EiE INSTRUMENTS 107 RT User manual

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 2 of 22

Organization’s ISO 9001:2015 Certificate

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 3 of 22

Forward

Dear valued customer,

We just want to take a moment out to thank you for your keen interest in our company

products. We greatly appreciate your business and the opportunity you provided us to assist

you. You have joined a selected group of customers who have switched to the technologically

superior and quality enhanced laboratory testing product.

Time has changed, so do the technology. Your purchase lists you on the cutting edge of 21st

century technology. The attached test report is an excellent way of expressing and maintaining

your trust in EIE’s - superior quality testing products. Our continued efforts and commitment is

to provide you efficient sales after services, prompt attention and highest level of customer

satisfaction. If for any reasons, you have questions or comments, we are delighted to hear from

you. Call us on 0091-79-660406013 or send us email at

email within 24-48 working hours.

Once again, thank you for your trust and kind patronage. We look forward to serve you better

in future.

Yours sincerely,

EIE Instruments

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 4 of 22

Table of Contents

Organization’s ISO 9001:2015 Certificate ............................................................................... 2

Forward ................................................................................................................................ 3

Table of Contents .................................................................................................................. 4

List of Figures ........................................................................................................................ 4

1Introduction of Rolling Thin Film Test Apparatus ............................................................ 5

2Technical Specification ................................................................................................... 5

2.1 Electrical.................................................................................................................. 5

2.2 Mechanical .............................................................................................................. 5

3Brief Construction Details............................................................................................... 6

4Component diagram of Thin Film Oven .......................................................................... 7

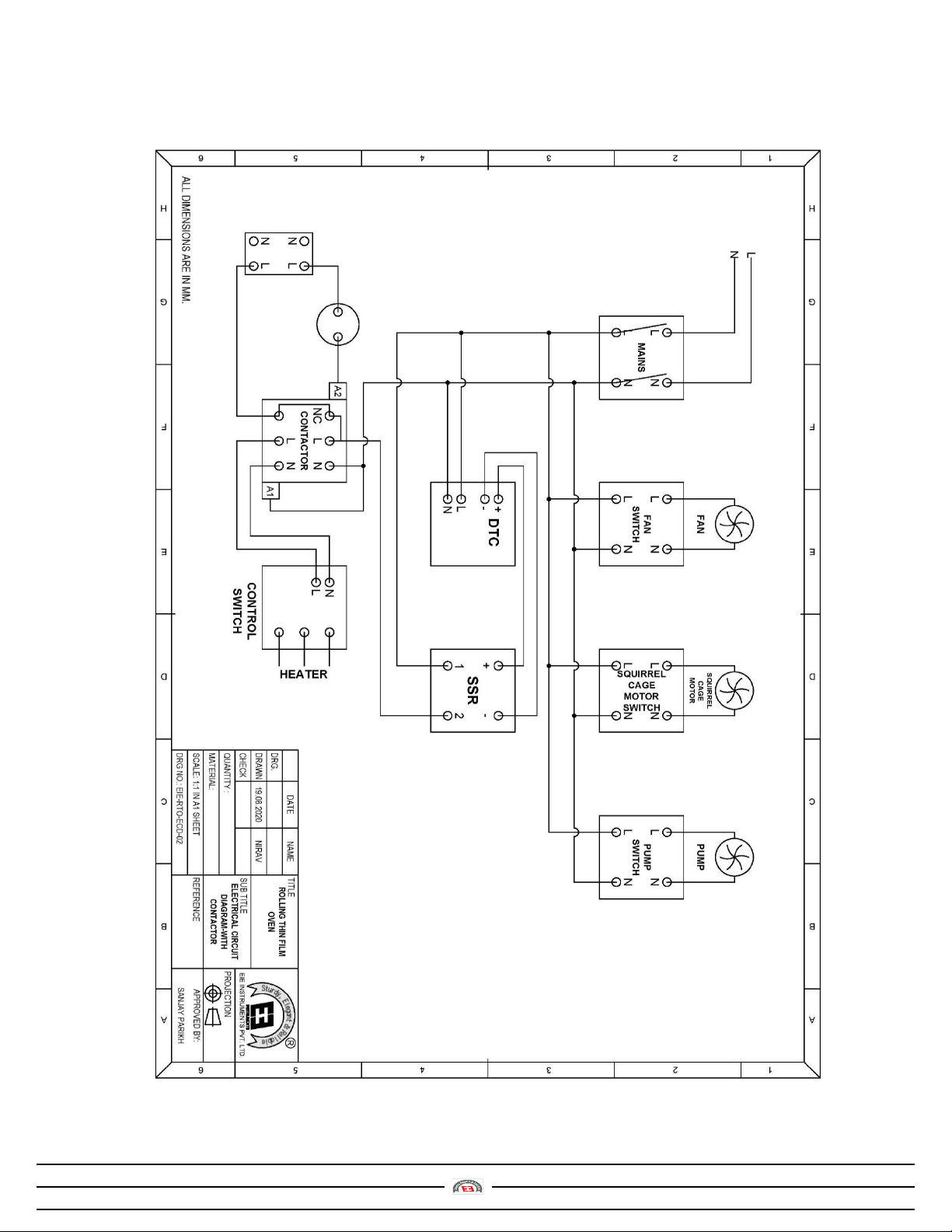

5Electric wiring Diagram of Thin film oven........................................................................ 8

6Delivery and Uncrating of apparatus .............................................................................. 9

6.1 How to make instrument ready for use? .................................................................. 9

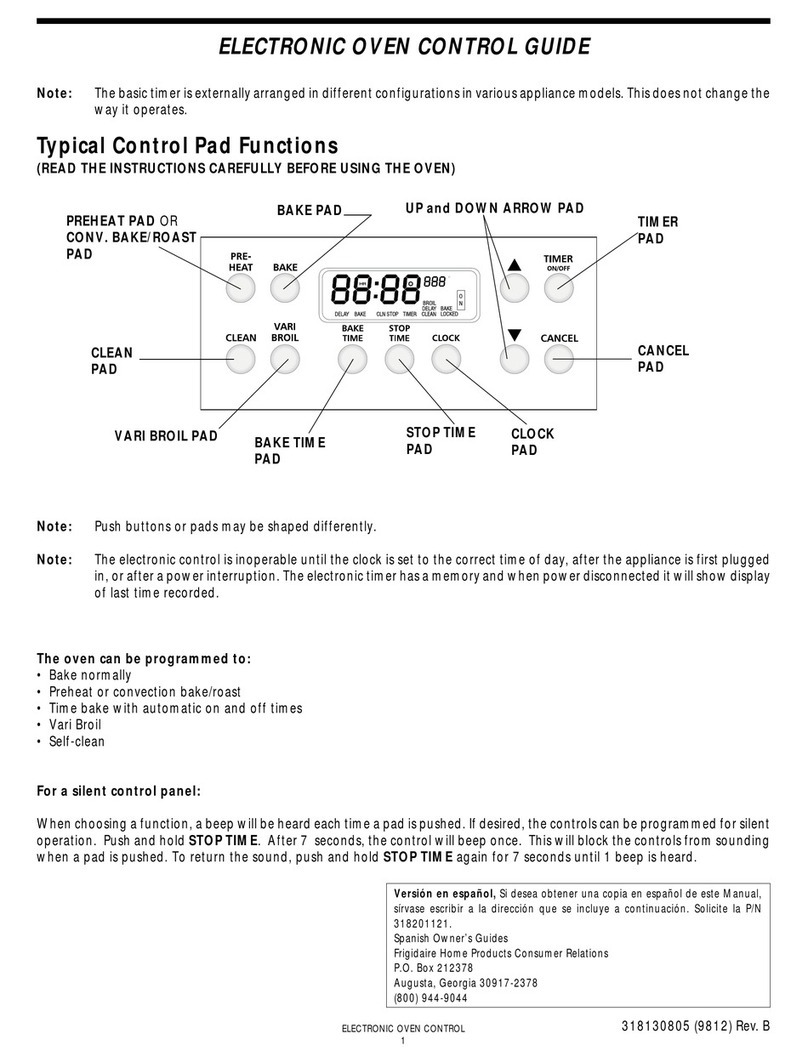

7Introduction of Control Panel ....................................................................................... 10

7.1 Guidelines for Operating Microprocessor based controller ..................................... 11

8Standard Operating Procedure ..................................................................................... 12

8.1 Report ................................................................................................................... 13

9Troubleshooting........................................................................................................... 14

10 Maintenance & Service ................................................................................................ 15

11 ASTM Standard for Test process ................................................................................... 16

Warranty Certificate............................................................................................................ 21

List of Figures

Figure 1 Component diagram of apparatus.................................................................................. 7

Figure 2 Electric circuit diagram of apparatus .............................................................................. 8

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 5 of 22

1Introduction of Rolling Thin Film Test Apparatus

This test method determines the effect of heat and air on a moving film of asphalt to serve as an indicator

of approximate change in properties during conventional hot-mixing. The results are reported in terms of

the changes in selected properties such as viscosity, penetration and ductility brought about by the RTFO

test, as evidenced by test data taken before and after the 75-minute oven cycle.

EIE –Rolling THIN FILM OVEN Conforms to the specifications of ASTM D2872

Double-walled electrically heated convection oven for rolling thin film oven tests on asphalts. Incorporates

all required features per ASTM specifications, including: door with double-pane viewing window;

symmetrical top and bottom vents; air plenum; squirrel cage-type 1325rpm fan; digital indicating

Microprocessor based temperature controller to control oven temperature at 163°C ± 0.5°C; vertical

circular carriage to mechanically rotate the samples at 15 ± 0.2rpm; air jets to blow heated air into each

sample bottle at its lowest point of travel; and a calibrated flowmeter to control air flow at 4000mL/min.

An over temperature cut-off circuit disconnects power to the unit in the event of control failure.

2Technical Specification

2.1 Electrical

POWER SOURCE : 230 Volts, 50 Hz, Single Phase AC Supply

POWER CONSUMPTION : Approx. 2.0 K.W

TEMPERATURE RANGE : Ambient to 200C

TEMPERATURE ACCURACY : 1 C or Better Result

TEMPERATURE RESOLUTION : 0.1C

TEMPERATURE CONTROLLER : Microprocessor Based PID –Controller.

SENSOR : RTD/ PT –100

FLOWMETER : 01 No. Ranging (200 –4000) ml/minute

2.2 Mechanical

Construction : Double walled

Inner Chamber : Stainless Steel

Outer body : M.S / STAINLESS STEEL (As per ordered)

Insulation : Mineral Wool

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 6 of 22

3Brief Construction Details

EIE –Rolling Thin Film Oven is ergonomically designed with latest German Technology for guaranteed

performance.

1) The oven is a double walled convection heated unit.

2) The double wall layer is supplied with separate inner chamber and exterior body as they do not have

direct physical contact with each other.

3) Inner chamber is made up of stainless steel with great care in order to eliminate the sharp edges.

4) All external cases of oven are constructed out of mild steel undergone with strong seamless welding

and covered with a thick layer of finished & attractive powder coating paint. This provides robust

and heat resistant surface having long-lasting attractive finish.

5) The gap between the double walled layer is filled with thick mineral glass wool to prevent the direct

heat losses and leakages and to ensure the maximum thermal efficiency.

6) The unit is fitted with a single door having special roller and spring type latch for proper locking

arrangement. A specially fabricated door having silicon rubber gasket fixed at its edges keeps the

inside temperature completely stable.

7) The fixed ventilators are provided on both sides of the oven wall.

8) The heating is achieved by 80/20 Nichrome wires installed as part of heater element. The unit has 2

special Heaters. The Heaters are made of high-quality Nichrome wire and finest ceramic Beads.

Heating element is placed at the bottom of the instrument as well as on both the sides of the unit.

9) Precise Temperature control is obtained by Microprocessor based PID temperature controller

(Advanced model) for ease of operation.

10) Especially designed air jets to blow heated air into each sample bottle at its lowest point of travel,

and a calibrated flowmeter to control air flow ranging (200 –4000) mL/min.

11) A circular carriage is mounted to hold the sample bottles and mechanically rotate the samples at a

speed of (15 ± 0.2) RPM.

12) The specially fabricated footrest keeps the whole oven in correct equilibrium.

13) The unit is fixed with Caution and other stickers, as per International Safety norms.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 7 of 22

4Component diagram of Thin Film Oven

sID

Description

ID

Description

ID

Description

1

Mains Switch

6

Diaphragm pump

11

Motor Cover

2

Alarm Switch

7

Control Switch

12

Door Handle

3

Blower Fan switch

8

Door Lock

13

Rotor Plate

4

Digital Temperature

Controller

9

Flow Meter

14

Viewing Glass

5

Squirrel Cage Motor

10

Castor Wheel

15

Copper Coil

Figure 1 Component diagram of apparatus

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 8 of 22

5Electric wiring Diagram of Thin film oven

Figure 2 Electric circuit diagram of apparatus

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 9 of 22

6Delivery and Uncrating of apparatus

1. Inspect equipment and shipping crate immediately upon receipt. If any damage is apparent,

immediately discuss it with the delivery person and contact the transportation company

immediately. Make notes of any damages on the bill of landing.

2. Retain all shipping material for later inspection.

3. Check packing slip carefully and ensure all materials have been received as indicated in packing slip.

4. Remove packing strip from surroundings of the instrument and all its accessories. Please inspect and

note whether any part of the instrument is damaged or any accessory is missing according to packing

slip? If it is so, then immediately make note of it and report to the manufacturer.

5. Due to the vibration incurred during shipping and handling, it is possible that mechanical connection

could become loose. Inspect all connection to ensure that they are secure.

6. After visual inspection, if everything is found to be okay, transit the instrument to suitable safe place

where it is intended to install. Caution: Handle with care.

7. Recycle the packing material. Do not throw it away for environment protection.

6.1 How to make instrument ready for use?

1) Keep the equipment in well ventilated place.

2) Place the equipment on a plain, even and sturdy surface leaving approx. 4”-5” inch space away from

the wall.

3) Do not use equipment in a corrosive environment. A corrosive environment may lead to poor

performance and deterioration of unit.

4) Keep instrument away from draft, sunlight, water or near a place of equipment, which emits heat as

well as electromagnetic conduction emission.

5) Keep Standard Operating Manual while operating the apparatus.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 10 of 22

7Introduction of Control Panel

The control panel is mounted at left hand side of the unit encompasses different control accessories

according to selected model. These control accessories differ in a way the temperature is controlled inside

the oven chamber.

The following are the switches for various functions on control panel:

Mains switch cum Indicator (Rocker Switch)

In this advanced model, mains switch serves the purpose of switching and indicating both. An operator can switch

on / switch off the entire unit from mains switch mounted on front panel. Also, the switch incorporates a lamp inside

which indicates that the mains supply is on and the unit is currently in the operating mode.

Alarm Indicator

This switch is mounted for safety purpose, as if the SSRs are damaged or out of date then the heat will

not be maintained as per DTC (set temperature value). As the chamber temperature rises above the set

point value then buzzer glows indicating for overheating of chamber.

Therefore, recommended to Turn “ON” Alarm switch before starting each test.

Fan (Blower) switch

This switch is provided on the control panel to control the working of fan (Blower) inside the oven

chamber. A circulating fan helps in maintaining & distributing uniform temperature inside the oven

chamber.

Digital Température Controller

RTFO incorporates the PID temperature controller to monitor and maintain the set-point temperature

value inside oven chamber. A proportional–integral–derivative controller (PID controller) is a

generic control loop feedback mechanism (controller) which calculates an "error" value as the difference

between a measured temperature value and a desired set-point value. The controller attempts to

minimize this error by adjusting the process control inputs.

Diaphragm Pump

This switch cum indicator is provided to turn “ON/OFF” pump which blows heated air jet inside each

sample at fixed flow rate, controlled by flowmeter mounted on the front panel.

Squirrel Cage Motor

This switch cum indicator is provided to turn “ON/OFF” cage motor which is holding the samples.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 11 of 22

Control Switch

Control switch is a rotary switch mounted on the front panel. It is marked with three numerical points

i.e. 0, 1, 2, and 3. To attain the low, medium and high heating application, the rotary switch should point

to corresponding numerical values according to following guidelines.

a) Off-setting : In this process, user should put the control switch at ‘0’th position indicating

that none of the heater is working.

b) Low-setting : When the control switch is kept at ‘1’st position, both the heaters will remain in

series connection and the temperature value up to 70° C could be determined.

c) Medium-setting: When the control switch is kept at ‘2’nd position, the heater with the maximum

kw (kilowatt) capacity works to determine the temperature range up to 150 °C.

d) High-setting : When the control switch is kept at ‘3’rd position, both the heaters remain in

parallel connection and the temperature range up-to 200 °C could be determined.

7.1 Guidelines for Operating Microprocessor based controller

SV For set value (Green/white display)

PV For Process value (Red display)

There are four tactile keys provided on the front panel for configuring the controller and setting up the

parameter values.

DOWN KEY : Press to decrease the parameter value.

UP KEY : Press to increase the parameter value.

To set the temperature for heating of the sample, press UP (Arrow key) to increase the temperature value

as desired set points increased than release the key at that point, set value will be auto saved and repeat

the same process to decrease the value.

Note:

The controller is factory set and it does not require any settings except required temp.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 12 of 22

8Standard Operating Procedure

1) Heat the sample of asphalt binder(sample) until it is fluid to pour. Stirr the sample to ensure

homogeneity and remove air bubbles.

2) If a determination of mass change is desired, label two RTFO bottles and weigh them empty. These

are designated as the “mass change” bottles. Record the weights.

3) Pour 35 ± 0.5g of asphalt binder into each bottle. Immediately after pouring each bottle, turn the

bottles on their side without rotating or twisting and place them on a cooling rack.

4) Allow all bottles to cool 60 to 180 minutes. After cooling, weigh the two mass change bottles again.

Record the weights.

5) When mass change is being determined, use two separate containers for this determination. After

cooling, separately place each of these containers vertically on an analytical balance, and determine

its mass to the nearest 0.001 g.

6) Connect the main cord to properly grounded outlet. Now, turn “ON” main switch cum indicator,

Indicator glows, indicating that apparatus is in operational mode.

7) DTC display also glows, displaying chamber temperature, now as per explained in section 4.1 set

desired temperature using UP/Down arrow key of controller.

8) Turn “ON” the Fan (Blower) switch for uniform heating throughout.

9) Set the airflow meter to read 4000 ± 200mL / min which is the same as described by ASTM D2872.

10) Place the sample bottles in the RTFO oven carriage, close the door, after that carriage rotates to an

accessible position at 15 ±0.2 RPM for 85 minutes. The test temperature 163 ± 0.5C shall be reached

within the first 10 minutes otherwise discontinue the test. Therefore, recommended to preheat the

oven chamber before place the test sample for test.

NOTE: For protection purpose, Push button is mounted just aside the main door, equipment stops

functioning if the door is open.

11) At the conclusion of the testing period, remove any sample for mass determination and place the

horizontally in the cooling rack. Then, remove each remaining glass sample container one at a time,

and transfer its content to a collection container having a capacity at least 30% greater than the total

expected volume of residue. This transfer shall be accomplished by first pouring out any residue that

will flow freely from the glass sample container and then scraping out as much of the remaining

residue as practical. While the residue is being removed from each sample container, the oven door

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 13 of 22

shall remain closed, with the heater power on, the air on, and the remaining samples rotating in the

carriage. The final container shall be removed from the oven within 5 min of removal of the initial

container.

12) After removing the residue from each of the glass containers, gently stir the collection container to

homogenize the residue without introducing air into it. Test the residue within 72 h of performing the

RTFO test.

13) If the mass change is being determined, allow the designated residue sample containers to cool on

the cooling rack for a minimum of 60 min and a maximum of 180 min. After cooling, place each

container vertically on an analytical balance and determine its mass to the nearest 0.001 g. Discard

the residue from mass change determination, and do not use it for other tests.

14) Now sample is ready to perform the test such as viscosity at 140°F (60°C) Ductility at 60°F (15.6°C) as

per requirement.

8.1 Report

1) Report the results from RTFO test in terms of the physical changes in the asphalt brought about by

this method. These values are obtained by performing appropriate ASTM tests on the asphalt

before and after the moving film oven cycle.

2) When determined, report the average mass change of the material in the two containers as a mass

percent of the original material. Report this calculated result to the nearest 0.001 %. A mass loss

shall be reported as a negative number while a mass gain shall be reported as a positive number.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 14 of 22

9Troubleshooting

Cause

Reason

Solutions

Heater is not working

(Heating is not

achieved inside the

chamber)

1) End terminals of heater element

may have lost the circuit

connection.

2) An operator may have kept the

control switch at “0” position.

3) SSR (Solid stat Relay) may have

stopped working.

Output dc voltage of 3-24 V from

micro-controller is not supplied to

SSR and in turn, SSR is not able to

supply 230 V to heater elements.

4) Control switch may not be

functioning.

1) Turn the oven upside down or

rest it on the side walls. Remove

the bottom cover. Find out the

loosen end terminal of heater

and fix it.

2) Keep the control switch position

on low, medium or high

according to user requirement.

3) Check Input voltage of SSR, it

should be 3 to 12-volt DC and

output voltage should be 230

volts AC.

If input is 3 -12 –volt not

available, DTC may be faulty.

If 230 volts AC not available

SSR may be faulty, Replace

the SSR.

4) Replace the control switch.

Top RED digits of

controller displays

“OPEN”

a) Sensor may not be

functioning well or it has

gone out of order.

a) Check the Sensor. It should

indicate between 110 –115

ohms, check it with the help

of multi-meter. If found

faulty replace it.

Unit is completely

dead. No part of it is

working.

1) Required operating power may

not be available.

1) Check the available mains power

in the socket with the help of

tester or multi-meter.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 15 of 22

2) Mains cord wire may have been

damaged.

3) Mains switch cum indicator on

control panel may not be

working.

2) Replace the cord wire.

3) Replace the mains switch cum

indicator.

10 Maintenance & Service

1) Always disconnect from power supply prior to maintenance & servicing.

2) To avoid electrical shock, this equipment must always use a properly grounded electrical outlet or

correct voltage and current handling.

3) Disassembly of this equipment is strictly limited to the qualified personnel and licensed engineers.

4) Maintain a safe distance of at least 5" to 6" from the wall while installing the oven.

5) Always check if the door is locked properly leaving no air leakage at all.

6) Please open/close the door gently. Recommend to replace the door gasket on yearly basis.

7) Ensure that ventilation shutters at both sides of the oven remain opened to complete the air

circulation cycle.

8) Clean the sensor near the heating element leaving sensor activate precisely.

9) Never place any test samples near the sensor element as it will affect and damage its accuracy.

10) Never place test samples directly on bottom part of the oven as the controlling circuit/wiring of the

entire unit is installed below this part.

11) The equipment is supplied with the brush-less AC motor, hence there is no need to replace the

carbon brush.

12) Keep the instrument tidy, clean and dry with mint cream. Before initiating the fresh day, use

preferably clean soft cloth. Brush up the unit body as to maintain its colour and finishing.

13) Never leave the instrument connected to mains after completion of Test.

14) In case of any difficulty, please do not try repairs without consulting us, especially when the

instrument is under guarantee period.

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 16 of 22

11 ASTM Standard for Test process

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 17 of 22

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 18 of 22

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 19 of 22

PRODUCT USER MANUAL : EIE_RTFO_PUM_00

Revision No.: EIE/RTFO/REV.00 Dtd. 15/08/2020

INSTRUMENT: Rolling Thin film oven

Page No.: 20 of 22

Table of contents

Popular Oven manuals by other brands

Gram

Gram KIP 17266 N instruction manual

M-system

M-system FD 96 Instruction for the use - installation advice

Frigidaire

Frigidaire FCS388WHCD Control guide

Atag

Atag CS66 C Series Instructions for use

KitchenAid

KitchenAid KEMC377KBL05 installation instructions

Whirlpool

Whirlpool GBD307PRY Use and care guide

EURO

EURO ESG600SX Installation and operation manual

Electrolux

Electrolux EVY 9741 AAX Troubleshooting

Kuppersbusch

Kuppersbusch EEB 6800.0 Instructions for use and installation instruction

Electrolux

Electrolux air-o-convect 20 GN 2/1 Brochure & specs

DèLonghi

DèLonghi SLM 60 PPP User & installation instructions

ILVE

ILVE OV60SNT3-BRZ Use and maintenance