracket

*EXRAY-Mxx CNC Machined

MEZ Ezgo, MCC ClubCar, MYAM, etc.

Installation Parts

> See end of this

book for model

number breakdown.

STEERING COLUMN MOUNTS:

Most installations will be on the Golf Cart Steering column using

the either the universal mount EXRAY-UBOLT, or optional CNC

6061-T6 Aluminum bracket EXRAY-MEZ. (Optional dashboard

mounting will include separate installation instructions).

Universal Bracket Mount

EXRAY-UBOLT

EXRAY-UXRT

The UBM will t on all column

diameters from 1” to 2”.

Note: Some vehicles have

plastic column cover in-

stalled. Some cutting may be

required for secure installa-

tion.

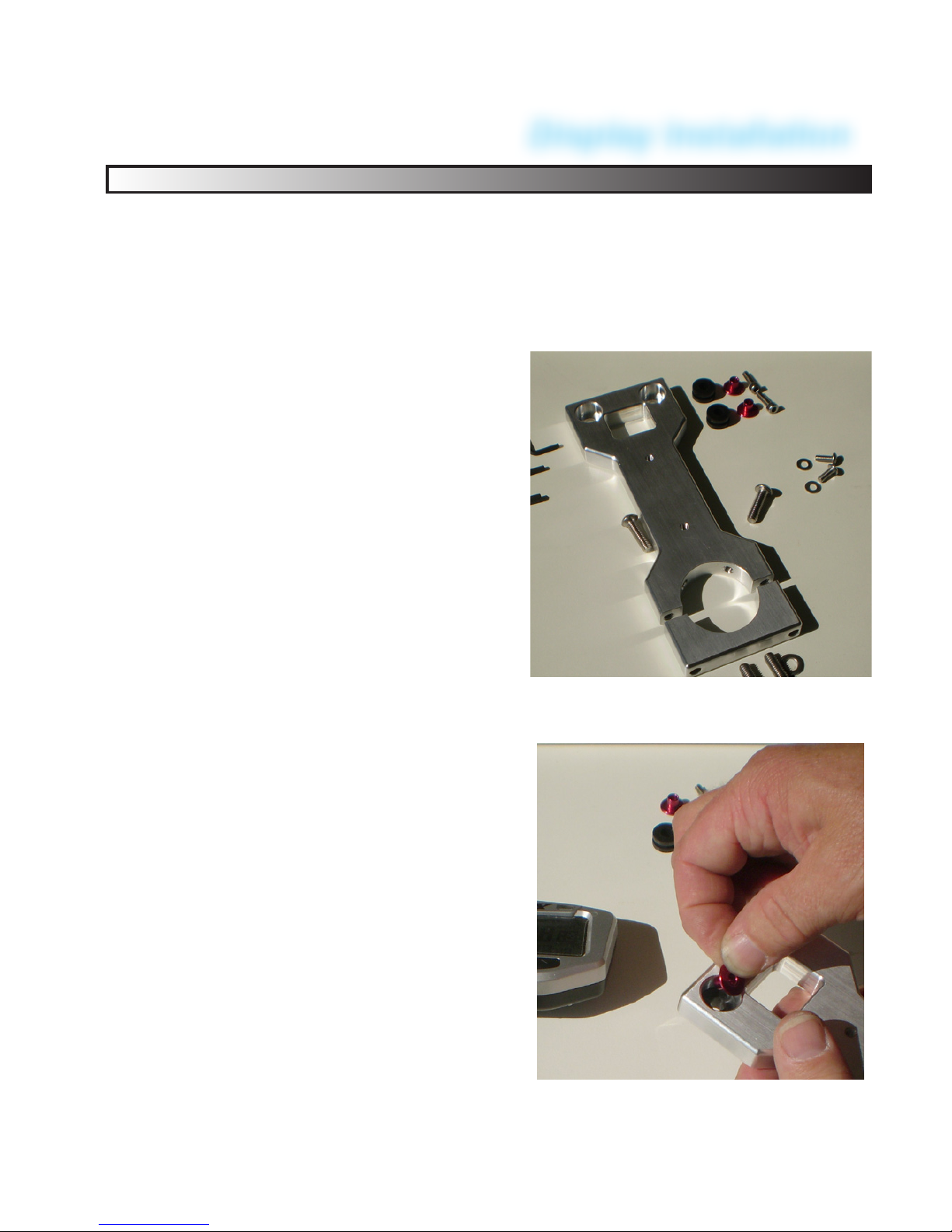

The parts shown include

rubber grommets inserted

into the display mounting

holes with 4mmx0.7x12mm

metric screws. Metric Allen

wrenches will be needed.

(See parts sheet)

The RED inserts are inserted

into the rubber grommets as

shown to the right. These are

stops to prevent the screws

from damaging the display.

The RED FLAT BACK is far-

thest away from the display. 13

Display Installation

Display Installation

14

Universal Bracket Mount:

Lay a soft cloth on the work surface

and lay the display face down. In-

stall the Display using the two 4mm x

12mm Allen head screws.

Notice the red at back is the bump

stop, the screws will stop when fully

compressed. The RED FLAT BACK

is farthest away from the display.

> DO NOT OVER TIGHTEN!

Install the pipe clamp onto the steer-

ing column.

Position the display 6 inches

(150mm) behind the steering wheel,

about 1 inch (25mm) away from the

steering wheel mounting hub.

Hand tighten the clamp bolt until the

display no longer moves and aligned

straight.

CNC Bracket Mount:

Steering tube column diameters vary between golf cart manufac-

turers, ensure you have the correct diameter before starting the

project. (Example: the 1.50” EZ-Go tube uses 1.51” Clamp)

MODELS:

• EXRAY-MEZ EZ-Go 1.51”

• EXRAY-MEZ-EZ RXV 1.59”

• EXRAY-MCC ClubCar 1.66”

• EXRAY-MYAM Yamaha 1.71”

• EXRAY-MCCP ClubCar with

Plastic Tube 1.76”

• EXRAY-MXRT-850E (ELEC)

EXRAY-MXRT-850G (Gas)

ClubCar XRT with Plastic

Tube 1.76”

The parts shown include rubber

grommets inserted into the display

mounting holes 4mm x 12mm met-

ric screws. Metric Allen wrenches

will be needed (not included). (See

parts sheet)

The RED inserts are inserted into

the DEEP DRILLED HOLE sec-

tion. These are stops to prevent the

screws from damaging the display.

The RED FLAT BACK is farthest

away from the display. 15

Display Installation

Display Installation

16

CNC Bracket Mount:

Lay a soft cloth on the work surface

and lay the display face down. In-

stall the Display using the two 4mm x

12mm Allen head screws.

Notice the red at back is the bump

stop, the screws will stop when fully

compressed.

> DO NOT OVER TIGHTEN!

Insert the two 6mmx40mm Allen

head bolts (Cap Screws) with 1-at

washer. (Note bolts may differ from

picture)

Position the display 6 inches

(150mm) behind the steering wheel,

about 1 inch (25mm) away from the

steering wheel mounting hub.

Hand tighten the 6mm bolts until

the display no longer moves and is

straight.

CLUB CAR with plastic tube see next

page. (MCCP and MXRT Models)

Club Car with plastic cover:

(MCCP and MXRT Models)

Tighten the bottom 6mmx40mm

bolts as shown on the previous

page.

Insert the two 6mmx20mm (or

6mmx25mm bolts, which ever

came with your kit) into the

45 degree staking holes. Hand

tight them to just touch the plastic

tube. Then making sure the display

is straight up, 1/4 turn each bolt

side. Do not overtighten.

The display should be inside the

steering wheel window. If the dis-

play is too high, move it farther

away down the steering column

and tighten.

Note: Some stainless steering cov-

ers differ in size. The tube may

need to be cut to allow the EX-RAY

to t directly onto the steel steering

column. Measure tube diameter.

Steering Column Mount:

Some Club Car models utilized plastic tube covers. The

diameter of the CNC bracket accounts for this tube and uses

45 degree “Stake bolts” which lock the display in place. This

process will “ding” the plastic tube permanently, but neces-

sary to lock the display in place.

Display Installation

17

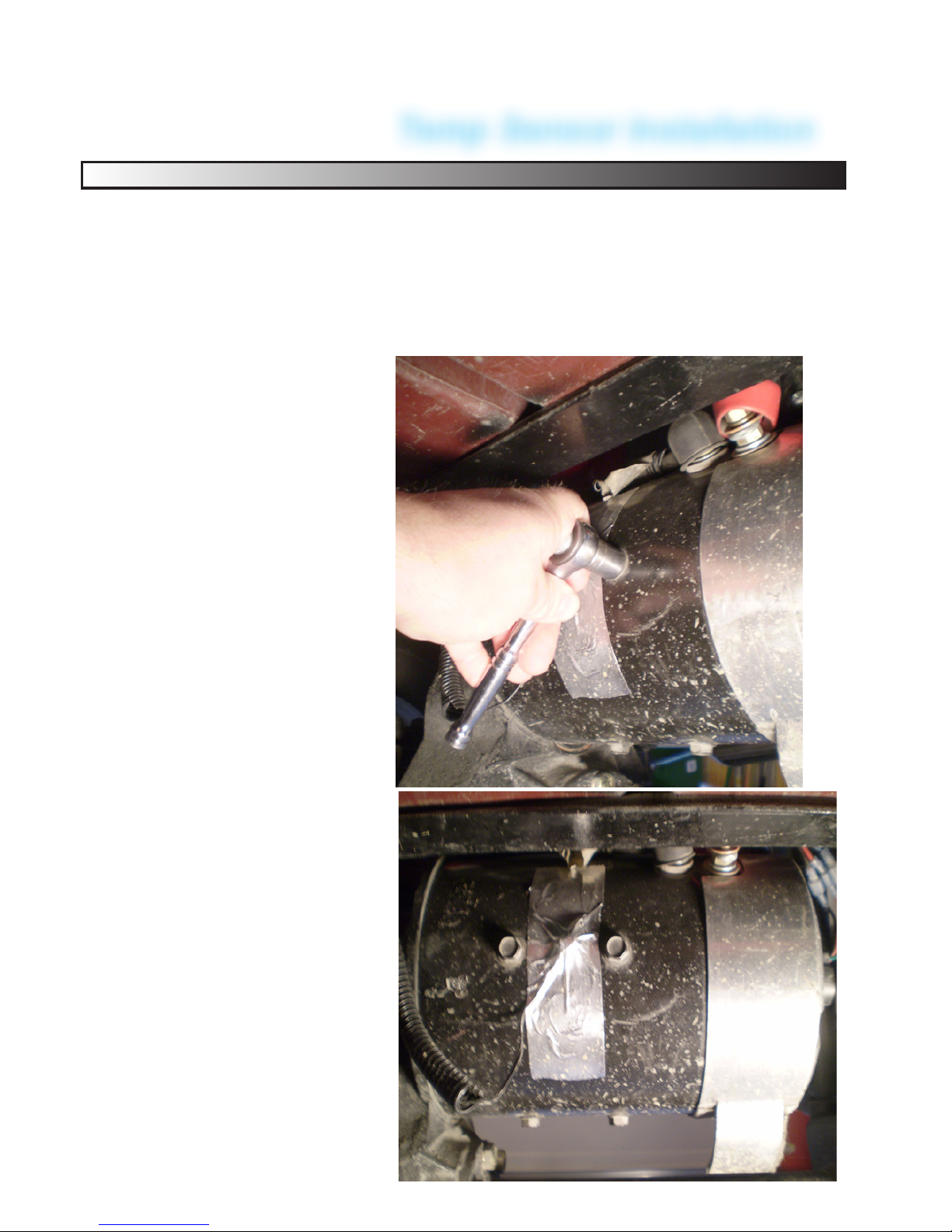

ELECTRIC MOTOR:

The temperature sensor

monitors the eld coil tem-

perature, an indication of

>75°C (167°F), the inter-

nal temperature is too hot.

Option 1: Performed by

authorized personnel,

Carefully remove the mo-

tor eld bolt and install the

temp sensor. Install the

bolt and torque to manu-

facturers specications.

Option 2: Use the sup-

plied tape, clean the area

with de-grease agent, dry,

and apply the tape over

the sensor and part of the

wire.

Temp Sensor Mount:

Electric Motor: Two options: 1) Motor eld coil bolt or secure

using the included Aluminized tape. (Both methods shown)

Gas Engine: 10mm bolt (optional water jacket sensor avail-

able, contact your dealer for more info).

Temp Sensor Installation

18

GAS ENGINE Temp Sensor Installation

GAS MOTOR:

Any bolt near the cylinder

head will provide good

indication. (Preferably a

mounting bolt that does

not require re-torquing the

head bolts).

CAUTION: THE CABLE

MUST NOT CONTACT

MUFFLER EXHAUST

COMPONENTS!

Secure the cable with

cable clamps. Watch for

CHAFFING points that

may damage the cable.

Follow the EXTENSION

CABLE guidelines to prop-

erly route the cable to the

display.

The Golf Cart gas engine Temp Sensor:

The typical installation is for Air Cooled engines. Cylinder

Head temperature is most critical. Oil temperature is also

a good indicator. Find a location that a bolt can safely be

removed and temp sensor can be installed.

19

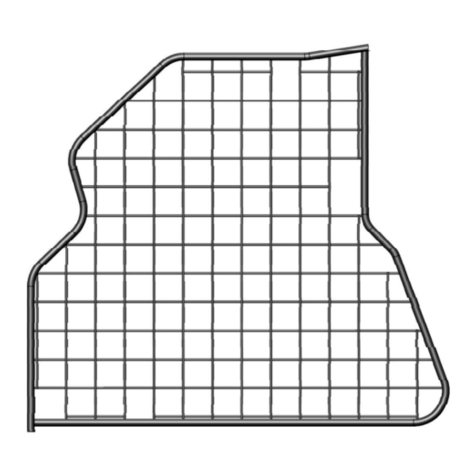

Temp Sensor EXTENSION Installation

Temp Extension Cable:

Install and use the supplied cable ties to secure the 6 foot

temperature extension cable. Ensure the connectors are

securely attached, do not apply any stress on the wires as the

motor moves up and down.

20

FACING FORWARD FACING REARWARD

TAPE THE SPLIT LOOM

(NOT SUPPLIED)

INSERT THE

CONNECTORS

Table of contents

Popular Automobile Accessories manuals by other brands

Kargo Master

Kargo Master 40816 Instruction guide

Safe Fleet

Safe Fleet Prime Design AR1911 Assembly instructions

STO N SHO

STO N SHO SNS 339 Installation procedures

Phonocar

Phonocar 05143 instruction manual

Metra Electronics

Metra Electronics 99-8208 installation instructions

TOP VEHICLE TECH

TOP VEHICLE TECH KWPOR15 installation manual