Electrolux Professional Combi DIGITAL User manual

Electrical and Gas Oven

Combi DIGITAL

EN User manual *

*Original instructions 0595402M00- 2023.02

2

Foreword

Read the following instructions, including the warranty terms before installing and using the appliance.

Visit our website www.electroluxprofessional.com and open the Support section to:

Register your product

Get hints & tips of your product, service and repair information

The installation, use and maintenance manual (hereinafter Manual) provides the user with information necessary for correct and

safe use of the appliance.

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for improving ap-

pliance performance in every respect and, above all, preventing injury to persons and animals and damage to property due to im-

proper operating procedures.

All persons involved in appliance transport, installation, commissioning, use and maintenance, repair and disassembly must con-

sult and carefully read this manual before carrying out the various operations, in order to avoid wrong and improper actions that

could compromise the appliance's integrity or endanger people. Make sure to periodically inform the user regarding the safety reg-

ulations. It is also important to instruct and update personnel authorised to operate on the appliance, regarding its use and

maintenance.

The manual must be available to operators and carefully kept in the place where the appliance is used, so that it is always at hand

for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding appliance use, do not hesitate to contact the Manufacturer or the au-

thorised Service Centre to receive prompt and precise assistance for better operation and maximum efficiency of the appliance.

During all stages of appliance use, always respect the current regulations on safety, work hygiene and environmental protection. It

is the user's responsibility to make sure the appliance is started and operated only in optimum conditions of safety for people, ani-

mals and property.

IMPORTANT

• The manufacturer declines any liability for operations carried out on the appliance without respecting the instructions

given in this manual.

• The manufacturer reserves the right to modify the appliances presented in this publication without notice.

• No part of this manual may be reproduced.

• This manual is available in digital format by:

– contacting the dealer or reference customer care;

– downloading the latest and up to date manual on the web site www.electroluxprofessional.com;

• The manual must always be kept in an easily accessed place near the appliance. Appliance operators and mainte-

nance personnel must be able to easily find and consult it at any time.

3

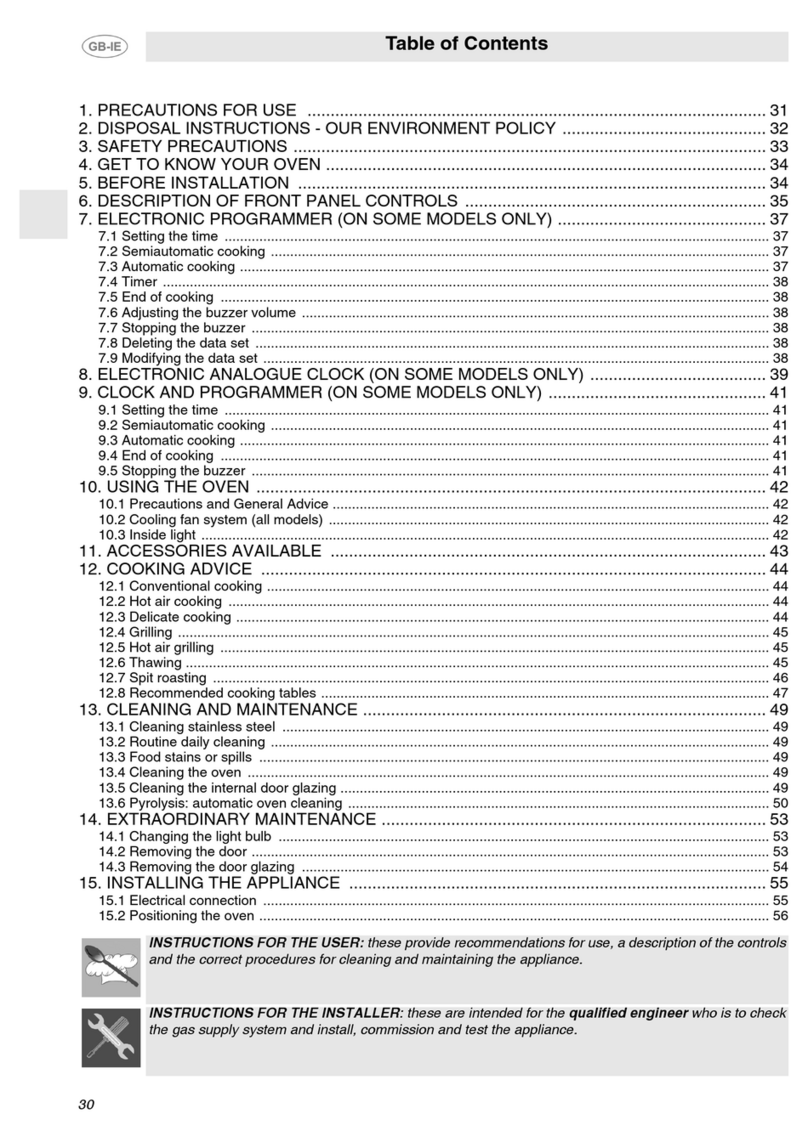

Contents

A WARNING AND SAFETY INFORMATION...................................................................................................5

A.1 General information ......................................................................................................................5

A.2 Personal protection equipment ........................................................................................................6

A.3 General safety .............................................................................................................................6

A.4 Protection devices installed on the appliance ...................................................................................... 7

A.5 Safety signs to be placed on the appliance or near its area ....................................................................8

A.6 Reasonably foreseeable improper use ..............................................................................................8

A.7 Residual risks ..............................................................................................................................8

A.8 Appliance cleaning........................................................................................................................9

A.9 Preventive Maintenance.................................................................................................................9

A.10 Parts and accessories ................................................................................................................. 10

A.11 Precautions for use and maintenance ............................................................................................. 10

A.12 Appliance maintenance................................................................................................................ 10

B WARRANTY ....................................................................................................................................... 10

B.1 Warranty terms and exclusions...................................................................................................... 10

C GENERAL INFORMATION .................................................................................................................... 11

C.1 Introduction ............................................................................................................................... 11

C.2 Intended use and restrictions ........................................................................................................ 11

C.3 Testing and inspection ................................................................................................................. 11

C.4 Copyright.................................................................................................................................. 11

C.5 Keeping the manual .................................................................................................................... 11

C.6 Recipients of the manual .............................................................................................................. 11

C.7 Definitions................................................................................................................................. 11

C.8 Responsibility ............................................................................................................................ 12

D NORMAL APPLIANCE USE................................................................................................................... 12

D.1 Characteristics of personnel enabled to operate on the appliance ......................................................... 12

D.2 Basic requirements for appliance use.............................................................................................. 12

E PRODUCT DESCRIPTION .................................................................................................................... 12

E.1 Use – Introduction ...................................................................................................................... 12

E.2 Appliance overview..................................................................................................................... 13

E.3 Opening and closing the oven door................................................................................................. 13

E.4 Control panel............................................................................................................................. 14

F OPERATING....................................................................................................................................... 14

F.1 Switch the oven ON .................................................................................................................... 14

F.2 Displays and controls description ................................................................................................... 15

F.3 Oven connectivity ....................................................................................................................... 16

F.4 Cooking cycle setting .................................................................................................................. 16

F.4.1 Set a COOKING CYCLE..................................................................................................... 16

F.4.2 Set the HUMIDITY............................................................................................................. 17

F.4.3 Set the cooking TIME......................................................................................................... 17

F.4.4 Preheating/Cooling phase................................................................................................... 17

F.4.5 Stop cycle ....................................................................................................................... 17

F.4.6 End cycle ........................................................................................................................ 17

F.4.7 VENT VALVE OPEN.......................................................................................................... 17

F.4.8 ECO DELTA..................................................................................................................... 18

F.4.9 COOLING DOWN ............................................................................................................. 18

F.4.10 CONTINUOUS COOKING .................................................................................................. 18

F.4.11 FOOD PROBE ................................................................................................................. 18

F.4.12 USB FOOD PROBE (on demand)......................................................................................... 19

F.4.13 MULTIPHASE .................................................................................................................. 19

F.4.14 UTILITIES ....................................................................................................................... 19

F.5 Programs.................................................................................................................................. 19

F.6 Indicator Lights .......................................................................................................................... 20

F.7 Special functions ........................................................................................................................ 20

F.8 Hood management ..................................................................................................................... 21

F.9 Cleaning cycle ........................................................................................................................... 21

F.9.1 Forced Cleaning ............................................................................................................... 23

F.9.2 Boiler descaling (dESC)...................................................................................................... 23

F.10 Switch the oven OFF................................................................................................................... 23

G OVEN CARE....................................................................................................................................... 24

G.1 Care information......................................................................................................................... 24

G.2 Cleaning introduction................................................................................................................... 24

G.3 Appliance cleaning...................................................................................................................... 24

G.4 Cooking chamber (cavity)............................................................................................................. 24

G.5 Boiler or steam generator (models equipped only) ............................................................................. 24

G.6 Cooking chamber filter................................................................................................................. 24

G.7 Air filter..................................................................................................................................... 24

G.8 Door gasket............................................................................................................................... 25

G.9 Inner, outer and cooking chamber glass........................................................................................... 25

G.10 Door area ................................................................................................................................. 26

G.11 Efficiency control of the discharge system ........................................................................................ 26

G.12 Condensate drip collector............................................................................................................. 26

4

G.13 Food probe ............................................................................................................................... 26

G.14 Other surfaces ........................................................................................................................... 26

G.15 Periods of non-use...................................................................................................................... 27

G.16 Replacing wear and tear components ............................................................................................. 27

G.17 Repair and extraordinary maintenance ............................................................................................ 27

G.18 Maintenance intervals.................................................................................................................. 27

G.19 Maintenance contacts (only for Australia)......................................................................................... 27

H TROUBLESHOOTING.......................................................................................................................... 28

H.1 Introduction ............................................................................................................................... 28

H.2 Error codes ............................................................................................................................... 28

I FURTHER INFORMATION .................................................................................................................... 37

I.1 Ergonomic features..................................................................................................................... 37

I.1.1 Certification ..................................................................................................................... 37

I.1.2 General recommendations .................................................................................................. 37

5

A WARNING AND SAFETY INFORMATION

A.1 General information

To ensure safe use of the appliance and a proper understanding of the manual it is

necessary to be familiar with the terms and typographical conventions used in the

documentation. The following symbols are used in the manual to indicate and identify the

various types of hazards:

WARNING

Danger for the health and safety of operators.

WARNING

Danger of electrocution - dangerous voltage.

CAUTION

Risk of damage to the appliance or the product.

IMPORTANT

Important instructions or information on the product

Equipotentiality

Read the instructions before using the appliance

Clarifications and explanations

• Incorrect installation, servicing, maintenance, cleaning or modifications to the unit may

result in damage, injury or death.

• Only specialised personnel are authorised to operate on the appliance.

• This appliance is to be intended for commercial and collective use, for example in

kitchens of restaurants, canteens, hospitals and in commercial enterprises such as

bakeries, butcheries, etc., not for continuous mass production of food. Any other use is

deemed improper.

• This appliance must not be used by minors and adults with limited physical, sensory or

mental abilities or without adequate experience and knowledge regarding its use.

• For your safety do not store or use gasoline or other flammable materials, vapours and

liquids in the vicinity of this or any other appliance.

• Do not store explosive substances, such as pressurized containers with flammable

propellant, in this appliance.

• Refer to the data given on the appliance’s data plate for relations with the Manufacturer

(e.g. when ordering spare parts, etc.).

• When scrapping the appliance, the marking CE must be destroyed.

• Save these instructions carefully for further consultation by the various operators.

6

A.2 Personal protection equipment

Summary table of the Personal Protection Equipment (PPE) to be used during the various

stages of the appliance's service life.

Stage Protective

garments

Safety

footwear

Gloves Glasses Safety

helmet

Transport ● ○ —○

Handling —● ○ — —

Unpacking —● ○ — —

Installation —● ●1— —

Normal use ● ● ●2— —

Adjustments ○ ● — — —

Routine

cleaning

○ ● ●1ˉ3○—

Extraordi-

nary

cleaning

○ ● ●1ˉ3○—

Maintenance ○ ● ○ — —

Dismantling ○ ● ○ ○ —

Scrapping ○ ● ○ ○ —

Key:

●PPE REQUIRED

○PPE AVAILABLE OR TO BE USED IF NECESSARY

—PPE NOT REQUIRED

1. During these operations, gloves must be cut-resistant. Failure to use the personal protection equipment by

operators, specialized personnel or users can involve exposure to damage to health (depending on the model).

2. During these operations, gloves must be heatproof to protect hands from contact with hot food or hot parts of

the appliance and/or when removing hot items from it. Failure to use the personal protection equipment by

operators, specialised personnel or users can involve exposure to chemical risk and cause possible damage to

health (depending on the model).

3. During these operations, gloves must be suitable for contact with chemical substances used (refer to the

safety data sheet of the substances used for information regarding the required PPE). Failure to use the

personal protection equipment by operators, specialized personnel or users can involve exposure to chemical

risk and cause possible damage to health (depending on the model).

A.3 General safety

• The appliances are provided with electric and/or mechanical safety devices for

protecting workers and the appliance itself.

• Never operate the appliance, removing, modifying or tampering with the guards,

protection or safety devices.

• Do not make any modifications to the parts supplied with the appliance.

• Several illustrations in the manual show the appliance, or parts of it, without guards or

with guards removed. This is purely for explanatory purposes. Do not use the appliance

without the guards or with the protection devices deactivated.

7

Disconnect the appliance from the power

supply before carrying out any installation,

assembly, cleaning or maintenance

procedure.

• Do not remove, tamper with or make illegible the CE marking, the safety, danger and

instruction signs and labels on the appliance.

• The A-weighted emission sound pressure level does not exceed 70 dB(A).

• Do not use products (even if diluted) containing chlorine (sodium hypochlorite,

hydrochloric or muriatic acid, etc.) to clean the appliance or the floor under it.

• Carefully avoid exposure of the equipment to ozone - do not use ozonizers in the rooms

where the equipment is installed.

• Do not spray aerosols in the vicinity of this appliance while it is in operation.

• Do not place flammable liquids (e.g. spirits) inside the oven during operation.

• Never check for leaks with an open flame.

• Install the appliance under conditions of adequate ventilation in order to provide a

suitable air change per hour. Make sure that the ventilation system, whatever it is,

always remains operational and efficient for the entire period of time during which the

equipment is operating.

The appliance must be installed under ventilation hood only.

• Improper ventilation of the oven can be hazardous to the health of the operator; and will

result in operational problems, unsatisfactory cooking results, and possible damage to

the equipment. Damage sustained as a direct result of improper ventilation OF THE

OVEN will not be covered by the Manufacturer's warranty.

• Do not obstruct the flow of combustion and ventilation air.

• The following operations have to be carried out by specialised authorised personnel or

Customer Care Service provided with all the appropriate personal protection equipment

(A.2 Personal protection equipment), tools, utensils and ancillary means, who can ask

the manufacturer to supply a servicing manual:

– Installation and assembly

– Positioning

– Electrical connection

– Appliance cleaning, repair and extraordinary maintenance

– Appliance disposal

– Work on electrical equipment

A.4 Protection devices installed on the appliance

Guards

The appliance has:

• fixed guards (e.g. casings, covers, side panels, etc.), fixed to the appliance and/or frame

with screws or quick-release connectors that can only be removed or opened with tools;

therefore the user must not remove or tamper with such devices. The Manufacturer

declines any liability for damage due to tampering or their non-use;

• interlocked movable guards (door) for access inside the appliance;

• appliance electrical equipment access panels or doors, made from hinged panels

openable with tools. The panel or the door must not be opened when the appliance is

connected to the power supply.

ON

OFF

8

A.5 Safety signs to be placed on the appliance or near its area

Prohibition Meaning

do not remove the safety devices

do not use water to extinguish fires (placed on electrical

parts)

Keep the area around the appliance clear and free from

combustible materials. Do not keep flammable materials in

the vicinity of the appliance

Danger Meaning

caution hot surface

danger of electrocution (shown on electrical parts with

indication of voltage)

A.6 Reasonably foreseeable improper use

Improper use is any use different from that specified in this manual. During appliance

operation, other types of work or activities deemed improper and that in general can involve

risks for the safety of operators and damage to the appliance are not allowed. Reasonably

foreseeable improper use includes:

• lack of appliance maintenance, cleaning and periodical checks;

• structural changes or modifications to the operating logic;

• tampering with the guards or safety devices;

• failure to use personal protection equipment by operators, specialised personnel and

maintenance personnel;

• failure to use suitable accessories (e.g. use of unsuitable equipment or ladders);

• keeping combustible or flammable materials, or in any case materials not compatible

with or pertinent to the work, near the appliance;

• wrong appliance installation;

• placing in the appliance any objects or things not compatible with its use, or that can

damage the appliance, cause injury or pollute the environment;

• climbing on the appliance;

• non-compliance with the requirements for correct appliance use;

• other actions that give rise to risks not eliminable by the Manufacturer.

A.7 Residual risks

The appliance has several risks that were not completely eliminated from a design

standpoint or with the installation of adequate protection devices. Nevertheless, through

this manual the Manufacturer has taken steps to inform operators of such risks, carefully

indicating the personal protection equipment to be used by them. In order to reduce the

risks, provide for sufficient spaces while installing the unit.

9

To preserve these conditions, the areas around the appliance must always be:

• kept free of obstacles (e.g. ladders, tools, containers, boxes, etc.);

• clean and dry;

• well lit.

For the Customer's complete information, the residual risks remaining on the appliance are

indicated below: such actions are deemed improper and therefore strictly forbidden.

Residual risk Description of hazardous situation

Slipping or falling The operator can slip due to water, any liquid or dirt

on the floor

Burns/abrasions (e.g. heating

elements, cold pan, cooling

circuit plates and pipes)

The operator deliberately or unintentionally touches

some components inside the appliance without

using protective gloves.

Electrocution Contact with live parts during maintenance

operations carried out with the electrical panel

powered

Falling from above The operator intervenes on the appliance using

unsuitable systems to access the upper part (e.g.

rung ladders, or climbs on it)

Crushing or injury The specialised personnel may not correctly fix the

control panel when accessing the technical

compartment. The panel could close suddenly.

Tipping of loads When handling the appliance or the packing

containing it, using unsuitable lifting systems or

accessories or with the unbalanced load

Chemical Contact with chemical substances (e.g. detergent,

rinse aid, scale remover, etc.) without taking

adequate safety precautions. Therefore always refer

to the safety cards and labels on the products used.

Sudden closure The operator for normal appliance use could

suddenly and deliberately close the lid/door/oven

door (if present, depending on the appliance type).

A.8 Appliance cleaning

IMPORTANT

In order to maintain the appliance performance and safeness, the appliance

shall be maintained and cleaned.

• Do not touch the appliance with wet hands or feet or when barefoot.

• Use a ladder with suitable protection for work on appliances with high accessibility.

• Put the appliance in safe conditions before starting any cleaning operation.

• Respect the requirements for the various routine and extraordinary maintenance

operations. Non-compliance with the instructions can create risks for personnel.

• Do not spray water or use water jets, steam cleaner or high pressure cleaner.

A.9 Preventive Maintenance

In order to ensure the safety and performance of your equipment, it is recommended that

service is undertaken by Electrolux Professional authorised engineers every 12 months, in

10

accordance with Electrolux Professional Service Manuals. Please contact your local

Electrolux Professional Service Centre for further details.

A.10 Parts and accessories

Use only original accessories and/or spare parts. Failure to use original accessories and/or

spare parts will invalidate the original manufacturer warranty and may render the appliance

not compliant with the safety standard.

A.11 Precautions for use and maintenance

• Risks mainly of a mechanical, thermal and electrical nature exist in the appliance.

Where possible the risks have been neutralised:

– directly, by means of adequate design solutions.

– indirectly by using guards, protection and safety devices.

• Any anomalous situations are signalled on the control panel display.

• During maintenance several risks remain, as these could not be eliminated, and must be

neutralised by adopting specific measures and precautions.

• Do not carry out any checking, cleaning, repair or maintenance operations on moving

parts. Workers must be informed of this prohibition by means of clearly visible signs.

• Make sure to periodically check correct operation of all the safety devices and the

insulation of electrical cables, which must be replaced if damaged.

In case of a significant anomaly (e.g. short circuits, wires coming out of the terminal block,

motor breakdowns, worn electrical cable sheathing, etc.) the operator for normal appliance

use must:

• immediately deactivate the appliance and disconnect all the supplies (electricity, gas,

water).

Before carrying out any operation on the appliance, always consult the manual which gives

the correct procedures and contains important information on safety.

A.12 Appliance maintenance

• The inspection and maintenance intervals depend on the actual appliance operating

conditions and ambient conditions (presence of dust, damp, etc.), therefore precise time

intervals cannot be given. In any case, careful and periodical appliance maintenance is

advisable in order to minimise service interruptions.

• It is advisable to stipulate a preventive and scheduled maintenance contract with the

Customer Care Service.

• Put the appliance in safe conditions before starting any maintenance operation.

• To guarantee appliance efficiency and correct operation, periodical maintenance must

be carried out according to the instructions given in the manual.

B WARRANTY

B.1 Warranty terms and exclusions

If the purchase of this product includes warranty coverage,

warranty is provided in line with local regulations and subject to

the product being installed and used for the purposes as

designed, and as described within the appropriate equipment

documentation.

Warranty will be applicable where the customer has used only

genuine spare parts and has performed maintenance in

accordance with Electrolux Professional user and mainte-

nance documentation made available in paper or electronic

format.

Electrolux Professional strongly recommends using Electrolux

Professional approved cleaning, rinse and descaling agents to

obtain optimal results and maintain product efficiency over

time.

The Electrolux Professional warranty does not cover:

• service trips cost to deliver and pick up the product;

• installation;

• training on how to use/operate;

• replacement (and/or supply) of wear and tear parts unless

resulting from defects in materials or workmanship reported

within one (1) week from the failure;

• correction of external wiring;

• correction of unauthorized repairs as well as any damages,

failures and inefficiencies caused by and/or resulting from;

11

– insufficient and/or abnormal capacity of the electrical

systems (current/voltage/frequency, including spikes and/or

outages);

– inadequate or interrupted water supply, steam, air, gas

(including impurities and/or other that does not comply with

the technical requirements for each appliance);

– plumbing parts, components or consumable cleaning

products that are not approved by the manufacturer;

– customer’s negligence, misuse, abuse and/or non-com-

pliance with the use and care instructions detailed within the

appropriate equipment documentation;

– improper or poor: installation, repair, maintenance

(including tampering, modifications and repairs carried out

by third parties not authorized) and modification of safety

systems;

– Use of non-original components (e. g.: consumables,

wear and tear, or spare parts);

– environment conditions provoking thermal (e. g. over-

heating/freezing) or chemical (e. g. corrosion/oxidation)

stress;

– foreign objects placed in- or connected to- the product;

– accidents or force majeure;

– transportation and handling, including scratches, dents,

chips, and/or other damage to the finish of the product,

unless such damage results from defects in materials or

workmanship and is reported within one (1) week of delivery

unless otherwise agreed;

• product with original serial numbers that have been

removed, altered or cannot be readily determined;

• replacement of light bulbs, filters or any consumable parts;

• any accessories and software not approved or specified by

Electrolux Professional.

Electrolux Professional warranty will be void and manu-

facturer shall have no liability related thereto in case of

any modification of the product or related hardware/

software/programming.

Warranty does not include scheduled maintenance activities

(including the parts required for it) or the supply of cleaning

agents unless specifically covered within any local agreement,

subject to local terms and conditions.

Check on Electrolux Professional website the list of authorized

customer care.

C GENERAL INFORMATION

WARNING

Refer to “WARNING and Safety

Information“.

C.1 Introduction

This manual contains information relevant to various applian-

ces. The product images in this guide are only an example.

The drawings and diagrams given in the manual are not in

scale. They supplement the written information with an outline,

but are not intended to be a detailed representation of the

appliance supplied.

The numerical values given on the appliance installation

diagrams refer to measurements in millimeters and/or inches.

C.2 Intended use and restrictions

This appliance is designed for cooking food. It is intended for

collective use.

Any other use is deemed improper.

NOTE!

The manufacturer declines any liability for

improper use of the product.

C.3 Testing and inspection

Our appliances have been designed and optimized, with

laboratory testing, in order to obtain high performance and

efficiency.

IMPORTANT

For 20 grids models only: the oven shall be used

with the supplied trolley or with the appropriate ones

listed in the accessory catalogue.

The appliance is shipped ready for use.

Passing of the tests (visual inspection - gas/electrical test -

functional test) is guaranteed and certified by the specific

enclosures.

C.4 Copyright

This manual is intended solely for consultation by the operator

and can only be given to third parties with the permission of

Electrolux Professional company.

C.5 Keeping the manual

The manual must be carefully kept for the entire life of the

appliance, until scrapping. The manual must stay with the

appliance in case of transfer, sale, hire, granting of use or

leasing.

C.6 Recipients of the manual

This manual is intended for:

• the employer of appliance users and the workplace

manager;

• operators for normal appliance use;

• specialised personnel - Customer Care service (see service

manual).

C.7 Definitions

Listed below are the definitions of the main terms used in the

manual. It is advisable to read them carefully before use.

Operator appliance installation, adjustment, use,

maintenance, cleaning, repair and trans-

port personnel.

Manufacturer Electrolux Professional SpA or any other

service centre authorised by Electrolux

Professional SpA.

Operator for

normal appli-

ance use

an operator who has been informed and

trained regarding the tasks and hazards

involved in normal appliance use.

Customer

Care service

or specialised

personnel

an operator instructed/trained by the

Manufacturer and who, based on his

professional and specific training, experi-

ence and knowledge of the accident-

prevention regulations, is able to appraise

the operations to be carried out on the

appliance and recognise and prevent any

risks. His professionalism covers the

mechanical, electrotechnical and elec-

tronics fields etc.

Danger source of possible injury or harm to health.

Hazardous

situation

any situation where an operator is

exposed to one or more hazards.

Risk a combination of probabilities and risks of

injury or harm to health in a hazardous

situation.

Protection

devices

safety measures consisting of the use of

specific technical means (guards and

safety devices) for protecting operators

against risks.

12

Guard an element of a appliance used in a

specific way to provide protection by

means of a physical barrier.

Safety device a device (other than a guard) that elimi-

nates or reduces the risk; it can be used

alone or in combination with a guard.

Customer the person who purchased the appliance

and/or who manages and uses it (e. g.

company, entrepreneur, firm).

Electrocution an accidental discharge of electric current

on a human body.

C.8 Responsibility

The Manufacturer declines any liability for damage and

malfunctioning caused by:

• non-compliance with the instructions contained in this

manual;

• repairs not carried out in a workmanlike fashion, and

replacements with parts different from those specified in

the spare parts catalogue (the fitting and use of non-original

spare parts and accessories can negatively affect appliance

operation and invalidates the original manufacturer

warranty);

• operations carried out by non-specialised personnel;

• unauthorized modifications or operations;

• missing, lack or inadequate maintenance;

• improper appliance use;

• unforeseeable extraordinary events;

• use of the appliance by uninformed and / or untrained

personnel;

• non-application of the current provisions in the country of

use, concerning safety, hygiene and health in the workplace.

The Manufacturer declines any liability for damage caused by

arbitrary modifications and conversions carried out by the user

or the Customer.

The employer, workplace manager or service technician are

responsible for identifying and choosing adequate and suitable

personal protection equipment to be worn by operators, in

compliance with regulations in force in the country of use.

The Manufacturer declines any liability for inaccuracies con-

tained in the manual, if due to printing or translation errors.

Any supplements to the installation, use and maintenance

manual the Customer receives from the Manufacturer will form

an integral part of the manual and therefore must be kept

together with it.

D NORMAL APPLIANCE USE

D.1 Characteristics of personnel enabled to

operate on the appliance

The Customer must make sure the personnel for normal

appliance use are adequately trained and skilled in their duties.

The operator must:

• read and understand the manual;

• receive adequate training and instruction for their duties in

order to operate safely;

• receive specific training for correct appliance use.

IMPORTANT

The Customer must make sure his personnel have

understood the instructions received and in partic-

ular those regarding work hygiene and safety in use

of the appliance.

D.2 Basic requirements for appliance use

• Knowledge of the technology and specific experience in

operating the appliance.

• Adequate general basic education and technical knowledge

for reading and understanding the contents of the manual,

including correct interpretation of the drawings, signs and

pictograms.

• Sufficient technical knowledge for safely performing his

duties as specified in the manual.

• Knowledge of the regulations on work hygiene and safety.

E PRODUCT DESCRIPTION

E.1 Use – Introduction

The instructions and information given in this manual are

important for correct and optimum oven use. If required, further

details regarding its characteristics and cooking performance

can be obtained from the dealer.

• To avoid obstructing the fume and steam discharge pipes,

do not place pans or utensils of any kind on the oven.

• Do not place objects (e. g. pans) under the bottom of the

oven, so as not to obstruct any cooling air inlet or outlet

holes.

IMPORTANT

In 20 Grids models run the cleaning cycles only

with trolley inside the oven. It helps the sealing in

closing the bottom openings between the cavity and

the door.

• Do not salt food inside the oven, in particular with humid

cycles.

• Do not place flammable liquids (e.g. spirits) inside the oven

during operation.

IMPORTANT

After the installation of 6, 10 and 20 grids ovens

(stacking installation included) is carried out, check

at which height the upper trays are placed in the

oven. If required, place the following sticker (sup-

plied) on the front of the oven and at a height of

1,60 m or higher above the floor.

CAUTION

To avoid burns, do not use recipients

containing liquids (or products that

become liquid with cooking) in shelves

positioned at levels higher than 1,6 m

above the floor. This is to prevent spilling

during handling.

13

Food loading on oven

No. of grids MODELS

6 GN 1/1 6 GN 2/1 10 GN 1/1 10 GN 2/1 20 GN 1/1 20 GN 2/1

Maximum

oven load

Kg 30 60 50 100 100 200

Maximum pan/

tray load

Kg 15 30 15 30 15 30

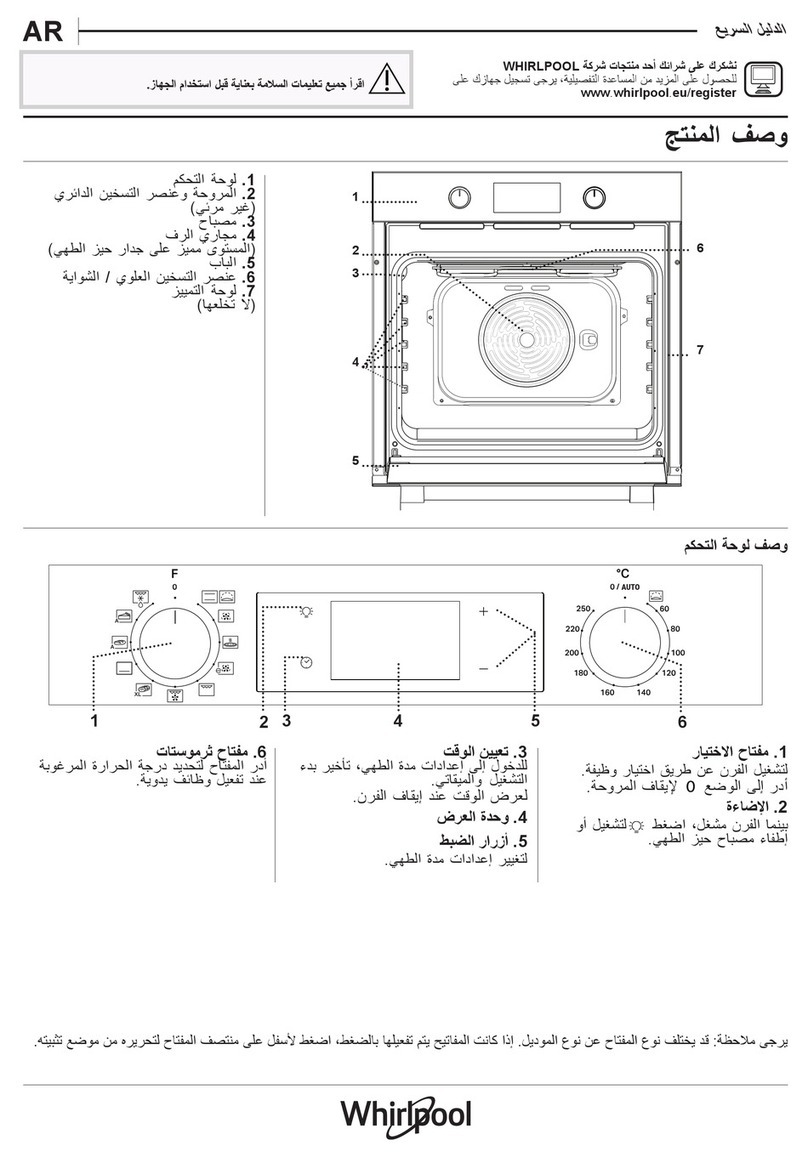

E.2 Appliance overview

1. Door handle (shape depending on the model)

2. Glass door

3. Led bar for lighting cavity

4. Grids support

5. Exhaust gas cavity heat exchanger (all gas models)

6. Steam discharge (electric and gas models)

7. Exhausting gas from steam generator (gas models with

boiler)

8. Air inlets (electric and gas models)

9. Control panel

10. Cavity filter – housing for detergent tabs (cavity washing)

11. ON/OFF button

12. USB pendrive position

13. Dataplate

14. Descaling/rinse agent drawer

15. Feet

16. Hand spray cleaning unit, if present in your model

NOTE!

The hand spray only works if the oven is

switched on.

E.3 Opening and closing the oven door

Below the instructions for closing and opening the oven door,

model by model.

6 GN and 10 GN Model

14

1. Turn the door handle clockwise or counterclockwise all the

way to fully open the oven door. The cooking cycle is

stopped, if in progress.

2. To close the door press it against the oven enough to lock

it.

20 GN Model

1. Rotate the handle by 90℃counterclockwise to open the

door completely. The cooking programme is stopped, if in

progress.

2. For closing rotate the handle by 90℃counterclockwise

until it stops and bring the door against the oven.

3. Keeping the door pressed against the oven, rotate the

handle back in its vertical position to complete its locking.

E.4 Control panel

WARNING

Refer to “WARNING and Safety Information“.

A. Digital panel

B. ON/OFF button

C. USB key in/out

D. Connection for accessory

E. Openable flap

F OPERATING

F.1 Switch the oven ON

Press the “I“ side of the button “O – I“ to switch the oven on.

Press the “O“ side of the same button to switch the oven off.

IMPORTANT

For gas models only: wait 5 minutes before

relighting.

A

B

CD

E

15

• the corresponding O - I button lights up;

• the control panel switches on;

The TIME display is lighted up:

• keep pressed the TIME button to set the year, month, day,

hours and minutes; on the keypad press the “>“ or “<“

buttons to move forward or backward to set the required

value;

(Example figure below 12:05)

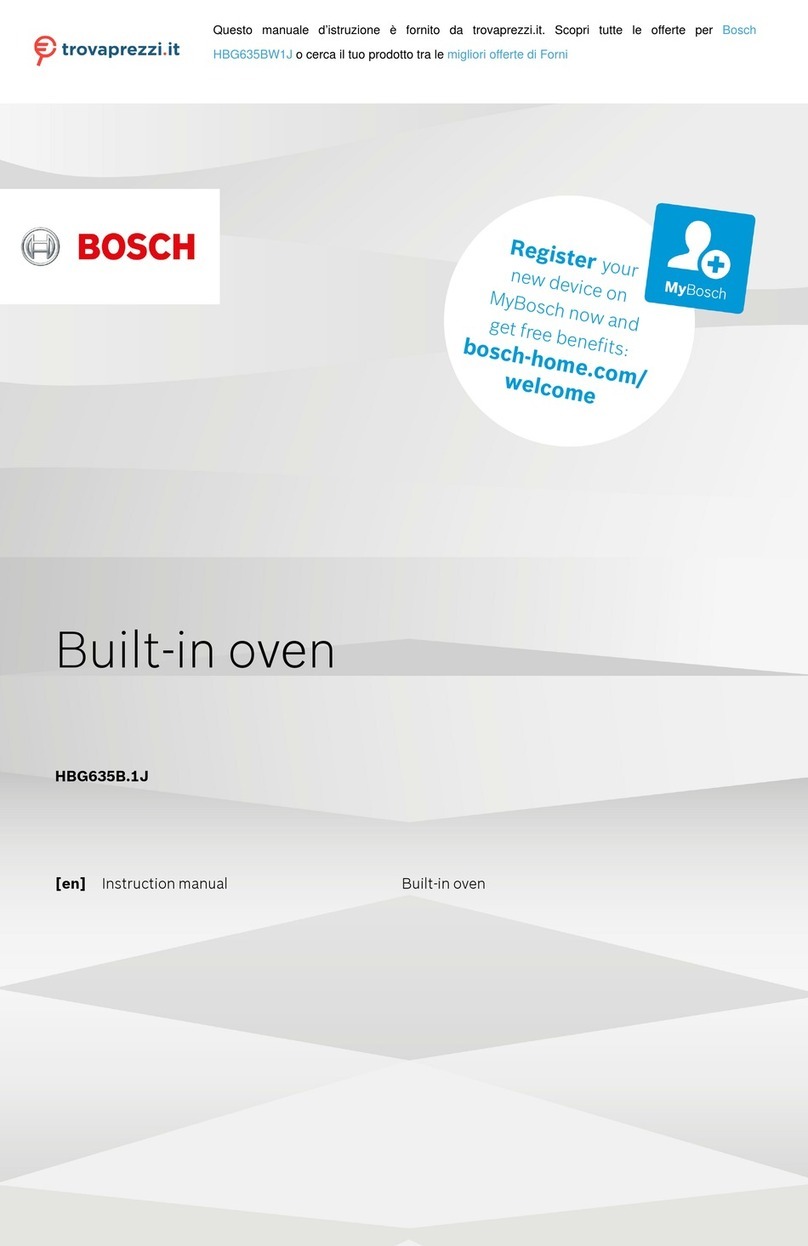

F.2 Displays and controls description

The oven allows cooking with different cooking modes

according to the type of food and your requirements.

It is possible to set the various modes from the display by

pressing the corresponding icon.

Level B model

Level C model (Boilerless)

A. Cooking cycles

B. Cooking parameters

C. Cooking options

D. Special functions

E. Utilities

F. Programs and Multiphase

G. Indicator Lights

H. Digit displays

I. Keypad

J. Cleaning cycles

K. Start button

Lights status:

• maximum brightness = active buttons

• minimum brightness = inactive buttons

• without brightness = buttons not available

• flashing light = request or warning

Displays status:

• Displays normally indicate values of humidity, temperature,

time, programs and multiphase. They can also show other

functions values or words to indicate warnings or actions to

be carried out.

A - Cooking cycles

CONVECTION Cycle

For roasting and gratinating

Maximum temperature up to 300 ℃.

in Boilerless models

COMBI Cycle (only in boiler models)

Superheated steam.

The steam generator and the cavity are used at the

same time to keep foods tender.

Maximum temperature up to 300℃.

STEAM Cycle (only in boiler models)

• Full Steam: ideal for steaming at 100℃.

• Low temperature steam for gentle cooking,

vacuum packed foods and for defrosting (temper-

ature from 25℃to 99℃);

• Superheated steam (temperature from 101℃to

130℃).

B - Cooking Parameters

Humidity

It allows to adjust:

• the required humidity level in Combi Cycle.

• the maximum humidity level in Convection Cycle.

• the humidification level from 10 to 100 in Boil-

erless models.

Temperature

Digital thermostat for cavity temperature

Time

Cooking time

C - Cooking Options

Vent Open (Convection cycle only)

For very dry cooking, it allows the remove the

humidity when necessary (max. temperature 300℃).

Eco Delta (Cooking with food probe cycle only)

The ECO DELTA function enables cooking without

harming the food with high temperatures;

This is an advanced cooking method, where the

oven cavity temperature varies according to the core

temperature of the food.

Food Probe

The food probe allows accurate control of the core

temperature of the product being cooked.

D - Special Functions

Water Injection

Manual injection of water in cavity: for instantly

increasing the humidity level during a cooking cycle.

Fan

It allows the adjustment of the fan speed.

A G

J

H

I

D

C

B

E

F

A G

K

H

I

D

J

C

B

E

F

G

H

I

D

C

B

E

F

A

A G

H

I

D

C

B

E

F

T

16

E - Utilities

Reduced Power (only in boiler models)

For gentle cooking, such as light patisserie. Combin-

able with all cycles.

Hold

For slow and prolonged cooking, typically for meat

(large cuts). Ideal to maintain a warm temperature at

the end of cooking. Combinable with all cycles.

Pause

For setting a pause between cooking cycles.

Cool Down

Fast cavity cooling: useful to switch from one type of

cooking to another at lower temperature.

It enables fan rotation and automatic injection of

water even with the door open.

WARNING

Risk of burns. Always open

the door with caution when

the oven is hot.

HACCP

(Hazard Analisys and Critical Control Points):

according to the system required, cooking data can

be recorded on USB pendrive.

Boiler Drain (only in boiler models)

Press this button to drain manually water from the

boiler.

F - Programs and Multiphase

Programs

This button allows to save and recall up to 99

programs (recipes).

Multiphase

Cooking with phases in sequence: this function

allows to set cooking programs with up to 4 phases

in automatic sequence.

G - Indicator Lights

Attention

It indicates a malfunction of the oven (warning /

error).

USB

It lights up when a USB device is connected to the

oven.

Wi-Fi

It indicates the successful connection to a Wi-Fi

network (with appropriate accessory only).

H - Digit Displays area

The Humidity Digital Display shows:

• the set humidity value in Combi Cycle or Con-

vection Cycle.

• the humidification level from 10 to 100 in Boil-

erless models.

The Temperature Digital Display shows:

• The cavity set temperature

• The ECO DELTA cavity temperature.

The Time/Food Probe Digital Display shows:

• The cooking time.

• The food probe set temperature.

I - Keypad

It allows to insert a numeric value in various

functions.

button

• Press it to decrease the value on display (<);

• Keep the same button pressed to delete a

phase or a program ( ).

button

• Press it to increase the value on display (>)

• Press the same button to select Continuous

cooking ( ) while setting the Time.

J – Cleaning cycle

Cleaning Cycle

This function allows to clean the oven cavity auto-

matically by means of dedicated cleaning cycles.

F.3 Oven connectivity

If the oven is connected remotely to Cloud, the below indicator

light illuminates or flashes according to the connection status.

Indicator light status

Indicator light on: the oven is connected to Cloud.

Full brightness: the Wi-fi signal is good.

Half brightness: the Wi-fi signal is medium or low.

Indicator light flashing:

For 1 minute: the oven is establishing a connection

to Cloud

Continuously: the oven is unable to connect to Cloud

or there is no Wi-fi connection.

F.4 Cooking cycle setting

F.4.1 Set a COOKING CYCLE

1. Press the relevant button to select a cooking cycle (for

example the CONVECTION one).

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

17

• boiler model

boilerless model

F.4.2 Set the HUMIDITY

2. Press the humidity button. Set the value on the numeric

keypad (for example 70%). The inserted value appears

on the digit display.

NOTE!

Regardless of the number entered, the values on

the display will always be rounded to the nearest

ten (10, 20, 30,... 90 and up to 99).

Entered values (%) Output values (%)

From 1 to 14 10

From 15 to 24 20

From 25 to 34 30

From 35 to 44 40

From 45 to 54 50

From 55 to 64 60

From 65 to 74 70

From 75 to 84 80

From 85 to 94 90

From 95 to 100 99

Humidity condition: WITH BOILER

• The Convection cycle allows to manage and adjust the

amount of humidity in the cavity without generating any

additional steam.

• Press the Humidity button and using the numeric keypad

set the maximum humidity with consequent adjusting of the

vent. By setting a value of 100, the valve closes ( ).

When the display shows the cavity does not manage the

humidity as the valve is closed.

• When the Vent button is activated, the humidity is not

adjustable. The vent is open and exhausts all the humidity

from the cavity.

Humidity condition: BOILERLESS

• The Convection cycle allows to manage the humidity level

in the cavity.

• Press the Humidity button and using the numeric keypad

set the humidity level.

• By setting a value of 0, the valve closes ( ) and the cavity

does not manage the humidity level.

• When the Vent button is activated, the humidity level is

not adjustable. The vent is open and exhausts all the

humidity from the cavity.

Temperature setting

3. Set the TEMPERATURE

• Press the temperature button.

Set the value on the numeric keypad (for example

230℃). The inserted value appears on the digit

display.

F.4.3 Set the cooking TIME

4. Press the time button.

Set the value on the numeric keypad (for example 45

minutes). The inserted value appears on the digit display.

5. Press the START button to start the cooking cycle.

If you have set the Autostart the cycle starts automatically

when closing the door.

F.4.4 Preheating/Cooling phase

• This preparation phase prepares the cavity temperature

before the beginning of the selected cycle.

The Temperature Display shows the set temperature; the

Time Display shows the message “PrEH“ or “COOL“

according to the cavity temperature; the Start button lights

up red.

Opening the door after the START button is pressed:

– If the door is opened, the Preheating is interrupted (the

Cooling phase keeps running); the Time Display shows the

message “door“.

– Once the door is closed, the Preheating restarts.

Skip Preheating/Cooling

– Keep pressed the start button to start immediately the

cooking cycle.

6. When the Preheating/Cooling is finished, the message

“LOAd“ appears on the Time Display; the Start button

flashes in red.

• Open the door;

• Insert the food in the appliance;

• Close the door: the cooking cycle starts.

F.4.5 Stop cycle

Keep pressed the START button to stop the cycle.

F.4.6 End cycle

7. When the set time has elapsed the cooking cycle will

stop automatically and the appliance's alarm will beep.

Open the door and unload the product.

The audible alarm can be muted by performing any

operation on the control panel or by opening the door.

• To stop the cooking cycle manually press the cycle

START button for a few seconds.

• To repeat the last cooking cycle with identical param-

eters press the START button again.

F.4.7 VENT VALVE OPEN

Humidity option: for Convection cycle only.

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

D

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

A G

J

H

D

B

E

F

A G

J

H

D

B

E

F

18

Vent valve OPEN for very dry cooking allowing the removal of

humidity when necessary.

Max. temperature up to 300℃)

F.4.8 ECO DELTA

Temperature options (for all cooking modes)

This function enables cooking without harming the food with

high temperatures; this ensures more gentle and more even

cooking, with less weight loss.

This is an advanced cooking method, where the oven

compartment temperature varies according to the core tem-

perature of the food.

1. Press the ECO-DELTA button to select this function.

2. Press this button again to digit the required value on the

keypad, for example 30℃.

It is possible to enter a value of delta temperature from 1

to 120℃.

3. Press the PROBE button . Set the required food core

temperature.

4. Insert the probe into the food (see the paragraph F.4.11

FOOD PROBE).

This function is particularly suitable for cooking large pieces of

food (at least 5kg, e.g. whole turkey, leg of pork, etc.).

In this case, cooking is moderate and long, since the cavity

temperature is automatically adjusted according to the temper-

ature inside the food (CORE PROBE), maintaining a constant

difference (ECO-DELTA) between them, from start to end of

cooking.

IMPORTANT

The ECO-DELTA function is only possible with the

core probe inserted.

NOTE!

With ECODELTA on, the mode “Cooking Time“

switches automatically to the “Core Probe“ mode,

that detects the inside temperature of the food.

F.4.9 COOLING DOWN

Fast cavity cooling

Useful for switching from one type of cooking to another at

lower temperature; it enables fan rotation and automatic

injection of water even with the door open. This option is not

available if the cavity temperature is higher then 180℃)

1. Press the COOLING DOWN button

2. Enter the temperature value that the oven has to reach for

the next cooking.

3. Press the Start button to reach the set temperature.

F.4.10 CONTINUOUS COOKING

Time option

The cooking time is endless.

1. Press the endless button .

The time display shows “cont“.

2. Press the START button to start cooking the food.

3. When the food is cooked keep pressed the START button

to stop the CONTINUOUS COOKING cycle.

F.4.11 FOOD PROBE

Time option

Adjustable PROBE to measure the product core temperature.

This function excludes the cooking time setting.

1. Press the PROBE button;

Set the core probe temperature on the numeric keypad

(eg 55); the Time display shows the value entered.

The core probe allows accurate control of the core temper-

ature of the product being cooked. When the set value is

reached, the oven stops automatically.

NOTE!

It is possible to set the probe temperature from

15 to 290℃for Combi and Convection cycles

and from 15 to 120℃for Steam cycle.

2. Close the oven door and press the START button to

start the probe cycle.

Wait until the Temperature display indicates the end of the

preheating phase. The message LOAD appears.

3. Open the door, insert the food into the cavity.

WARNING

Risk of burns. Always open

the door with caution when

the oven is hot.

4. Remove the core probe from its seat;

5. Insert it in the product without forcing excessively;

Make sure the tip - the sensitive part – is positioned near

the centre of the product.

IMPORTANT

The core probe is a precision component. Abso-

lutely avoid impacts, forcing when inserting, and

pulling of the flexible cable (in particular when using

the trolley-mounted structures).

The warranty does not cover the replacement of

core probes damaged by improper use.

6. Close the oven door.

The PROBE CYCLE keeps running.

End Probe cycle

• When the required product core temperature is reached the

oven stops automatically. The Time display shows the

duration of cooking cycle;

Probe cycle deactivation

• To deactivate the PROBE cycle simply press the TIME

button and set a cooking time. This action automatically

cuts out the core probe and viceversa. When the oven is

switched off the core probe option is also deactivated.

T

T

A G

J

H

I

D

C

B

E

F

19

NOTE!

With vacuum packed food products it is necessary

to use the special external core probe (accessory

available on request), to be connected to the USB

pendrive. For its use see the dedicated paragraph.

F.4.12 USB FOOD PROBE (on demand)

Time option

1. Press the PROBE button and keep it pressed for

almost 1 second.

The indicator light starts flashing (0,5 sec ON - 0,5

sec OFF).

Set the final core probe temperature on the numeric

keypad (e.g. 55); the Time display shows the value

entered.

NOTE!

It is possible to set the probe temperature from

15 to 290℃for Combi and Convection cycles

and from 15 to 120℃for Steam cycle.

2. Close the oven door and press the START button to

start the probe cycle.

Wait until the Temperature display indicates the end of the

preheating phase. The message LOAD appears.

3. Open the door, insert the food into the cavity.

WARNING

Risk of burns. Always open

the door with caution when

the oven is hot.

4. Insert the needle of the USB probe in the centre of the

product without forcing excessively;

5. Insert the USB end into the USB socket of the oven.

The indicator light is on steady.

6. Close the oven door. The indicator light flashes (0,5

sec ON - 0,5 sec OFF).

IMPORTANT

If the indicator light flashes rapidly (0,1

sec ON - 0,1 sec OFF), the bigger display

shows the flashing text label “UPrb“ and an

acoustic alarm sounds, make sure the USB

probe is connected. In the meantime cooking is

on hold.

The PROBE CYCLE keeps running.

When the set value is reached, the oven stops

automatically.

F.4.13 MULTIPHASE

Food can be cooked using different phases.

The oven allows to set up to 4 phases for each cycle.

During a multiphase cooking cycle the oven switches auto-

matically from one phase to the next one. The cycle stops

when all phases are completed.

To set a multiphase cycle:

1. Set first a cooking cycle (refer to F.4 Cooking cycle setting

paragraph);

2. Keep pressed the multiphase button to add phase 2;

3. Set phase 2

• It is possible, at this stage, to set the parameters of the

new phase.

• Repeat the sequence for all phases to be set.

4. At the end press START button to start the cooking

cycle.

To delete a phase:

1. Select the phase to be deleted using the arrows < / > on

the keypad

2. Keep pressed the waste bin icon.

NOTE!

By deleting an intermediate phase, the following

phases will also be automatically cancelled.

F.4.14 UTILITIES

Utilities are functions that can be added to the cooking cycle.

They are activated simply by pressing the relative button.

Pause

• Add a new phase;

• Press the Pause button ;

• Set the desired duration using the TIME button.

NOTE!

This utility can be used as delay start if set at the

beginning of a multiphase cycle.

Hold

• Pressing the Hold button will add the holding phase at

the end of the cooking cycle.

During the holding phase the letter H appears in the

Multiphase Display while the Time display shows HOLd.

• If cooking is time driven, the holding temperature is + 65 ℃.

If cooking is probe driven the holding temperature is 5 ℃

more than the set core temperature.

Boiler Drain

• The boiler can not be drained during a cycle.

Cool Down

• The cool down can not be activated during a cycle.

• The default temperature is 25 ℃, but can be changed by

setting it on the keypad.

• To see the actual temperature of the cell, keep the Temper-

ature button pressed for more than 2 seconds.

F.5 Programs

The Programs button allows to recall cooking cycles already

stored or create and store new ones.

To exit from the Programs keep pressed one of the cooking

modes.

Program saving

• Set first a cooking cycle (refer to F.4 Cooking cycle setting

paragraph);

• Keep pressed the Programs button. The display shows the

first program number available;

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

20

• Select the desired Program number (01– 99) using the

arrows < / >;

• The Programs Display will continue to flash for a few

seconds; to complete the procedure keep pressed again

the same button for a few second until beep confirms the

program saving;

• Press now the Start button to start the program.

NOTE!

In models with boiler two preset programs for

Regeneration are already saved and available in

Program number “1“ and “2“.

Regeneration programs:

1. Regeneration on Plate - ideal for banqueting

Double phase:

• Convection cycle of 2 minutes, 120 ℃, flap

closed and ventilation at 4;

• Combi cycle of 5 minutes, 120 ℃, 20%

humidity and ventilation at 4.

2. Regeneration on tray – ideal for

rethermalizing

Combi cycle of 15 minutes, 120 ℃, 40%

humidity and ventilation at 5.

Program deleting

• Select the program to be deleted;

• Keep pressed the < (delete) button for a few seconds and

press the same button again to confirm deleting procedure.

Uploading / downloading Programs – USB

This procedure is only possible from the starting oven

status.

NOTE!

To reach the oven starting status keep pressed

one of the available cooking modes as shown in

the figure.

1. Insert the USB pendrive into the socket.

2. To upload / download Programs, keep pressed the

Programs button until the PrOG appears on the Temper-

ature display.

3. Use the arrows buttons < / > on the keypad to select

“upload“ or “download “ command.

The word “dnLo“ or “UPLO“ appears on the Time display

according your selection.

4. Keep pressed the Programs button to start the uploading

or downloading procedure.

All the control panel indicators light flash.

5. At the end, on the Time Display the flashing word End

appears to confirm the completed operation.

6. Remove the USB pendrive from the socket.

Programs from Cloud

The oven is able to connect to Internet and receive cooking

programs (recipes) from cloud.

When the cloud has sent one or more programs to the

appliance, the message “CLOU PrOG shows up in Temper-

ature and Time displays.

The number of programs downloaded is shown in Program

display.

• Press any key to add the new programs to the appliance.

The message CLOU PrOG disappears.

Downloading HACCP log

This procedure is only possible from the starting oven status.

1. Insert the USB pendrive into the socket.

2. To download the HACCP log, keep pressed the HACCP

button until the word HACP appears on the Temperature

display.

The word “dnLo“ appears on the Time display.

3. All the control panel indicators light flash.

4. At the end, on the Time Display the flashing word End

appears to confirm the completed operation.

5. Remove the USB pendrive from the socket.

F.6 Indicator Lights

NOTE!

The indicator lights are not buttons, but only

function or warning lights.

ALARM

The light flashes to indicate the presence of a

malfunction. It can be a warning or an error.

USB

This light indicates the insertion of an USB

device. At the beginning it flashes, then when

the USB has been recognized it becomes fixed.

Wi-Fi

This light indicates the connection to a Wi-Fi

network (with appropriate accessory only).

F.7 Special functions

The special functions allow to improve the use of the oven and

can be used with more or less intensity.

WATER INJECTION

During a cooking cycle it is possible to increase

the humidity in the cavity for certain types of

cooking.

Press repeatedly this buttons to adjust the injection duration in

seconds (every dash = 10 s intervals).

In the figure above (for example) 3 dashes corresponding to 30

seconds of water injection are indicated.

A G

J

H

I

D

C

B

E

F

A G

J

H

I

D

C

B

E

F

Table of contents

Other Electrolux Professional Oven manuals

Electrolux Professional

Electrolux Professional Combi TOUCH 6 GN 1/1 User manual

Electrolux Professional

Electrolux Professional Combi TOUCH 6 GN 1/1 User manual

Electrolux Professional

Electrolux Professional thermaline MBVG CPO Series User manual

Electrolux Professional

Electrolux Professional Touch and Digital User manual

Popular Oven manuals by other brands

Kooper

Kooper 5900989 User instructions

GE

GE JRP20SKSS - 24" Single Electric Wall Oven Dimensions and installation information

Siemens

Siemens HB573AB 0 Series User manual and installation instructions

Blanco

Blanco BMS 755 manual

Morgan

Morgan MBO-7700D user manual

Prince Castle

Prince Castle DHB2PT-33 Specification sheet