MANUAL

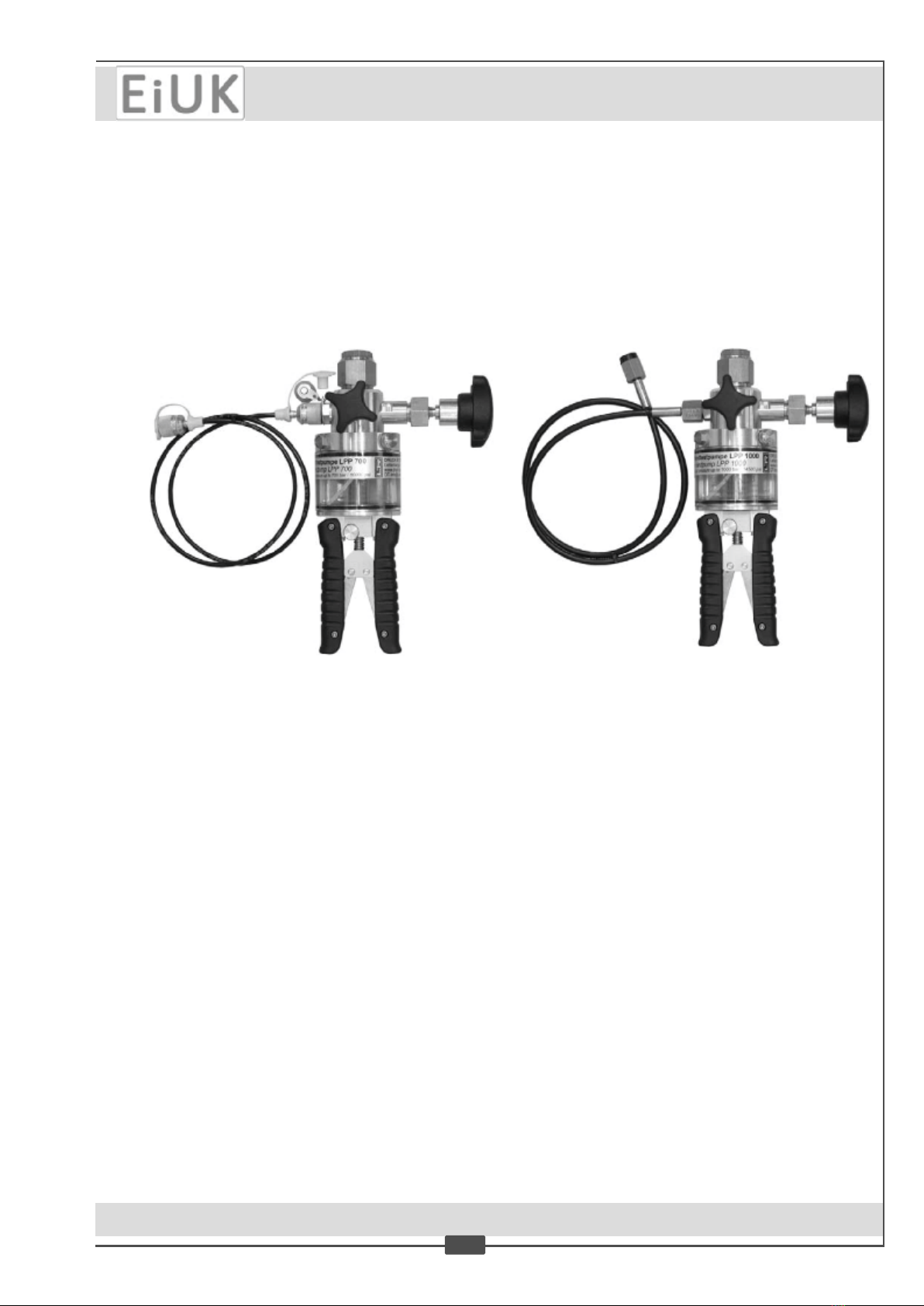

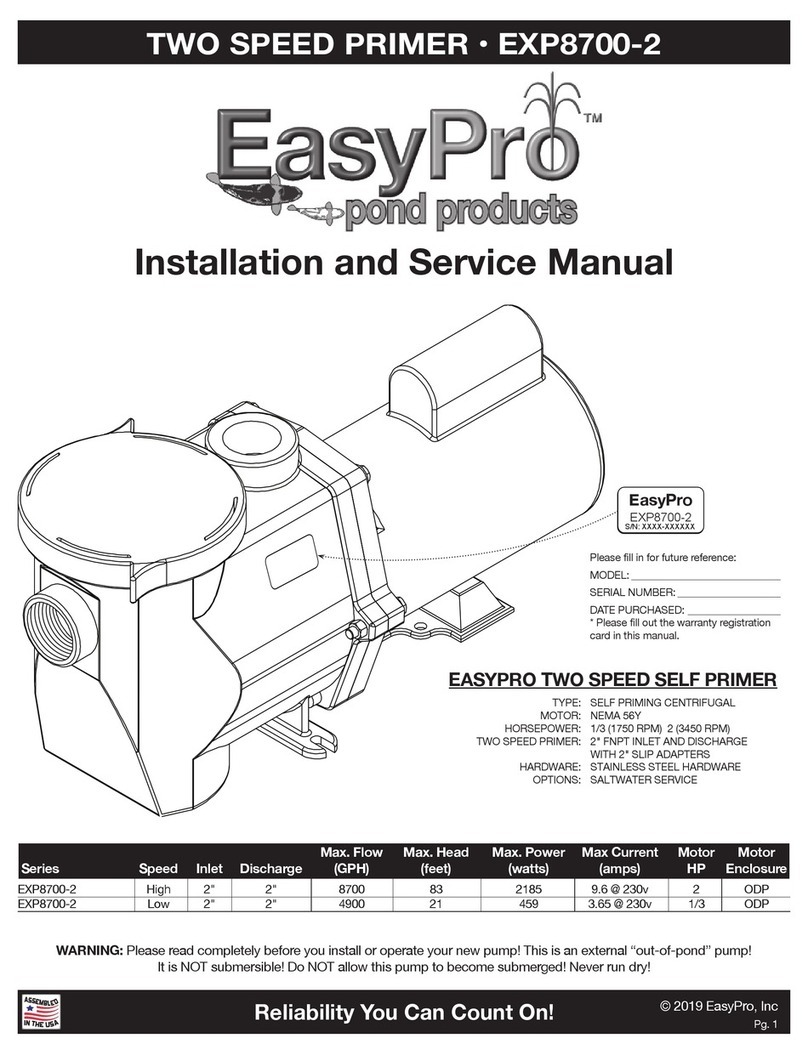

Pressure Test Pumps PGS 700 / PGS 1000

EiUK Eurotron Instruments (UK) Ltd. • Royal Oak Ind. Estate - Unit 18 Ausn Way • Daventry NN11 8QY (Northants) • UK

T

el. +44 1327 871044 • F

ax +44 1327 301255 • order

[email protected] • www

.eurotron-uk.c

om

7

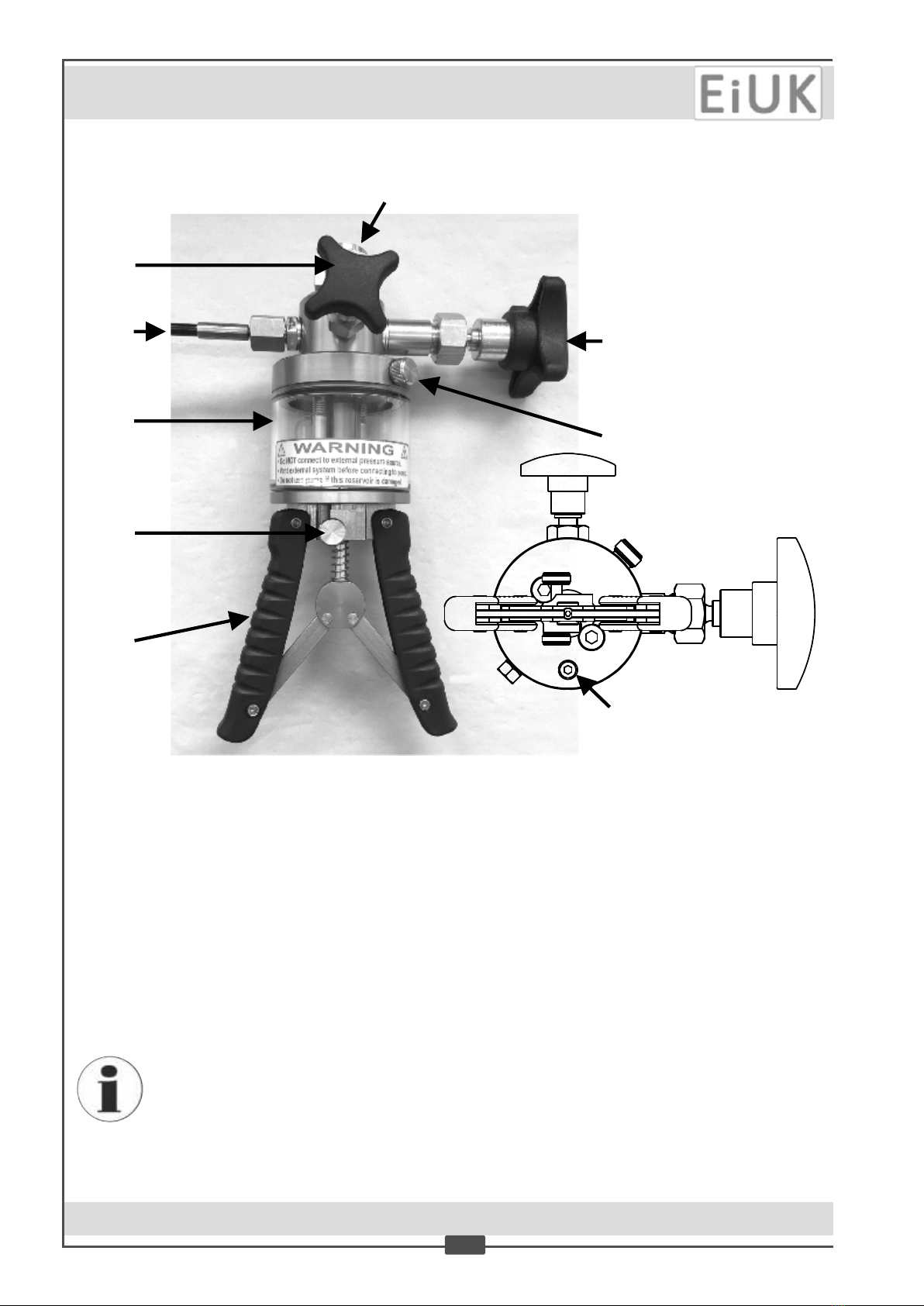

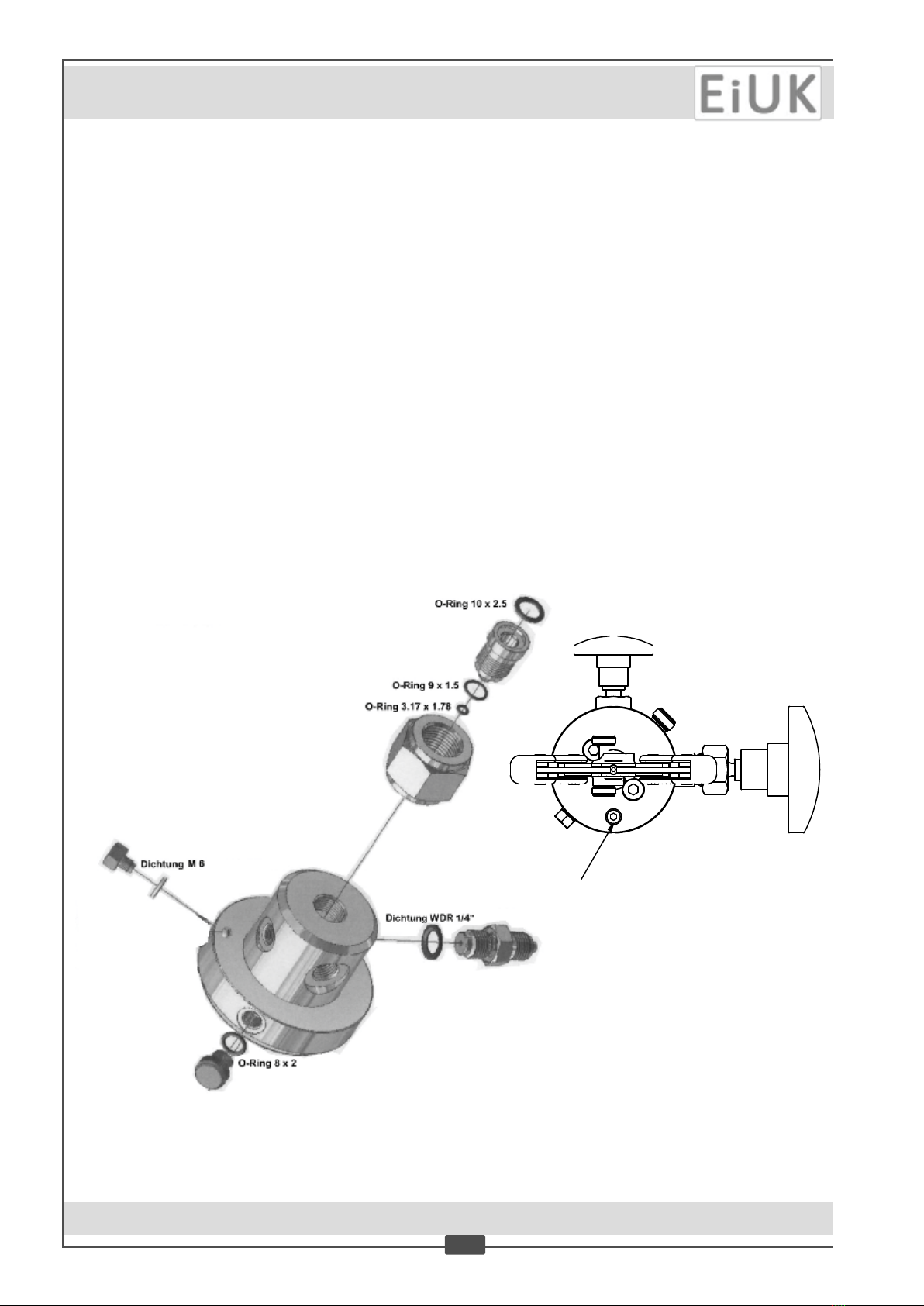

(Version PGS 700: MINIMESS 1620 test hose with 1/4" BSP female thread at open end,

1/4" BSP female rotang, with O-Ring, at the open end of the supplied test hose.

Pressure port for unit under test:

Pressure port for reference pressure instrument:

1/2" BSP female rotang swivel nut, with O-ring, at the top of the pump. (Aer dismounng of this

swivel nut using a Allen key, the 3/8" BSP female thread can be used.)

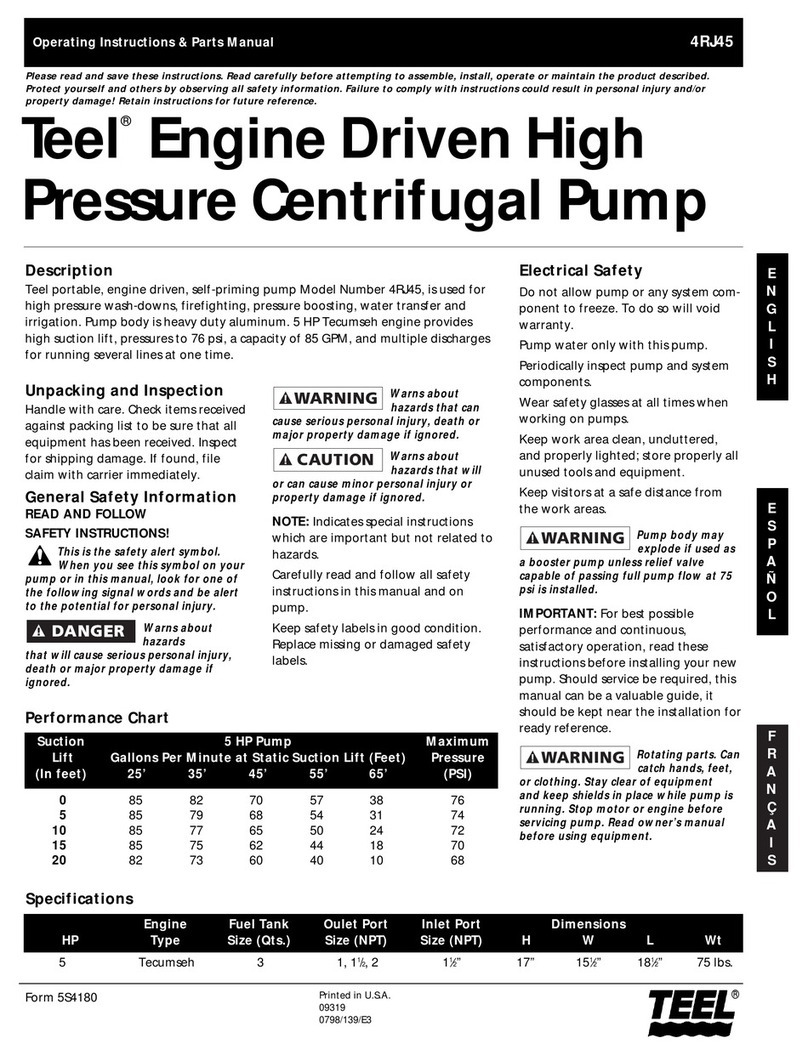

3. Specificaons

Instruments bearing this mark comply with the relevant European direcves.

CE, Communauté Européenne

The type label shows, that these operang instrucons have to be read before usage of this device.

Furthermore, model name and pressure range are printed on the type label. The serial number is

stamped on the boom side of the pump‘s body..

2.5 Labelling, safety marks

The pressure test pumps PGS 700 and PGS 1000 may also be operated with clean deslled water.

In this case, the pump must be emptyed aer each usage. We recommend deslled water as used

for steam iron plates (NOT perfumed!) or for car baeries.

2.4.2 Other liquids

Emergency treatment of acute effects:

Aspiraon: Send to hospital immediately.

Inhalaon: Remove to fresh air, if nausea persists seek medical aenon.

Skin contact: Where skin rashes or other abnormalies occur as a result of prolonged or repeated

contact, medical advice should be obtained as soon as possible.

On request, the model PGS 1000 is also available in a version suitable for SKYDROL or break fluids.

This version is marked by „-S“ in the serial number stamped on the boom side of the pump‘s

body. The SKYDROL version may NOT be used with water or mineral oil based hydraulic fluids.

Eye contact: Wash with copious amounts of water for at least 10 minutes. If irritaon results or

persists, obtein medical advice.

Reservoir: >200 cm³, can be refilled during pump operaon,

Ingeson: Do not induce voming. Administer 250 ml milk or olive oil. The main hazard following

accidental ingeson is aspiraon of liquid into lungs.

Version PGS 1000: high pressure hose)

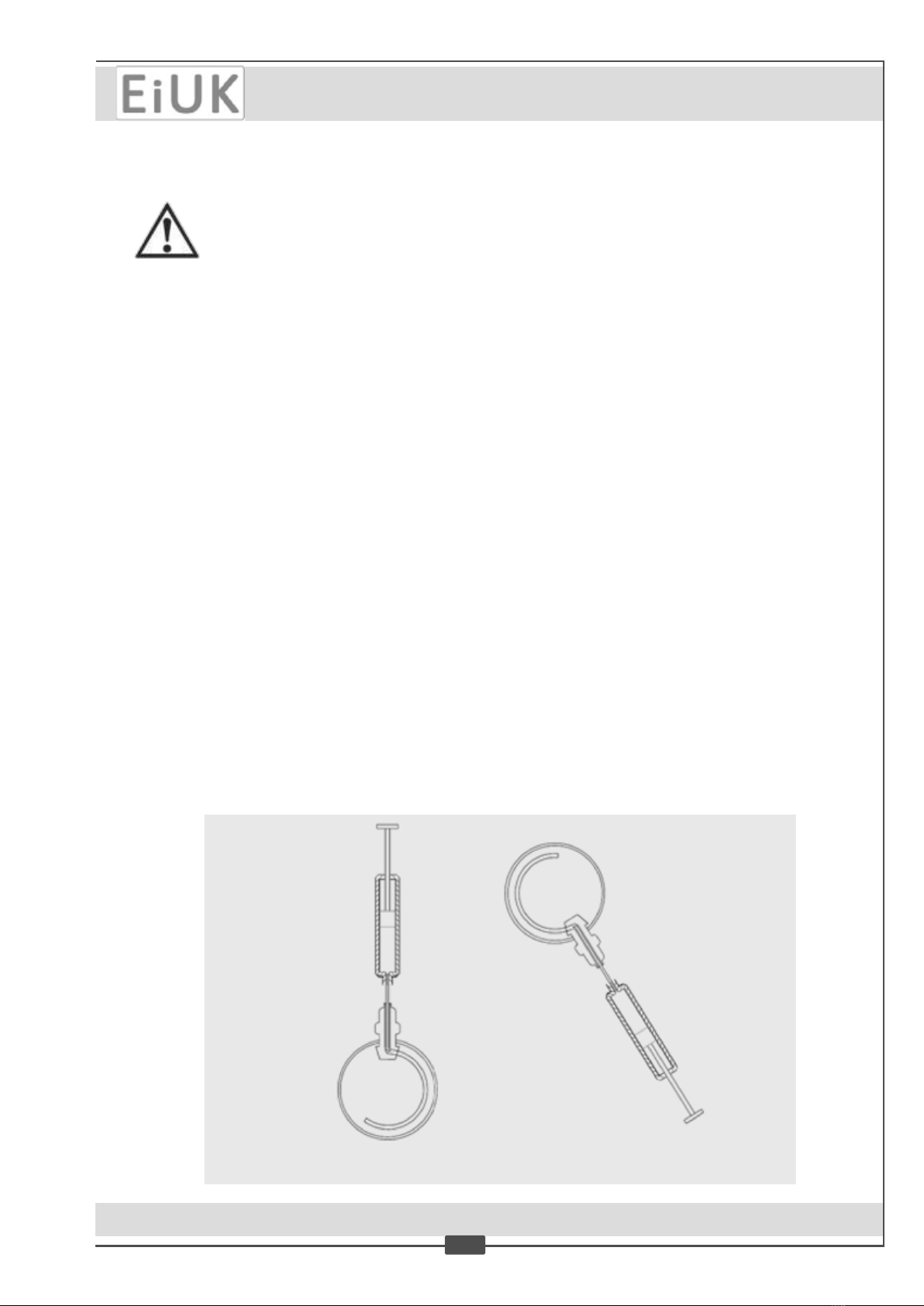

with drain screw (for 4 mm allen key) for dumping of the operaon fluid

Pressure adjustment: handles, volume fine adjustment valve and pressure release valve

Volume per stroke: priming pressure 81.6 mm³, high pressure 21 mm³

Dimension: approx. 270 x 160 x 120 mm (without test hose)

Weight: approx. 1.3 kg (without test hose)