EFFEKTIV TRIUMPHATOR 2000X User manual

TRIUMPHATOR 2000X

Coverstitch Machine

EN USER MANUAL ES MANUAL DE USUARIO

FR MANUEL DE L’UTILISATEUR

TR KULLANIM KILAVUZU

IT MANUALE D’USO

DE BENUTZERHANDBUCH

CONTENIDOCONTENTS

EN

1. ACQUAINTANCE WITH THE MACHINE .......6

1.1 Name of Parts .........................................................6

1.2 Standard Accessories ...........................................7

2. GETTING READY TO SEW............................7

2.1 Connecting the Machine to Power Supply ........7

2.2 Controlling Sewing Speed .....................................8

2.3 Raising or Lowering the Presser Foot.................9

2.4 Attaching the Presser Foot................................. 10

2.5 Presser Foot Pressure Adjustment................... 11

2.6 Adjustment of Stitch Length .............................. 11

2.7 Changing the Needles ......................................... 12

2.8 Adjustment of Differential Dial .......................... 12

2.9 Needle Threader ................................................... 13

2.10 Setting the Telescopic Thread Guide ............... 13

2.11 Setting the Spool Cones...................................... 14

2.12 Threading the Machine ....................................... 15

2.13 Threading the Needles: ....................................... 16

2.14 How to Use the Threader.................................... 18

2.15 Threading the Looper .......................................... 19

3. STITCH TYPES ..........................................20

3.1 Triple Cover Stitch ................................................ 20

3.2 Cover Stitch ........................................................... 23

3.3 Upper Thread Tension Balance ........................ 24

3.4 Chain Stitch ........................................................... 26

4. FINISHING THE SEAM ...............................28

4.1 Beginning of the Seam........................................ 28

4.2 End of the Seam ................................................... 28

4.3 Knotting the Threads........................................... 29

4.4 Removing the Fabric in the Middle of the

Stitching ................................................................. 29

4.5 Hemming with the Cover Stitch ........................ 30

4.6 Triple Cover Stitch Applications ........................ 30

5. MAINTENANCE OF THE MACHINE............31

ES

1. INFORMACION DE LA MÁQUINA ........................35

1.1 Nombre de las piezas.......................................................35

1.2 Accesorios estándar ........................................................36

2. PREPARACIÓN PARA LA COSTURA ...................36

2.1 Conexión de alimentación...............................................36

2.2 Control de velocidad de costura ....................................37

2.3 Levantar y bajar el prensatelas de presión...................38

2.4 Cómo instalar un prensatelas de sujeción ..................39

2.5 Cambio en la presión del prensatelas sobre la tela ...40

2.6 Cambiar la longitud de la puntada ................................40

2.7 Cambio de aguja ..............................................................41

2.8 Cambio diferencial Alimentación de tela .....................41

2.9 Enhebrador ........................................................................42

2.10 Instalación de la guía de hilo ..........................................42

2.11 Instalación de carretes ....................................................43

2.12 Enhebrado de hilos en la maquina.................................44

2.13 Enhebrado de agujas........................................................45

2.14 Cómo usar el enhebrador................................................47

2.15 Enhebrado del prensatelas..............................................48

3. VARIEDADES DE COSTURAS ..............................49

3.1 Triple costura .....................................................................49

3.2 Puntada de cobertura: .....................................................52

3.3 Equilibrio de tensión del filamento superior ................53

3.4 Cadeneta ............................................................................55

4. FINALIZACIÓN DE LA COSTURA ........................57

4.1 Inicio de la costura ...........................................................57

4.2 Fin de la costura ...............................................................57

4.3 Enhebrado...........................................................................58

4.4 Quitar tela en medio de la costura.................................58

4.5 Terminación el borde con una puntada de cobertura59

4.6 Aplicación de costura triple ............................................59

5. CUIDADO DE LA MÁQUINA..................................60

CONTENU

FR

1. DECOUVERTE DE LA MACHINE:..................... 64

1.1 Nom des parties .......................................................... 64

1.2 Accessoires standarts ...............................................65

2. PREPARATION AVANT DE COUDRE ............... 65

2.1 Allumage de la machine............................................. 65

2.2 Contrôle de la vitesse de couture............................. 66

2.3 Réglage de la pression du pied presseur................ 67

2.4 Comment installer le pied presseur......................... 68

2.5 Changement de la pression du pied sur le tissu ... 69

2.6 Modification de la longueur du point....................... 69

2.7 Changement d’aiguilles.............................................. 70

2.8 Modification de l’alimentation différentielle........... 70

2.9 L'enfile-aiguille ..............................................................71

2.10 Installation du guide-fil télescopique.......................71

2.11 Installation des bobines.............................................72

2.12 Enfilage de la machine ............................................... 73

2.13 Enfilage des aiguilles .................................................. 74

2.14 Comment utiliser l'enfile-aiguille .............................. 76

2.15 Enfilage du boucleur................................................... 77

3. VARIÉTÉS DE COUTURES............................... 78

3.1 Point de recouvrement triple.....................................78

3.2 Point de recouvrement............................................... 81

3.3 Équilibre de la tension du fil supérieur .................... 82

3.4 Point de chaînette ....................................................... 84

4. ACHEVEMENT DE LA COUTURE..................... 86

4.1 Début de la couture.....................................................86

4.2 Fin de la couture..........................................................86

4.3 Nouage des fils............................................................87

4.4 Retrait du tissu au milieu de la ligne........................ 87

4.5 Finition de la bordure avec un point de

recouvrement...............................................................88

4.6 Usage d’un point de recouvrement triple................ 88

5. ENTRETIEN DE LA MACHINE ......................... 89

INHALT

DE

1. HERANFÜHRUNG AN DIE MASCHINE...... 93

1.1 Bezeichnung der Teile .........................................93

1.2 Standard-Zubehör ................................................94

2. VORBEREITUNG AUFS NÄHEN.................94

2.1 Stromanschluss....................................................94

2.2 Steuerung der Nähgeschwindigkeit..................95

2.3 Anheben und Absenken des Druckfußes ........96

2.4 So stellen Sie den Druckfuß ein.........................97

2.5 Ändern des Fußdrucks auf den Stoff................98

2.6 Ändern der Stichlänge.........................................98

2.7 Nadelwechsel........................................................99

2.8 Ändern des differentiellen Stoffvorschubs......99

2.9 Nadeleinfädler.................................................... 100

2.10 Einbau der teleskopischen Fadenführung.... 100

2.11 Einbau der Spulen ............................................. 101

2.12 Einfädeln der Maschine Vorsicht:................... 102

2.13 Einfädeln der Nadel........................................... 103

2.14 So verwenden Sie den Nadeleinfädler........... 105

2.15 Beschicken des Greifers .................................. 106

3. ARTEN VON NÄHTEN ............................. 107

3.1 Dreifach-Überdecknaht .................................... 107

3.2 Überdecknaht:.................................................... 110

3.3 Oberfadenspannung ausgleichen.................. 111

3.4 Kettenstich.......................................................... 113

4. BEENDIGUNG DER NAHT........................ 115

4.1 Anfang der Naht ................................................ 115

4.2 Ende der Naht .................................................... 115

4.3 Führen Sie die ................................................... 116

4.4 Entfernen des Stoffes in der Mitte der Naht 116

4.5 Bearbeitung der Kante mit einer Überdecknaht:

.............................................................................. 117

4.6 Anwendung der Dreifach-Überdecknaht....... 117

5. WARTUNG DER MASCHINE.................... 118

TRIUMPHATOR 2000X

32

BASIC SAFETY PRECAUTIONS

Please read this manual before using the machine.

Do not use the machine at an ambient temperature higher than 45°C or lower

than 5°C, in humid rooms or outdoors, otherwise the machine may not work

properly. To avoid condensation on electronic devices, it is not recommended

to turn on the machine immediately after it has been moved from outdoors to

indoors. It is necessary to wait until the machine reaches room temperature.

Do not use the device in unstable electrical network or in places where there

is a strong electric or magnetic field, otherwise the machine will malfunction.

It is necessary to install the machine on a flat stable surface, taking into

account the required distance from fixed objects.

Do not drop the machine as this may result in injury or damage to the machine.

OPERATING THE MACHINE

Be careful when operating the machine; protect your hands from getting into

the working area of moving parts, especially in close proximity of needles.

To avoid electric shock or short circuit, make sure that all cables are in good

condition and not damaged (cuts, burns, etc.), not in contact with damp or

corrosive environments. The power cable must have good contact with the

mains. When disconnecting the power cable from the mains, do not pull on

the cable.

SAVE THESE INSTRUCTIONS

This machine is intended for domestic use only.

This device is not intended for use by persons (including children) with

reduced physical or mental capabilities, or lack of knowledge and skills,

unless they are supervised or trained by a person responsible for their safety.

Supervise children and prevent them from playing with this device.

If the operating conditions and storage rules of the machine are observed,

the service life will be at least 8 years.

CONTENUTI

IT

1. CONOSCENZA DELLA MACCHINA..................122

1.1 Denominazione delle parti..........................................122

1.2 Accesori standard........................................................ 123

2. PREPARAZIONE ALLA CUCITURA................... 123

2.1 Allacciamento elettrico ............................................... 123

2.2 Controllo velocita’ cucitura .........................................124

2.3 Salita e discesa del piedino ....................................... 125

2.4 Come si monta il piedino ............................................ 126

2.5 Variazione della pressione del piedino sul tessuto 127

2.6 Variazione della lunghezza del punto....................... 127

2.7 Sostituzione degli aghi ................................................128

2.8 Variazione del trasporto differenziale del tessuto . 128

2.9 Infila ago.........................................................................129

2.10 Posizionamento del guidafili telescopico................ 129

2.11 Posizionamento dei rocchetti.................................... 130

2.12 Infilatura della macchina.............................................131

2.13 Infilatura degli aghi....................................................... 132

2.14 Come usare l’infila ago................................................ 134

2.15 Infilatura del crochet.................................................... 135

3. TIPOLOGIE DEI PUNTI.....................................136

3.1 Punto di copertura a tre fili......................................... 136

3.2 Рunto di copertura:....................................................... 139

3.3 Livello di tensione del filo superiore.......................... 140

3.4 Punto catenella.............................................................142

4. TERMINE DEL PUNTO......................................144

4.1 Inizio del punto.............................................................. 144

4.2 Termine del punto........................................................ 144

4.3 Allacciatura dei fili ........................................................145

4.4 Come togliere il tessuto in mezzo all’impuntitura.. 145

4.5 Orlatura con il punto di copertura:.............................146

4.6 Uso del punto di copertuta a tre fili........................... 146

5. MANUTENZIONE DELLA MACCHINA.............. 147

İÇİNDEKİLER

TR

1. MAKİNE İLE TANIŞMA ........................... 151

1.1 Parça Adları ........................................................ 151

1.2 Standart Aksesuarlar........................................ 152

2. DİKİŞ ÖNCESİ HAZIRLIK ........................ 152

2.1 Güç bağlantısı .................................................... 152

2.2 Dikiş hızı kontrolü .............................................. 153

2.3 Baskı ayağının kaldırılması ve çıkarılması .... 154

2.4 Baskı ayağı nasıl takılır ..................................... 155

2.5 Baskı Ayağı Basıncını Değiştirme................... 156

2.6 Dikiş uzunluğu.................................................... 156

2.7 İğne değişimi...................................................... 157

2.8 Diferansiyel beslemenin değiştirilmesi.......... 157

2.9 İplik geçirici......................................................... 158

2.10 Teleskopik iplik sehpasının takılması ........... 158

2.11 Makaraların takılması ....................................... 159

2.12 Makineye iplik geçirme..................................... 160

2.13 İplik iğneleri......................................................... 161

2.14 İplik geçirici nasıl kullanılır ............................... 163

2.15 Lüpere iplik geçirme.......................................... 164

3. DİKİŞ ÇEŞİTLERİ..................................... 165

3.1 Üçlü kapak dikişi................................................ 165

3.2 Kapak dikişi:........................................................ 168

3.3 Üst iplik tansiyon dengesi................................ 169

3.4 Zincir dikiş........................................................... 171

4. DİKİŞ TAMAMLAMA ...............................173

4.1 Dikişin başında................................................... 173

4.2 Dikişin sonu ........................................................ 173

4.3 İplerin bağlanması............................................. 174

4.4 Dikişin ortasında kumaşın çıkarılması........... 174

4.5 Kenarı bir kapak dikişiyle tamamlamak: ....... 175

4.6 Üçlü kapak dikişi uygulaması.......................... 175

5. MAKİNE BAKIMI ..................................... 176

TRIUMPHATOR 2000X

54

ACQUAINTANCE WITH THE MACHINE

Name of Parts

1. Differential Dial

2. Length Dial

3. Balance Wheel

4. Thread Reel Stand

5. Spool Cushion

6. Telescopic Thread Guide

7. Three-Extension Rod

8. Looper Thread Tension Dial

9. Right Needle Thread Tension Dial

10. Center Needle Thread Tension Dial

11. Left Needle Thread Tension Dial

12. Pressure Adjusting Dial

13. Cs Looper

14. Power Switch

15. Looper Cover

16. Presser Holder

17. Presser Foot

18. Blade

19. Cloth Cover

20. Needle Plate

21. Presser Bar Connection Rod

22. Left Needle#14

23. Center Needle#14

24. Right Needle#14

Standard Accessories

1. Screw driver

2. Cleaning brush

3. Hexagonal wrench

4. Tweezers

5. Nets x 4

6. Set of needles

7. Needle threader

8. Spool holder caps x4

9. Oil feeder

10. Accessory box

GETTING READY TO SEW

Connecting the Machine to Power Supply

1. Turn off the power switch, and connect

the machine plug to the machine

socket.

2. Connect the power supply plug to your

power supply.

3. Turn the power switch.

TRIUMPHATOR 2000X

76

EN

USER MANUAL

Controlling Sewing Speed

Sewing speed can be varied by the

foot control.

The harder you press on the control,

the faster the machine runs. Step on

the foot control with the presser foot

lifter up, and practice controlling the

speed.

For Your Safety:

• While the machine is in operation, always keep your eyes on the sewing

area, and do not touch any moving parts such as the loopers, balance

wheel or needles.

• Always disconnect the machine from the power supply:-when leaving the

machine unattended.-when attaching or removing parts.-when threading

or cleaning the machine.

• Do not place anything on the foot control, except when the machine is

in use.

Operating instruction:

• The symbol "O" of a switch indicates the "off" position of a switch.

How to Turn the Balance Wheel

Always turn the balance wheel

toward you (counterclockwise).

Balance wheel

Opening and Closing looper

cover

To open: (A) While pushing with the

thumb to the right as far as it will go,

pull the loooper cover toward you.

NOTE: When the looper cover is

opened, the motor will switched off

immediately although the power

switch is at position”1”.

To close: (B) Lift the looper cover and push it against the machine. The looper

cover snaps into its position automatically.

Looper cover

Raising or Lowering the Presser

Foot

By raising or lowering the presser

foot lifter, the presser foot goes

down or up.

The presser foot should always be

lowered when sewing, except when

you are threading the machine or

testing it without threading.

NOTE: Raising the presser foot lever

loosens the thread tension.

When the presser foot is lifted, the

motor stops automatically even

though the power button is at

position “I”.

Presser Bar Connection Rod

TRIUMPHATOR 2000X

98

EN

USER MANUAL

1. Turn off the power switch and

unplug the machine.

2. Turn the balance wheel toward

you to raise the needle.

Raise the presser foot.

3. Press the lever located on the

back of the foot holder. The

presser foot will drop off.

Balance Wheel

Lever

Presser Holder

Attaching the Presser Foot

1. Turn off the power switch and

unplug the machine.

2. Place the presser foot so that

the pin on the foot lies just

under the groove of the presser

holder.

3. Lower the presser holder to

lock the foot into place.

4. Raise the presser bar

connection rod to check that

the presser foot is secure.

Presser Holder

Groove

Pin

Presser Foot Pressure Adjustment

The preset presser foot pressure on

the machine is suitable for medium

fabrics. For most fabrics, the presser

foot pressure does not need to be

altered. If you intend to work with

lighter or heavier fabrics, however,

it may be necessary to reset the

pressure. In this case, you can choose

from six position; make your selection

with the presser foot pressure lever.

The standard setting is "N".

Presser Foot Pressure Lever

Adjustment of Stitch Length

To adjust the stitch length, turn the dial.

The larger the number, the longer the

stitch.

For regular sewing, set the stitch length

at 3 - 3.5.

1. Stitch length dial

2. Setting mark

3. To lengthen

4. To shorten

TRIUMPHATOR 2000X

1110

EN

USER MANUAL

Adjustment of Differential Dial

The differential dial can be altered

by turning the dial.

The number on the dial indicates the

ratio between the main and the sub

feed motion.

• Set the dial at 1.0 for regular

sewing.

• Set the dial at a lower number

when sewing fine fabrics that

tend to pucker.

• Set the dial at a higher number

when sewing stretch fabrics

such as knits, jersey and tricot.

Differential dial

Setting mark

To shrink

To stretch

Changing the Needles

Turn the Balance wheel toward you to

raise the needle to its highest position.

Balance wheel

Then loosen the needle clamp screw for

the needle you are going to remove.

Needle clamp screw Hexagonal

wrench

Insert a new needle into the needle clamp

with the at side to the back and push it

up against the stopper, then tighten the

needle clamp screw.

Flat side

WARNING:

Turn the power switch off and unplug

the machine before changing needles.

Needle Threader

To attach the needle easily, use the

end of the needle threader to hold the

needle.

Insert a needle into the needle threader/

holder with the at side facing back as

shown.

Hold the stem and insert the needle into

the needle clamp and push it up as far

as it will go.

Tighten the needle clamp screw rmly

while supporting the holder in place.

Pull the holder own to remove it.

Needle threader / holder

NOTES: Use needles EL X 705 CF. Do not use any needle which is bent or

blunt.

Setting the Telescopic Thread

Guide

Pull the telescopic thread guide up

as far as it will go. Turn the it so that

the thread guides are right above the

spool pins.

Telescopic thread guide

Three-extension rod

Spool stand base

Stoppers

NOTE: Make sure the two stoppers on

the thread guide post, as shown, are

set in at the correct position.

TRIUMPHATOR 2000X

1312

EN

USER MANUAL

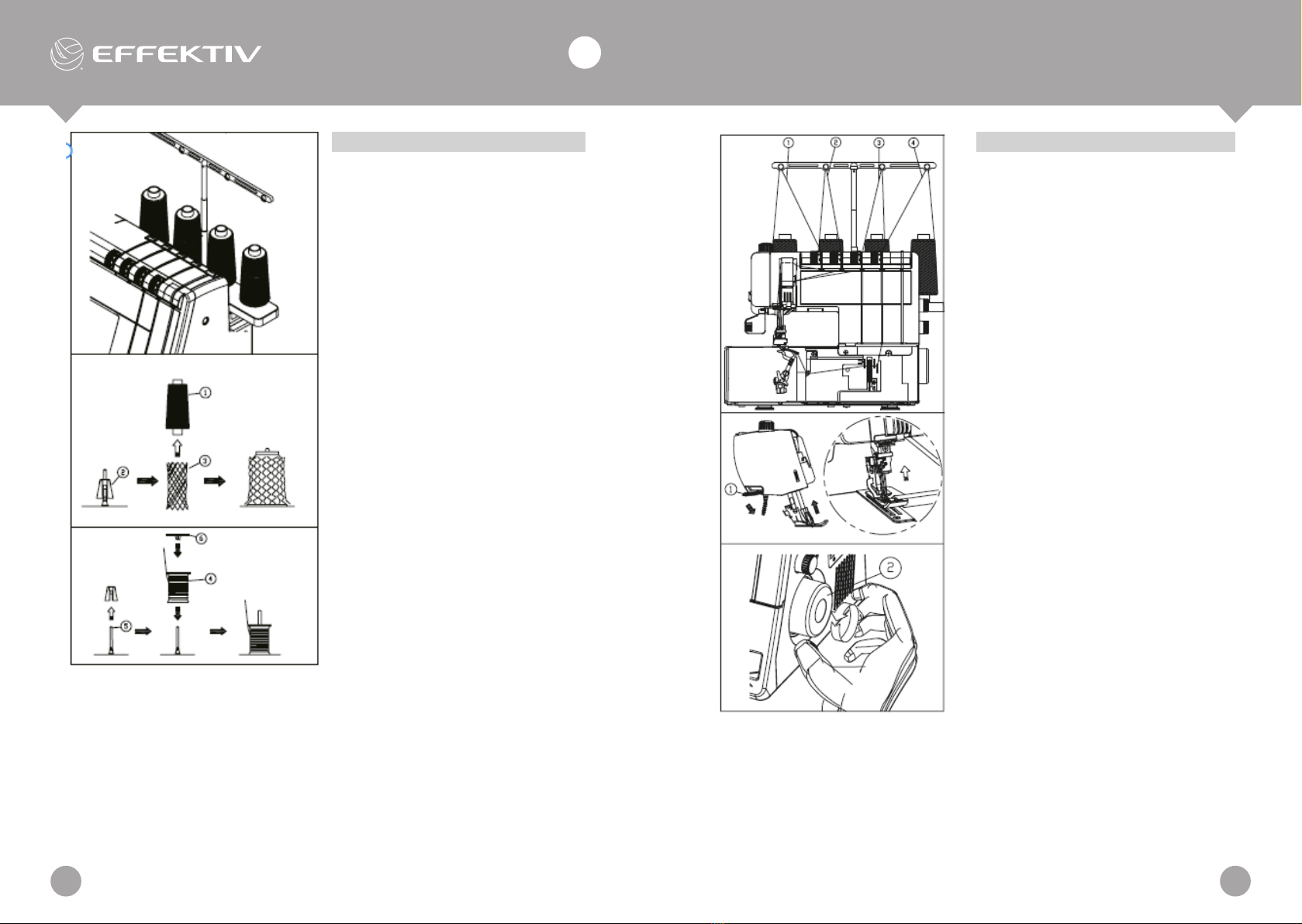

Setting the Spool Cones

Place the spool cones on the spool

cushion. Thread the machine in the

following order: If the thread slips

down from a spool cone during

threading and/or sewing, put a net

over the spool cone as illustrated to

prevent jamming.

Spool Cone

Spool cushion

Net

When using small spools, remove the

spool holders from the spool pins.

Small spool of thread

Spool pin

Place the spool with its slit side up, and put the spool holder cap on top of it.

Spool Holder Cap

Threading the Machine

WARNING:

Turn the power switch off and unplug

the machine before threading the

machine. Thread the machine in the

following order:

Left needle thread

Center needle thread

Right needle thread

Looper thread

Raise the presser foot lifter.

Presser foot lifter

NOTE: When threading the machine a

ways raise the presser foot.

Turn the balance wheel toward you

to bring the needles to their highest

position.

Balance wheel

TRIUMPHATOR 2000X

1514

EN

USER MANUAL

Threading the Needles:

Thread each needle in the

following order:

1. Pull out the thread through

the holes of the telescopic

thread guide from the left

side from back to front.

2. Pass the thread through

the holes on the left side of

the thread guide plate as

illustrated.

Thread Guide Plate

3. Holding the thread on both

sides, insert it between the

tension discs and tighten it

a little. (Raise the presser

foot lever so that the thread

can easily pass between the

tension discs)tension discs)

Tension disks

1. Pass the thread through the

thread guide plate A from the

right.

Thread guide plate A

2. Draw the thread to the left and

pass it through the thread guide

plate B. Draw the thread down

and slip it behind the upper take-

up lever

Thread guide plate B

Upper take-up lever

3. Pull the thread down and pass it

behind the thread guide plate C.

Thread guide plate C.

4. Thread each needle as follows:

Left Needle: Pass the thread behind

the upper take-up lever plate from the

Bring the thread between the rst and

second tooth on the left side.

Center needle: Pass the thread behind

the thread guide plate on the right

side. Bring the thread between the two

inner teeth.

Right needle: Pass the thread behind

the thread guide plate on the right

side. Bring the thread between the rst

and second teeth on the right side.

Thread guide plate

Needle bar guide

TRIUMPHATOR 2000X

1716

EN

USER MANUAL

How to Use the Threader

1. Take a needle threader. The triangular

mark on the handle should face up.

Insert the thread into the slit of the Y

shaped notch.

Triangle mark

Y-shaped notch

2. Place the V shaped notch over the

needle just above the needle eye.

3. Slide the threader down along the

needle while pushing it against the

needle, until the threader pin enters

into the needle eye

V-shaped notch

Threader pin

4. Push the threader and the thread

will go through the needle eye

5. Remove the threader from the

needle. Use the hook to grab the

loop. Pull the ends of the threads

back.

Hook

Threading the Looper

Thread the looper in the following order:

1. Pass the thread through the

telescopic rod thread guide from

the right side from back to front as

shown in the illustration.

Telescopic thread guide

2. Pass the thread through thread

guide on the right and let the thread

pass the tension disc of the tension

adjustment dial.

Thread guide

3. Holding the thread on both sides,

insert it between the tension discs

and tighten it a little. (Raise the

presser foot lever so that the thread

can easily pass between the tension

discs)

Tension disc

4. Pass the thread down through the

looper thread guide (A) on the right

side. Pass it through the looper

thread guide (A) while holding the

thread against the thread guide

plate.

TRIUMPHATOR 2000X

1918

EN

USER MANUAL

Thread guide plate A

5. Continue threading according to

steps (5)-(9).

6. Pull the looper release handle. The

looper will tilt to the right for easy

access when threading.

(B) Looper release handle

7. Insert the thread into the eye of the

looper thread guide, and then into

the eye of the looper itself. Pull the

ends of the threads 10 cm back.

NOTE:

You may use a pair of tweezers.

STITCH TYPES

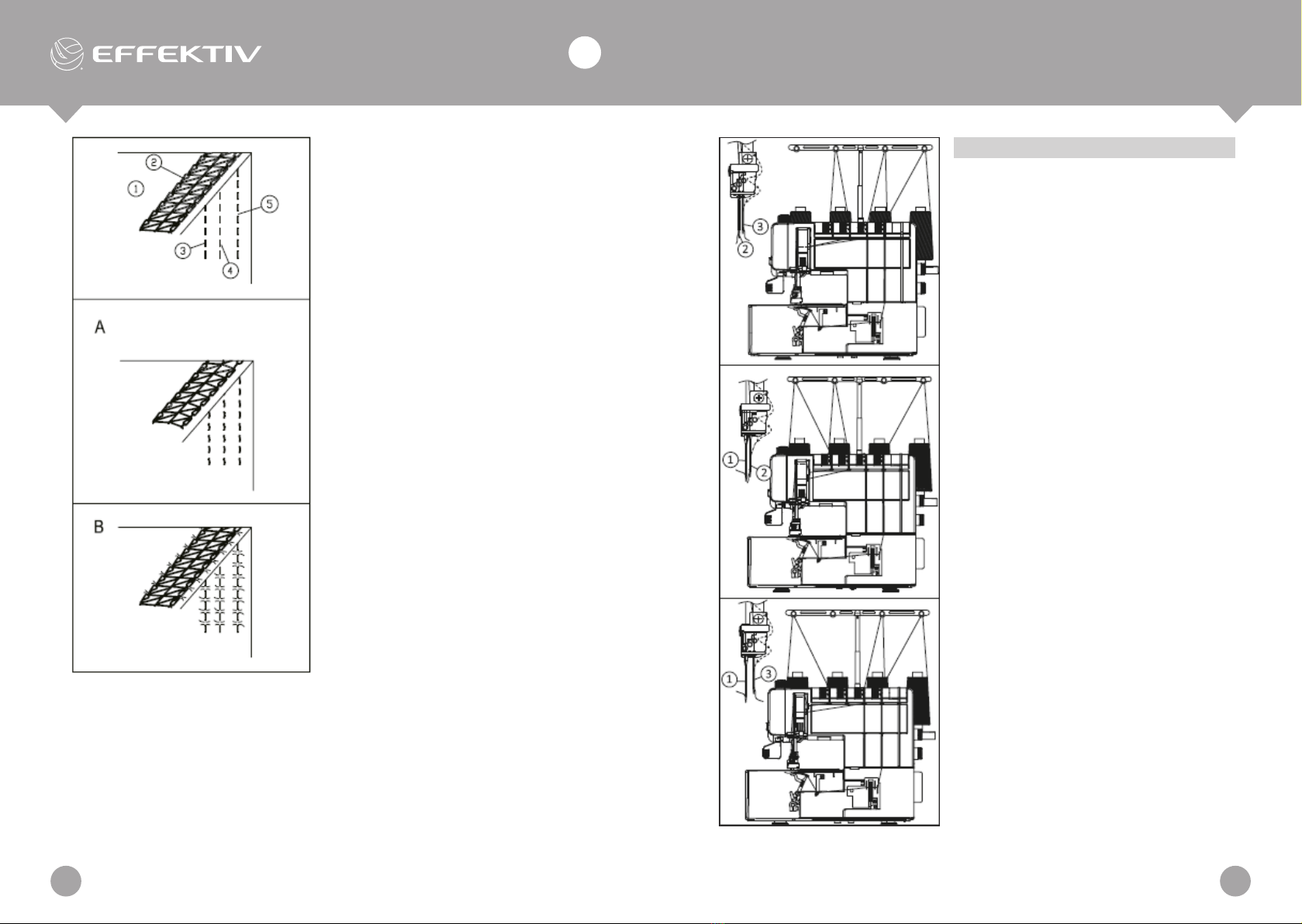

Triple Cover Stitch

The triple cover stitch is sewn with all three needles. This stitch forms three

parallel rows of the straight stitch on the right side, ideal for hemming,

attaching elastics, decorative stitches etc.

Left needle

Center needle

Right needle

NOTE: The machine is installed with the

EL X 705 CF needles.

Balancing the thread tension

1. Set the tension dials as follows:

Left needle thread tension dial: 4

Center needle thread tension

dial: 4

Right needle thread tension dial:

4

Looper thread tension dial: 4

2. Check the tension balance by test

stitching on the same fabric and

threads as actual garment.

Adjust the tension as necessary.

Type of Fabric Needle

Size Type of

Thread

Light to

medium

weight

Fine

knits

Fine

jersey

80/12

or

90/14

#60-90

Spun

Heavy

Weight Jersey

Fleece 90/14 #60

Spun

TRIUMPHATOR 2000X

2120

EN

USER MANUAL

Balanced tension:

The rows of stitches on the right side

of the fabric are straight and even. The

looper thread forms the dual rows of

squares with diagonals.

Wrong side of the fabric

Looper thread

Left needle thread

Center needle thread

Right needle thread

(A) If the needle thread tension is too

loose:

• The stitches on the right side are

irregular and loose

• There is a gap between head and

tail of the looper thread crossing

points.

Tighten the needle thread tension,

and/or loosen the looper thread

tension to correct it.

(B) If the needle thread tension is too

tight:

• The fabric puckers.

Loosen the needle thread tension, and

/ or tighten the looper thread tension

to correct it.

Cover Stitch

This stitch is sewn with two needles

and forms two parallel rows of straight

stitches on the right side, widely used on

cuffs and stretch welts of T-shirts etc.

There are three types of cover stitch:

• Narrow-right (3 mm wide)

• Narrow-left (3 mm wide)

• Wide (6 mm wide).

1. Narrow-right (3 mm wide)

Remove the left needle. Thread the looper,

right and center needles.

NOTE:

Tighten the needle clamp screw on the

side that is Not being used to prevent

losing the screw.

Center needle Right

needle

2. Narrow-left (3 mm wide)

Remove the left needle. Thread the looper,

left and center needles.

NOTE::

Tighten the needle clamp screw on the

side that is not being used to prevent

losing the screw.

Left needle Center needle

3. Wide (6 mm wide)

Remove the center needle. Thread the

looper, right and left needles.

TRIUMPHATOR 2000X

2322

EN

USER MANUAL

NOTE:

Tighten the needle clamp screw on the side that is not being used to prevent

losing the screw.

Left needle Right needle

Upper Thread Tension Bal-

ance

1.Set the tension dials as

follows:

For narrow-right (3 mm wide):

A. Center needle thread tension

dial: 4

B. Right needle thread tension

dial: 4

C. Looper thread tension dial: 4

For narrow-left (3 mm wide):

A. Left needle thread tension

dial: 4

B. Centre needle thread tension

dial: 4

C. Looper thread tension dial: 4

For Wide (6 mm wide):

A. Left needle thread tension

dial: 4

B. Right needle thread tension

dial: 4

C. Looper thread tension dial: 4

2. Check the tension balance by test

stitching on the same fabric and

threads as actual garment.

Adjust the tension as necessary.

Balanced tension:

The rows of stitches on the right side

of the fabric are straight and even. The

looper thread forms a row of square with

diagonals.Reverse side of the fabric

Looper thread

Left needle thread

Right needle thread

(A) If the needle thread tension is too loose:

• The stitches on the right side are irregular and loose.

• A gap is formed between the upper and lower weave points of the looper

thread.

Tighten the needle thread tension, and/or loosen the looper thread tension

to correct it.

(B) If the needle thread tension is too tight:

• The fabric puckers. Loosen the needle thread tension, and/or tighten the

looper thread tension to correct it.

TRIUMPHATOR 2000X

2524

EN

USER MANUAL

Chain Stitch

This stitch is sewn with a single

needle and forms a chain of

looper thread on the wrong side

of the fabric.

This is a durable and exible

stitch used for seaming knit

fabrics, attaching elastics,

attaching bias tapes etc.

Thread one of the three needles

and looper. Remove the needles

not to be used.

NOTE:

Tighten the needle clamp

screws on the sides that are

not being used to prevent

losing the screws.

Balancing the thread tension

1. Set the tension dials as

follows:

Needle thread tension dial: 4

Looper thread tension dial: 4

NOTE:

Adjust the tension dial for the

needle being used

2. Check the tension balance by test

stitching on the same fabric and

threads as actual garment. Fine-

tune the tension as necessary.

Balanced tension

The straight stitch on the right side of the

fabric is straight and even. The looper

thread forms a chain.

Reverse side of the fabric

Looper thread

Needle thread

A: If the needle thread tension is too

loose:

a. The stitch on the right side is irregular

and loose.

b. The needle thread forms loops on the

wrong side of the fabric.

Tighten the needle thread tension, and/

or loosen the looper thread tension to

correct it.

B: If the needle thread tension is too

tight:

a: The fabric puckers.

Loosen the needle thread tension, and/

or tighten the looper thread tension to

correct it.

TRIUMPHATOR 2000X

2726

EN

USER MANUAL

FINISHING THE SEAM

To achieve the best results, use a piece

of scrap fabric at the beginning and end

of the seam.

Beginning of the Seam

A. Raise the presser foot and insert a piece

of scrap fabric under the foot. Lower the

foot and turn the balance wheel several

times toward you.

Step on the foot controller and start

sewing slowly.

Balance wheel

B. Stop sewing at the end of the scrap

fabric.Insert the main fabric after the

scrap as shown, then start sewing on the

main fabric.

Scrap fabric

Main fabric

End of the Seam

C. Stop sewing at the end of the main

fabric. Insert another piece of scrap fabric

after the main fabric as shown, then sew

through the scrap.

Another scrap fabric

D. Cut the connecting threads between the

main fabric and scrap fabric.

Connecting threads

Knotting the Threads

Draw the needle threads to the wrong side

of the fabric by using a pair of tweezers

and knot them together.

Removing the Fabric in the Middle of

the Stitching

1. Raise the needles to their highest

position by turning the balance wheel

toward you.

Balance wheel

2. Raise the presser foot with the

presser foot lifter.

Presser foot lifter.

3. Pull the needle threads before the

needle eyes. This prevents the

threads from being caught when

removing the fabric.

4. Pull the fabric to the rear.

5. Remove the fabric and cut threads

with the thread cutter.

Thread cutter

TRIUMPHATOR 2000X

2928

EN

USER MANUAL

Hemming with the Cover Stitch

1. Fold up the edge of the fabric to the

wrong side and press.

2. Drawa line with a tailor’s chalk on the

right side of the fabric to mark the

fabric edge.

3. Place the fabric so the left needle

drops just to the left side of the marked

line. Lower the presser foot.

4. Sew carefully along the marked line.

5. After finishing sewing. Raise the

presser foot and remove the fabric to

the rear.

6. Draw the needle threads to the wrong

side of the fabric and knot them

together.

Marked line

Left needle

Right needle

Right side of the fabric

Triple Cover Stitch Applications

1. Hemming the sleeves

Sleeve

2. Attaching laces and tapes

Tap or lace

Right side of the fabric

Reverse side of the fabric

MAINTENANCE OF THE MACHINE

3. Attaching elastics

Right side of the fabric

Elastic

Reverse side of the fabric

4. Decorative stitch

Right side of the fabric

Reverse side of the fabric

Cleaning the Feed Dogs and Looper

Area

WARNING:

Turn the power switch off and unplug

the machine before cleaning.

NOTE:

Do not dismantle the machine in any

way other than as explained in this

section.

1. Remove the presser foot and

needles.

2. Remove the set screw and needle

plate.

3. Clean the feed dogs with a

cleaning brush.

Needle plate

Set screw

Cleaning brush

TRIUMPHATOR 2000X

3130

EN

USER MANUAL

4. Open the looper cover and clean

the looper and surrounding area

with the cleaning brush.

5. Replace the needle plate, needles

and presser foot.

Close the looper cover.

Problem Cause Reference

Needle Thread breaks The machine is not threaded correctly See pages 15-20

The thread tension is too tight See pages 20, 24-27

The needle is bent or blunt See page 12-13

The needle is not set correctly See page 12-13

A wrong needle is used See page 12-13

Needle bends or breaks The needle is bent or blunt See page 12-13

The needle is not set correctly See page 12-13

The needle clamp screw is loose See page 12-13

The fabric is forcedly pulled Do not pull the fabric

Skipped stitches The needle is not set correctly See page 12-13

The needle is bent or blunt See page 12-13

The tension is out of balance See pages 16, 19, 20

The machine is not threaded correctly See pages 15-20

Seam puckering The tension is out of balance See pages 20, 24-27

Machine does not operate The machine is not connected to the

power supply

See page 7

The foot control is not plugged in

firmly

See page 7

TRIUMPHATOR 2000X

3332

EN

USER MANUAL

PRECAUCIONES

Antes de usar la máquina, lea esta guía.

No utilice la máquina a una temperatura ambiente superior a 45 °C o inferior

a 5 °C, en habitaciones con alta humedad o al aire libre, de lo contrario la

máquina puede funcionar incorrectamente. Para evitar la condensación

en los dispositivos electrónicos, no se recomienda encender la máquina

inmediatamente después del frío. Deje que se caliente a temperatura

ambiente (instale en el calor). No se recomienda utilizar la máquina en caso

de funcionamiento inestable de la red eléctrica o en lugares donde hay un

fuerte campo eléctrico o magnético, de lo contrario la máquina no funcionará

correctamente. Es necesario instalar la máquina en una superficie plana y

estable, teniendo en cuenta que la máquina tenga una distancia suficiente

de los objetos estacionarios y no entre en contacto con ellos.

No deje caer del automóvil, puede provocar lesiones o daños en la máquina.

ANTES DE USAR LA MAQUINA

Tenga cuidado al trabajar en la máquina, proteja sus manos de entrar en

la zona de operación de las partes móviles de la máquina, especialmente

en el campo de trabajo de las agujas. Para evitar descargas eléctricas o

cortocircuitos: todos los cables deben estar en buenas condiciones y libres

de daños (cortes, quemaduras, etc.), no estar en contacto con un ambiente

húmedo o agresivo. El cable de alimentación debe tener un buen contacto con

la red eléctrica. Al desconectar el cable de alimentación de la red eléctrica,

no tire del cable.

GUARDE ESTAS INSTRUCCIONES

Esta máquina está destinada solo para uso doméstico. Este dispositivo no está

destinado a ser utilizado por personas (incluidos niños) con discapacidades

físicas, sensoriales o mentales o que carezcan de conocimientos y habilidades

suficientes, excepto cuando esté supervisado o vigilado por personas

responsables de la seguridad. Sujeto a las condiciones de operación y las

reglas de almacenamiento de la máquina de coser, la vida útil es de 8 años.

INFORMACION DE LA MÁQUINA

Nombre de las piezas

1. Perilla de control alimentación

diferencial de la tela

2. Regulador de ajuste de longitud de

puntada

3. Rueda de mano

4. Bastidor de bobinas

5. Soporte de bobina

6. Guía de hilo

7. Polo de guía de hilo

8. Regulador de tensión de hilo en

aguja izquierda

9. Regulador de tensión de hilo de

aguja derecha

10. Control de tensión de hilo en

enlazador superior

11. Control de tensión de hilo en

enlazador inferior.

12. Tornillo de regulación del

prensatelas

13. Prensatelas

14. Interruptor de encendido

15. Cubierta

16. Soporte de sujeción para

prensatelas

17. Prensatelas de sujeción

18. Cortador

19. Panel cerrado

20. Placa de la aguja

TRIUMPHATOR 2000X

3534

MANUAL DE USUARIO

ES

Accesorios estándar

Destornillador

Brocha

Llave hexagonal

Pinzas

Cuadrícula

Juego de agujas

Enhebrador

Disco de carrete

Aceitera

Caja de accesorios

PREPARACIÓN PARA LA COSTURA

Conexión de alimentación

1. Apague la alimentación e inserte en el

enchufe el conector de la máquina.

2. Enchufe a la toma de corriente.

3. Encienda la alimentación.

21. Palanca de elevación de pie de sujeción

22. Aguja izquierda (Nº 90/14)23.

23. Aguja central (Nº 90/14) 24.

24. Aguja derecha (No90/14)

Control de velocidad de costura

La velocidad de costura está regulada

por el pedal. Cuanto más lo presione,

más rápido funcionará la máquina.

Levante el pedal de sujeción y

presiónelo

Apriételo y practique trabajando a

diferentes velocidades.

Para su seguridad:

• Mientras trabaja, siempre mire el área de costura. No toque las partes

móviles de la maquina, a saber: accionamiento de hilo, prensatelases,

rueda manual, aguja, cuchillas.

• Siempre apague la alimentación si:

- deja la maquina desatendida

- cambia o agrega cualquier pieza, si llena el hilo o limpia la máquina

• No ponga nada en el prensatelas, especialmente mientras la máquina

está funcionando.

Instrucciones de uso: El "0" en el interruptor indica la posición "OFF".

Rotación de la rueda manual: Siempre gire la rueda manual de inercia

sobre usted mismo (en sentido contrario a las manecillas del reloj).

La rueda de mano

TRIUMPHATOR 2000X

3736

MANUAL DE USUARIO

ES

Cómo abrir y cerrar la cubierta del

prensatelas

Para abrir: (A)

Empujando la tapa con el dedo

hacia la derecha, baje la cubierta de

la bisagra sobre usted mismo.

⚠ Nota: Al abrir la tapa del

prensatelas, el motor se apaga

automáticamente, aunque el botón

de encendido esté encendido en la posición "I" para cerrar: (B).

Levante la tapa de la bisagra y empuje hacia la máquina. La tapa se

sujetará en su lugar automáticamente.

Cubierta del prensatelas

Levantar y bajar el prensatelas de presión

El prensatelas de sujeción se eleva

y baja mediante la palanca de

elevación de prensatelas.

Cuando se trabaja, el prensatelas

siempre debe estar abajo, excepto

cuando está suspendida la

maquina o sin llenar los hilos.

Nota: Al levantar la palanca

del prensatelas de presión la

tensión de los hilos se debilita.

Cuando se eleva la carga

aerodinámica, el motor se detiene

automáticamente, aunque el botón

de encendido esté encendido en la

posición "I".

1. Palanca del prensatelas de

presión

2. Apague la alimentación y

desenchufe la máquina.

3. Gire la rueda manual de inercia

sobre usted mismo y levante la

aguja. Levante el prensatelas

de presión. Presione la palanca

detrás del soporte de sujeción

del prensatelas. El prensatelas

rebotará.

Rueda manual

Palanca

Soporte del prensatelas

Cómo instalar un prensatelas de

sujeción

1. Apague la alimentación y

desenchufe la máquina.

2. Coloque el prensatelas de

presión de modo que la varilla

esté directamente debajo del

enganchador del soporte.

3. Baje el soporte del prensatelas y

ajústelo.

4. Levante la palanca del

prensatelas de presión y

compruebe que el prensatelas

esté bien sujeto

Soporte del prensatelas

enganchador

Varilla

TRIUMPHATOR 2000X

3938

MANUAL DE USUARIO

ES

Table of contents

Languages:

Other EFFEKTIV Sewing Machine manuals