- 7 -

Ŷ%HIRUHDORQJSHULRGRIVWRSSDJHZHHNRUPRUH

Depressurize the system and stop air/gas supply. Do not install/store

the pump:

- In a flammable/corrosive atmosphere.

- In a dusty/humid environment.

- In direct sunlight or wind & rain.

- Under vibration.

- Where ambient temperature can exceed 0-40°C.

Maintenance

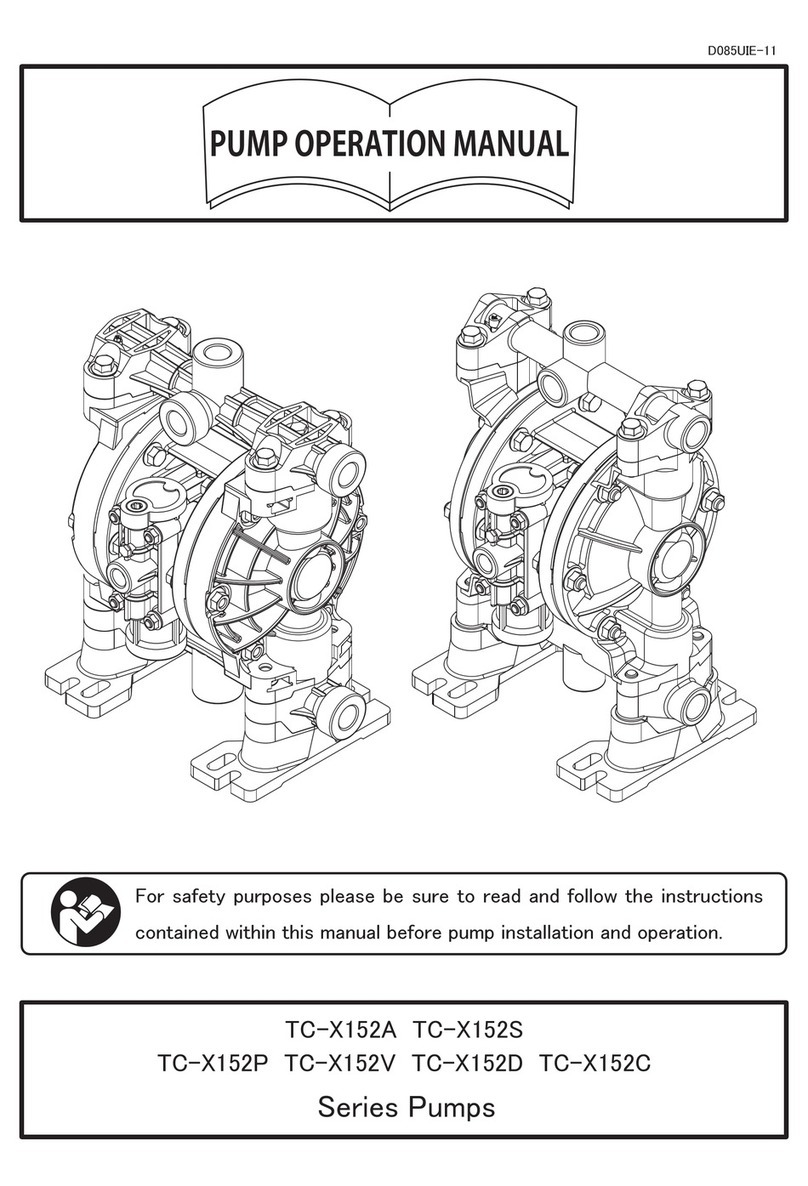

This section describes troubleshooting, inspection, wear part

replacement, exploded views and specifications.

2EVHUYHWKHIROORZLQJSRLQWV

- Follow instructions in this manual for replacement of wear

parts. Do not disassemble the pump beyond the extent of the

instructions.

7URXEOHVKRRWLQJ

If you notice any abnormal or hazardous conditions, suspend opera-

tion immediately and check the following points. If the following meas-

ures do not help remove problems, contact your nearest distributor.

States Possible causes Solutions

The pump

does not

run.

The pump is not powered. Check the pump is powered.

Power voltage is too low or too

high. Observe the rated voltage of

24VDC.

Wrong tubing or poor connec-

tion &KHFNDQG¿[WXELQJFRQQHF-

tions.

'LDSKUDJP¿[LQJVFUHZLV

loose. Tighten the screw.

(FFHQWULFVKDIWKDVEURNHQ Replace the connecting rod

unit. Contact us.

The pump

does not

run.

Connecting rod bearing has

worn. Replace the connecting rod

unit. Contact us.

Motor trouble Replace the motor. Contact

us.

Suction line pressure is higher

than atmospheric pressure. Keep it lower than atmospher-

ic pressure.

Pump

operation

uninten-

tionally

stops.

Power voltage is too low or too

high. Observe the rated voltage of

24VDC.

Connecting rod bearing has

worn. Replace the connecting rod

unit. Contact us.

Motor trouble Replace the motor. Contact

us.

Suction line pressure is higher

than atmospheric pressure. Keep it lower than atmospher-

ic pressure.

Discharge line pressure is high-

er than atmospheric pressure. Keep it lower than 0MPa.

$QDLUÀRZ

rate and a

discharge

pressure

are too

low.

Wrong tubing or poor connec-

tion &KHFNDQG¿[WXELQJFRQQHF-

tions

Pump head mounting screws

are loose. Tighten the screws.

'LDSKUDJP¿[LQJVFUHZLV

loose. Tighten the screw.

Diaphragm is broken. Replace the diaphragm.

Filter is clogged. &OHDQWKH¿OWHU

Valve has worn. Replace the valve.

6LJQL¿FDQW

noise Pump head mounting screws

are loose. Tighten the screws.

'LDSKUDJP¿[LQJVFUHZLV

loose. Tighten the screw.

Diaphragm is broken. Replace the diaphragm.

(FFHQWULFVKDIWKDVEURNHQ Replace the connecting rod

unit. Contact us.

Connecting rod bearing has

broken. Replace the connecting rod

unit. Contact us.

Motor trouble Replace the motor. Contact

us.