eicos FC34B02-M12 User manual

40m20m

L2

A1

A2

A1+

A2-

+

+

R

Reed Switch Reed Switch

2K2 - 2W

D = 20 ~ 40m

22R 5W

R

220R 5W

{

Manual

C.01/Nov2018

Models for G 3/4” Port

FC Series

eicos.net

| |

IMPORTANT !

YOU MUST CHECK BEFORE INSTALLATION

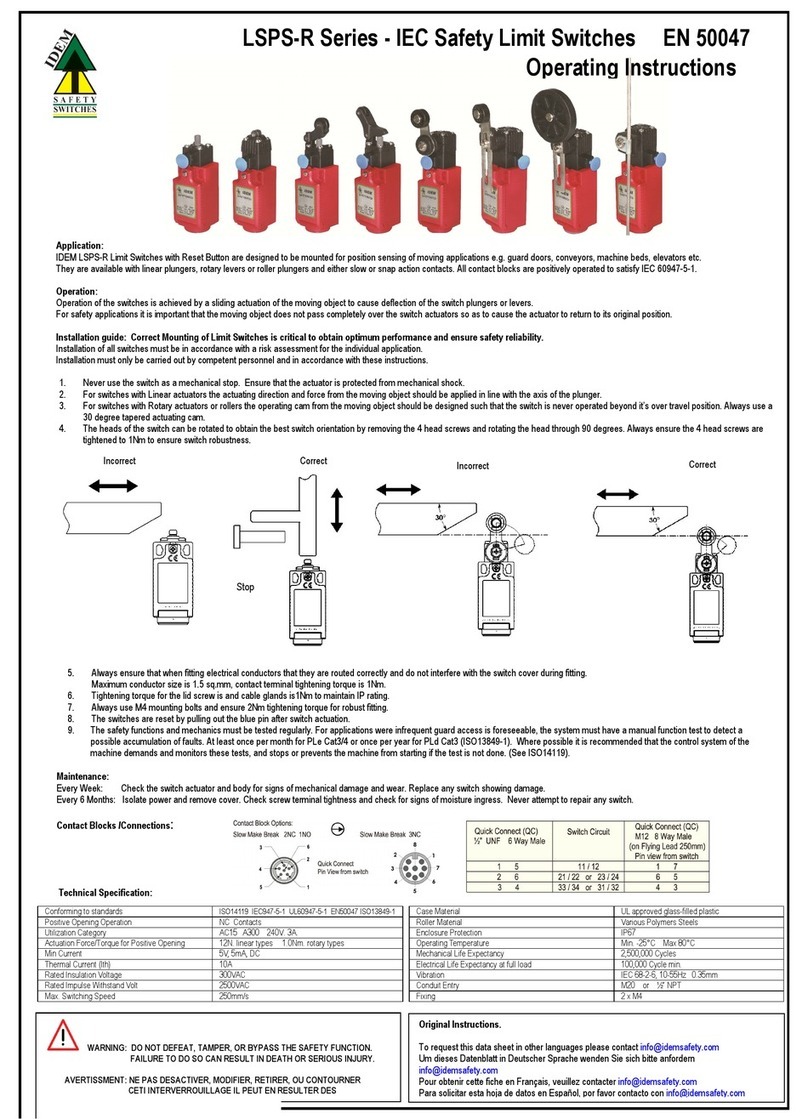

AC Current: Use K8*Filter in parallel with the coil (A1 A2) of a contactor or relay.

DC Current: Use KD*Filter in parallel with the coil (A1 A2) of a contactor or relay.

*For sale on accessories.eicos.us

Direct connection

to the sensor

Use 22R 5W*

resistor in series Use

24Vdc Voltage

•

•

Use mini contactor or auxiliary relay.

• ELECTRONIC EQUIPMENT:

Use 4K7 10W resistor.

Use 220R 5W* resistor.

Operation

• require prior testing. Use

lter before the Sensor to prevent the internal piston from locking. Not

recommended for industrial water waste.

• require technical

analysis: the Sensor contains magnetic components inside. Use a

magnetic lter before the Sensor to avoid deposition/settling that will

prejudice its operation.

The sensors work in all voltage and current ranges displayed in the table bellow:

Operating Voltage Peak Current

110Vac 20VA 0,2A 0,5A @20ms

220Vac 20VA 0,1A 0,5A @20ms

5Vdc 2,5W 0,5A 1A @20ms

12Vdc 5W 0,5A 1A @20ms

24Vdc 10W 0,5A 1A @20ms

NOT recommended

On datasheets.eicos.us available technical specications

02 (two) years warranty.

All Sensors have been tested and approved during the manufacture process.

K8 Snubber Filter for

electrical installation (AC)

(included)

Filter

Installing the snubber lter extends the

lifespan of the sensor’s electrical contact.

*On accessories.eicos.us check models and prices of Filters

- Attention to Install

Note: Reed Switches have reached over one million operations in tests with

contactor and K8* snubber lter.

Reed Switches are hermetically sealed contacts

actuated by a magnetic eld.

The life expectancy of a reed switch refers to a

kind of load to be used. Reed Switches of the highest reliability are applied in

our sensors, and their life expectancy can reach above two million operations.

However, when they are switching lamps, inductive or capacitive loads, this

number may decrease.

It is important to consider that the power specied by an electrical load is

often referred to the permanent working state.

For higher power, use an auxiliary relay or contactor as recommended below,

or similar.

This resistor dampens the peak voltage caused by the

capacitance of cables and electronic equipment input.

due to CAPACITANCE, which

can occur depending on the distance and cable used in the connection to the contactor.

K8*Filter mounted in

parallel with the coil of an

AC contactor, increases the

contact life.

• Switching inductive loads

0.1µF 400V

• Connecting the sensor to a contactor in long distances, use resistor:

• Connecting the sensor to an electronic equipment:

Important: For installation with , use 4K7 10W resistor.

•Timing relay

•Frequency inverter

•Etc.

Flow Switches and Level Switches for liquids

KD*Filter mounted in

parallel with the coil of a

DC relay, increases the

contact life.

BY448

or

1N4007

Important: For distances , use 24Vdc voltage.

K8*

K8*

KD*

Initial: 31.7VA

Rated: 5.1VA

Contactor Contactor

K8 for AC

KD for DC

072LPM

94

38140

1

3

A-coding

FLOW INCREASE - ON

FLOW DECREASE - OFF

Technical Specications

PPA (Polyphthalamide)

AISI 302 stainless steel

266mm2

25bar

0°C to 100°C | 140°C @1h

G 3/4” female (BSP - Parallel)

NBR (nitrilic rubber) O’Ring

M12 male plug (2 pins)

M12 female connector NOT included

IP66

Reed Switch 20W/VA (NA SPST)

300g

Body

Spring

Internal clearance

Maximum operating pressure

Operating temperature range

Inlet/outlet port

Sealing

Output connection

Enclosure rating

Electrical contact

Weight

Suitable for Detection of Medium Flows

Fluid ow through the sensor triggers precise displacement of a magnetic piston acting on an electrical contact (Reed Switch).

Model Actuation Range in Water

(in LPM)

FC34B02-M12 From ~2.1 to ~52

FC34B04-M12 From ~3.2 to ~72

Installation

• In applications without excessive vibration;

• Minimum distance of 20mm from any ferrous surface;

• Mounting with parallel port connection and O’Ring.

Mounting

Dimensions in millimeters.

Sealing

Flow Rate Sensitivity Adjustment

In water. Set point accuracy: ±15%.

Repeatability (not considering the viscosity change of liquids): ±10%.

Results of the

sensitivity test

(xed in the package)

Allen wrench to

adjust the sensitivity

(included)

Maintenance

1. Open the plug, remove the spring and clean using a brush if

there is encrustation;

2. Mount the sensor again as illustrated beside;

3. Test the electrical contact using an ohmmeter, moving the

magnetic piston.

On datasheets.eicos.us available technical specications Flow Switches and Level Switches for liquids

O’Ring (NBR) for sealing

Parker code 2-120

(included)

GAS (BSP) Thread

The sealing is made on the ring.

It’s not necessary sealant tape or

over tightening

Check compatibility with NPT

thread on datasheets.eicos.us

Scale

Output plug

M12 plug

Allen

Wrench

12mm

Plug

Piston

Spring

O’Ring

Hex screw for

sensitivity adjustment

WRONG CORRECT

M12 female

connector

Male M12 plug

2 pins

Flow

Switch

Electrical Connection

3-BL

FLOW

FLOW

1-BR

Brush

This manual suits for next models

1

Other eicos Switch manuals

Popular Switch manuals by other brands

Tecsis

Tecsis EGS08 operating manual

SMART Embedded Computing

SMART Embedded Computing ATCA-F140 Series Installation and use

Belkin

Belkin OmniView SOHO F1DD102L user manual

Advantech

Advantech EKI-2548I user manual

MSNswitch

MSNswitch UIS-322 user manual

Allied Telesis

Allied Telesis AT-FS709 installation guide