Edwards E1M40 User manual

A540-00-880

Issue C Original

Instruction Manual

EOF Pumped Oil Filtration System Adapter Kit

Description Item Number

E1M40/E2M40 A540-00-002

E1M80/E2M80 A540-00-004

This page has been intentionally left blank.

© Edwards Limited 2009. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

A710-04-880 Issue D

Note: For earlier models with serial numbers prior to those listed above please contact Edwards.

Note: For serial numbers beyond those quoted please see amended instruction at the end of this publication.

1. Wipe area around drain tap. Open the discharge to atmosphere or alternatively wipe area around oil filler and

remove filler.

2. Fully drain oil into a clean suitable size container with a capacity of at least 4.5 litre (E1M40, E2M40), 7 litre

(E1M80, E2M80). (Illustration 1).

CAUTION

If the rotary pump has been used on an application generating toxic, volatile, corrosive or in any other way

hazardous contaminants proper safety precautions appropriate to the level of hazard should be taken when

draining the oil or working on any area allied to the lubrication system.

3. Undo and remove the six screws securing the outlet port side panel. Lift away the side panel (Illustration 2).

4. The next item to be removed is the motor assembly. Although there are dowels top and bottom to correctly

locate the motor assembly these should not be relied upon to take the weight of the assembly. Use suitable size

wood blocks under the motor assembly. Using a 6 mm Allen key undo and remove the four socket head screws

securing the motor plate to the pump body (Illustration 3).

5. Carefully separate the motor assembly from the pump body (Illustration 4).

6. Undo and remove the two Allen socket grub screws securing the driven half coupling and fan assembly to the

pump shaft. A 3 mm Allen key should be used for this (Illustration 5).

7. Insert one socket grub screw in free threaded hole and tighten. This will release the taper lock (Illustration 6).

8. Lift away taper lock and fan assembly (Illustration 7).

9. Undo and remove the socket plug at the end of the oil return port line (Illustration 8). Remove traces of thread

lock from the thread in the pump body.

10.Using a suitable size Allen key undo and remove the suction port socket plug on the side of the pump body.

Beware residual oil will drain out when the plug is removed. Remove traces of thread lock from the thread in the

pump body.

11.Fit an aluminium washer to the banjo bolt, insert bolt into union followed by the second aluminium washer

(Illustration 9).

12.Apply Loctite 275 to the banjo bolt thread and fit banjo assembly to the end of the oil return line (Illustration

10). Modification. If the return port is counterbored 16 mm x 1.3 mm deep insert Viton O-ring code number

H02123119 into counterbore prior to insertion of banjo bolt.

13.Apply Loctite 275 to the pipe adaptor and fit to end of union assembly (Illustration 11).

14.Apply Loctite 275 to the second pipe adaptor and fit to the suction port (Illustration 11).

15.Knock out the two circular sections and fit the side panel to the two tap adaptors. Secure in place with the 6

screws.

16.Slacken the elbow nut, push on to the pipe adaptor and tighten the securing nut (Illustration 12).

17.Apply Loctite 275 to the threads and fit the two disconnects to the elbows (male-top, female-bottom)

(Illustrations 13 and 14).

Pump From Serial Number To Serial Number

E1M40 720 1281

E2M40 3168 8301

E1M80 463 900

E2M80 1926 4674

A710-04-880 Issue D

Page 2 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

© Edwards Limited 2009. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

A710-04-880 Issue D

A710-04-880 Issue D

Page 4 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

18.Refit the taper lock assembly. The clearance between the back face of the coupling and the face of the motor

gland box should be set to 1.0 - 1.5 mm (Illustrations 15 and 16).

19.Generally reassembly is the reverse sequence to dismantling. The following additional points should be noted:

a) The original metal side panel should be discarded and replaced by the plastic side panel.

b) When refitting the motor assembly tighten the four socket head securing screws in a diagonal and progressive

manner.

c) Do not forget to refill the rotary pump with oil, 4.5 litre (E1M40, E2M40), 7 litre (E1M80, E2M80).

1. Wipe area around drain tap. Open the discharge to atmosphere or alternatively wipe area around oil filler and

remove filler.

2. Fully drain oil into a clean suitable size container with a capacity of at least 4.5 litre (E1M40, E2M40), 7 litre

(E1M80, E2M80). (Illustration 1).

CAUTION

If the rotary pump has been used on an application generating toxic, volatile, corrosive or in any other way

hazardous contaminants proper safety precautions appropriate to the level of hazard should be taken when

draining the oil or working on any area allied to the lubrication system.

3. Undo and remove the six screws securing the outlet port side panel. Lift away the side panel.

4. Using a suitable size Allen key undo and remove the suction port socket plug on the side of the pump body.

Beware residual oil will drain out when the plug is removed. Remove traces of thread lock from the thread in the

pump body.

5. Remove both ¼ inch BSP pressure plugs which will be revealed once the side panel has been removed. Clean

threads of oil and dirt.

6. Apply Loctite 275 to the pipe adaptors and assemble into the ¼ inch BSP ports.

7. Slacken the elbow nut, push on to the pipe adaptor and tighten the securing nut.

8. Apply Loctite 275 to the threads and fit the two disconnects to the elbows (male-top, female-bottom).

Note: It is imperative that the fittings are handled in this way to ensure correct connection of the filter system.

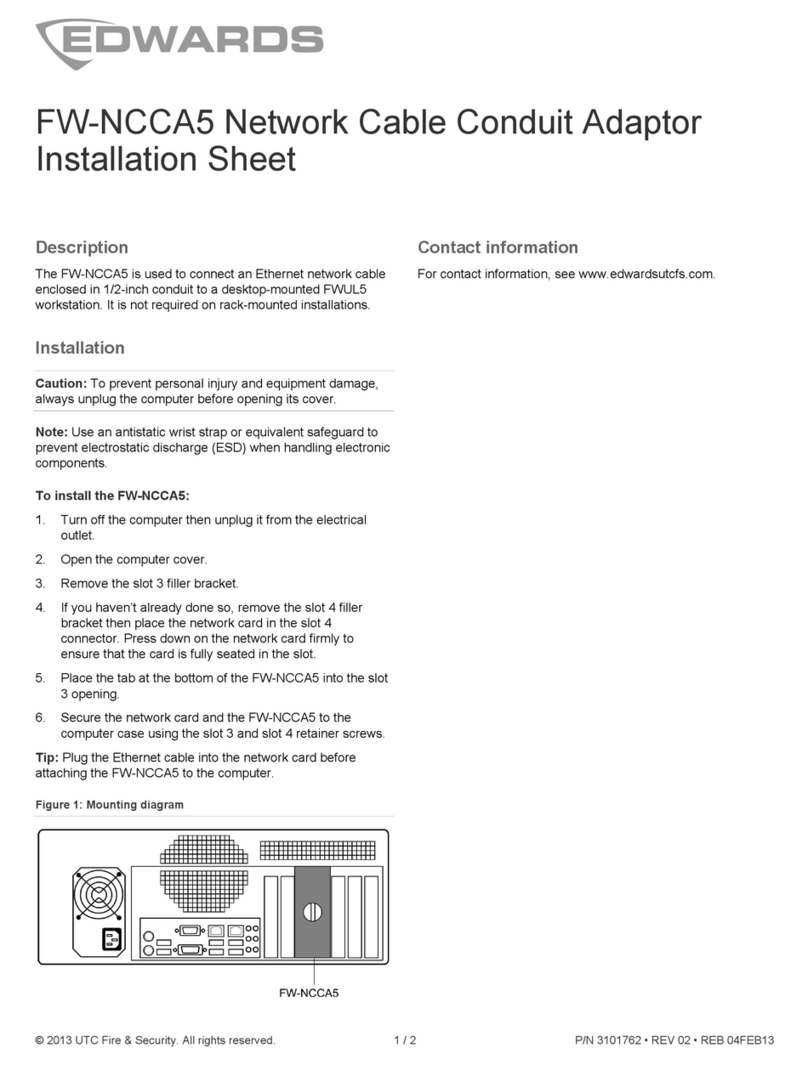

See Figure 1 overleaf.

9. Generally reassembly is the reverse sequence to dismantling. The following additional points should be noted:

a) The original metal side panel should be discarded and replaced by the plastic side panel.

b) Do not forget to refill the rotary pump with oil, 4.5 litre (E1M40, E2M40), 7 litre (E1M80, E2M80).

Pump From Serial Number

E1M40 1281

E2M40 8301

E1M80 900

E2M80 4674

© Edwards Limited 2009. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

A710-04-880 Issue D

Figure 1 - Correct Handling of Disconnect Fittings

1. Suction (female connection) 2. Return (male connection)

A710-04-880 Issue D

Page 6 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

This page has been intentionally left blank.

This page has been intentionally left blank.

Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a

completed Declaration of Contamination of Vacuum Equipment and Components – Form HS2. The

HS2 form tells us if any substances found in the equipment are hazardous, which is important for

the safety of our employees and all other people involved in the service of your equipment. The

hazard information also lets us select the correct procedures to service your equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum

equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

If a pump is configured to suit the application, make a record of the configuration before

returning the pump. All replacement pumps will be supplied with default factory settings.

Do not return a pump with accessories fitted. Remove all accessories and retain them for

future use.

The instruction in the returns procedure to drain all fluids does not apply to the lubricant in

pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in

HS1, fill in the electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, we will not accept the return of the

equipment.

P80081000, Issue A

P800‐80‐000IssueT

edwardsvacuum.com

Other manuals for E1M40

1

This manual suits for next models

5

Other Edwards Adapter manuals