Page 3

1.

RECOMMENDATIONS

a.

General Recommendations

1.

This manual forms an integral part of the appliance. It is to be kept safe and

accessible for consultation if necessary and must accompany the appliance in case

of transfer to another owner or user and / or transfer to another installation.

2.

Carefully read the instructions and understand the advice provided. This will ensure the

safe installation, use and maintenance of the appliance.

Failure to do so may invalidate the warranty.

3.

This appliance must only be used for its intended purpose. The manufacturer can

under no circumstances be held liable for damages resulting from improper,

incorrect or unreasonable use or from non-observance of the instructions contained

in this manual.

4.

Installation, maintenance and other work must be carried out by a competent

person in accordance with the relevant regulations and the manufacturer's

instructions.

5.

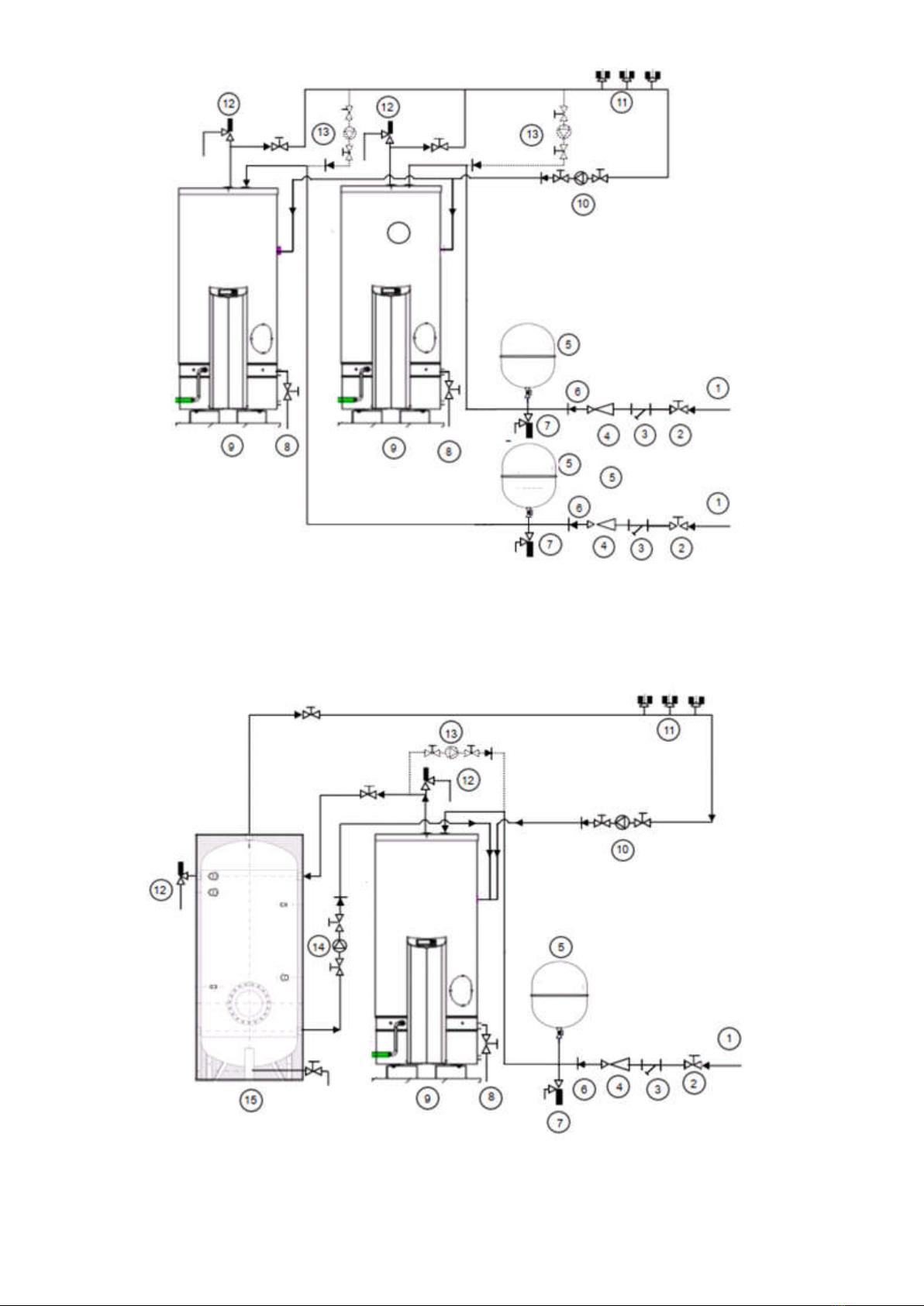

This appliance is designed to produce hot water for domestic use. It should be

connected to the distribution mains supply for domestic hot water in accordance with

the performance levels and power-rating of the appliance.

6.

The manufacturer shall not be liable for damage to persons, animals or property

caused by improper installation.

7.

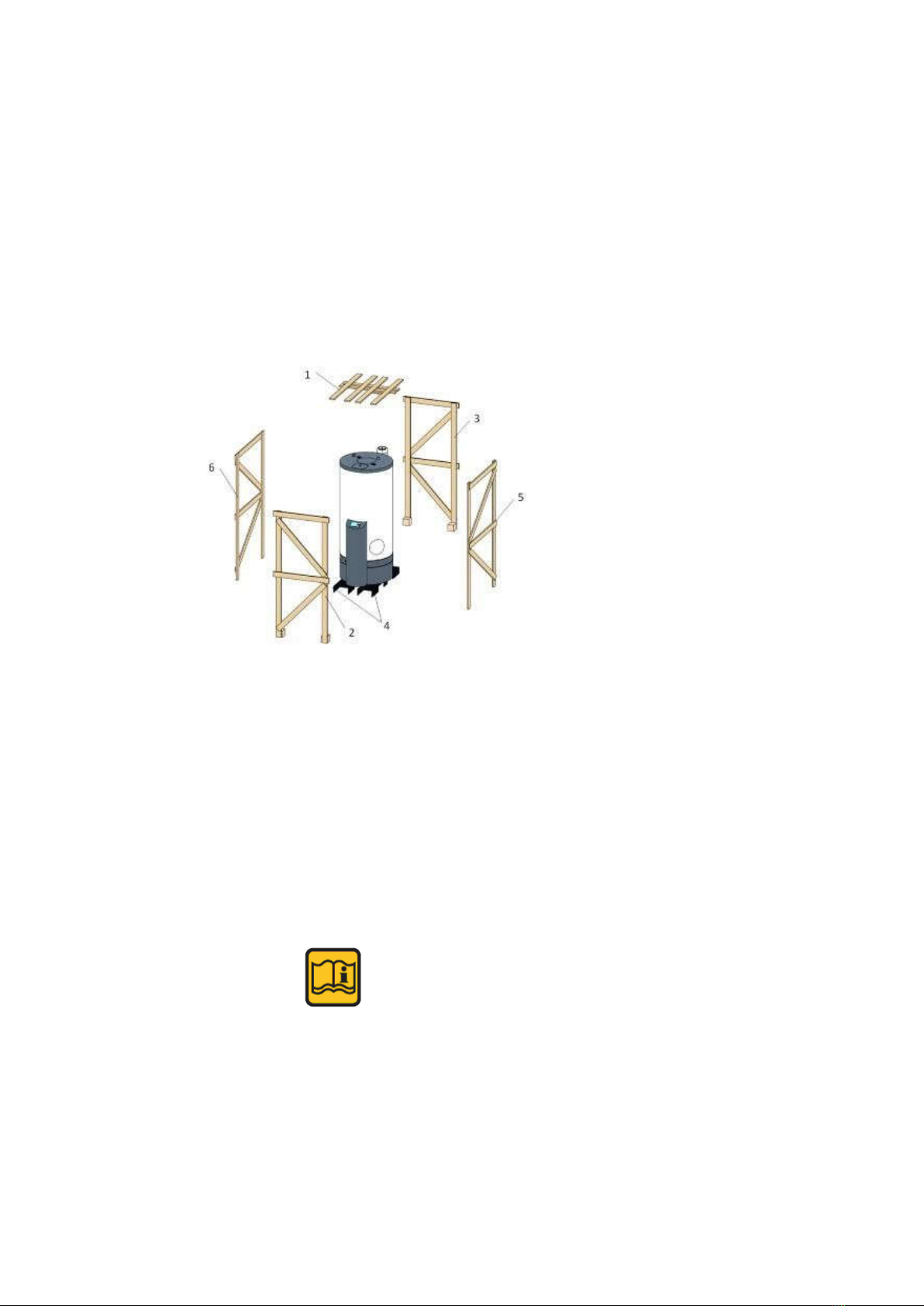

Ensure that all packing materials are safely disposed of (staples, plastic bags,

expanded polystyrene, etc.), as they represent a sources of danger, especially for

children.

8.

Do not touch the appliance if you have bare feet or with wet parts of the body.

9.

In the event of faults and/or malfunctions, switch the appliance off and shut off the

gas valve. Do not attempt to perform any repairs yourself but contact an

authorised service technician.

10.

For repairs, contact an authorised service technician and specify the use of only

original spare parts where possible. Failure to comply with the above may

compromise safety and disclaim all liability of the manufacturer.

11.

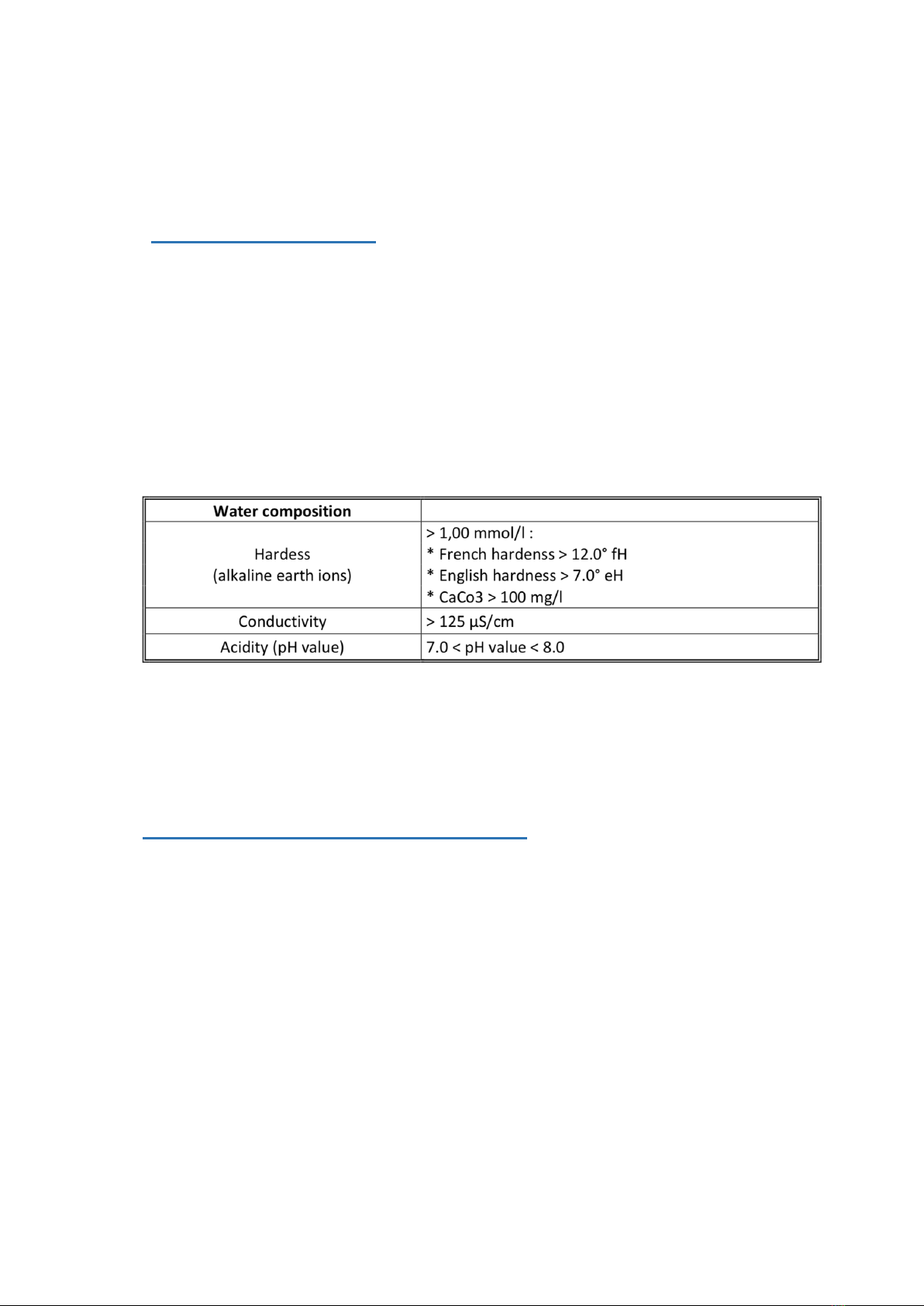

The hot water temperature is controlled by thermostat which also serves as a safety

device (requiring manual reset) to prevent dangerous water temperatures. To avoid

any risk of scalding, do not exceed a maximum temperature of 50 °C at the tap

discharge via suitable mixers. To avoid the risk of legionella issues, the control

thermostat must be set to at least 60 °C.

12.

Ensure that the electrical connection is as indicated in the relevant section-10

13.

No flammable objects should be stored in the vicinity of the appliance.

14.

If the appliance is out of service for more than one month, close the hydraulic

circuits connected to the water heater and drain the appliance. If the appliance is

left unused in winter for a long period in an unheated space, it is advisable to

drain it completely to avoid any risk of freezing. The manufacturer shall not be liable

for damage caused by freezing or leaking water from the installation.

15.

The appliance must not be installed in damp areas (RH ≤ 80%) and must be protected

against splashing water to avoid damage to electrical and thermal components.