Electro-Sensors SG1000F User manual

SG1000F general description

The SG1000F is a Two-Turn Shaft Monitor with a 4-20 mA

output. The SG1000F is a rugged, medium cost encoder-based

monitoring device that enables the end-user to very accurately

monitor a process shaft’s position, allowing very accurate

operations. The SG1000F has two modes: calibration mode,

and normal operating mode. A simple calibration procedure

teaches (programs) the SG1000F the fully-closed (0% open) and

fully-open (100% open) process positions. Once programmed,

the SG1000F outputs a 4 mA DC signal when the process is in

the fully-closed position, and outputs a 20 mA DC signal when

the process is in the fully-open position. Any process position

between fully-closed and fully-open, is represented by the output

signal being proportionally between 4 and 20 mA.

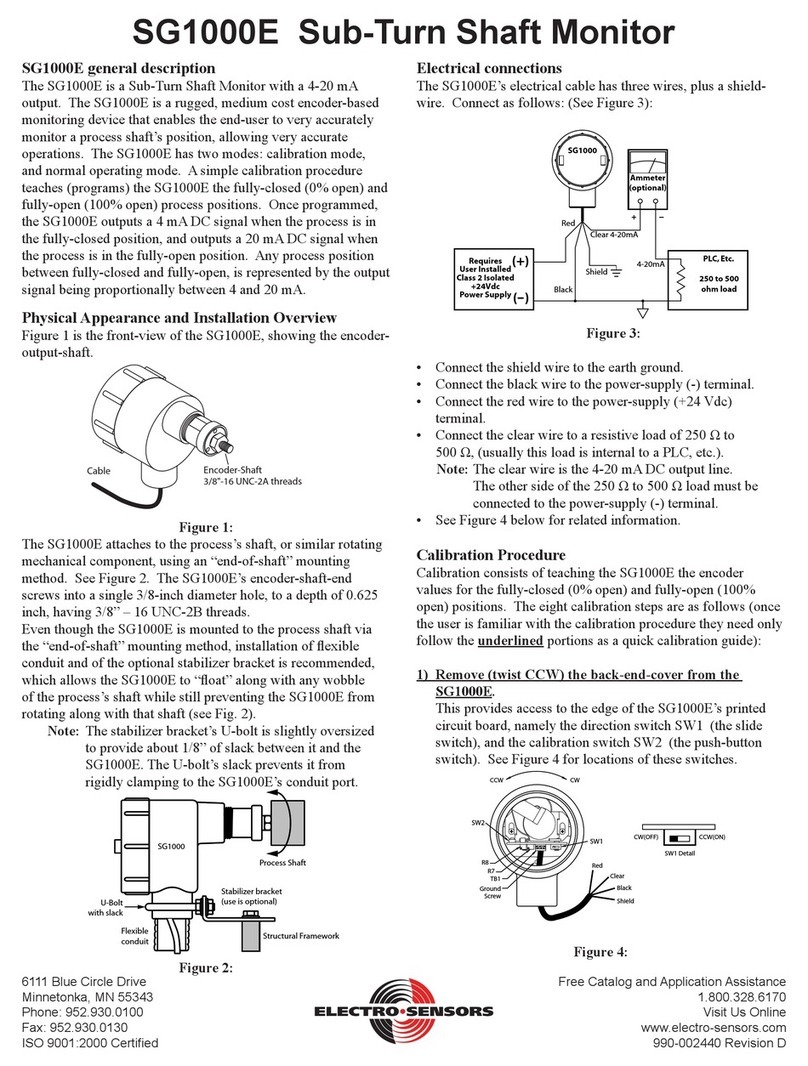

Physical Appearance and Installation Overview

Figure 1 is the front-view of the SG1000F, showing the encoder-

output-shaft.

Encoder-Shaft

3/8"-16 UNC-2A threads

3/8" Split Lockwasher

(Washer Shipped with

Stabilizer Bracket Kit)

Cable

Figure 1:

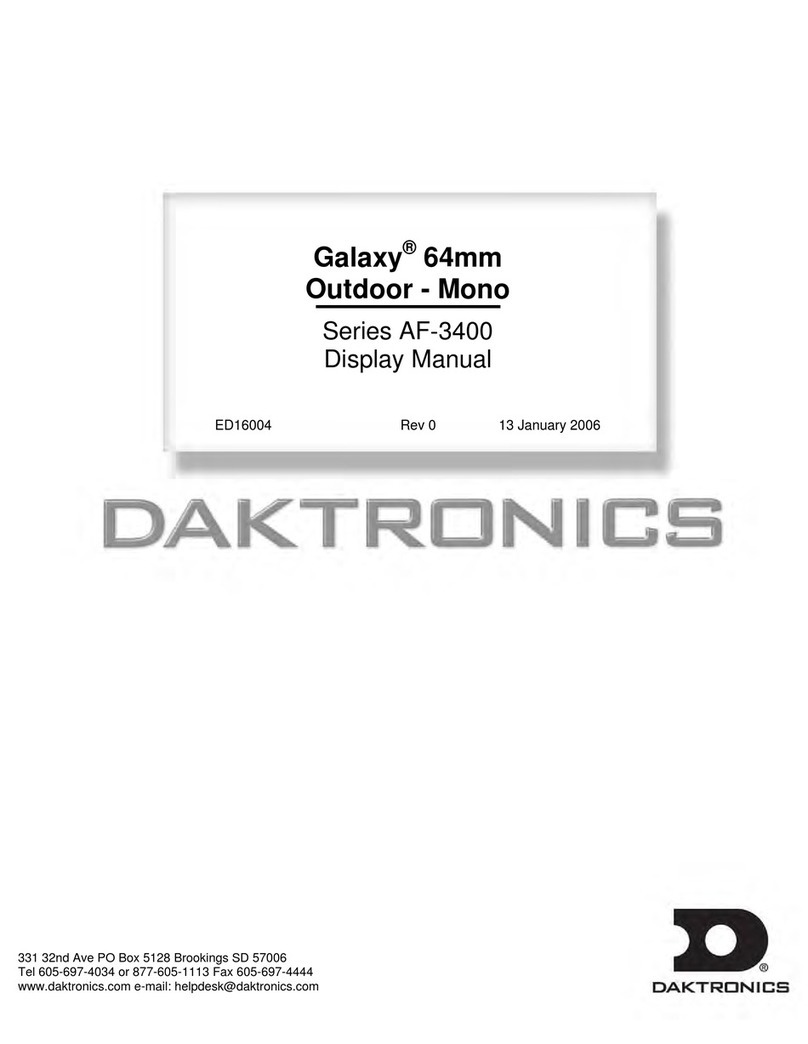

The SG1000F attaches to the process’s shaft, or similar rotating

mechanical component, using an “end-of-shaft” mounting

method. See Figure 2. The SG1000F’s encoder-shaft-end

screws into a single 3/8-inch diameter hole, to a depth of 0.625

inch, having 3/8” – 16 UNC-2B threads. (Install the 3/8” split

lockwasher, apply thread locker compound, and torque to 8ft-

lbs).

Even though the SG1000F is mounted to the process shaft via

the “end-of-shaft” mounting method, installation of exible

conduit and the stabilizer bracket is recommended, which

allows the SG1000F to “oat” along with any wobble of the

process’s shaft while still preventing the SG1000F from rotating

along with that shaft (see Fig. 2).

Note: The stabilizer bracket’s U-bolt is slightly oversized

to provide about 1/8” of slack between it and the

SG1000F. The U-bolt’s slack prevents it from

rigidly clamping to the SG1000F’s conduit port.

Process Shaft

SG1000

Stabilizer bracket

U-Bolt

with slack

Structural Framework

Flexible

conduit

Figure 2:

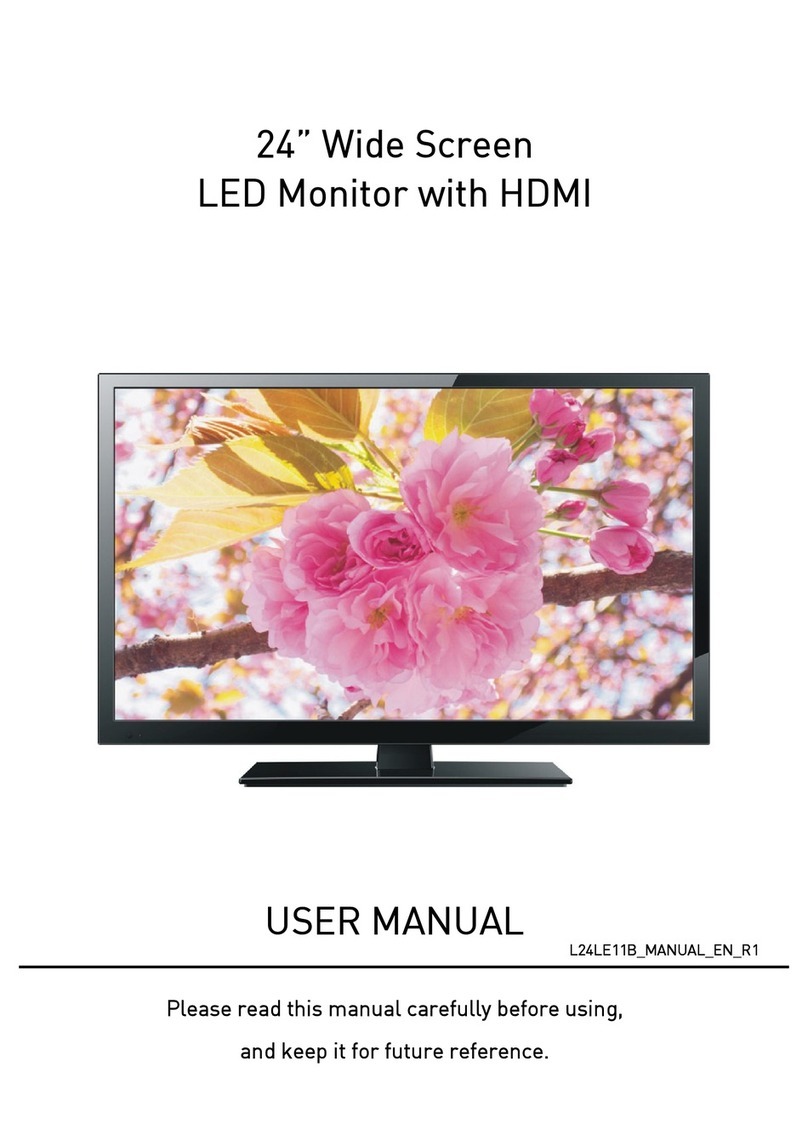

Electrical connections

The SG1000F’s electrical cable has three wires, plus a shield-

wire. Connect as follows: (See Figure 3):

Requires

User Installed

Class 2 Isolated

+24Vdc

Power Supply (-)

(+) PLC, Etc.

SG1000

-

+

Clear 4-20mA

4-20mA

Shield

Red

Black

250 to 500

ohm load

Ammeter

(optional)

Figure 3:

• Connect the shield wire to the earth ground.

• Connect the black wire to the power-supply (-) terminal.

• Connect the red wire to the power-supply (+24 Vdc)

terminal.

• Connect the clear wire to a resistive load of 250 Ω to

500 Ω, (usually this load is internal to a PLC, etc.).

Note: The clear wire is the 4-20 mA DC output line.

The other side of the 250 Ω to 500 Ω load must be

connected to the power-supply (-) terminal.

• See Figure 4 below for related information.

Calibration Procedure

Calibration consists of teaching the SG1000F the encoder values

for the fully-closed (0% open) and fully-open (100% open)

positions. The eight calibration steps are as follows (once the

user is familiar with the calibration procedure they need only

follow the underlined portions as a quick calibration guide):

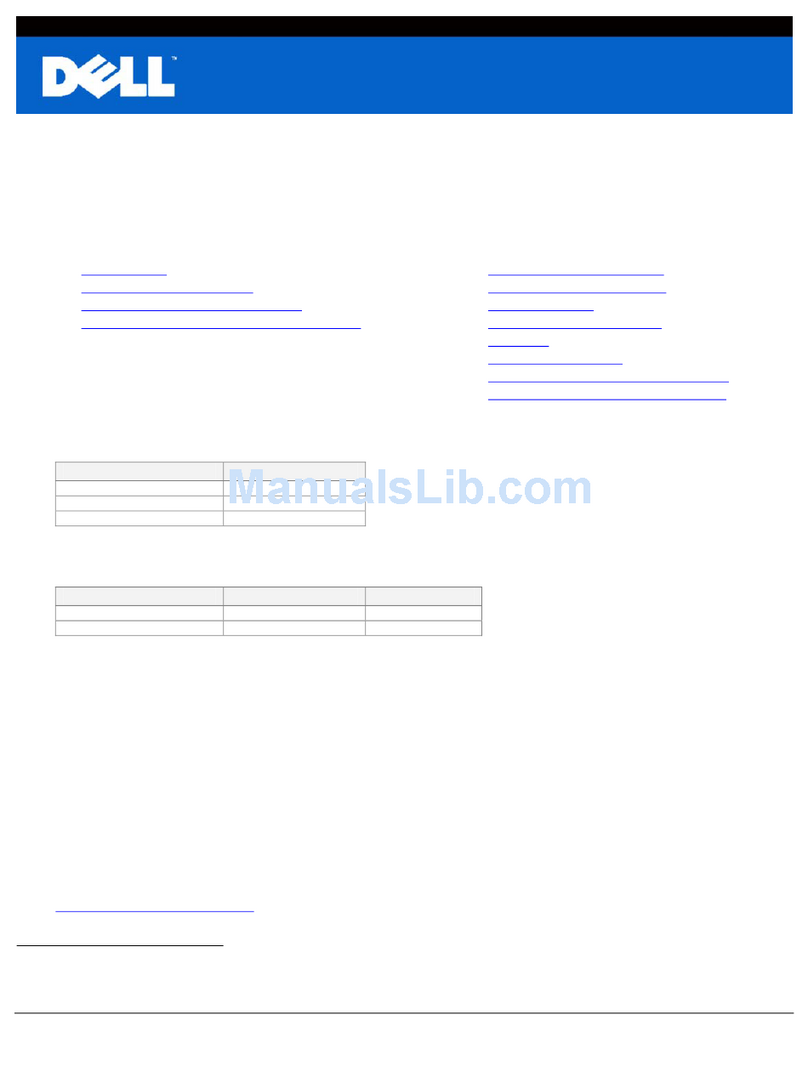

1) Remove (twist CCW) the back-end-cover from the

SG1000F.

This provides access to the edge of the SG1000F’s printed

circuit board, namely the direction switch SW1 (the slide

switch), and the calibration switch SW2 (the push-button

switch). See Figure 4 for locations of these switches.

Shield

Black

Clear

Red

CCW CW

R8

SW1 Detail

CW(OFF)

CCW(ON)

SW2

SW1

R7

TB1

Ground

Screw

Figure 4:

SG1000F Two-Turn Shaft Monitor

6111 Blue Circle Drive

Minnetonka, MN 55343

Phone: 952.930.0100

Fax: 952.930.0130

ISO 9001:2000 Certied

Free Catalog and Application Assistance

1.800.328.6170

Visit Us Online

www.electro-sensors.com

990-002450 Revision C

Note: Also on the edge of the PC board are two adjustment

potentiometers, R7 and R8, and a 3-pin terminal TB1.

Pot R7 is for tweaking the 4 mA output level. Pot R8 is

for tweaking the 20 mA output level. These two pots are

factory-adjusted, and the user normally should not have to

adjust them. It is best to leave these two pots alone.

The user normally should not have to disconnect the

3-wire cable from the SG1000F. But if they do so, they

must reconnect the 3-wire cable to the SG1000F as

follows:

• Power supply (+24Vdc) terminal red wire to TB1-1.

• 4-20mA signal clear wire to TB1-2.

• Power supply (-) terminal black wire to TB1-3.

2) Before entering Calibration Mode, set the direction

switch SW1 on the SG1000F’s PC board to the proper

position for the application.

SW1 tells the SG1000F the direction the encoder turns,

CW or CCW, as the process is moved from the fully-closed

to the fully-open position. The CW or CCW direction is

dened via the viewer looking at the back-cover-end of the

enclosure, and not the encoder-shaft-end of the enclosure:

• If the encoder shaft turns in the CW direction as the

process shaft is moved from the fully-closed to the fully-

open position, then set SW1 to the OFF position (i.e.,

toward the center of the PC board). See Figure 4.

• If the encoder shaft turns in the CCW direction as the

process shaft is moved from the fully-closed to the fully-

open position, then set SW1 to the ON position (i.e.,

toward the edge of the PC board). See Figure 4.

Note: The direction switch SW1 is monitored only briey as

the SG1000 enters into Calibration Mode. But once

inside Calibration Mode, SW1 is no longer relevant.

Hence, changing SW1 at this point has no eect.

Because of this, SW1 must be set to the desired

position before Calibration Mode is entered in order

to capture the desired setting of SW1.

3) There are two ways to enter Calibration Mode:

• One, remove the +24Vdc power, press-in and hold the

calibration switch SW2, then reapply the +24Vdc power.

(This is referred to as “power-up” entry into calibration

mode).

• Or two, while the SG1000 remains powered, press-in

and hold the calibration switch SW2, for a constant 5 to

6 seconds. (This is referred to as “on-the-y” entry into

calibration mode).

(Do not press SW2 multiple times or allow it to change state,

just keep it pressed-in). Continue to keep SW2 pressed-in

for a few seconds until the SG1000 outputs a constant 12 mA

from its signal line, then release the button.

The SG1000F is now in the calibration mode.

4) Move the process shaft to the fully-closed position (i.e.,

0% open).

5) Press the calibration switch SW2.

• This captures the present encoder count. This value is

then used for the fully-closed position (0% open).

• The output signal remains at 12 mA.

6) Move the process shaft to the fully-open position (i.e.,

100% open).

Note: As the process shaft moves from fully-closed to fully-

open, the SG1000F’s encoder shaft must turn at least

30º, but not more than a 718º turn (i.e. just shy of two

full turns.) Hence, if the shaft turns more than 718º,

or less than 30º, then the SG1000F will not work

properly for the application.

7) Press the calibration switch SW2.

• This captures the present encoder count. This value is

then used for the fully-open position (100% open).

• The SG1000F then automatically exits the calibration

mode and enters the normal operating mode.

Note: The calibration mode is exited at this point for both

valid and invalid calibrations.

For a valid calibration: If the user does not

immediately move the process shaft, then the

output signal is 20 mA. (Because the process shaft

was left in the fully-open position from step 6, the

output signal is at 100%, which is 20 mA).

For an invalid calibration: The output signal

remains at 12 mA.

See the “Valid Calibration” and “Invalid Calibration”

sections below for details regarding whether, or not, your

SG1000F accepted the shaft’s two calibration positions.

8) Replace the back-end-cover onto the SG1000F.

This ends the calibration procedure.

Valid Calibration (Normal Operating Behavior)

Assuming the user followed the calibration procedure correctly,

the SG1000F behaves as follows:

• When the process shaft is at the fully-closed position (0%

open), the output signal is 4 mA.

• When the process shaft is at the fully-open position (100%

open), the output signal is 20 mA.

• Any process shaft position between 0% open and 100%

open is represented by the output signal being proportionally

between 4 mA and 20 mA.

• If the process shaft is moved to a position that is slightly

beyond (outside of) the fully-closed (0% open) calibrated

position, then the output signal remains at 4 mA. This is

known as 0% ‘run-out’, and it holds to a certain point. If

the encoder is turned far enough beyond the fully-closed

calibrated position, then the encoder “wraps-around” and the

output signal jumps to the fully-open value of 20 mA.

2-4

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-002450 Revision C

Valid Calibration (cont.)

• If the process shaft is moved to a position that is slightly

beyond (outside of) the fully-open (100% open) calibrated

position, then the output signal remains at 20 mA. This is

known as 100% ‘run-out’, and it holds to a certain point.

If the encoder is turned far enough beyond the fully-open

calibrated position, then the encoder “wraps-around” and the

output signal jumps to the fully-closed value of 4 mA.

• For a properly calibrated SG1000F, the direction of

calibration (CW or CCW), and the encoder values for the

fully-closed and fully-open process shaft positions are all

stored in the SG1000F’s EEPROM memory.

Note: Since a properly calibrated SG1000F can never enter the

calibration mode again by itself after the calibration mode

is exited, the direction switch SW1 and the calibration

switch SW2 are ignored (during normal operating mode).

This means that for a properly calibrated SG1000F the

calibration results are protected until the user wants to

purposefully enter calibration mode again.

If re-calibration is needed, see the section below titled

“How to clear-out the existing calibration and

reprogram the SG1000F.”

Invalid Calibration (Error condition behavior)

Assuming the user followed the calibration procedure

incorrectly, the SG1000F behaves as follows:

• The output signal remains at a constant 12 mA after the

calibration mode is automatically exited.

An “invalid calibration” is most likely due to one of the

following errors:

- If the user did not move the process shaft (or moved it but

less than a 30º turn) between teaching the SG1000F the

fully-closed and fully-open positions, then the closed and

open positions have the same (or nearly the same) encoder

count.

- The user “double-pressed” SW2 during power-up or while

teaching the SG1000F the fully-closed position.

Power-ups; calibration vs. normal operating mode

• An SG1000F that is un-calibrated (or if the calibration

attempt was invalid) automatically powers-up in the

calibration mode, the next time power is applied.

• A properly calibrated SG1000F powers-up in the normal

operating mode, when power is applied.

• If the user accesses calibration mode via the “power-up”

method then any previous calibration is immediately cleared.

• If the user accesses calibration mode via the “on-the-y”

method, then any previous calibration is retained until the

new calibration points have been acquired. (This allows

the user the option to bail out of calibration mode before

completing the new calibration by simply removing the

+24Vdc power. In this case of intended power interruption,

the EEPROM never gets called to save any new calibration,

thus the old calibration is retained).

Troubleshooting Hints

As an aid to troubleshooting, see gure 3 on how to connect an

ammeter to directly measure the 4-20mA output signal.

1) If your SG1000F outputs a 4 mA to 20 mA signal, but not at

the process shaft positions expected, then double-check the

following:

A) Before you performed the calibration procedure, did you

set the direction switch SW1 to the proper position (CW

or CCW) before entering calibration mode?

B) As your process shaft moves from fully-closed to fully-

open, does the SG1000F’s encoder shaft turn more than

718º (i.e. two turns), or less than a 30º turn? If so, then

the SG1000F will not work in your application.

C) Is your SG1000F terminal TB1 wiring correct?

• Power supply (+24Vdc) terminal red wire is TB1-1.

• 4-20mA signal clear wire is TB1-2.

• Power supply (-) terminal black wire is TB1-3.

D) Assuming conditions (A), (B), and (C) are proper, and

your SG1000F still seems to behave improperly, then try

re-calibrating again, paying close attention to the eight

calibration steps.

2) If you have gone through troubleshooting hints (1A), (1B),

(1C), and (1D), and if your SG1000F seems to otherwise

respond properly, from fully-closed to fully-open, with

the only exception being that strange values other than 4

mA and 20 mA are output for the fully-closed/fully-open

positions (e.g., 3 mA at one-end and 23 mA at the other-

end), then possibly the R7 and R8 factory potentiometer

settings have been tampered with. See Figure 4 for

location of these pots.

Evidence of R7 and R8 tampering is most easily seen

when in the calibration mode. When R7 and R8 are at

their factory-settings, the output signal is 12 mA during

calibration mode. (Recall that the output signal remains

at 12 mA until the calibration procedure is completed). If

during calibration mode the output signal is not 12 mA,

then most likely the R7 and R8 factory-settings have been

tampered with.

If you feel condent that you have followed the calibration

procedure properly (perhaps have done it several times

over), and followed the troubleshooting hints in (1A),

(1B),(1C), and (1D), AND you still see strange values

other than 4 mA at one end and 20 mA at the other, then

you can attempt to restore R7 and R8 to the factory-settings

by doing the following: (This assumes you have already

calibrated your SG1000F for the fully-closed and fully-

open process shaft positions).

A) During normal operating mode, move the process shaft

to your fully-closed calibrated position. Adjust R7

until 4 mA is output from the signal line.

B) During normal operating mode, move the process shaft

to the fully-open calibrated position. Adjust R8 until

20 mA is output from the signal line.

C) You can now test and verify that your R7 and R8 are

3-4

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-002450 Revision C

indeed set back to factory settings. Do this by re-

entering the calibration procedure. If the 4 mA to 20

mA output signal is at 12 mA (or fairly close) when in

the calibration mode, then you have properly restored

R7 and R8 settings.

D) Continue and complete the calibration procedure for

the process’s fully-closed and fully-open positions.

How to clear-out the existing calibration, and

reprogram the SG1000 (Two methods)

One, remove +24Vdc power, then press and hold-in the SW2

button while re-applying the +24Vdc power to the SG1000.

Continue to keep the SW2 button pressed-in for a few seconds

until the SG1000 outputs 12 mA, then release the SW2 button.

The old calibration has now been cleared-out, and the SG1000 is

in calibration mode awaiting new calibration.

Or two, while powered, press and hold-in the SW2 button for 5

to 6 seconds to enter calibration mode.

See the “Calibration Procedure” section for complete details.

SG1000F General Specications:

Input Power Input Current

REQUIRES USER INSTALLED

CLASS 2 ISOLATED

+24 VDC ±10% Power Supply

40mA max (when output

signal is at 20mA)

Input Signal Parameters

Type Rotating shaft connected to internal 9 bit, 0 to

511 count, absolute position encoder

Range of Operation

Continuous rotation with no physical end stops.

Calibratible span of 1/12th turn to almost 2 turns

of output shaft.

Internal Gear Ratio 2:1

Analog Output

Signal Parameters

Type

4-20 mA DC, with programmable end-points:

(4 mA @ user’s fully closed position)

(20 mA @ user’s fully open position)

Accuracy Resolve to 1 encoder count of calibrated span

position (span from fully closed to fully open).

4-20 mA

Resolution

Varies linearly from best of 0.2% of span,

to worst of 5.0% of span

depending on calibration

0.2% resolution occurs when calibrated at the maximum span of

511 encoder counts, which is just less that two complete turns

(718º) of the output shaft. That is, 1 count out of 511 counts is

about 0.002, or 0.2 %

5.0% resolution occurs when calibrated at the minimum span of 21

encoder counts, which is 1/12th turn (30º) of the output shaft. That

is, 1 count out of 21 counts is about 0.05, or 5 %

Since the 4-20 mA output has a 16 mA span, a 0.2% resolution

gives an incremental change of 0.032 mA, and a 5.0% resolution

gives an incremental change of 0.800 mA.

Required

impedance 4-20 mA output needs a 250 to 500 Ω load

Mechanical Parameters

Mounting End of Shaft, single drilled and tapped hole.

Mounting Threads 3/8-16 UNC x 0.625 in.

Mounting Torque

8ft-lbs, with threadlocker compound.

Note: If a torque wrench is not available, then

still apply thread locker compound,

then gently tighten encoder-shaft to

application until you feel the split lock

washer has fully compressed, then go

1/16th turn more.

Housing Material Cast Aluminum

Housing Dimensions Cylindrical, with diameter of 3-11/16”, length

of 7-5/8” (length includes housing & shaft)

Stabilizer Bracket

Mounted semi-rigidly to application’s

framework using two user supplied 5/16”

bolts.

Physical/Enviroment Parameters

Class I, Groups C, D

Class II, Groups E, F, G

UL File: E249019

Additional Rating NEMA 4X, Gasket Provided

Temperature Range -40ºC to +65ºC (-40ºF to +149ºF)

Humidity 0% to 90% non-condensing

Operator Interface Parameters

One Pushbutton Enter calibration mode and calibrate for fully

closed/fully open process shaft positions

One Slide Switch Select calibration direction CW/CCW

Memory EEPROM retains calibration during power

failure or power shut down

Operation Modes

Normal Operating Mode: (output signal per process shaft position).

- Output: 4 mA to 20 mA signal proportional to process shaft

position, for a properly calibrated SG1000.

- Output: Constant 12 mA for an uncalibrated or miscalibrated

SG1000.

Calibration Mode: (select calibration direction, calibrate for fully-

closed / fully-open process shaft positions).

- Output: Holds at a constant 12 mA in this mode.

Additional Information

To get additional information about the SG1000F, visit our

website at: www.electro-sensors.com

Notice:

Copyright © 2019 Electro-Sensors, Inc. All rights reserved. No part

of this document can be duplicated or distributed without the express

written permission of Electro-Sensors, Inc.

While the information in this manual has been carefully reviewed for

accuracy, Electro-Sensors, Inc. assumes no liability for any errors or

omissions in the information. Electro-Sensors, Inc. reserves the right

to make changes without further notice to any part of this manual or

product described in this manual.

4-4

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-002450 Revision C

Other Electro-Sensors Monitor manuals