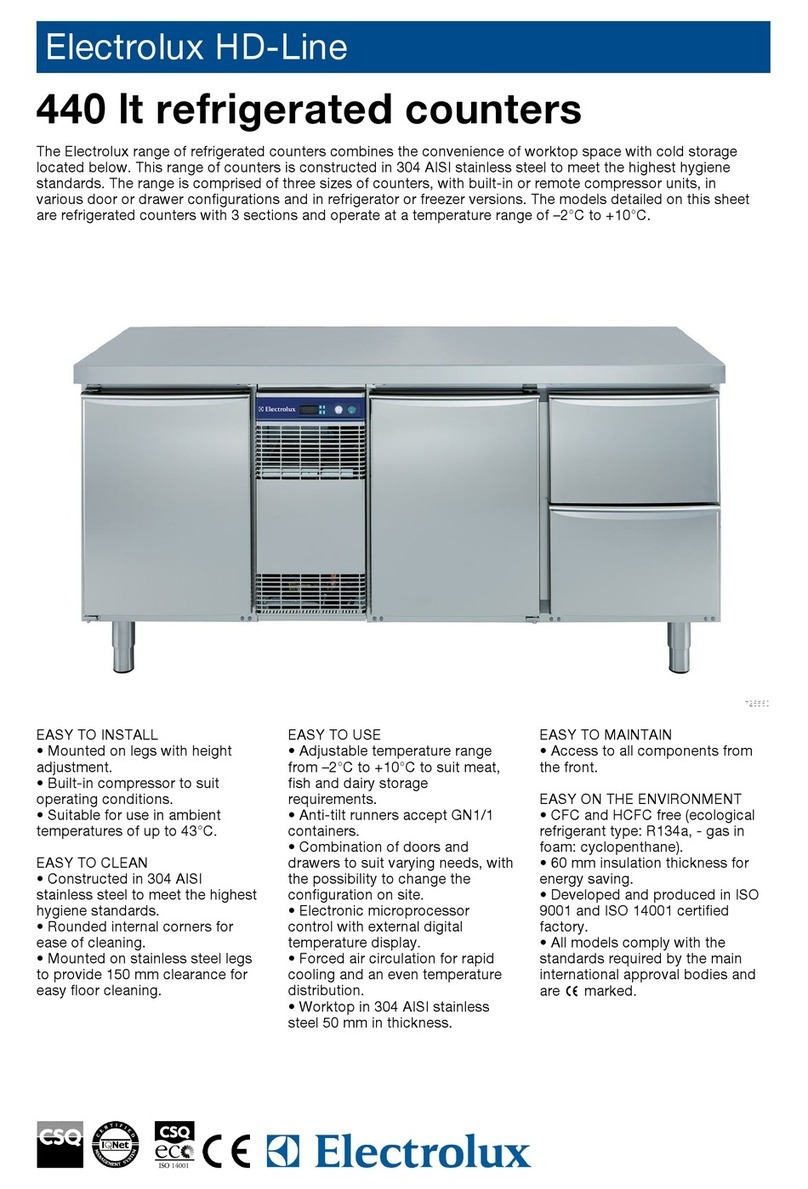

Electrolux air-o-chill

Blast Chiller/Freezers 50-50kg

Internet: http://www.electrolux.com/foodservice

HDBB0202011-07-14Subject to change without notice

WATER REMOTE UNIT FOR C/FREEZER LW 50KG 880033

TROLLEY FOR SLIDE-IN RACK 6&10X1/1GN 922004 922004

TRAY RACK+WHEELS 8X1/1GN, 80MM PITCH 922009 922009

TRAY RACK+WHEELS 10X1/1GN, 65MM PITCH 922006 922006

SLIDE-IN RACK SUPP.10 1/1 BC+BCF 50KG-LW 881028 881028

SET OF 5 S/S RUNNERS-6&10 GN 1/1 BCF LW 880087 880087

RILSAN COATED GRID 881061 881061

PRINTER FOR HACCP BASIC VERSION 881532 881532

PASTRY 8X(400X600)RACK+WHLS-80MM,10X1/1 922066 922066

PAIR OF 1/1 GN AISI 304 S/S GRIDS 921101 921101

KIT HACCP EKIS 922166 922166

KIT HACCP ADVANCED CONNECT. BC/BCF LW+CW 880183 880183

KIT 4 WHEELS FOR BLAST C/FREEZERS 880111

BANQUET RACK-30PLATES-65MM PITCH-10GN1/1 922015 922015

AIR REMOTE UNIT FOR C/FREEZER LW 50KG 880030

3-POINT-SENSOR PROBE-BL.C/FREEZERS LW 880212 880212

3 SINGLE-SENSOR PROBES-BL.C/FREEZERS LW 880215

2 SINGLE-SENSOR PROBES-BL.C/FREEZERS LW 880214

1 SINGLE-SENSOR PROBE-BL.C/FREEZERS LW 880213 880213

ACCESSORIES

SET OF 5 S/S RUNNERS-6&10 GN 1/1 BCF LW 2 2

3-POINT-SENSOR PROBE-BL.C/FREEZERS LW 1 1

INCLUDED ACCESSORIES

installed-electric 4.26 0.42

Power - kW

at evaporation temperature - °C -30 -10

Refrigerant power

Refrigeration power - W 2540 7150

Refrigerant quantity - g. 4500

Refrigerant type R404a R404a

Compressor power - HP 2.9 ;

N° of positions/pitch, mm 36, 20 36, 20

Max load capacity - trays h 65 mm - n° 10 10

Trays type 600x400; GN 1/1; Ice Cream 600x400; GN 1/1; Ice Cream

Door hinges Left Left

height 1730 1730

depth/with open doors 1007, 1379 1007

width 895 895

External dimensions - mm

Thermometers Digital Digital

Thermostat Electronic Electronic

Cooling unit Built-In Remote

Gross capacity (D.I.N. 8952) - l. 560 560

UK Guide lines - chilling / freezing 50, 50 50, 50

NF Regulations - chilling / freezing 36, 36 36, 36

Productivity per cycle - kg.

Type Blast freezer - 50 kg Blast freezer - 50 kg

TECHNICAL DATA

AOFPS101C

726305

AOFPS101CR

726307

PERFORMANCE

• Blast Chilling cycle: 50 kg from

+90°C up to + 3°C in less than 90

minutes.

• Blast Freezing cycle: 50 kg from

90ºC up to -18 ºC in less than four

hours.

• Multi-purpose internal structure is

suitable for 10 grids GN 1/1 (36

positions available with 20 mm pitch)

10 grids or trays 600 x 400 mm (36

positions availabe with 20 mm pitch)

or 18 ice-cream basins of 5 kg each

(h 125 x 165 x 360).

• Chilling and freezing times can vary

according to food quantity, density,

moisture contents and type of

containers. Chilling capacity

according to NF* regulations is 36 kg.

CONSTRUCTION

• Internal and external finishing in

304 AISI stainless steel and back

panel in stainless steel.

• High density polyurethane

insulation, 60 mm thickness, HCFC

free.

• Environmentally friendly: R404a as

refrigerant fluid.

• Developed and produced in ISO

9001 and ISO 14001 certified factory.

• Inner cell with fully rounded corners.

• Door equipped with removable

magnetic gasket with hygienic design.

• All motors and fan waterproof

protected IP23.

• Evaporator with anti rust protection.

• Ventilator (fan) swinging hinged

panel for access to the evaporator for

cleaning.

• Automatic heated door frame.

• Hot gas defrosting system.

• Solenoid valves.

• 1 thermostatic expansion valve.

• Feet 150 mm high.

• Stand alone printer as optional, built

in on request.

• PC connection on request, gate RS

485.

INSTALLATION

• No water connections required.

• Waste can be plumbed into drain,

but can also be collected in optional

waste container.

*NF HYGIENE ALIMENTAIRE

certifying authority : AFAQ AFNOR

CERTIFICATION. Address:11, Avenue

Francis de Pressense - 93571

Saint-Denis La Plaine Cedex - France.

Conformity with regulation NF031.

Certified guarantees: fitness for cleaning,

thermal performance.

Installation diagram:

EQ - Equipotential screw

EH - HACCP

TCA - Technical connection area

RO - Refrigerant outlet