EESiFlo 6000 Series User manual

Page 1of 4

Simplified Installation of the 4-20mA Output

on the EESiFlo 6000 Series Ultrasonic Flow Meter

Note: The 4 to 20 mA outputs on FlowRental.com rental meters are

“ACTIVE”OUTPUTS

Setting up the 4-20 mA output on the 6000 Series Ultrasonic Flow Meter involves four distinct steps.

1. Define the Pipe and Medium Parameters (PAR on the main menu)

2. Setting up the 4 to 20 mA output (SF on the main menu)

3. Selecting the Output Options (OPT on the main menu)

4. Enter the Measure Mode (MEA on the main menu)

Defining the Pipe and Medium Parameters >PAR<

1) Start by turning the instrument ON by pressing the ON/C button

2) Plug the Transducers into the receptacle marked Channel A (or B) and the 6000 SERIES will

automatically detect which transducers are installed by displaying that information on the LCD.

3) Using the 4 or 6 keys scroll to PAR (parameters) on the main menu and press ENTER.

4) Press ENTER again to view Channel A Parameters or use the 2 and 8 keys to select

Channel B.

5) Enter the pipes Outer Diameter then press ENTER.

6) Or, if the pipes diameter is not known, simply enter 0.00 in the diameter and the 6725 will

prompt you to enter the Pipe Circumference.

7) Next, enter Wall Thickness

8) Select a Pipe Material by using the 2 and 8 keys to scroll up and down through the available

list.

219 East Main Street

Mechanicsburg, PA

USA, 17055

Toll Free: 866-337-4356

Fax: (717) 697-2122

Page 2of 4

9) Answer YES or NO to the prompt for Lining. If you answered YES, then enter the Lining

Type (using the 2 and 8 keys) and then the Lining Thickness

10) Enter the internal Roughness of the pipe

11) Using the 2 and 8 keys, select the Medium (Liquid Type) from the available list.

12) Enter the approximate Medium Temperature and you'll return to the Main Menu.

Setting up the 4 to 20 mA Output >SF<

1. At the Main Menu, use the 4 and 6 keys to navigate to >SF< Special Functions menu

2. Scroll down to “System Settings” and press ENTER

3. Scroll down to “Proc. Outputs” and press ENTER

4. When the screen displays “Install Output” use the Up (8) and Down (2) Arrows to select

“Current I1” then press ENTER.

5. Use the Left (4) or Right (6) arrows to select >NO< at the “I1 Disable” prompt then press

ENTER.

6. At the “I1 Source Channel” prompt use the Up (8) and Down (2) Arrows to select the

channels into which the transducers are plugged (step 2 above). Press ENTER to continue.

7. At the “Source Item” prompt, use the Up (8) and Down (2) Arrows to select the type of

output you want the 4 to 20 mA output signal to reflect, then press ENTER. Select the type of

output from the next screen then press ENTER.

8. At the “I1 Output Range”prompt use the Up (8) and Down (2) Arrows to select “4/20 mA”

then press ENTER.

9. At the “Error-value” prompt use the use the Up (8) and Down (2) Arrows to select which

value you’d like output if an error is encountered, then press ENTER.

10. Hook a multi-meter set to measure mA outputs to the jacks on the back of the 6000 SERIES

(Positive to Red, Negative to Black) Place the multi-meter in the DC current measuring mode.

11. At the “Output Test” prompt, enter a valid number between 4 and 20 mA then press ENTER.

The value you entered will be output by the 6000 SERIES and should appear on the multi-meter.

12. At the “Again ? no <YES>” prompt you can enter another number to test, or enter NO. It is

recommended that you answer YES a number of times and enter a couple of values between 4

and 20 mA to ensure the 4-20 mA output feature is functioning correctly.

13. Once you’ve answered <NO> to the above prompt you’ll be returned to the System Settings

Menu.

14. Press the red BRK key once and you’ll return to the Main Menu, and the 4 to 20 mA output

on your multi-meter will drop to 0 mA.

Page 3of 4

Setting the Output Options >OPT<

1. At the Main Menu use the 4 and 6 keys, scroll to OPT (Output Options) then press ENTER.

2. Choose Channel A (or B) then press ENTER

3. The 6000 SERIES will prompt you for the Physical Quantities for your desired output. Use

the 2 and 8 keys to scroll up and down through the available list. Press ENTER.

4. Using the 2 and 8 keys, choose your Velocity In units from the available list then press

ENTER.

5. Answer NO to the prompt for Temperature T1 then press ENTER

6. Answer NO to the prompt for Temperature T2 then press ENTER

7. Choose a Damping (averaging) time in seconds then press ENTER

8. Answer NO to Store Measured Data then press ENTER or YES if required.

9. Answer NO to Serial Output then press ENTER or YES if required.

10. Enter YES to the Current Loop I1: prompt.

11. Choose either Absolute or Signed at the Measured Values prompt to indicate if you

would like only positive (Absolute) or both positive and negative (Signed) flow.

12. At the Zero-Scale Value prompt enter a value that will represent the 4 mA output signal.

13. At the Full-Scale Value prompt enter a value that will represent the 20 mA output signal.

Once entered you will return to the Main Menu.

Enter the Measure Mode >MEA<

1) Using the 4 and 6 keys, scroll back to MEA (Measuring) then press ENTER

2) Below each channel will appear a minus sign (-), a check mark (√)or a dot (∙). Using the 4

and 6 keys, select Channel A (or B), then ensure there is a check mark below that channel by

pressing the 2 or 8 keys. Then press ENTER

3) The next prompt to appear may be different, depending upon how the 6000 SERIES has been

initialized. If Reflection Mode appears, continue with step 4 below. If a prompt appears

asking for a Sound Path, continue with step 5 below.

4) If Reflection Mode prompt appears, choose NO and the 6000 SERIES will measure in the

Direct Mode, where the transducers are mounted on opposite sides of the pipe. If you

choose YES, the 6000 SERIES will measure in the Reflection Mode where the transducers

are mounted on the same side of the pipe. It is recommended you answer YES and mount the

transducers on the same side of the pipe. However, if problems are experienced getting good

solid flow data, it is recommended you go through the MEA routine again, this time answering

Page 4of 4

NO to this prompt, then remembering that transducers will be mounted on opposite sides of

the pipe. Continue at step #6 below.

5) If A: Sound Path appears, the number indicated below this prompt represents the number of

Sound Paths (as indicated on page 5-4 of the 6000 SERIES Operating Instructions). This value

may be manually adjusted by the User. After reading pages 5-4 through 5-10 of the 6000 SERIES

Operating Manual, choose a Sound Path that matches your exact needs, then press ENTER.

6) Press ENTER and the 6000 SERIES will indicate how far apart the transducers must be

separated. This display may indicate the values are in millimeters, when in fact they are in

inches.

7) Select an appropriate transducer Installation Site by following the guidelines in the manual

pages 3-1 and 3-2

8) Apply Ultrasonic Couplant to the bottom of the Transducers

9) Install Transducers with arrows pointing in the same direction, with the arrow pointing in

the normal direction of flow.

10) Ensure Transducers are correct distance apart by pressing ENTER and reviewing the SIGNAL

STRENGTH as discussed on page 5-2

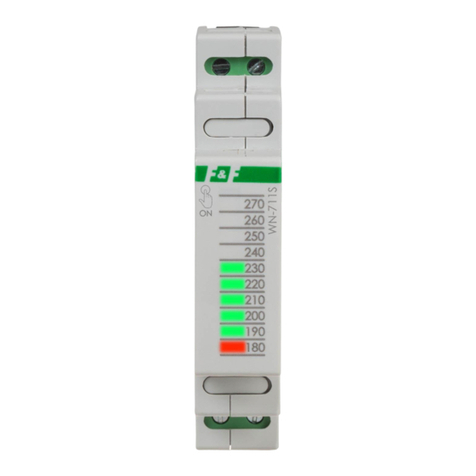

11) A GREEN signal indicates you have sufficient signal strength to begin measuring. A RED signal

indicates you should re-check your transducers installation.

12) Press ENTER again to confirm the transducer separation distance, and you will begin displaying

the flow data you've selected, and outputting the appropriate value via the 4 to 20mA output

port!!!

Once measurements are complete, press BRK 3 times to shut the instrument off, and it will retain

your setup information for your next installation.

Don’t forget to re-charge the battery after lengthy installations.

219 East Main Street

Mechanicsburg, PA, USA 17055

Toll Free: 866-337-4356

Fax: (717) 697-2122

Website http://www.FlowRental.com

Table of contents

Other EESiFlo Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Panasonic

Panasonic KW8M user manual

Promega

Promega PowerPlex ESI 17 Fast System Technical manual

PCB Piezotronics

PCB Piezotronics IMI Sensors M606B61 Installation and operating manual

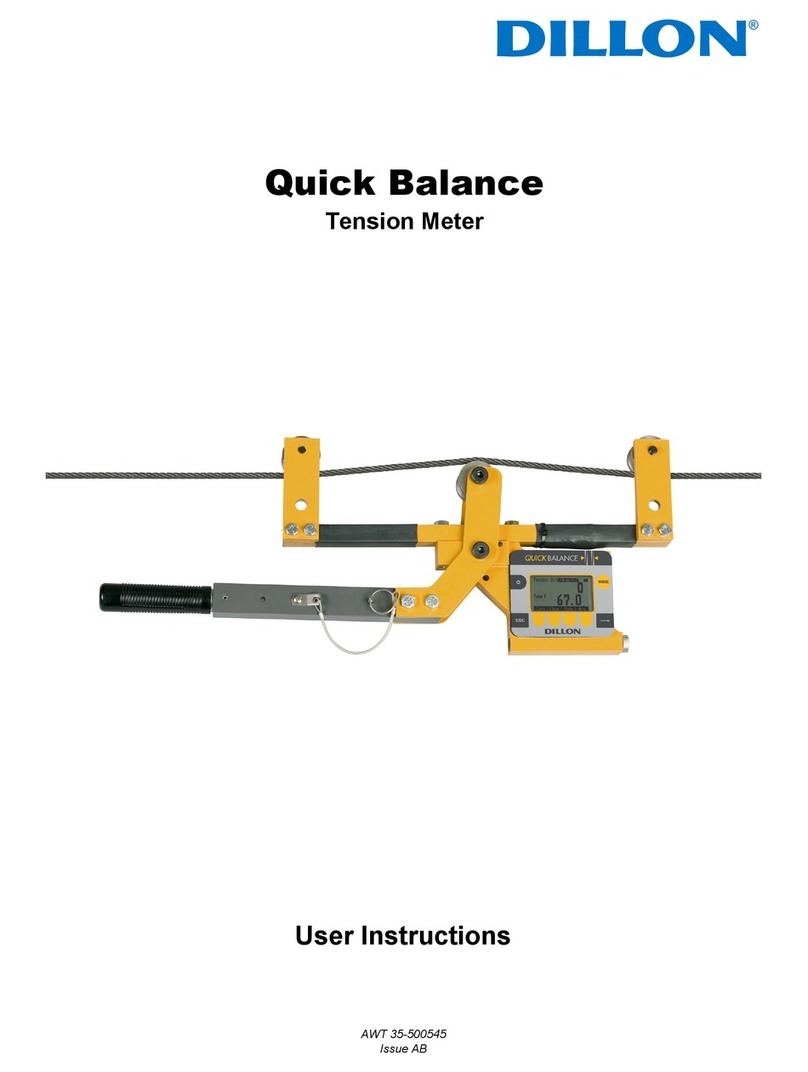

Dillon

Dillon Quick Balance User instructions

Omega

Omega SP-010 user guide

Comweld Medical

Comweld Medical EZI-FLOW Instructions for use