EIUK PGS-40 User manual

Rel. 20120523

Operang Manual

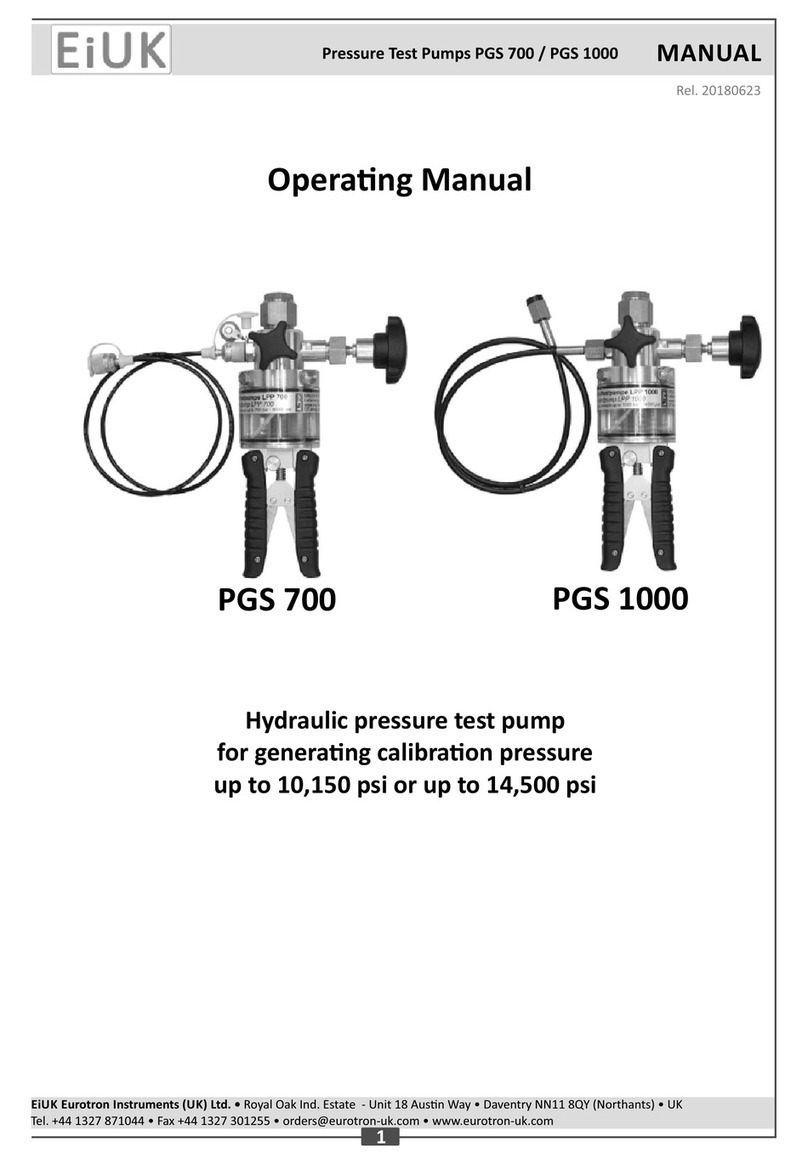

PGS‐40 PGS‐60

Calibraon Test Pumps

Content:

Page 2: 1. Safety Instrucons

Page 2: 2. Product Descripon

Page 2: 3. Mounng Instrucons

Page 2: 4. Operaon (pressure)

Page 3: 5. Operaon (vacuum)

Page 4: 6. Maintenance Instrucons

Page 4: 7. Cause of Fault

Page 4: 8. Technical Data

Page 4: 9. Available Accessories / Spares

Tips

This symbol provides you with ps, informaon and notes.

WARNING!

This symbol warns you against acons that can cause damage to persons or to

the instrument.

EiUK ‐ Eutrotron Instruments UK Ltd. • Unit 13 Riley Close • Royal Oak Ind Est • Daventry • Northants NN11 8QT • England U.K.

Phone: +44 (0) 1327 871044 • E‐Mail: sales@eurotron‐uk.com • Internet h p://www.eurotron‐uk.com

Operang Manual

•PGS‐40 PGS‐60

1

Operang Manual

PGS‐40 • PGS 60

EiUK ‐ Eutrotron Instruments UK Ltd. • Unit 13 Riley Close • Royal Oak Ind Est • Daventry • Northants NN11 8QT • England U.K.

Phone: +44 (0) 1327 871044 • E‐Mail: sales@eurotron‐uk.com • Internet h p://www.eurotron‐uk.com

1. Safety Instrucons

Read this manual carefully prior to

operang the calibraon test pump

PGS‐40 or PGS‐60. The pressure inside

the pump can be extremly high. Ensure

that all pressure connecons have been

established correctly.

2. Product Descripon

The calibraon test pump is used to generate

pressure and vacuum for checking, adjusng and

calibrang mechanical and electronic pressure

measuring instruments by comparave

measurements. These pressure tests may be

carried out in laboratories, workshop or on site at

the measuring point.

If the instrument to be tested and a sufficiently

accurate reference measuring instrument are

connected up to the test pump, the same pressure

is applied to the two measuring instruments when

the pump is operated.

By comparing the two measure values at random

pressure values, the accuracy can be verified or the

instrument under test can be adjusted.

Despite its compact dimensions, the calibraon

test pump is easy to operate and allows for exact

generaon of the required test pressures; a

change‐over switch enables the generaon of

vacuum as well. The pump is fi ed with a fine

adjustment valve for generaon of high pressure

and precise adjustment of pressures. The

reference instrument is screwed directly on the top

of the pump and the unit under test is connected

by means of the connecon tube incorportang an

adapter 1/4" BSP female thread, contained in the

scope of delivery.

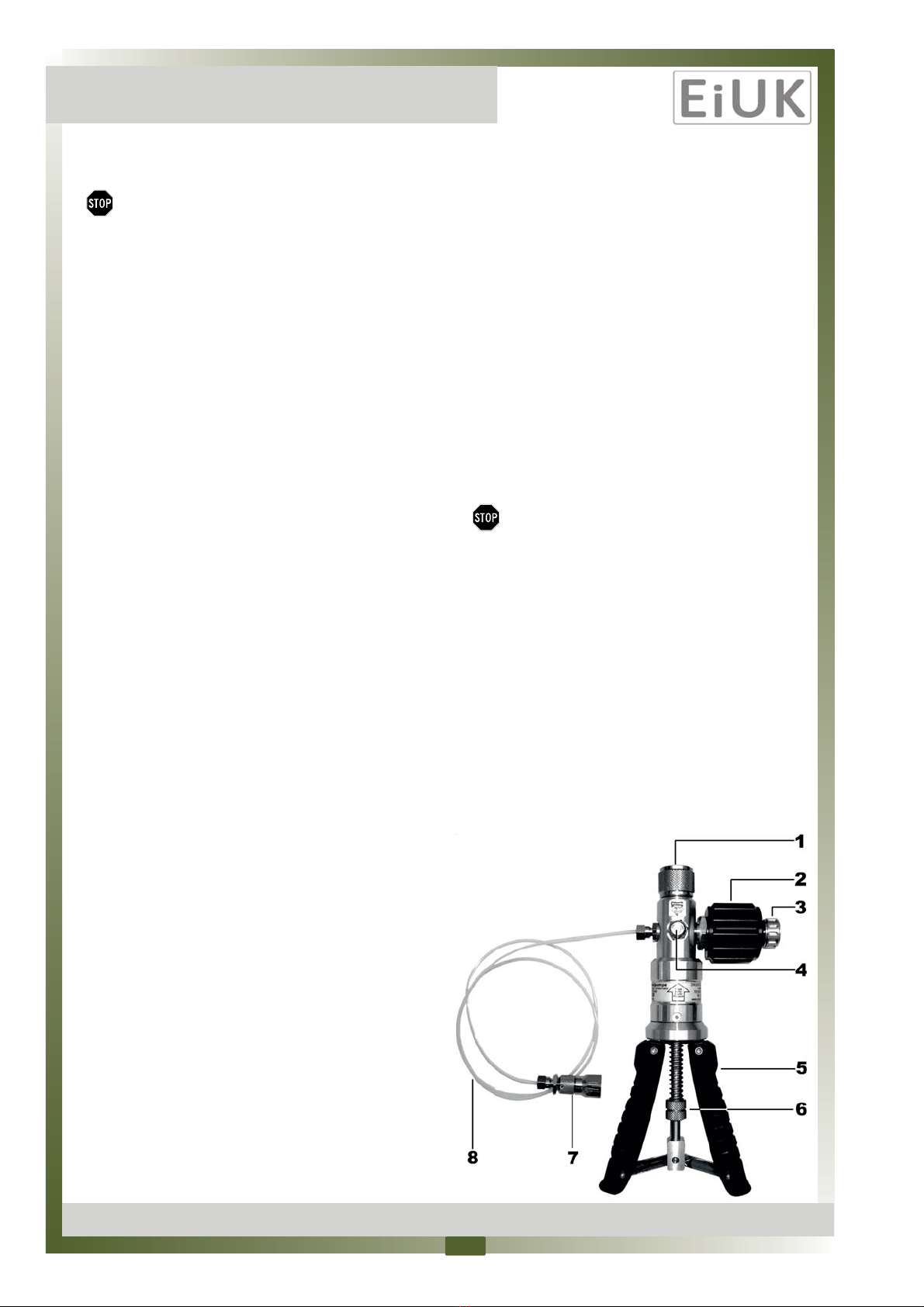

(1) = pressure connector for reference instrument

(2) = high pressure generaon and

fine adjustment valve

(3) = pressure relief valve

(4) = change‐over switch for pressure / vacuum

(5) = handles

(6) = adjustable knurled nut for the adjustment

of the delivery rate of the pump

(7) = pressure port for test specimen

(8) = test tube, length approx. 0.5 m

3. Mounng Instrucons

The reference instrument is fi ed to the upper side

of the calibraon pump. Fingerght fastening of

the reference instrument with the knurled nut is

sufficient. The reference instrument is sealed by

the integral O‐ring sealing gasket.

The unit under test is mounted to the end of the

flexible tube. Fingerght fastening of the unit

under test is sufficient. The unit under test is

sealed by the integral O‐ring sealing gasket.

In order to adapt different connecon threads of

units under test, use adaptors of the several

adapter sets with integral O‐ring sealing gaskets,

available as accessory for the calibraon pump.

Do not use Teflon tapes,

this may damage your test pump.

You can unsrew the tube and also directly a ach

the unit under test to the pump body, using a

suitable thread adapter. This decreases the volume

of the calibraon circuit and makes operaon of

the test pump more easy.

4. Operaon (pressure)

First, check wether the change‐over valve (4) has

to be actuated (see scker on the device). For this

purpose use a pen or a small screw‐driver. The

encasement of the switch is intended to help

prevent unintenonal actuaon.

2

EiUK ‐ Eutrotron Instruments UK Ltd. • Unit 13 Riley Close • Royal Oak Ind Est • Daventry • Northants NN11 8QT • England U.K.

Phone: +44 (0) 1327 871044 • E‐Mail: sales@eurotron‐uk.com • Internet h p://www.eurotron‐uk.com

Operang Manual

•PGS‐40 PGS‐60

Never actuate the change‐over valve (4)

when the test pump is under pressure or

vacuum! Actuate the change‐over valve

only, when the relief valve (3) is open.

Make sure that the pressure relief valve (3) is not

closed completely.

Turn the fine adjustment valve (2) anclockwise up

to the end (smooth „stop“ can be felt).

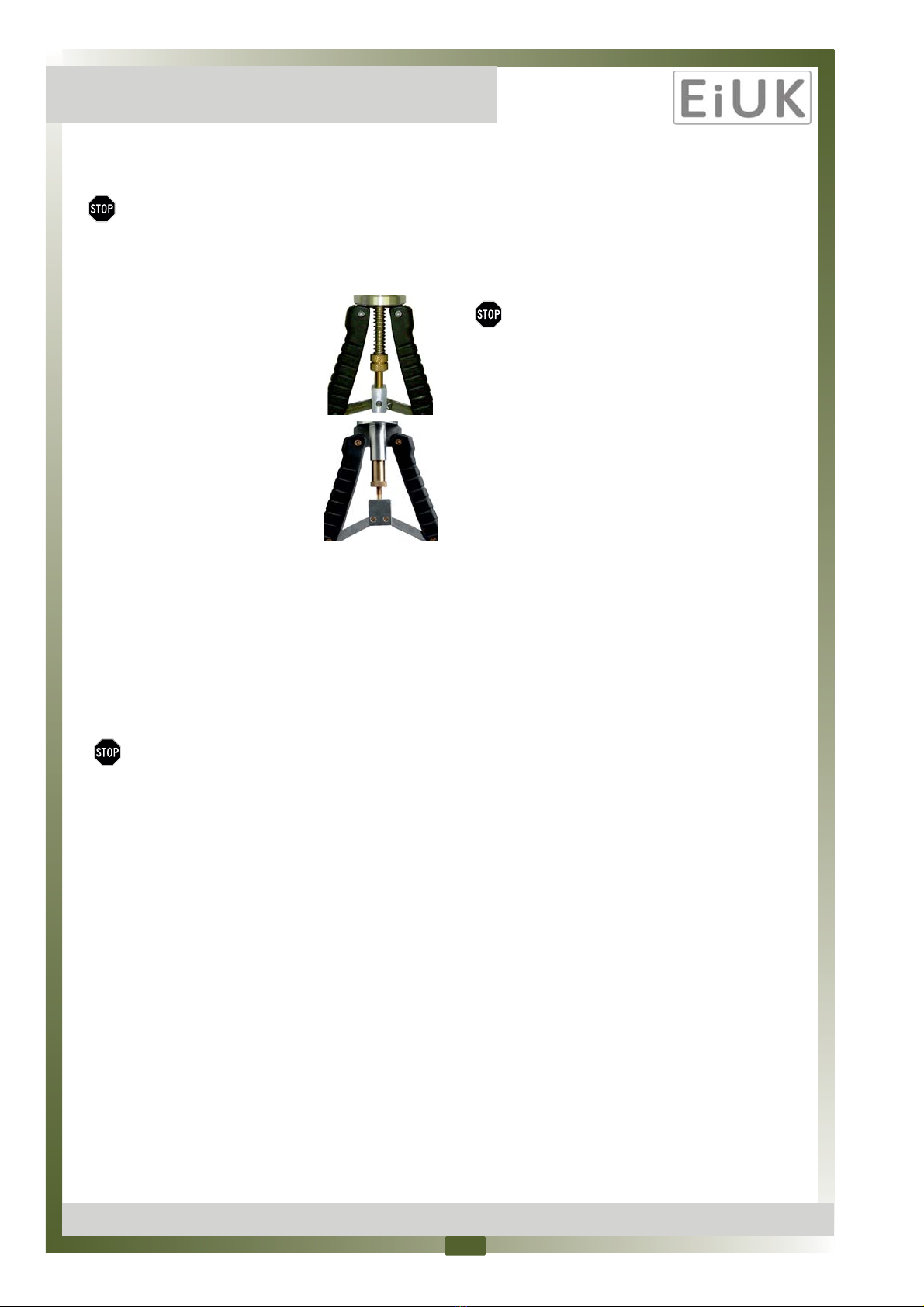

Make sure, that the adjustable knurled nut (6) is in

such a posion, that the visible spring (or bushing)

above the nut has some clearance, if the handles

(5) are pressed together.

Carefully turn the pressure relief valve (3) unl the

valve closes. You will not nofy any „hard stop“.

Operate the hand pump (5) unl the max. priming

pressure is achieved:

PGS‐40: approx. 20 ‐ 25 bar

PGS‐60: approx. 35 ‐ 40 bar

Turn the fine adjustment valve (2) clockwise to

increase the pressure to maximum

PGS‐40: approx. 40 bar

PGS‐60: approx. 60 bar.

The max. pressure value depends on the volume of

the calibraon circuit.

Move the fine adjustment valve (2) unl the

requested test pressure has been reached

precisely (to be read on the reference instrument).

Aer increasing the pressure, the reading

may slightly drop again for about 30 sec.

This is caused by thermodynamic effects,

the tube connecon and the sealing

gaskets. If the pressure drop does not

come to a standsll, check the measuring

circuit for ghtness.

Due to the low volume of each

compression stroke of the test pump,

only small volume test specimen should

be tested.

A pressure reducon is achieved by turning the

fine adjustment valve (2) counter‐clockwise first

and then by carefully opening the relief valve (3).

Remove the reference instrument or the

test specimen only when the relief

valve (3) is open and no pressure is in the

test pump any more.

5. Operan (vacuum)

First, check wether the change‐over valve (4) has

to be actuated (see scker on the device). For this

purpose use a pen or a small screw‐driver. The

encasement of the switch is intended to help

prevent unintenonal actuaon.

Never actuate the change‐over valve (4)

when the test pump is under pressure

or vacuum! Actuate the change‐over

valve only when the relief valve (3) is

open.

Make sure that the pressure relief valve (3) is not

closed completely.

Make sure, that the adjustable knurled nut (6) is in

such a posion, that the visible spring (or bushing)

above the nut has some clearance, if the handles

(5) are pressed together.

Turn the fine adjustment valve (2) clockwise up to

the end (“stop“ can be felt).

Carefully turn the pressure relieve valve (3) unl

the valve closes. You will not nocy any „hard

stop“.

Operate the handles (5) smoothly and slowly unl

approx. ‐0.9 bar of vacuum are reached.

Turn the fine adjustment valve (2) an‐clockwise to

increase vacuum up to ‐0.95 bar. Turn this valve for

fine‐adjustment.

Aer increasing the vacuum, the reading

may slightly drop again for about 30 sec.

This is caused by thermodynamic effects,

the tube connecon and the sealing

gaskets. If the vaccum drop does not

come to a standsll, check the measuring

circuit for ghtness. Due to the low

volume of each compression stroke of the

test pump, only small volume test

specimen should be tested.

3

Operang Manual

PGS‐40 • PGS 60

EiUK ‐ Eutrotron Instruments UK Ltd. • Unit 13 Riley Close • Royal Oak Ind Est • Daventry • Northants NN11 8QT • England U.K.

Phone: +44 (0) 1327 871044 • E‐Mail: sales@eurotron‐uk.com • Internet h p://www.eurotron‐uk.com

A vacuum reducon is achieved by carefully

opening the relief valve (3).

Remove the reference instrument or the

test specimen only when the relief

valve (3) is open and no vacuum is in the

test pump any more.

For a maximal performance of the

test pump, please make sure that

the adjustable knurled nut is

adjusted to a posion that the

visible spring (or bushing) get some

clearance. If you operate with a

reference or test item with small

pressure range, you can reduce the

performance of the pump by

turning the nut (6) upwards. This

reduces the volume per stroke.

6. Maintenance Instrucons

Prior to connecng the reference instrument and

the test specimen, the sealing gaskets in the two

connectors should be checked for correct posion

and wear, and should be replaced, if and when

necessary. A service kit, consisng of spare sealing

gaskets and o‐rings, is available as an accessory.

The test pump must not be soiled, and in

parcular it must not get into contact

with fluid or agressive media.

7. Case of Fault

If the pressure or vacuum cannot be generated

correctly or if the set pressure or vacuum does not

stay stable, this is likely to be caused by the

incorrectly posioned or selected sealing gaskets.

Please also check wether any adapters used on the

test specimen have been ghtened sufficiently to

eliminate leaks.

Before assuming there is a leak in the test pump:

First of all, check if the relief valve (3) is closed and

if the pressure/vacuum change‐over switch (4) is

correctly posioned and has not come to test in a

„centre posion“.

If the test pump has not been used for a longer

period of me, the first li may be somewhat

sluggish. This effect will disappear again during

further operaon.

By no means apply any force to the operang

elements of the test pump.

Never connect an external pressure

supply system to the PGS‐40 / PGS‐60

test pump.

8. Technical Data

Pressure range:

PGS‐40 PGS‐60

‐0.95...+40 bar ‐0.95...+60 bar

Medium: air

Pressure ports (standard version):

1/2" BSP female rotang for reference instrument

1/4" BSP female rotang for test specimen

High pressure generaon and Fine adjustment:

Fine adjustment valve

Overpressure:

Adjustable by means of knurled nut.

Material: Aluminium, brass, ABS, NBR

Dimensions:

PGS‐40 PGS‐60

220 x 120 x 65 mm 290 x 185 x 65 mm

Standard supply:

connecon tube, length approx. 0.5 m

9. Available Accessories / Spare Parts

• Sets of adapters for test specimen

‐ BSP threads (1/8", 3/8", 1/2", 1/2" male)

‐ NPT threads (1/8", 1/4", 3/8", 1/2")

‐ Metric (M12x1.5, M20x1.5, Minimess 1620)

• Transit case with custom foams

• Service kit

• Spare part: hose assembly

• Spare part: volume control with relief valve

4

This manual suits for next models

1

Other EIUK Water Pump manuals

Popular Water Pump manuals by other brands

EINHELL

EINHELL GE-DP 7330 LL ECO Original operating instructions

Varian

Varian HS452 instruction manual

Neptun

Neptun NCBP-E 18 Original operating instructions

GORMAN-RUPP

GORMAN-RUPP T6A60S-4045T-ESP Installation, operation and maintenance

Dover

Dover Wilden Advanced Metal P200 Series operation & maintenance

EBARA

EBARA EV-A10 instruction manual