elco LOGON SOL plus User manual

03/2005 12 042 390

Operating Manual

for operators

LOGON SOL plus

Solar controller in wall-mount enclosure

Table of Contents

2

Safety instructions .......................................................................................... 3

Product description and technical data ........................................................... 3

Accessories and package contents................................................................. 3

Wall-mount enclosure installation ................................................................... 4

Relay connection diagram .............................................................................. 5

Sensor connection diagram ............................................................................ 6

Domestic water backup heating using a boiler................................................ 7

System-related sensor/relay connections ....................................................... 8

Controller operation ........................................................................................ 9

Information level .......................................................................................... 11

User level ..................................................................................................... 18

3

Table of Contents

Safety instructions

Product description, specifications

Accessories, package contents

Safety instructions

All electrical work shall be carried out

exclusively by licensed electricians.

When installing or repairing electrical

equipment, always be sure that it is

completely isolated from the supply. Do

not work on live parts.

Install the controller in a dry room and

at a location where it is not exposed to

temperatures > 50°C.

Temperatures can reach as high as

90°C in the connected storage tanks.

As a result, boiling protection must be

provided for domestic hot water storage

tanks (Heizungsanlagenverordnung

Section 8, Clause 2 (heating systems

directive).

The supplied wall-mount enclosure

shall only be used for a stationary in-

stallation.

Product description

Solar controller installed in wall-

mount enclosure to control solar

heating systems for domestic hot

water heating and backup heating.

Ausstattung des Reglers:

Controller features:

Installation

The assembly and initial start-up

shall be done exclusively by author-

ized professionals who assume

responsibility for proper installation

and start-up.

Following initial startup, the opera-

tor will be given instructions regard-

ing user-related features of the con-

troller.

This training is the responsibility of

the authorized professional in-

staller.

Details regarding warranty condi-

tions

The warranty does not cover dama-

ge resulting from any of the follo-

wing:

• improper use

• improper installation or start-up by the

purchaser or third parties, including

the use of third-party components

Adhering to the following will ensu-

re that the warranty applies:

• operating the equipment as it was

designed to be used.

Technical data

• supply voltage: 230 V (AC) 50...60

Hz, power consumption 3 VA

• enclosure type 2 according to EN

60730, enclosure type IP 40 per DIN

40050

• electrical connection via a RAST 5

connector inside the wall-mount en-

closure (controller can be plugged in)

• 10 sensor inputs for NTC temperature

sensors

(range: -20 to +149 °C) and solar

sensor

• 1 input for measuring volume flow

• 6 relay outputs: 3 standard (2A) and 3

solid-state relays (1 A) for variable

speed control

• 1 relay output (low voltage) for ba-

ckup heating enable

• auxiliary module for e-Bus connection

or two additional relay outputs

Package contents

• wall-mount enclosure

• LOGON SOL plus controller

• collector sensor (NTC red cable)

for temperatures up to 250°C

temperature measuring range

-20°C to 150°C

rated temperature range

-20°C to 250°C

• two sensors (NTC white cable)

for installation as storage tank and

return-line sensor

temperature range

-20°C to 150°C

rated temperature range

-20°C to 250°C

• thermowell – 100 mm / ½ "

for installation in the collector

• adjustable thermowell, maximum

length 350 mm / ½ " for installation of

the return-line sensor

• thermowell – 150 mm / ½"

for installation of the storage tank

sensor

• large, clearly arranged LCD screen

displays all key system temperatu-

res at a glance

• controller can be plugged into so-

cket in wall-mount enclosure

• seven timer channels for backup

heating using a conventional boiler

or auxiliary heater and for special

functions

• differential temperature control for

solar systems with up to two collec-

tor panels and three storage tanks

• twelve predefined system circuits to

configure the solar system and faci-

litate start-up

• speed control for up to three circula-

ting pumps

• solar system heat gain calculation

• priority selection for multiple storage

tank systems

• backup heating via heating circuit

return flow boosting

• bypass circuit for large collector

surfaces and long piping runs

• external heat exchanger for large

systems with several buffer storage

tanks

• low flow concept ideal for stratified

heat transfer technology

• freeze protection and overheating

protection features for collector and

storage tank

• hot water destratification and Legio-

nella protection functions

• thermostat, temperature compari-

son and timer functions

• connection port for data logger

• oscillation heating to utilize residual

heat

4

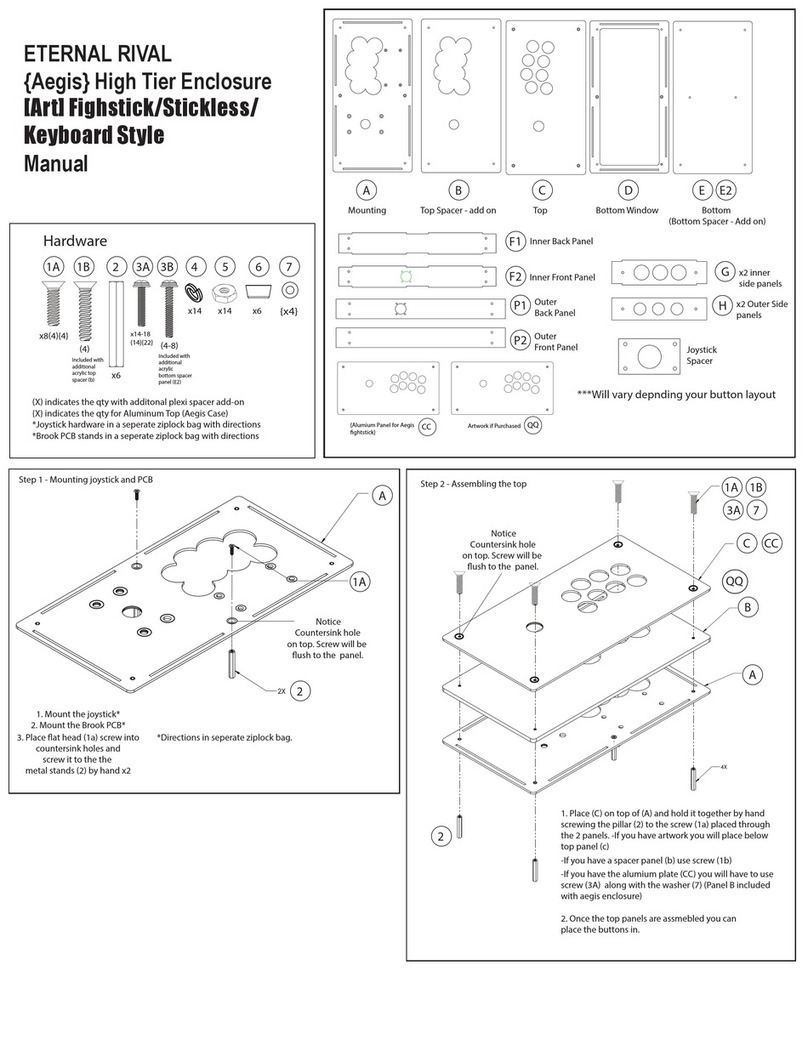

Wall-mount enclosure installation

Tools and installation

The following tools are required to

install the controller:

• drill

• 6 mm drill bit

• Screwdriver

Open up the enclosure. You can

use the bottom part as a template

to locate the mounting holes. Drill 6

mm holes at the marked locations.

Fasten the bottom part of the enclo-

sure to the wall using the anchors

and screws provided. Connect the

sensor, supply and pump wiring to

the terminals as shown in the dia-

gram below.

Mount the controller on the connec-

tor provided. You can now refasten

the bottom cover of the enclosure.

Ensure that the electrical wiring is

connected properly and use the

strain relief provision when faste-

ning the wires.

Sensor location

The collector sensors shall be mounted

in the supply connection (hot side) of

the collector.

Some solar system components can

become very hot (risk of burn injuries).

The return-line sensors can be mounted

in the lower part of the storage tank or the

return line from the solar heating system.

Thermowells are installed about halfway

up the storage tank to mount the upper

storage tank sensors.

5

Wiring diagram

LOGON SOL plus

Relay assignment

K1 solar circuit pump 1

K2 solar circuit pump 2 (application dependent)

K3 solar circuit pump 3 (application dependent)

K4

K5

K6

application-specific relay connections

6

Wiring diagram

LOGON SOL plus

Sensor assignment

VM volume flow sensor

S1 TC1 collector temperature, collector panel 1

S2 TC2 collector temperature, collector panel 2

S3 TSP1

upper storage tank temperature, storage tank 1

S4 TSR1

lower storage tank temperature, storage tank 1

S5 TSP2

upper storage tank temperature, storage tank 2

S6 TSR2

lower storage tank temperature, storage tank 2

S7 TSP3

upper storage tank temperature, storage tank 3

S8 TSR3

lower storage tank temperature, storage tank 3

S9 AW

S10 ES

GND common terminal

application dependent

radiation sensor

7

Domestic water backup heating using a boiler

When the LOGON SOL plus

controller is used to control a boiler

that provides supplemental heat for

the domestic water, it must be inter-

connected with the boiler controller

(sensor-side terminals 14 and 15,

see connection diagram). The follo-

wing LOGON SOL plus features

make it capable of interacting fle-

xibly with the boiler controller. A

jumper located on the back of the

controller can be used to choose

between a changeover switch with

resistors and a zero-resistance

changeover switch.

Place the jumper in position Y to

use LOGON SOL plus in conjunc-

tion with LOGON controllers

(SYSTRON, UNON, VARION) to

control domestic water backup

heating (see diagram).

The connected resistors are used

to simulate temperatures.

Off = 1320 ohms = 70°C

On = 8200 ohms = 25°C

Place the jumper in position X to

use LOGON SOL plus in conjun-

ction with non-LOGON controllers

(THISION, TRIGON, STRATON or

third-party boilers) to control dome-

stic water backup heating. This se-

lects a changeover switch with zero

resistance.

The jumper is in position X when

the controller leaves the factory.

After installing the controller, choose the

correct system configuration (number of

collectors/storage tanks) from the sys-

tem circuit diagrams provided.

The manual shows the wiring for the

required sensors and relays for the

selected circuit schematic.

The respective "Sensor assignment"

tables identify which additional sensor

inputs can be connected.

The respective "Relay assignment"

tables identify which relays are availa-

ble for additional functions.

The connections and settings for the

most important auxiliary functions are

summarized in the manual. If it beco-

mes necessary to choose settings for

the system that deviate from the factory

settings, the changed values should be

noted in this manual. This will be useful

for later servicing of

the installation.

Sensor/Schematic S 1 S 2 S 3 S 4 S 5 S 6 S 7 S 8

1 TC 1 TSP 1 TSR 1

2 TC 1 TSP 1 TSR 1 TSP 2 TSR 2

3 TC 1 TSP 1 TSR 1 TSP 2 TSR 2

4 TC 1 TSP 1 TSR 1 TSP 2 TSR 2

5 TC 1 TSP 1 TSR 1 TSP 2 TSR 2 TSP 3 TSR 3

6 TC 1 TSP 1 TSR 1 TSP 2 TSR 2 TSP 3 TSR 3

7 TC 1 TSP 1 TSR 1 TSP 2 TSR 2 TSP 3 TSR 3

8 TC 1 TC 2 TSP 1 TSR 1

9 TC 1 TC 2 TSP 1 TSR 1 TSP 2 TSR 2

10 TC 1 TC 2 TSP 1 TSR 1 TSP 2 TSR 2 TSP 3 TSR 3

11 TC 1 TC 2 TSP 1 TSR 1 TSP 2 TSR 2

12 TC 1 TC 2 TSP 1 TSR 1 TSP 2 TSR 2 TSP 3 TSR 3

schematic

Relay 1 Relay 2 Relay 3 Relay 4 Relay 5 Relay 6

1 Solarpumpe

2 solar pump

storage tank 1 solar pump

storage tank 2

3 solar pump transfer heat to storage

tank 2

4 solar pump transfer heat to storage

tank 1 transfer heat to storage

tank 2

5 solar pump

storage tank 1 solar pump

storage tank 2 solar pump

storage tank 3

6 solar pump transfer heat to storage

tanks 2/3 transfer heat to storage

tank 3

7 solar pump transfer heat to storage

tank 1 transfer heat to storage

tank 2 transfer heat to storage

tank 3

8 solar pump

collector 1 solar pump

collector 2

9 solar pump

collector 1 solar pump

collector 2 transfer heat to storage

tank 1 transfer heat to storage

tank 2

10 solar pump

collector 1 solar pump

collector 2 transfer heat to storage

tank 1 transfer heat to storage

tank 2 transfer heat to storage

tank 3

11 solar pump

collector 1 solar pump

collector 2 transfer heat to storage

tank 2

12 solar pump

collector 1 solar pump

collector 2 transfer heat to storage

tanks 2/3 transfer heat to storage

tank 3

The sensors can be freely programmed for special functions (thermostat, temperature comparison, heat gain calculation, solar sensor).

System-dependent sensor assignment

Relay assignment

8

System-dependent sensor assignment

Relay assignment

1pump operation indicator

2item identifier

3lower storage tank return temperature

4upper storage tank temperatures

5collector temperatures TCI and TC2

6information

7"increase" key

8"decrease" key

12 next

11 time of day

10 timer settings

9on / off switch

1 2 3 4 5

9 10 11 12

6

7

8

Icons displayed on LCD screen

9

Controller ON / controller OFF

When the controller is switched on,

the display is "normal". The collector

temperature and the upper and lower

storage tank temperature of the (first)

storage tank can be viewed at a glan-

ce.

When the controller is turned off, the

display shows "OFF", the time of day

and the day of the week.

The controller can be switched off by

pressing the [On/Off] key for five se-

conds.

Controller operation

Turning the controller on and off

First collector tempera-

ture

Second collector tempe-

rature

Upper storage tank tem-

perature

Lower storage tank tem-

perature

Pump ready

Pump on

Backup heating

Alarm

Freeze protection

10

In addition, the Info sequence shows

the total heat gain (ERT), the daily heat

gain (ERTd) and the speed of pumps

P1.. P3 (ED1..ED3).

It is preferable to use a volume flow

sensor for the total or daily heat gain

calculation. Parameter VSA = 1 or 2

(E3-4.3) confirms that a volume flow

sensor is being used. The heat gain

display is enabled when confirmation is

received that a volume flow sensor is

present.

If no volume flow sensor is present,

heat gain values can only be displa-

yed if the minimum lower set point

for the heat transfer pump is set to

100 percent. In this situation the heat

gains are calculated on the basis of the

default liquid flow rate.

ERT total heat gain in kWh; range: 0 .. 199999 kWh

Total heat gain can be reset to zero by pressing and holding the [-] key for five seconds while a value is being displayed.

ERTd daily heat gain in kWh; range: 0 .. 999 kWh

The day's heat gain can be reset to zero by pressing and holding the [-] key for five seconds while a value is being displayed.

ED1 speed of pump P1 in %, range 30 .. 100 %

ED2 speed of pump P2 in %, range 30 .. 100 %

ED3 speed of pump P3 in %, range 30 .. 100 %

The speeds (ED1 … ED3) are only displayed if the respective minimum set point (USW1.. USW3) is < 100 %.

Default assignment for measurement inputs (vary with system circuit schematic):

S1 TC1 collector temperature or collector temperature sensor for collector panel 1

S2 TC2 collector temperature or collector temperature sensor for collector panel 2

S3 TSP1 upper storage tank temperature or upper storage tank temperature sensor for storage tank 1

S4 TSR1 lower storage tank temperature or lower storage tank temperature sensor for storage tank 1

S5 TSP2 upper storage tank temperature or upper storage tank temperature sensor for storage tank 2

S6 TSR2 lower storage tank temperature or lower storage tank temperature sensor for storage tank 2

S7 TSP3 upper storage tank temperature or upper storage tank temperature sensor for storage tank 3

S8 TSR3 lower storage tank temperature or lower storage tank temperature sensor for storage tank 3

S9 application dependent

S10 application dependent

collector sensor:

temperature measuring range: -20° .. 150°C, rated temperature range: -20° .. 250°C

storage tank/return-line sensor:

temperature measuring range: -20° .. 150°C, rated temperature range: -20° .. 90°C

The following measured values can be assigned to any measured value input depending on the system configuration or on the acti-

vated functions. The measured values - if activated - can be checked using the Info key.

TRH backup heater return-line temperature

TR return-line temperature for heat gain calculation

TX comparative value for heater return-line temperature when backup heating function is activated (e.g., in conjunction

with VISTRON V750 LC.

TW heat exchanger or bypass temperature:

TWW temperature of the first storage tank for hot water destratification

TH1 temperature measurement for first thermostat function:

TH2 temperature measurement for second thermostat function:

TVA1 temperature A for first temperature comparison function:

TVB1 temperature B for first temperature comparison function:

TVA2 temperature A for second temperature comparison function:

TVB2 temperature B for second temperature comparison function:

SE solar sensor to measure impinging solar radiation in W/m2:

VM volume flow measurement or volume flow sensor (GND, VM), measuring range: 50 .. 1500 l/h

VM Volumenstrom-Messwert bzw. Volumenstromsensor (GND, VM), Messbereich: 50 .. 1500 l/h

11

Information level

If the appropriate sensors are connected, all rele-

vant storage tank and collector temperatures are

available for display.

Storage tanks can be freely activated or deactiva-

ted at the user level. Their status can be displayed

at the information level.

12

Information level

TRH

backup heater return-line temperature

Sensor input S9 (fixed) is assigned

via parameter STX (STX set at level

E3 - 1 / 10).

TR

return-line temperature for heat gain

calculation Use parameter STR to as-

sign a sensor input. (Level E3 – 4 / 1)

TX

comparison value for heater return-line

temperature when backup heater func-

tion enabled (e.g., in conjunction with

VISTRON V750LC). Use parameter

STX to assign a sensor input

(parameter 10, E3 – 1 / 10).

TW

heat exchanger or bypass temperature:

A sensor input is automatically assi-

gned when the relevant schematic is

selected (KON, level E 3 -1 / 1).

13

Information level

TWW

temperature of the first storage tank for

hot water destratification: Sensor input

S7 is automatically assigned when the

relevant schematic is selected (KON,

E3 -1 / 1).

TSPO

Temperature measurement in the up-

per part of the storage tank for which

hot water destratification was activated.

TH1

temperature measurement for first ther-

mostat function: Use parameter STH1

to assign a sensor input (parameter 56,

Level E3 – 7/ 1).

TH2

temperature measurement for second

thermostat function: Use parameter

STH2 to assign a sensor input

(parameter 60, E3 – 7 / 5).

14

Information level

TVA1

temperature A for first temperature

comparison function: Use parameter

VSA1 to assign a sensor input

(parameter 64, Level E3 – 8 / 1).

TVB1

temperature B for first temperature

comparison function:

Use parameter VSB1 to assign a sen-

sor input (parameter 65, Level E3 – 8 /

2).

TVA2

temperature A for second temperature

comparison function: Use parameter

VSA2 to assign a sensor input

(parameter 69, Level E3 – 8 / 6).

TVB2

temperature B for second temperature

comparison function: Use parameter

VSB2 to assign a sensor input

(parameter 70, Level E3 – 8 / 7).

15

Information level

SE

solar sensor to measure impinging so-

lar radiation in W/m2:

The new, modified SE solar sensor can

be connected to any temperature

measurement input, S1 to S10.

Use parameter SSE to assign the input

(parameter 17, E3 – 1 / 17).

VM

volume flow measurement or volume

sensor (terminals: GND, VM), measu-

ring range: 50 .. 1500 l/h

16

Information level

In addition, the Info sequence shows

the total heat gain (ERT), the daily heat

gain (ERTd) and the speed of pumps

P1.. P3 (ED1..ED3).

It is preferable to use a volume flow

sensor for the total or daily heat gain

calculation. Parameter VSA = 1 or 2

(E3 - 4 / 3) confirms that a volume flow

sensor is being used. The heat gain

display is enabled when confirmation is

received that a volume flow sensor is

present. If no volume flow sensor is

present, heat gain values can only be

displayed if the minimum lower set

point for the heat transfer pump is set

to 100 percent. In this situation the heat

gains are calculated on the basis of the

default liquid flow rate.

ERTA total heat gain in kWh;

cumulative annual heat gain

range: 0 .. 199999 kWh

Total heat gain can be reset to zero by

pressing and holding the [-] key for five

seconds while a value is being dis-

played.

ERT0 previous day's heat gain

in kWh;

previous day's heat gain displayed

range: 0 .. 999 kWh

Heat gain can be reset to zero by

pressing and holding the [-] key for five

seconds while a value is being dis-

played.

ERTd daily heat gain in kWh;

Shows the running total for the day's

heat gain. The total is reset to zero at

12:00 a.m.

range: 0 .. 999 kWh

The day's heat gain can be reset to

zero by pressing and holding the [-] key

for five seconds while a value is being

displayed.

17

Information level

Speeds (ED1 … ED3) are only dis-

played if the respective minimum set

point (USW1.. USW3) is < 100 %.

(parameters 30, 32, 34, level E3 – 2 / 8,

10, 12).

ED1 speed of pump P1 in %, range

30 .. 100 %

ED2 speed of pump P2 in %, range

30 .. 100 %

ED3 speed of pump P3 in %, range

30 .. 100 %

18

User level

In addition to operational settings, the

time of day and the timer settings for

the activated timer channels can be set

at the user level. If no functions are

activated by timer channels, the clock

key can only be used to display and set

the time of day.

MAX1

Maximum storage tank heat transfer

temperature for storage tank 1 (upper

heat transfer temperature limit) with

reference to measurement TSP1 when

temperature sensor TSP1 is connected

or with reference to measurement

TSR1 if temperature sensor TSP1 is

not connected.

MAX1

range: 10 .. 90°C;

default setting: MAX1 = 70°C.

MAX2

Maximum storage tank heat transfer

temperature for storage tank 2 (upper

heat transfer temperature limit) with

reference to measurement TSP2 when

temperature sensor TSP2 is connected

or with reference to measurement

TSR2 if temperature sensor TSP2 is

not connected. MAX2 is only displayed

if the system configuration includes

storage tank 2.

MAX2

range: 10 .. 90°C;

default setting: MAX2 = 70°C.

MAX3

Maximum storage tank heat transfer

temperature for storage tank 3 (upper

heat transfer temperature limit) with

reference to measurement TSP3 when

temperature sensor TSP3 is connected

or with reference to measurement

TSR3 if temperature sensor TSP3 is

not connected. MAX3 is only displayed

if the system configuration includes

storage tank 3.

MAX3

range: 10 .. 90°C;

default setting: MAX3 = 70°C.

Navigate to the user level by pressing

the (+) or (-) key. The parameter set-

tings can be changed after pressing the

(+) or (-) key a second time. Press the

enter key to move to the next displayed

value.

Some of the parameters are accessible

from the user level and some from the

professional installer level (level "E3")

User level parameter settings (AE)

Parameter settings that need to be set

by the user are set at the user level. Do

not adjust the user settings until after

the appropriate system circuit schema-

tic has been selected (E3 - 1 No 1),

since all parameters are reset to the

factory default setting when a different

schematic is selected.

19

User level

NTH

low temperature set point for backup

heating:

The storage tank low temperature set-

ting that initiates backup heating refers

to the storage tank selected by parame-

ter setting SNH = n (n = 1 .. 3, level E3

– 1 / 7).

It is the temperature that initiates dual-

source backup heating with reference

to measurement TSPn (or TSRn if

TSPn is not connected).

Wird die minimale If the temperature

falls below the low temperature setting

during the time the backup heating

SPA1

YES/NO – setting:

Activate or temporarily deactivate stor-

age tank 1.

No 3

Deactivation occurs because the maxi-

mum storage tank heat transfer tempe-

rature is internally preset to 10°C. This

setting is not affected by the collector

safety function.

SPA1 = YES: storage tank 1 activated

SPA1 = NO: storage tank 1 deacti-

vated

default setting: SPA1 = YES

Parameter SPA1 is disabled for

system configurations 1 and 8.

function is enabled, backup heating is

activated until temperature TSPn (or

TSRn) >= NTH + NHD, or until the ena-

ble time has elapsed.

NTH setting range: 10 .. 90°C;

default setting: NTH = 40°C

The backup heating function is as-

signed to timer channel CH1. Backup

heating enable times are programmed

using CH1. If no times are set, backup

heating is always enabled.

(NHD adjustable at level E3 – 2 / 7)

SPA2

YES/NO – setting:

Activate or temporarily deactivate stor-

age tank 2.

No 4

Deactivation occurs because the maxi-

mum storage tank heat transfer tempe-

rature is internally preset to 10°C. This

setting is not affected by the collector

safety function.

SPA2 = YES: storage tank 2 activated

SPA2 = NO: storage tank 2 deactivated

default setting: SPA2 = YES

Parameter SPA2 is disabled for

system configurations 1 and 8.

SPA3

YES/NO – setting:

Activate or temporarily deactivate stor-

age tank 3.

No 5

Deactivation occurs because the maxi-

mum storage tank heat transfer tempe-

rature is internally preset to 10°C. This

setting is not affected by the collector

safety function.

SPA3 = YES: storage tank 3 activated

SPA3 = NO: storage tank 3 deacti-

vated

default setting: SPA3 = YES

Parameter SPA3 is disabled for

system configurations 1,2,3,4,8,9 and

11

20

User level

Displaying and setting the day and time

Displaying and setting the date

To set the time of day, press the following controller

keys in sequence:

time -> enter -> Use plus or minus to set the hour. ->

enter -> Use plus or minus to set the minute. ->

enter -> Use plus or minus to set the day. ->

Press the clock key to confirm the changes.

Return to the normal display without saving the chan-

ges by pressing the On/Off key.

To set the date, press the following controller keys in sequence:

time -> question mark -> Use plus or minus to set the year. ->

enter -> Use plus or minus to set the day. ->

enter -> Use plus or minus to set the month. ->

Press the clock key to confirm the changes.

Return to the normal display without saving the changes by pressing the On/Off key.

Table of contents