EEC 6900S Series User manual

6900S Series

6905S/6910S/6920S/6930S/6950S

AC Power Source

User Manual

E1.01

WARRANTY

EEC certifies that the instrument listed in this manual meets or exceeds published manufacturing

specifications. This instrument was calibrated using standards that are traceable to the National

Institute of Standards Taiwan.

Your new instrument is warranted to be free from defects in workmanship and material for a

period of (2) year from date of shipment. During the warranty period, you must return the

instrument to EEC or branch offices or its authorized distributor for repair. EEC reserves the right

to use its discretion on replacing the faulty parts or replacing the assembly or the whole unit.

Under the following circumstances, EEC will void your warranty.

•Operate under non-normal, contrived omission, or accidental calamity (including, temblor,

floods, rebellion, and fire etc.)

•Any non-authorized modifications, tampering or physical damage.

•Elimination of any connections in the earth grounding system or bypassing any safety

systems.

•Use of non-authorized parts in the repair of this instrument. Parts used must be parts that

are recommended by EEC as an acceptable specified part.

This warranty does not cover accessories not out of EEC manufacture.

Except as provided herein, EEC makes no warranties to the purchaser of this instrument and all

other warranties, express or implied (including, without limitation, merchantability or fitness for

a particular purpose) are hereby excluded, disclaimed and waived.

EEC recommends that your instrument need to be calibrated on every twelve month cycle.

Modification history

Date

Version

Content

2017/5

C1.00

First edition

CONTENT

CHAPTER 1. INTRODUCTION ......................................................................................1

1.1 Product Marking Symbols .....................................................................................................1

1.2 Safety Precaution ..................................................................................................................1

1.3 Service and Maintenance......................................................................................................1

CHAPTER 2. GETTING STARTED ..................................................................................3

2.1 Unpacking and Inspection .....................................................................................................3

2.2 Preparation For Use...............................................................................................................3

2.2.1 Power Requirements....................................................................................................3

2.2.2 Power Cable..................................................................................................................3

2.3 Environmental Conditions.....................................................................................................4

CHAPTER 3. SPECIFICATIONS......................................................................................5

3.1 Specification ..........................................................................................................................5

3.2 Front Panel Description.........................................................................................................9

3.3 Rear Panel Description ........................................................................................................12

CHAPTER 4. MANUAL OPERATION...........................................................................14

4.1 Manual Operation ...............................................................................................................14

4.2 System Parameter Setup .....................................................................................................16

4.3 Displayed Messages.............................................................................................................18

CHAPTER 5. CALIBRATION PROCEDURE...................................................................20

5.1 Calibration Procedure..........................................................................................................20

CHAPTER 6. SERVICE AND MAINTENANCE..............................................................23

1

CHAPTER 1. INTRODUCTION

1.1 Product Marking Symbols

Product will be marked with this symbol when it is necessary to refer to the

operation and service manual in order to prevent injury or equipment damage.

Product will be marked with this symbol when hazardous voltages may be present.

1.2 Safety Precaution

•This product and its related documentation must be reviewed with full

acknowledgement on safety markings and instructions before operation.

•Before applying power, verify that the instrument is set to the correct line voltage and

installed the correct fuse.

•When using an oscilloscope to measure DUT waveform, please refer description below to

avoid DUT, instrument and oscilloscope damages. When the output of AC source has N-G

or L-G shorted, customer must use differential isolation type of oscilloscope probe or

using isolated oscilloscope.

To prevent accidental injury or death, these safety procedures must be strictly observed

when handling and using the test instrument.

1.3 Service and Maintenance

User Service

To prevent electric shock do not remove the instrument cover. There are no user serviceable

parts inside. Routine maintenance or cleaning of internal parts is not necessary. Any

external cleaning should be done with a clean dry or slightly damp cloth. Avoid the use of

cleaning agents or chemicals to prevent any foreign liquid from entering the cabinet through

ventilation holes or damaging controls and switches, also some chemicals may damage plastic

parts or lettering. Any replacement cables and high voltage components should be acquired

directly from EEC or its distributor.

Service Interval

The instrument must be returned at least once a year to an EEC authorized service center for

calibration and inspection of safety related components. EEC will not be held liable for injuries

2

suffered if the instrument is not properly maintained and safety checked annually.

User Modifications

Unauthorized user modifications will void your warranty. EEC will not be responsible for any

injuries sustained due to unauthorized equipment modifications or use of parts not specified

by EEC. Instruments returned to EEC with unsafe modifications will be returned to their

original operating condition at the customer’s expense.

3

CHAPTER 2. GETTING STARTED

This section contains information for the unpacking, inspection, preparation for use and

storage of your EEC product.。

2.1 Unpacking and Inspection

Your instrument was shipped in a custom foam insulated container that complies with ASTM

D4169-92a Assurance Level II Distribution Cycle 13 Performance Test Sequence

If the shipping carton is damaged, inspect the contents for visible damage such as dents,

scratches, or broken display. If the instrument is damaged, notify the carrier and EEC's

customer support department. Please save the shipping carton and packing material for the

carrier’s inspection. Our customer support department will assist you in the repair or

replacement of your instrument. Please do not return your product without first notifying us.

Please retain all of the original packaging materials.

2.2 Preparation For Use

2.2.1 Power Requirements

This instrument requires a power source of 110 volts AC ± 10%, 50/60 Hz single phase or 220

volts AC ±10%, 50/60 Hz single phase. Please check the rear panel to be sure the proper

switch setting is selected for your line voltage requirements before turning your instrument

on.

Do not switch the line voltage selector switch located on the rear panel

while the instrument is on or operating. This may cause internal damage

and represents a safety risk to the operator.

2.2.2 Power Cable

Before connecting power to this instrument, the protective ground (Earth)

terminals of this instrument must be connected to the protective conductor

of the line (mains) power cord. The main plug shall only be inserted in a socket outlet

(receptacle) provided with a protective ground (earth) contact. The main terminal shall only

be connected to a connector provided with a protective ground (earth) contact. This

protective ground (earth) must not be defeated by the use of an extension cord without a

protective conductor (grounding).

!!! Please must use the Class I product to be as the load.

CAUTION

WARNING

4

2.3 Environmental Conditions

Operating Environment

Temperatures:0°- 40°C (32-104F)

Relative humidity: 20% - 80%

Altitude: 2,000 meters (6,560 inches)

Please keep unimpeded around the units for good ventilation and convenient maintenance.

The instrument should also be protected against temperature extremes which may cause

condensation within the instrument.

Storage and Shipping Environment

This instrument may be stored or shipped in environments with the following limits:

Temperature......................... -40°to +55°C

Altitude: …………………… 7,620 meters (25,000 inches)

The instrument should also be protected against temperature extremes, which may cause

condensation within the instrument.

Packaging

Original Packaging

Please retain all original packaging materials that you originally received. If you are

returning your instrument to us for servicing please repackage the instrument in its original

container. Please enclose the instrument with all options, accessories and test leads.

Indicate the nature of the problem or type of service needed. Also, please mark the

container "FRAGILE" to insure proper handling.

Other Packaging

If you do not have the original packaging materials, please follow the below guidelines:

Wrap the instrument in a bubble pack or similar foam. Enclose the same information as

above.

Use a strong double-wall container that is made for shipping instrumentation. 350 lb.

test material is adequate.

Use a layer of shock-absorbing material 70 to 100 mm (3 to 4 inch) thick around all sides of

the instrument. Protect the control panel with cardboard.

Seal the container securely.

Mark the container "FRAGILE" to insure proper handling.

5

CHAPTER 3. SPECIFICATIONS

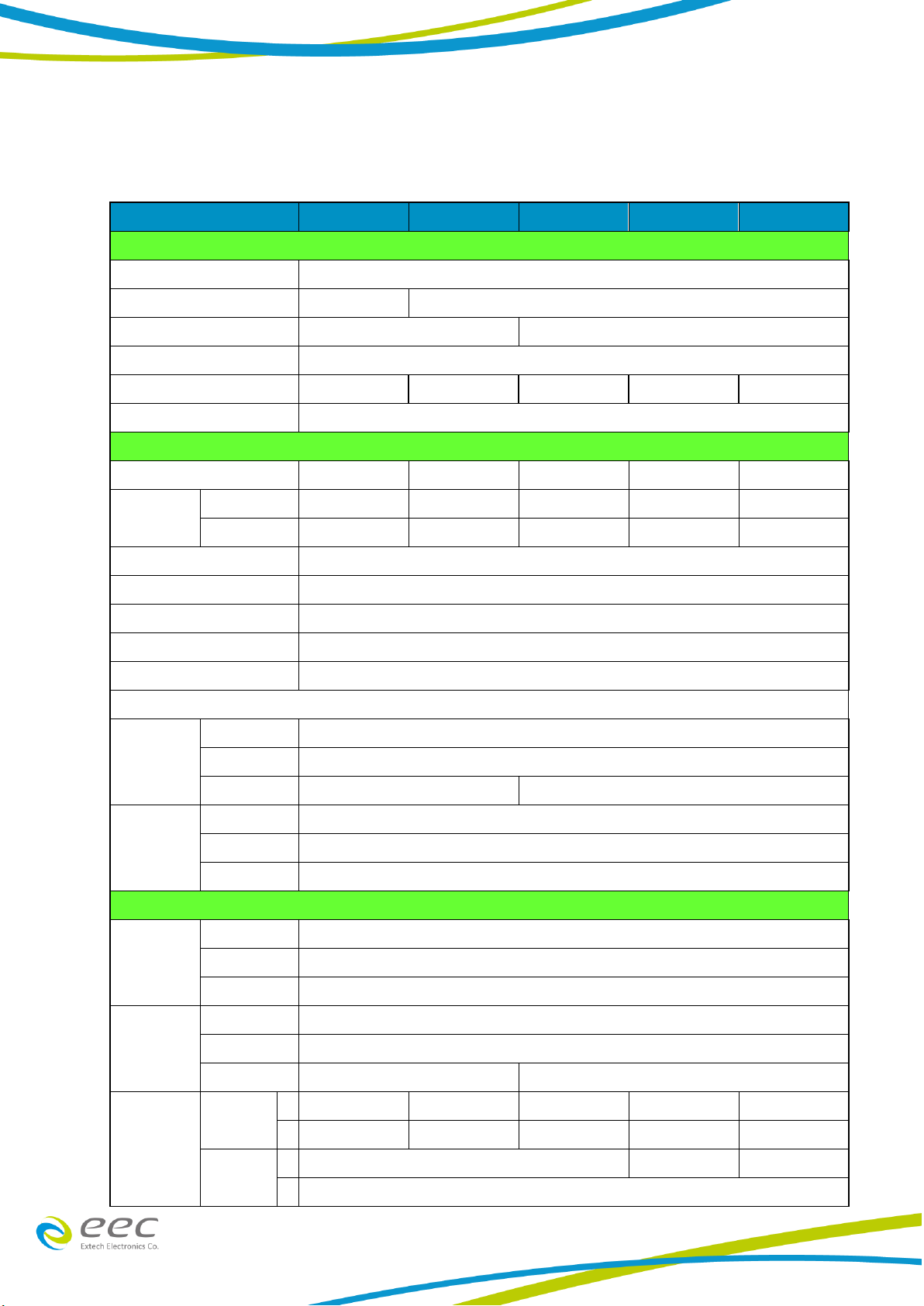

3.1 Specification

Model

6905S

6910S

6920S

6930S

6950S

INPUT

Phase

1

Terminal

Inlet

Terminal

Voltage

110 / 220Vac ± 10%

220Vac ± 10%

Frequency

47 –63Hz

Max. Current

10A / 5A

20A / 10A

20A

30A

50A

Power Factor

≧0.67

OUTPUT

Power rating

500VA

1000VA

2000VA

3000VA

5000VA(1)

Max. Current

(r.m.s)(2)

0-155V

4.6A

9.2A

18.4A

27.6A

46.0A

0-310V

2.3A

4.6A

9.2A

13.8A

23.0A

Phase

1Ø /2W

Total Harmonic Distortion (THD)

<0.3% at 110 / 220V & 50 / 60Hz (Resistive Load)

Crest Factor

≧3

Line Regulation

±0.1V

Load Regulation

± (0.5% of output + 0.5V) at Resistive Load

SETTING

Voltage

Range

0 - 310V, 155 / 310V Auto Range

Resolution

0.1V

Accuracy

±(1% of setting + 0.1% f.s)

±(1% of setting + 0.2% f.s)

Frequency

Range

40 - 450Hz Full Range Adjust

Resolution

0.1Hz at 40.0 - 99.9Hz , 1Hz at 100 - 450Hz

Accuracy

±0.03% of setting

MEASUREMENT

Frequency

Range

0.0 - 450.0Hz

Resolution

0.1Hz

Accuracy

±0.1Hz

Voltage

Range

0.0 - 400.0V

Resolution

0.1V

Accuracy

±(1% of reading + 0.1% f.s)

±(1% of reading + 0.2% f.s)

Current

(r.m.s)

Range

L

0.005A - 0.600A

0.005A - 1.200A

0.005A - 2.400A

-

-

H

0.50A - 6.50A

1.00A - 13.00A

2.00A - 26.00A

0.05A - 39.00A

0.05A - 65.00A

Resolution

L

0.001A

-

-

H

0.01A

6

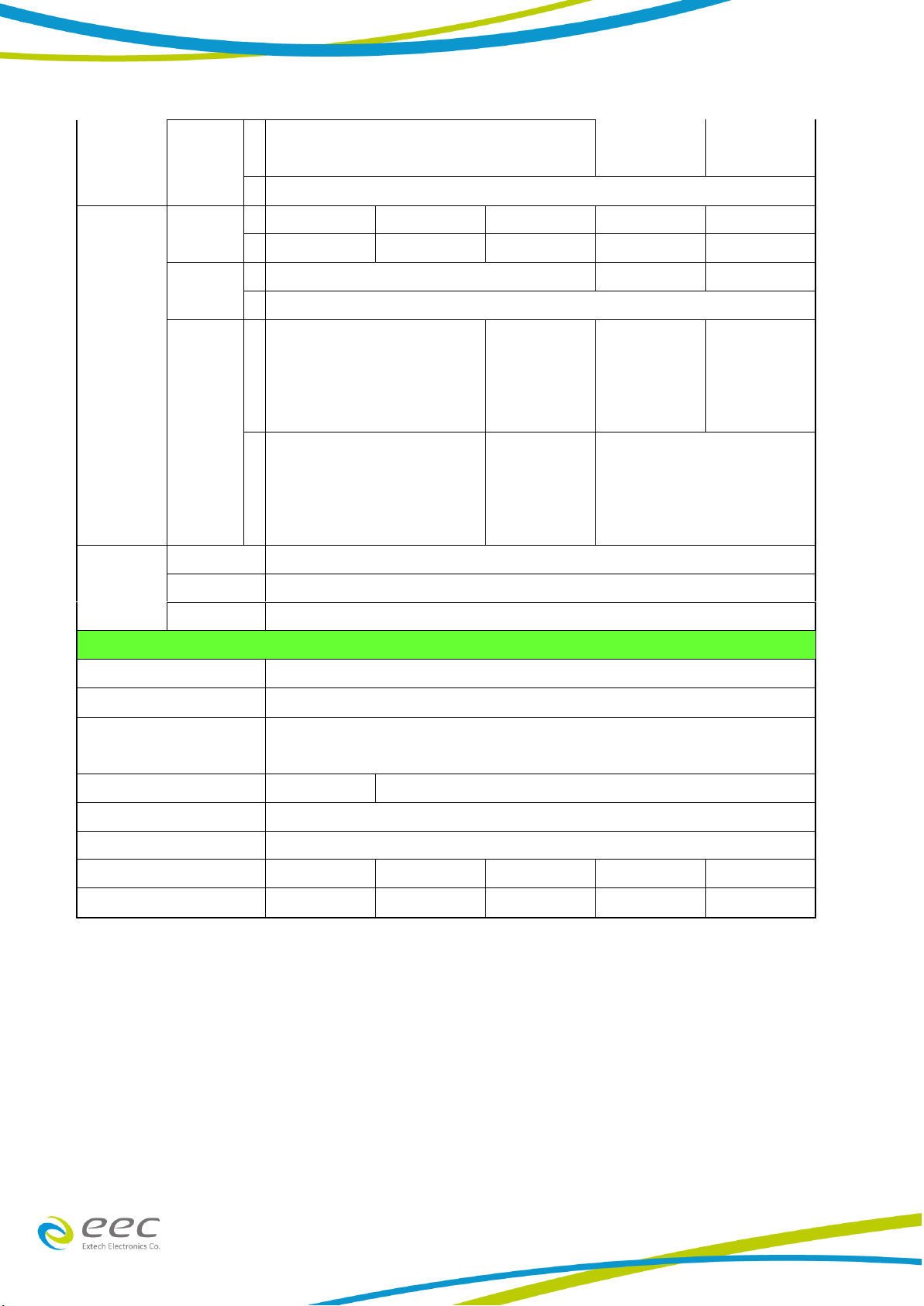

Accuracy

L

± (1% of reading + 0.005A)

at voltage > 5V

-

-

H

± (1% of reading +0.05A)

Power

Range

L

0.0W - 60W

0.0W - 120W

0.0W - 240W

-

-

H

50W - 650W

100W - 1300W

200W - 2600W

0W - 3900W

0W - 6500W

Resolution

L

0.1W

-

-

H

1W

Accuracy

L

± (2% of reading +1.5W)

at PF>=0.2 & voltage > 5V

± (2% of reading +

3W)

at PF>=0.2 &

voltage > 5V

-

-

H

± (2% of reading + 5W)

at PF>=0.2 & voltage > 5V

± (2% of reading

+10W)

at PF>=0.2 &

voltage > 5V

± (2% of reading + 5W)

at PF>=0.2 & voltage > 5V

Power Factor

Range

0 –1.000

Resolution

0.001

Accuracy

W / VA ,Calculated and displayed to three significant digits

GENERAL

Memory

3 memories

Display

Green LED

Over Current Fold Back

On/Off , Setting On when output current over setting Hi-A value it will fold back output voltage

to keep constant output current is setting Hi-A value, Response time < 1.4s

Efficiency

≧78%

≧80%

Protection

OCP, OVP, OPP, OTP, Short Circuit and Alarm

Operation Environment

0-40℃/ 20-80%RH

Dimension (W x H x D), mm

430 x 89 x 300

430 x 89 x 400

430 x 89 x 500

430 x 222 x 500

430 x 222 x 500

Weight

12.5Kg

18.2Kg

30Kg

57Kg

65Kg

Product specifications are subject to change without notice.

*1 When PF 0.8 output can work continuously

.

*2 At working voltage 110V / 220V

【Ordering Information】

OPT.629 Input Voltage 100V / 200V for 6905S & 6910S

OPT.630 Input Voltage 120V / 240V for 6905S & 6910S

OPT.631 Input Voltage 200V for 6920S & 6930S & 6950S

OPT.632 Input Voltage 240V for 6920S & 6930S & 6950S

7

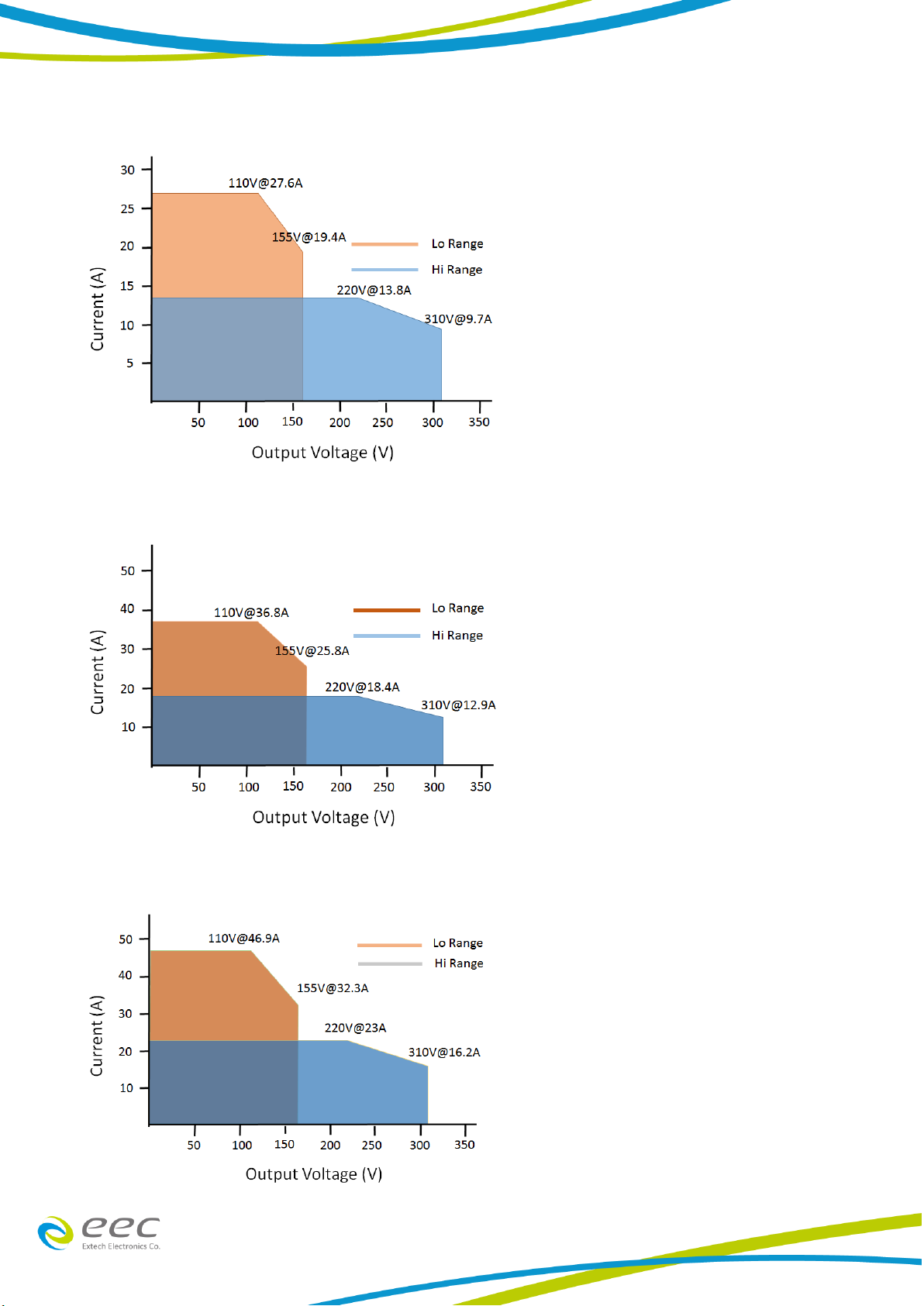

6905S rated output current (PF=1)

6910S rated output current (PF=1)

6920S rated output current (PF=1)

8

6930S rated output current (PF=1)

6950S rated output current (PF=1)

6950S rated output current (PF=0.8)

9

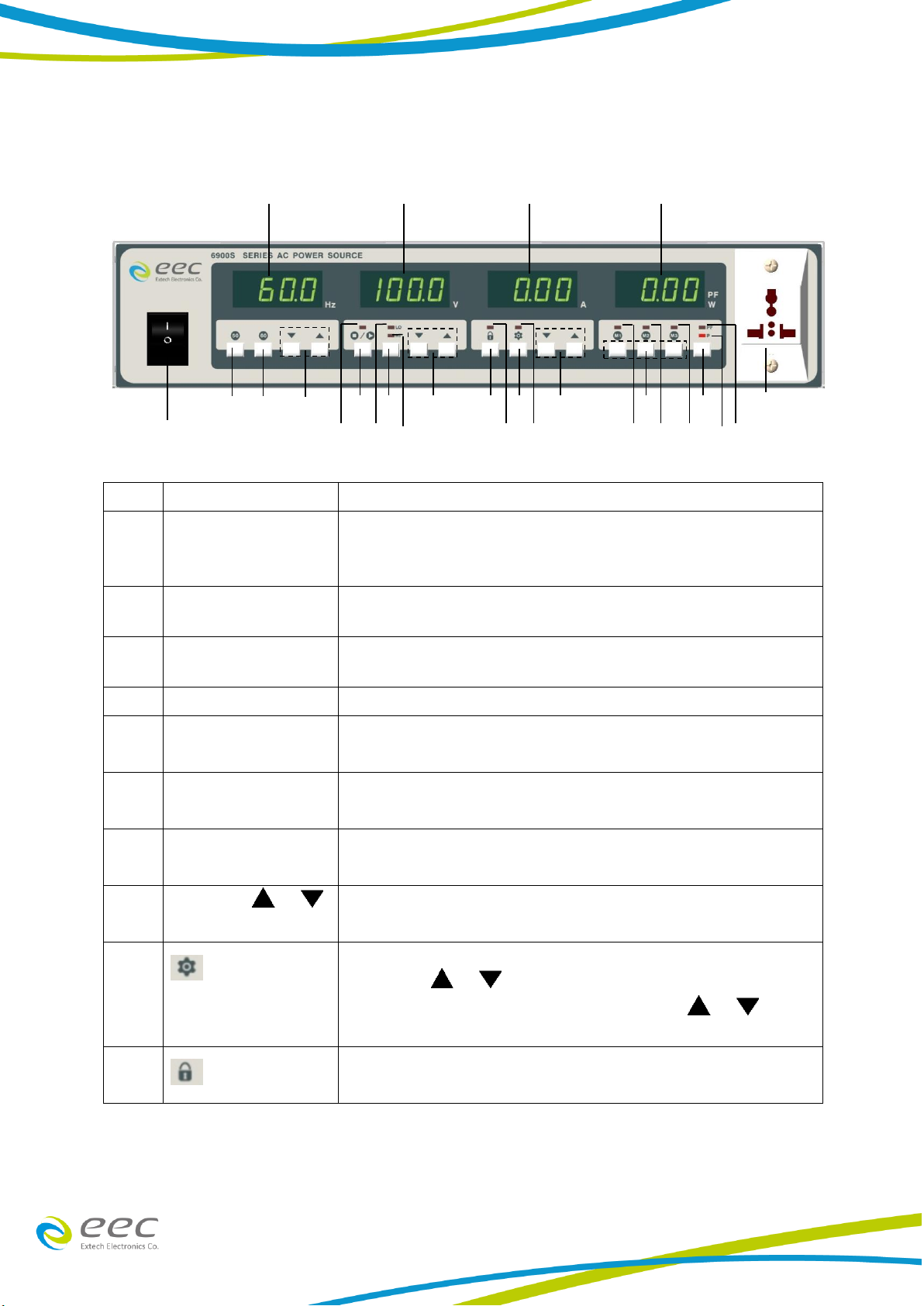

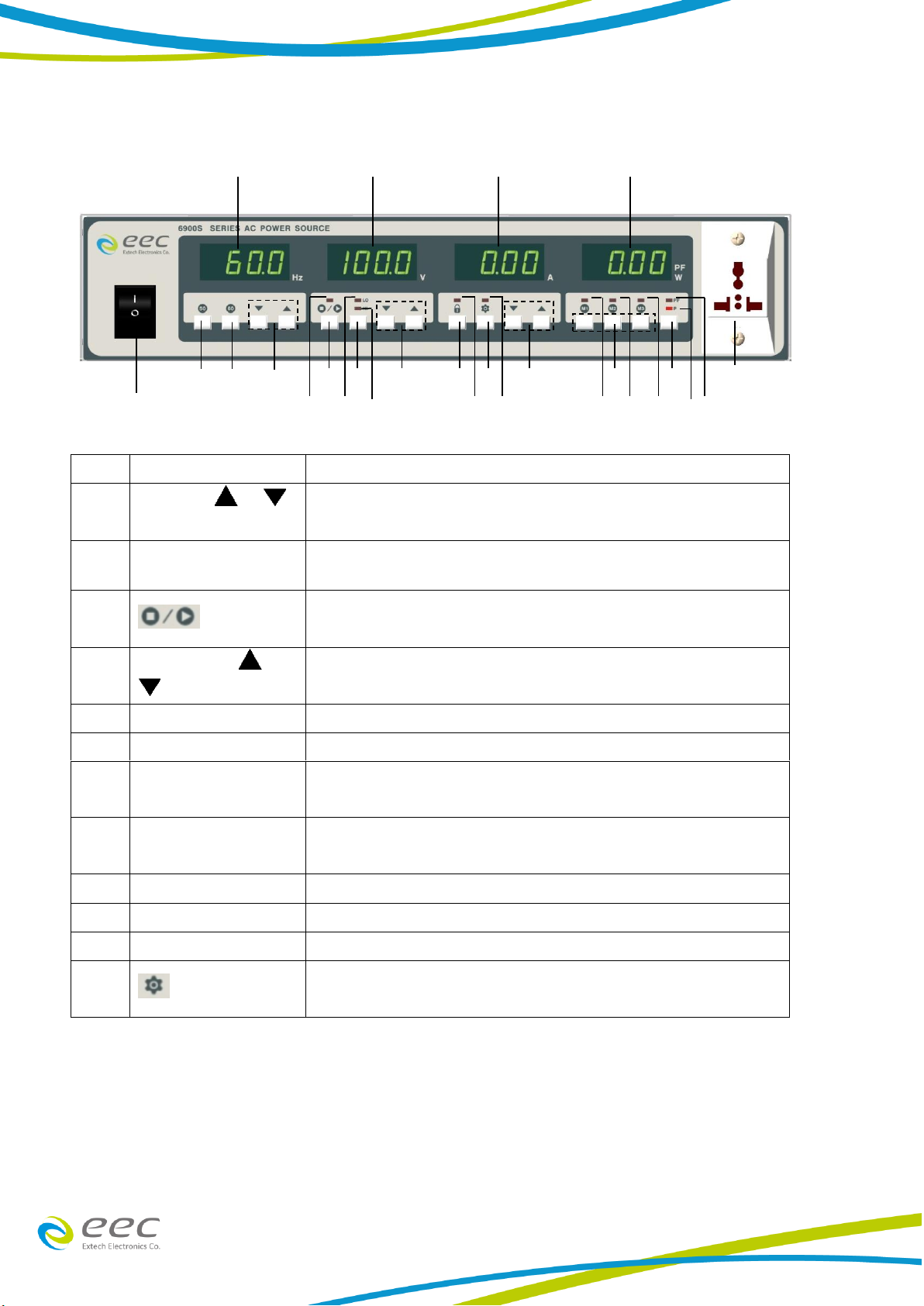

3.2 Front Panel Description

NO.

Item

Explain

1

FREQUENCY

It will display the output frequency. When the output is OFF,

it shows the frequency setting. Otherwise, it shows the

frequency of the output.

2

VOLTAGE

When the output is OFF it shows the output voltage setting.

Otherwise it shows the voltage of the output.

3

CURRENT

When the output is OFF it shows the output current setting.

Otherwise it shows the current of the output.

4

MULTI FUNCTION

Display the value of output wattage or power factor

5

UNIVERSAL AC

OUTPUT SOCKET

Trip Current (20A)

6

P / PF SELECT

BUTTON

Select the display of output wattage or power factor value.

7

M1, M2 AND M3

BUTTON

Store setting memories. [Press and hold for a second or

above].

8

CURRENT /

KEY

To increase or reduce the output current higher than the

display value. Or be a selection key for System conditions.

9

KEY

Enter or exit from the setting of system parameter. You can

utilize the / keys under VOLTAGE meter to select

the parameter that you need to set, and the / keys

under CURRENT meter to set parameters.

10

KEY

To disable all the keys on the front panel. It switches between

Lock and Unlock.

5

1

2

3

4

8

11

10

9

14

13

12

15

16

17

24

23

22

25

26

27

6

7

19

18

21

20

10

NO.

Item

Explain

11

VOLTAGE /

KEY

To increase the output voltage higher than the display value.

Or be a selection key for System items.

12

HI/LO KEY

High Range Voltage is 0 - 310V and Low Range Voltage is 0 -

155V.

13

KEY

To turn the output ON and OFF, and press RESET key as

abnormal operation occurs.

14

FREQUENCY /

KEY

To increase or reduce the output frequency to higher or lower

than the display value.

15

60 Hz KEY

Press to set the output frequency to 60 Hz.

16

50 Hz KEY

Press to set the output frequency to 50 Hz.

17

POWER FACTOR

INDICATOR

When the LED is ON, the display shows the output power

factor.

18

WATTMETER

INDICATOR

When this LED is ON, the display shows the output power.

19

M3 INDICATOR

When the LED is ON, the output is set according to M3.

20

M2 INDICATOR

When the LED is ON, the output is set according to M2.

21

M1 INDICATOR

When the LED is ON, the output is set according to M1.

22

INDICATOR

When the LED is ON, the SYSTEM default setting is activated.

5

1

2

3

4

8

11

10

9

14

13

12

15

16

17

24

23

22

25

26

27

6

7

19

18

21

20

11

NO.

Item

Explain

23

INDICATOR

When this LED is lit, all the keys are disabled.

24

HI INDICATOR

When the LED is lit, the output is set to high range.

25

LO INDICATOR

When the LED is lit, the output is set to low range.

26

INDICATOR

When the LED is lit, it is at normal operation, whereas when

the LED is blinking, it is at abnormal operation.

27

POWER SWITCH

Rocker style power switch with international ON ( ) and OFF

(0) markings.

5

1

2

3

4

8

11

10

9

14

13

12

15

16

17

24

23

22

25

26

27

6

7

19

18

21

20

12

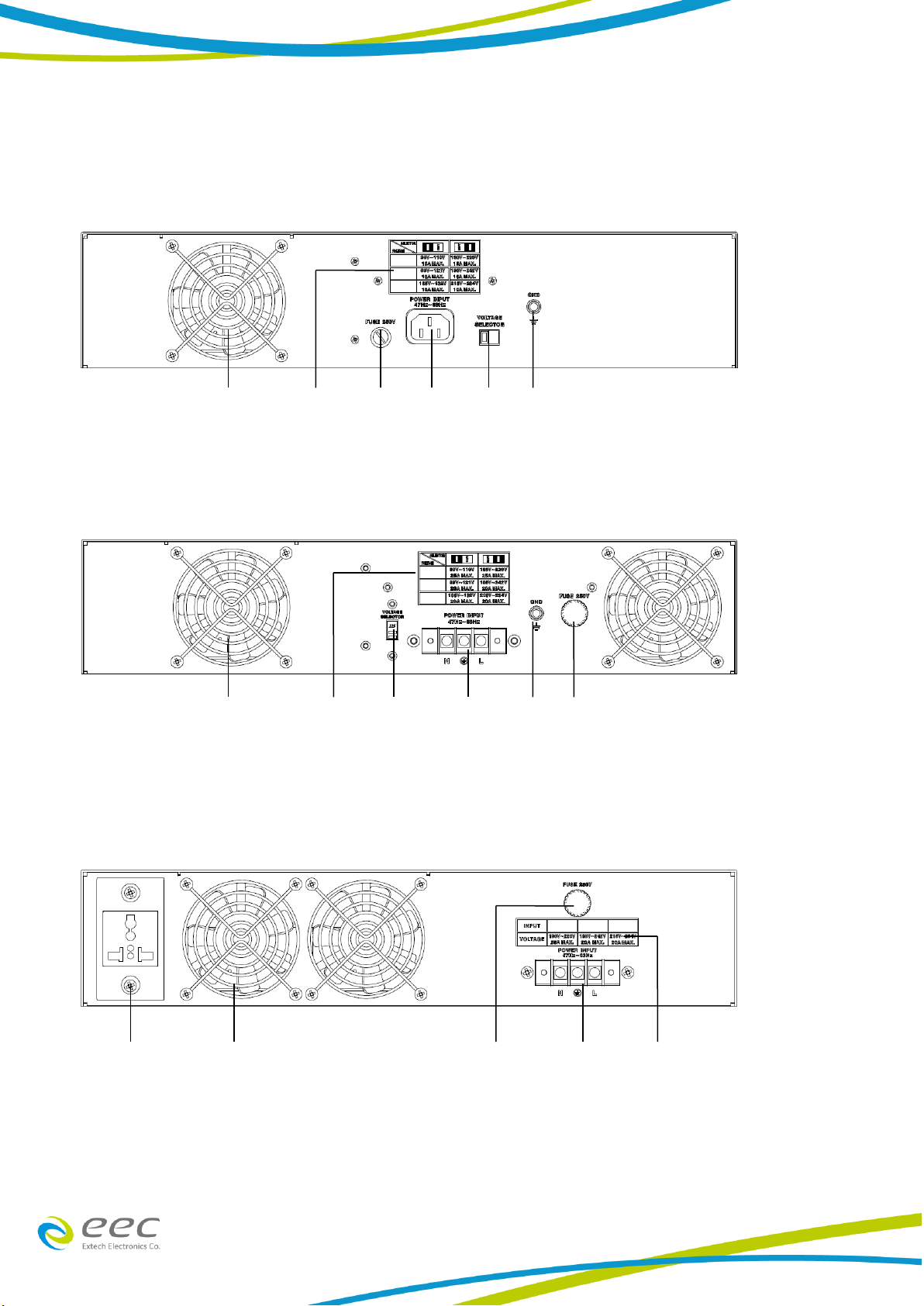

3.3 Rear Panel Description

6905S rear panel

6910S rear panel

6920S rear panel

1

1

2

2

3

3

4

5

5

6

8

8

1

2

6

7

8

13

6930S & 6950S rear panel

NO.

Item

Explain

1

THERMAL FAN

To cool the instrument.

When the temperature exceeds 60 °C, the fan will enter

the second speed.

2

FUSE RECEPTACLE

To change the fuse unplug the power (mains) cord and turn

the fuse cap counter clockwise to remove the fuse.

3

CHASSIS GROUND

This terminal should be connected to a good earth ground

before operation

4

INPUT POWER

RECEPTACLE

Standard IEC 320 connector for connection to a standard

NEMA style line power (mains) cord.

5

INPUT POWER SWITCH

Line voltage selection is set by the position of the switch.

In the left position, it is set for 110-volt operation, in the

right position it is set for 220-volt operation.

6

Input Terminal Power

Block

Provides input power to the instrument.

7

UNIVERSAL AC

OUTPUT SOCKET

Trip Current (20A)

8

Indicated the input

voltage range

Instrument input voltage indication

9

Input Circuit Breaker

Input power switch.

10

Output Terminal

Power Block

Provides output power to the DUT.

1

9

10

8

6

14

CHAPTER 4. MANUAL OPERATION

4.1 Manual Operation

1. Setting Of Output Voltage

High range voltage can be set between 0 - 310V while low range voltage is 0-155V under

AC mode. Press and hold the or key will firstly clear the decimal number of

setting to zero. Subsequently, every 0.3 seconds will change a step and thereafter a first

integer of setting number will vary and then to the second integer and third integer of the

voltage setting respectively. For the third integer, it takes 0.1 seconds only to vary every

step in order to speed up the scrolling.

Press and hold “︿”, decimal (clear to 0) → 1st Integer (0.3sec / step) → 2nd Integer (0.3sec / step)

→ 3rd Integer(0.1sec/step)

If the voltage is adjusted when the indicator is ON, the AC Power Source will

generate the output voltage accordingly. When the voltage display is blinking, the output

voltage remains the same as the previous set voltage. After 2 second the voltage display

will stop blinking and the new set voltage is accepted. Any invalid setting may not be

accepted.

2. Setting Of Output Frequency

For frequency setting in the range of 40-99.9 Hz, each change on the setting are

0.1Hz/step for normal setting and 1Hz/step for coarse setting. In 100-450 Hz range, each

change on the setting are 1Hz/step for normal setting and 10Hz/step for coarse setting. As

the 50 Hz or 60 Hz key is pressed, the desired frequency will be immediately updated. (The

same method applied like voltage setting to scroll the display).

3. Setting Of Voltage Range

If the desired voltage is lower than 155 V, press the HI / LO Key first. The LO LED is lighted

to indicate the AC source is in 0 - 155 Volt range and allow a higher range of current limit.

For the 0 - 310V of voltage range, the range of current limit drops to half as comparing the

current limit at the 0 - 155V range (Refer to the specification table). Setting of voltage

range may not influence the existing output voltage setting. Anyhow, changing the voltage

range during the indicator is ON will lead to the output voltage cutoff (about 20

ms) and this should be avoided if possible.

4. Setting Of Current

While the OUTPUT is not activated, pressing the or key will enter to the setting

mode of low-limit current. Press further or key to continue scrolling the display

in order to change the current limit. If the setting is hold for 2 seconds, it will return to a

standby mode from current setting mode. Meanwhile, at the standby mode, the output

capacity (Refer to the specification table) limits the output current or allows setting the

low limit current. The AC Power Source cuts off the output immediately when the actual

current has exceeded the limits and a HI-A error message is shown. Any invalid current

setting will not be accepted

This manual suits for next models

5

Table of contents

Other EEC AC Power Distribution manuals