Elcometer 215 User manual

User Guide

Elcometer 215

Oven Data Logger

www.elcometer.com

R

Section

Page

1

Gauge Overview

en-2

2

Box Contents

en-2

3

Getting Started

en-3

3.1

Fitting the Batteries

en-3

3.2

Selecting Your Language

en-3

3.3

Selecting the Measurement Units

en-4

3.4

Setting the Date Format

en-4

3.5

Setting the Time and Date

en-4

3.6

Setting the Logging Interval

en-4

3.7

Connecting the Probes

en-5

3.8

The Thermal Barrier & Heat Sink Block

en-6

4

Using the Logger

en-7

4.1

Before You Start

en-7

4.2

Start Logging

en-7

4.3

Stop Logging

en-7

4.4

Downloading Data

en-8

4.5

Clearing the Memory

en-8

5

Spares & Accessories

en-9

5.1

Temperature Probes

en-9

5.2

Probe Identification Tags

en-10

5.3

Thermal Barriers & Heat Sink Block

en-10

6

Warranty Statement

en-11

7

Technical Specification

en-11

8

Legal Notices & Regulatory Information

en-12

®

Appendix A: Using ElcoMaster

en-13

Appendix B: The Heat Sink Block

en-21

CONTENTS

www.elcometer.com

en-1

R

For the avoidance of doubt, please refer to the original English language version.

Dimensions: Logger only: 153 x 101 x 23mm (6 x 4 x 0.9")

Logger in Thermal Barrier: 245 x 245 x 115mm (9.65 x 9.65 x 4.5")

Weight: Logger only: 450g (15.8oz)

Logger in Thermal Barrier: Model S: 4kg (8.8lb); Model T: 6kg (13.2lb)

A Material Safety Data Sheet for the heat sink material in the heat sink block supplied with the Elcometer 215 Model T

and available as an accessory, is available to download via our website:

www.elcometer.com/images/stories/MSDS/elcometer_215_heat_sink.pdf

© Elcometer Limited 2009 - 2017. All rights reserved. No part of this document may be reproduced, transmitted,

transcribed, stored (in a retrieval system or otherwise) or translated into any language, in any form or by any means

(electronic, mechanical, magnetic, optical, manual or otherwise) without the prior written permission of Elcometer Limited.

www.elcometer.com en-2

R

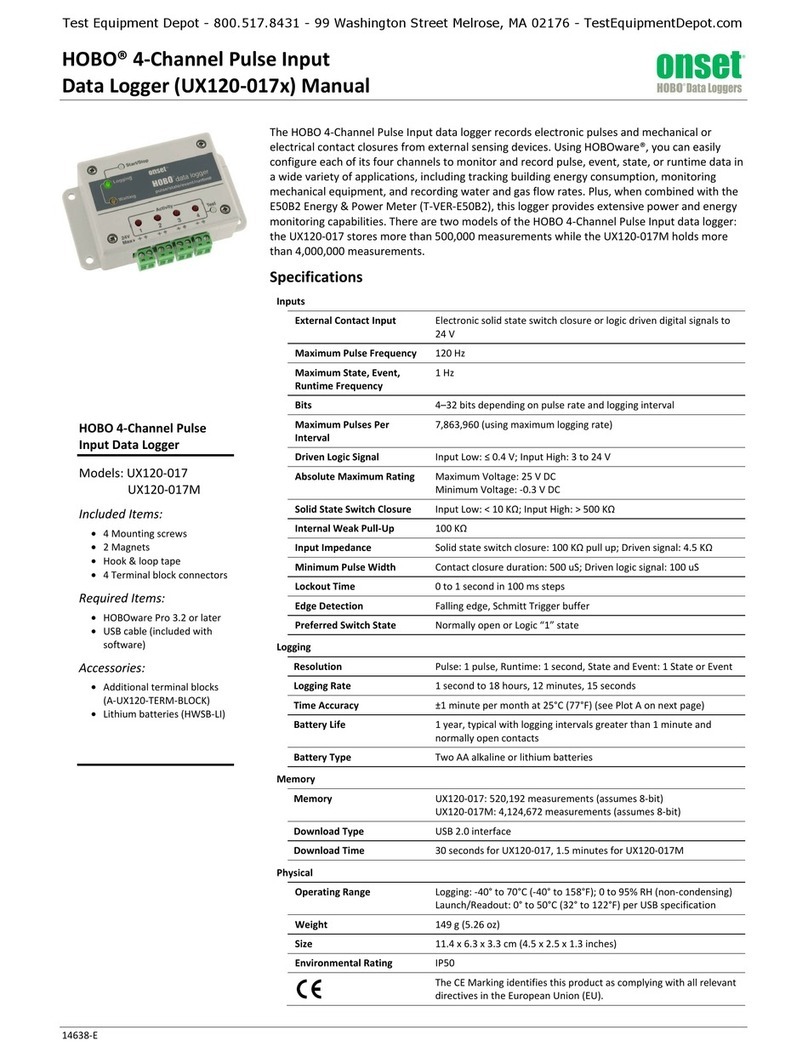

1 GAUGE OVERVIEW

1 Thermal Barrier

2 Heat Sink Block

3 Oven Data Logger

4 ‘Func’ Key; selects the function

5 ‘Sel’ Key; selects the channel or sub-function

a

6 ‘Set’ Key; changes any of the settings

7 Battery Compartment; on the rear of the logger

8 USB Socket

9 K-type Temperature Probe Socket; 6 off

1

3456

8

9

7

2 BOX CONTENTS

Elcometer 215 Oven Data Logger

Thermal Barrier (Model S only)

Thermal Barrier with Heat Sink Block (Model T only)

AA Batteries; x2

Transit Case

®

ElcoMaster Software

USB Cable

Calibration Certificate (if ordered)

User Guide

Note: The Elcometer 215 is not suppled with k-type temperature probes - probes must

be ordered separately, see Section 5.1 ‘Temperature Probes’ on page en-9.

a Settings can not be changed whilst logging.

www.elcometer.com

en-3

R

3.1 FITTING THE BATTERIES

The Elcometer 215 is powered by 2 x AA alkaline batteries (supplied).

Note: The maximum operating temperature for the batteries supplied is 50°C (122°F).

Prolonged use of the logger in excess of this temperature may require the use of

alternative batteries.

To insert or replace the batteries:

1 Remove the battery cover located on

the rear of the logger.

The cover is held in place by a magnetic catch.

2 Insert 2 batteries taking care to ensure

correct polarity.

3 Refit the battery cover.

To view the approximate percentage of battery life remaining, press

the ‘Func’ key until ‘BATTERY’ is displayed.

Two AA batteries should give 200 hours of operation using the default

®

settings. Excessive use of communications via ElcoMaster Software

however, will dramatically reduce battery life.

When batteries are fitted, the logger is switched on but in an idle state,

press the ‘Func’ key to wake the logger.

Note: Remove the batteries if the logger is to remain unused for a long period of time.

This will prevent damage to the logger in the event of malfunction of the

batteries.

Note: Batteries must be disposed of carefully to avoid environmental contamination.

Please consult your local Environmental Authority for information on disposal in

your region. Do not dispose of any batteries in fire.

3.2 SELECTING YOUR LANGUAGE

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘SET’ is displayed.

3 Repeatedly press the ‘Sel’ key until ‘SET language’ is displayed.

4 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to change’ is displayed.

5 Press the ‘Set’ key to select the required language.

English, German, French, Spanish and Italian are available for selection.

6 Press the ‘Func’ key to exit the menu.

3 GETTING STARTED

3.3 SELECTING THE MEASUREMENT UNITS

The Elcometer 215 can display readings in °C or °F. The default

setting is °C.

To change the measurement units:

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘SET’ is displayed.

3 Repeatedly press the ‘Sel’ key until ‘SET range’ is displayed.

4 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to change’ is displayed.

5 Press the ‘Set’ key to select the required measurement units.

°C Range: -200/1300°C; °F Range: -328/2372°F

6 Press the ‘Func’ key to exit the menu.

Note: Any runs stored in the logger must be deleted before changing the measurement

units, see Section 4.5 ‘Clearing the Memory’ on page en-8.

3.4 SETTING THE DATE FORMAT

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘SET’ is displayed.

3 Repeatedly press the ‘Sel’ key until ‘SET format’ is displayed.

4 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to change’ is displayed.

5 Press the ‘Set’ key to select the required date format.

DD/MM/YY, MM/DD/YY or YY/MM/DD

6 Press the ‘Func’ key to exit the menu.

3.5 SETTING THE TIME AND DATE

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘TIME/date’ is displayed.

3 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to change’ is displayed.

4 Set the date and time using the ‘Sel’ and ‘Set’ keys.

5 Press the ‘Func’ key to exit the menu.

3.6 SETTING THE LOGGING INTERVAL

The Elcometer 215 measures continuously but takes and saves

readings at time intervals set the by user ranging from 0.125 s

(8 readings per second) to 2 hours. The default setting is every

2 seconds.

3 GETTING STARTED (continued)

www.elcometer.com en-4

R

The maximum recording period depends on the number of probes

being used and the specified recording time.

To change the logging interval:

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘INTERVAL’ is displayed.

3 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to change’ is displayed.

4 Set the required logging period using the ‘Sel’ and ‘Set’ keys.

5 Press the ‘Func’ key to exit the menu.

The logging interval can also be set within ElcoMaster® and ®

transferred to the logger, see Appendix A ‘Using ElcoMaster ’ on

page en-13 for further information.

3.7 CONNECTING THE PROBES

The Elcometer 215 has six input sockets

(channels) for K-type temperature probes.

Probes should be connected to each

socket in turn, starting with channel 1,

followed by channel 2, etc.

Each probe plug has a narrow and a wide terminal, ensure that the

plug is orientated correctly before making the connection.

To view details of the probe connected to each channel, press the

‘Func’ key until ‘METER’ is displayed and repeatedly press the ‘Sel’

key to display each probe in turn. If no probe is connected, ‘open’ is

displayed.

Note: The Elcometer 215 is not supplied with k-type temperature probes - probes must

be ordered separately, see Section 5.1 ‘Temperature Probes’ on page en-9.

Note: A set of probe identification tags is available to purchase as an optional

accessory to help match each probe with its assigned channel, see Section 5.2

‘Probe Identification Tags’ on page en-10.

3 GETTING STARTED (continued)

www.elcometer.com

en-5

R

3 GETTING STARTED (continued)

3.8 THE THERMAL BARRIER & HEAT SINK BLOCK

The Elcometer 215 Model S and T are supplied

with a thermal barrier as standard.

To ensure the logger does not exceed

its maximum operating temperature, it

should be placed inside the protective

thermal barrier prior to going into the

oven.

Place the logger in the thermal barrier,

ensuring that the probe leads are passed

through the barrier’s cable guide and they

are not twisted or trapped.

Always take the logger out of the

thermal barrier immediately after

passing through the oven.

DO NOT touch surfaces which

become hot during high temperature

operation.

Thermal Barrier with Heat Sink Block

The Elcometer 215 Model T is supplied with

a thermal barrier compatible with the heat

sink block, also supplied.

When used together, they enable the logger

to be used at elevated temperatures over a

longer time period, see ‘Thermal

Characteristics’ table on page en-7.

DO NOT use the heat sink block if the heat sink material is in

liquid form, see Appendix ‘ he Heat Sink Block’ on page B T

en-21 for further information.

Note: A Material Safety Data Sheet for the heat sink material in the heat sink block

supplied with the Elcometer 215 Model T and available as an accessory, is

available to download via our website:

www.elcometer.com/images/stories/MSDS/elcometer_215_heat_sink.pdf

Incorrect: Probe leads

are twisted

Correct: Probe leads are

not twisted or trapped

www.elcometer.com en-6

R

3 GETTING STARTED (continued)

b Other time / temperature combination thermal barriers are available on request. Please contact

Elcometer or your local supplier for further details.

b

THERMAL CHARACTERISTICS

Temperature

Time at Temperature

Standard

Thermal Barrier

High Temperature Thermal

Barrier with Heat Sink Block

100°C (212°F)

140 minutes

340 minutes

150°C (302°F)

80 minutes

195 minutes

200°C (392°F)

60 minutes

130 minutes

250°C (482°F)

50 minutes

100 minutes

300°C (572°F)

-

30 minutes

4.1 BEFORE YOU START

1 Set-up the logger, see Section 3.2 to 3.6 on page en-3.

2 Connect the probes, see Section 3.7 on page en-5.

3 Place the logger in the heat sink block (if required) and thermal

barrier.

4.2 START LOGGING

The Elcometer 215 can store up to 260,000 readings in up to 8 production

runs.

To start logging:

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘LOG no runs’ is displayed.

3 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to start’ is displayed, logging will commence.

®

The logger can be pre-programmed via ElcoMaster to start logging

immediately after holding the ‘Set’ key; after a set period; when a set

temperature has been reached or when the rate of temperature

increase rises above a set value - see Appendix A: Section A.2

‘Creating a Settings File’ on page en-14 for further details.

4.3 STOP LOGGING

Logging will stop when the maximum run time has been reached

®

unless the logger is pre-programmed via ElcoMaster to stop after a

set time period has elapsed or the temperature falls below a set

value, see Appendix A: Section A.2 ‘Creating a Settings File’ on page

en-14 for further details.

4 USING THE LOGGER

www.elcometer.com

en-7

R

Logging can also be stopped manually by the user at anytime, which

will override any pre-programmed stop triggers.

To manually stop logging:

1 Press the ‘Func’ key to wake the logger.

2 Press and hold the ‘Set’ key to stop logging.

When logging has stopped, ‘run complete’ is displayed and if cure

®

parameters have been set via ElcoMaster , see Appendix A: Section

A.3 ‘Creating a New Paint Type’ on page en-15, an indication will also

be given whether the latest run has met the cure parameters.

®

Batch data can be downloaded to ElcoMaster for further reporting

and analysis, see Section 4.4.

4.4 DOWNLOADING DATA

When one or more runs have been recorded, the data can be

downloaded to PC for further analysis and reporting using

ElcoMaster® software and the USB cable supplied, see Appendix A

®

‘Using ElcoMaster ’ on page en-13 for further information.

4.5 CLEARING THE MEMORY

The Elcometer 215 can store up to 260,000 readings in up to 8 production

runs. When all 8 runs are complete, start logging will automatically

overwrite the oldest. It is therefore not necessary to clear the memory

however, this can be done if required.

To clear the memory:

1 If idle, press the ‘Func’ key to wake the logger.

2 Repeatedly press the ‘Func’ key until ‘TOOLS’ is displayed.

3 Repeatedly press the ‘Sel’ key until ‘clear’ is displayed.

4 Press and hold the ‘Set’ key for approximately 5 seconds whilst

‘Hold to continue’ is displayed. ‘ok’ is displayed and all runs are

deleted.

Note: All stored runs will be deleted. It is not possible to select which runs are

deleted.

4 USING THE LOGGER (continued)

www.elcometer.com en-8

R

5 SPARES & ACCESSORIES

5.1 TEMPERATURE PROBES

A wide range of K-type temperature

probes is available with 1.5m (4' 9"), c

3m (9' 8") or 6m (19' 7") cable lengths .

All probes offer:

Perfect contact between the probe and

the surface.

Low mass and optimised shape to

avoid influence on the temperature of

the sample.

Extremely strong, highly flexible and

®

easy to clean Teflon coated cables.

The probes listed below have a continuous maximum operating

temperature of 250°C (428°F) and a short term maximum temperature

c

of 300°C (570°F) .

Note: The Elcometer 215 is not suppled with k-type temperature probes - probes must

be ordered separately.

c Probes with longer cable lengths and for use at higher temperatures are available on request. Please

contact Elcometer or your local supplier for further information.

www.elcometer.com

en-9

R

Probe Type

c

Cable Length / Part Number

1.5m (4' 9")

3m (9' 8")

6m (19' 7")

Clamp Air Probe

T21521275

T21521276

T21521277

Magnetic Air Probe

T21521287

T21521288

T21521569

Clamp Surface Probe

T21521278

T21521279

T21521280

Magnetic Surface Probe

T21521281

T21521282

T21521283

Combined Magnetic Clamp

Air and Surface Probe

T21521284

T21521285

T21521286

5 SPARES & ACCESSORIES (continued)

5.2 PROBE IDENTIFICATION TAGS

Available to purchase as an optional accessory,

each tag is numbered 1 to 6 to help match each

probe with its assigned channel.

Description Part Number

Probe Identification Tags, Pack of 6 T21521241

5.3 THERMAL BARRIERS & HEAT SINK BLOCK

The Elcometer 215 Model S and T are supplied

with a thermal barrier as standard.

The thermal barrier supplied with the

Elcometer 215 Model T is compatible with the

heat sink block. When used together, they

enable the logger to be used at elevated

temperatures over a longer time period, see

‘Thermal Characteristics’ table on page en-7 for

further . information

DO NOT use the heat sink block if the heat sink material is in

liquid form, see Appendix B ‘The Heat Sink Block’ on page

en-21 for further information.

Description Part Number

Standard Thermal Barrier (supplied with Model S) T21521222

High Temperature Thermal Barrier (supplied with Model T) T21521217

d

Heat Sink Block (supplied with Model T) T21521219

Note: The heat sink block can only be used with the high temperature thermal barrier

which has a larger cavity. It is not compatible with the Standard Thermal Barrier.

www.elcometer.com en-10

R

d Heat Sink Block not included.

7 TECHNICAL SPECIFICATION

Model

Model e

S

Model Tf

Measurement

Range

-200°C to 1300°C (-328°F to 2372°F)

Operating

Temperature

Logger only: -30°C to 65°C (-22°F to 149°F)

g

Max : 250°C (482°F)

for 50 minutes

g

Max : 300°C (572°F)

for 30 minutes

5°C to 500°C: ±0.5°C (41°F to 932°F: ±1.0°F)

> 500°C: ±1.0°C (> 932°F: ±2.0°F)

Accuracy

Number of

Channels

6

Measuring

Intervals

Adjustable from 8 per second to 1 per hour

Memory

260,000 readings or 8 production runs

Power Supply

2 x AA batteries

Dimensions

Logger only: 153 x 101 x 23mm (6 x 4 x 0.9")

245 x 245 x 115mm (9.65 x 9.65 x 4.5")

Weight

Logger only: 450g (15.8oz)

4kg (8.8lb)

6kg (13.2lb)

www.elcometer.com

en-11

R

6 WARRANTY STATEMENT

The Elcometer 215 Oven Data Logger and temperature probes are

supplied with a 12 month warranty against manufacturing defects,

excluding contamination and wear.

e Technical specification quoted using the supplied standard thermal barrier.

f Technical specification quoted using the supplied high temperature thermal barrier with heat sink block.

g See page en-7 for thermal characteristics using different time / temperature combinations.

www.elcometer.com en-12

R

8 LEGAL NOTICES & REGULATORY INFORMATION

The Elcometer 215 meets the Electromagnetic Compatibility Directive when used with sensor

leads up to 3m long; compliance may be affected by using longer leads.

The Elcometer 215 is Class B, Group 1 ISM equipment according to CISPR 11.

Group 1 ISM product: A product in which there are intentionally generated and/or used

conductively coupled radio-frequency energy which is necessary for the internal functioning of

the equipment itself.

Class B product are suitable for use in domestic establishments and in establishments directly

connected to a low voltage power supply network which supplies buildings used for domestic

purposes.

®

and ElcoMaster are registered trademarks of Elcometer Limited, Edge Lane,

Manchester, M43 6BU. United Kingdom

All other trademarks acknowledged.

The Elcometer 215 is packed in a cardboard package. Please ensure that this packaging is

disposed of in an environmentally sensitive manner. Consult your local Environmental

Authority for further guidance.

R

www.elcometer.com

en-13

R

®

Using ElcoMaster , supplied with the Elcometer 215 and available to

download via www.elcometer.com, the user can:

Configure the logger for different oven applications.

Create a ‘Paint Cure Library’ by manufacturer and / or paint

type with automatic calculation of the percentage cure.

Set up templates for different products incorporating

annotated images with diagrams of measurement locations.

Create and transmit PDF reports incorporating all data in a

professional, easy to read format.

The Elcometer 215 is pre-loaded with some basic settings that allow

temperature data to be collected straight out of the box however, the

functionality can be greatly increased by uploading a settings file to the

logger.

Logger settings are broken down into four areas:

Oven Logger Settings; configure basic settings.

Paint Type; add cure time and temperature information for the

cure calculation.

Product; add supplementary information regarding the

product including diagrams and probe location.

Template; combine all of the above into a template which can

be uploaded to the logger.

A.1 BEFORE YOU START

®

1 Ensure ElcoMaster is installed on

the PC. ®

2 Switch ElcoMaster to ‘Advanced

Mode’ by clicking on the expand

arrow and selecting ‘Advanced

Mode’.

®

APPENDIX A: USING ELCOMASTER

www.elcometer.com en-14

R

®

APPENDIX A: USING ELCOMASTER (continued)

A.2 CREATING A SETTINGS FILE

1 Click on the ‘Oven Profiling’ tab.

2 Click ‘New’’Oven Logger’. A

new file is created labelled ‘New

Logger Setup x'. To rename file,

right-click and select ‘Rename’.

Various tabs are now available which

allow different settings to be configured.

Description: make general notes about the logger.

Channel Set-up: label each channel for example, ‘Air Probe Top’,

‘Surface Probe Bottom’.

Sample Rate Setup: configure

how often readings should be

taken and how many different

batches of readings can be held

on the logger at any one time. For

example, if ‘4 Batch Runs’ is

selected, the logger will hold 4

batches and when the fifth is

created, batch 1 will be deleted.

Note: The maximum run time for each

batch, calculated using the selected

reading rate and number of batches, is

displayed in the yellow box.

Start/Stop Triggers: configure when

to start and stop logging. For start

triggers, the options are to start

logging after holding the ‘Set’ key;

Manual: start immediately.

Manual with Delay: start logging after

a pre-defined set interval.

Threshold Temperature: start logging

when the temperature of the probe

connected to channel 1 rises above

the set temperature.

Temperature Differential: start

logging after the rate of temperature

increase of the probe connected to

channel 1 rises above the set value.

www.elcometer.com

en-15

R

Stop triggers are handled in a similar way:

Run Duration: will stop logging after a pre-defined set time.

Threshold Temperature: will stop logging when the temperature of

the probe connected to channel 1 falls below the set temperature.

If nothing is selected, the logging will stop when either the

maximum run time is reached or logging is stopped manually.

Once the settings file has been created, click ‘Upload’ to upload the

data directly to the logger and follow the on-screen instructions.

A.3 CREATING A NEW PAINT TYPE

Time and temperature data for the paint type can be added to allow

the logger to perform a cure calculation providing the user with a

numerical value for how well the coating has cured at each probe

location.

A cure calculation of 100 represents a coating which has only just

cured with less representing a coating which has not cured enough. A

cure calculation greater than 100 is not usually an issue as long as the

maximum temperature is not exceeded. If significantly greater than

100 however, there may be scope for increasing efficiency by speeding

up the process or turning the oven temperature down.

The cure calculation result is shown both on the logger screen and

®

also within ElcoMaster at the end of the run.

To create a new paint type:

1 Click on the ‘Oven Profiling’ tab.

2 Click ‘New’’Paint Type’. A new

file is created labelled ‘New Paint

x'. To rename file, right-click and

select ‘Rename’.

Various tabs are now available for data

entry.

Description: add basic data regarding the paint type and upload

the manufacturers’ data sheet (pdf format) if available.

®

APPENDIX A: USING ELCOMASTER (continued)

www.elcometer.com en-16

R

Setup Cure Parameters: enter

details of the cure temperature

parameters, cure calculation method

and temperature limits.

Cure Temperature Parameters: enter

the maximum, mid and / or minimum

cure temperature and time values.

At least two sets must be completed

for the cure calculation to work.

Cure Curve Type: choose between linear and exponential based

on how well the line on the cure curve fits with the time /

temperature points.

Cure Temperature Limits: if the minimum crosslink and maximum

safe temperatures are known, these should be entered to

increase the accuracy of the cure calculation and provide a

warning if the product is getting too hot.

A.4 CREATING A NEW PRODUCT

Allows the user to add additional information regarding the product

under test including annotated diagrams and labels for each individual

thermocouple as well as their location on the product.

To create a new product:

1 Click on the ‘Oven Profiling’ tab.

2 Click ‘New’’Product’. A new file

is created labelled ‘New Product x'.

To rename file, right-click and

select ‘Rename’.

3 Click ‘Select Image’ to import a

diagram or image of the product.

4 Use the tools at the top of the

image preview to rotate the image

to the correct orientation.

5 Click on ‘Direction of Travel’ at the

bottom of the image preview to cycle

through the different direction options.

6 Label each channel in turn and

click and drag the probe indicator

mark to the appropriate location on

the image.

®

APPENDIX A: USING ELCOMASTER (continued)

www.elcometer.com

en-17

R

A.5 CREATING A NEW TEMPLATE

A template combines logger settings, paint type and product

information for upload to the logger. Any combination of the three

settings can be used to create a template.

To create a new template:

1 Click on the ‘Oven Profiling’ tab.

2 Click ‘New’’Template’. A new file

is created labelled ‘New Template

x'. To rename file, right-click and

select ‘Rename’.

3 Click ‘Select Oven Logger’ and

select the required oven logger

settings file. Repeat for ‘Select

Paint Type’ and ‘Select Product’ if

required.

4 Add descriptive text under

‘Template Description’ if required.

Once the template has been created, click ‘Upload’ to upload the data

directly to the logger and follow the on-screen instructions.

A.6 UPLOADING SETTINGS AND TEMPLATES

®

Settings and templates created in ElcoMaster can be uploaded to the

Elcometer 215 ensuring that all runs through the oven have the

correct calculations performed and the correct supplementary data

recorded against them. Different paint types, products and templates

can be applied at a later date to each batch but logger settings cannot

be changed.

To upload via the ‘Oven Profiling’ Tab:

1 Connect the logger to the PC using the USB cable supplied and

click on the ‘Download’ tab. ®

2 Connect the logger to ElcoMaster using the ‘Connect Gauge’

wizard.

3 Click on the ‘Oven Profiling’ tab and select the required oven-

logger settings file or template.

4 Click ‘Upload’ and follow the on-screen instructions to connect the

logger.

®

APPENDIX A: USING ELCOMASTER (continued)

www.elcometer.com en-18

R

5 A window will appear with the

options to ‘Set Gauge Clock’

(recommended) and ‘Upload

Setup to Gauge’.

6 Click ‘Upload Setup to Gauge’ to

upload the selected settings file or

template.

To upload via the ‘Download’ Tab:

1 Connect the logger to the PC using

the USB cable supplied and click

on the ‘Download’ tab. ®

2 Connect the logger to ElcoMaster

using the ‘Connect Gauge’ wizard.

3 Click on ‘Upload to Gauge’ and

follow the on-screen instructions.

A.7 DOWNLOADING DATA

When one or more ‘runs’ have been recorded, the data can be

downloaded to PC for further analysis and reporting.

To download data:

1 Connect the logger to the PC using

the USB cable supplied and click

on the ‘Download’ tab. ®

2 Connect the logger to ElcoMaster

using the ‘Connect Gauge’ wizard.

3 Click on ‘Download from Gauge’

and follow the on-screen

instructions.

® ®

Data can be downloaded to an ElcoMaster batch file, Excel

spreadsheet or text file.

®

Note: To view the data in ElcoMaster and generate reports using the report wizard,

®

the data must be downloaded to an ElcoMaster batch file.

®

APPENDIX A: USING ELCOMASTER (continued)

www.elcometer.com

en-19

R

A.8 VIEWING DATA

Downloaded data can be viewed at any time by clicking on the ‘View’

tab and selecting the appropriate Elcometer 215 project.

The temperature trace graph is

displayed with tabs to view the ‘Cure

Progress’, ‘Histogram’ and ‘Product’

information (if available).

Toggle the ‘Showing Multiple Lines’

button to on to view the temperature

trace lines for all channels on one

graph. Toggle off to view the

temperature trace line for the selected

channel only.

Below the graph are a series of tabs

containing the following batch

information:

Details: batch header and traceability

information including serial numbers

and dates / time that logging

commenced.

Statistics: summary statistics for

each channel including cure value

information and maximum

temperature warnings.

Measurements: a list of all the

measurement taken.

Notes / Photos: add supplementary

information, images or drawings as

required.

Oven Logger Settings: summary of

the logger settings used for the batch.

Paint Parameters: summary of the

paint parameters used for the batch.

Product: summary of the product

information used for the batch.

®

APPENDIX A: USING ELCOMASTER (continued)

Table of contents

Languages: