ELEKTROMET PANNEX DUO COMBI VVB 160L User manual

ver.01/2 PANNEX DUO COMBI VVB 160L

1

HOT TAP WATER HEATERS

type WJ/W-Q

with a helical coil and

an electric heater

INSTALLATION AND USER’S MANUAL

GUARANTEE TERMS

ver.01/2 PANNEX DUO COMBI VVB 160L

2

INDEX

1. CONSTRUCTION AND USE …………….……………….……………….……………….………………3

2. INSTALLATION …………….……………….……………….……………….……………….…………….5

Connecting to the water supply and central heating systems…………….……………….…………….5

Connecting to the wiring system …………….……………….……………….……………….…………..6

Connecting to the circulation system …………….……………….……………….……………….……...6

Start-up …………….……………….……………….……………….……………….………………….…...7

3. MAINTENANCE AND USAGE …………….……………….……………….……………….…………….7

Operation of the heater connected to a boiler …………….……………….……………….…………….7

Maintenance tips …………….……………….……………….……………….……………….……………7

Magnesium anode rod replacement …………….……………….……………….……………….……….7

4. WARRANTY TERMS AND CONDITIONS…………….…………………….……………….……………8

Please read „Instructions for Use” and „ Warranty Terms and Conditions”

carefully before heater installation and start up.

Heater installation and start up should be performed in accordance with the

“Instructions for Use” by a qualified person.

ver.01/2 PANNEX DUO COMBI VVB 160L

3

1. CONSTRUCTION AND USE

WJ/W-Q type water heaters with spiral coil pipe are used for heating usable water

and its storage. They can be used in houses, small blocks of flats and other types of

buildings equipped with low-temperature water boilers and electric supply of ~400V

(in case of the heaters with the electric heater). These appliances are ready to

operate with the water supply systems with pressure of 1,0 MPa.

In both types, the heating water necessary to heat the usable water is delivered

(e.g. from the central heating boiler) to the spiral coil pipe, which has a big heating

surface and is installed inside the tank of the heater. The heating water inside the

pipe heats the surface of the coil pipe which warms the usable water stored in the

tank.

The pressure tank is made of steel sheet covered with a layer of ceramic enamel

inside, which together with the magnesium anode rod installed in the top end cap

protects the tank against corrosion and guarantees good quality of the usable water.

The anode rod functions on the basis of the difference between the electrochemical

potentials of the anode rod and the tank materials. The access to the anode rod

which requires periodical inspection and replacement is secured by a removable

insert The tank is insulated with polyurethane foam (contains no FCKW) screened

with metal jacket made from thin steel sheet covered with powder paint and upper

and lower plastic lids. The heaters should be mounted on walls or other suitable and

solid constructions in vertical position.

The heater PANNEX DUO COMBI VVB 160L is additionally equipped with the

so-called “dry” electric heater with the heating power of 3000 W supplied with the

three-phase electric current of ~400 V. In this type of heaters it is possible to

replace heating elements without the necessity of draining the tank.

Thanks to modern construction and technologies used to produce the WJ/KW

types heaters they are economical, durable and their installation, usage and

maintenance are easy and safe. They can be installed in every type of room with the

water-supply and wiring system connections, except for the places where the danger

of explosion or fire may occur or in which the temperature may fall below 0°C. Pic.

1 presents the construction and dimensions of both versions of the heater.

ver.01/2 PANNEX DUO COMBI VVB 160L

4

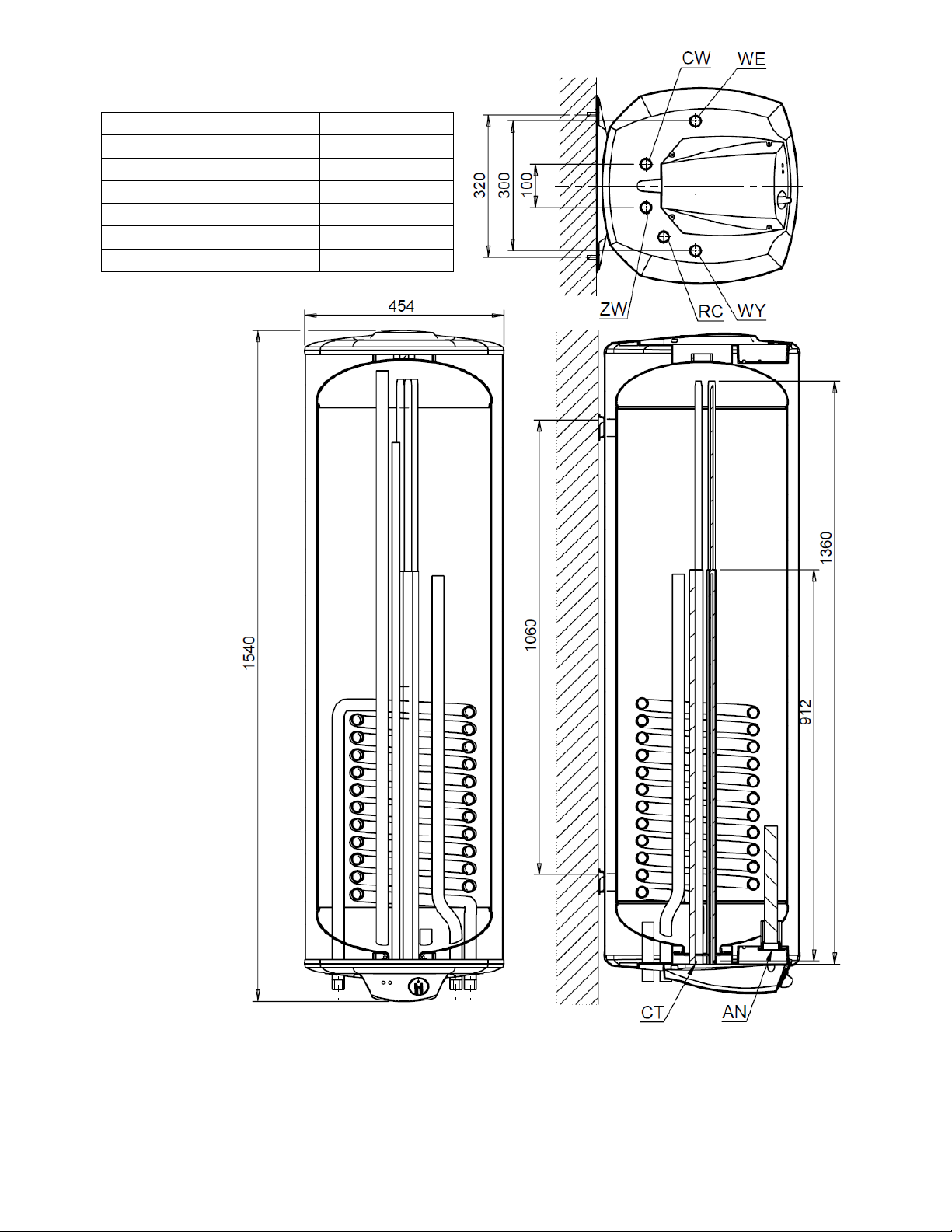

Picture 1. Construction and dimensions of PANNEX DUO COMBI VVB 160L heaters.

Table 1. Technical specification of PANNEX DUO COMBI VVB 160L heaters

WE –Heating Water Inlet

¾”

WY –Heating Water Outlet

¾”

CR –Circulation

¾”

ZW –Cold Water

¾”

CW –Hot Water

¾”

CT –Temperature sensor

ø16 mm

AN –Magnesium Anode

1¼” [30 x 270]

ver.01/2 PANNEX DUO COMBI VVB 160L

5

Type

PANNEX DUO COMBI VVB 160L

Capacity

dm³

158

Coil surface

m²

0,9

Coil capacity

dm³

4,0

Permanent usable water heating capacity

80/10/45ºC*

70/10/45ºC

60/10/45ºC

dm³/h

337

253

190

Permanent heating power

80/10/45ºC

70/10/45ºC

60/10/45ºC

kW

15,3

11,5

8,6

Demanded amount of heating water

m³/h

3

Heating water flow resistance in coil

mbar

120

Sound power level

dB

15

Water heating energy efficiency class

C

Annual electricity consumption

kWh/a

2652

Declared load profile

L

Specific energy efficiency

%

39

Tank operating parameters

Max. pressure and operationl temp.

pr=1,0 MPa tm = 80ºC

Heating agent parameters

Max. pressure and operationl temp.

pr=1,0 MPa tm = 100ºC

Heater mass w/o water

kg

77

WE –heating water supply

G out.¾”

WY –heating water return

G out.¾”

CR –circulation

G in. 1/2”

ZW –cold water

G out.¾”

CW –hot water

G out.¾”

CT –temperature sensor

ø16

80ºC, 70ºC, 60ºC – heating water temp. at coil pipe inlet

10ºC –usable cold water temp.

45ºC – usable hot water temp.

Technical specification of the electric heater installed

Nominal voltage ………………….…...400V 50Hz

Heater nominal power………………...3000 W

Water temperature control range….....20 - 75ºC

2. INSTALLATION

Taking construction of the heater into consideration, it must be mounted

vertically with the use of the mounting holders situated on the back side of the casing

(see picture 1). Before installation it is advised to make sure that the wall on which

the heater is to be mounted is solid enough and the hammer drive plugs are suitable

for the type of the wall and the mass of the heater filled with water.

Connecting to the water-supply and heating systems.

The heater is meant to work with the connection to the water-supply system

with water pressure that does not exceed the level of 1,0 Mpa. However, if the

pressure is higher than 0,7 Mpa it is recommended to install a pressure reducing

valve or an expansion tank on the water supply line before connecting the heater to

the water supply system in order to limit water leaks from the safety valve. The

spiral coil pipe may be supplied with water from the low-temperature water boiler

ver.01/2 PANNEX DUO COMBI VVB 160L

6

operating in a closed system with the expansion vessel or in an open system with

the pressure vessel. The temperature sensor which controls the work of the boiler

supplying the heating system of the heater should be placed in the thermometer pipe

situated under the cover of the control panel in the lid of the stub pipe of the bottom

end cap. In order to avoid heat losses it is recommended to use short and insulated

kinds of hoses/pipes to create line supplying water from the central heating system.

It is forbidden to use heaters without safety valve installed or with the

damaged safety valve as it may cause damage to the heater or put people’s

health or life in danger.

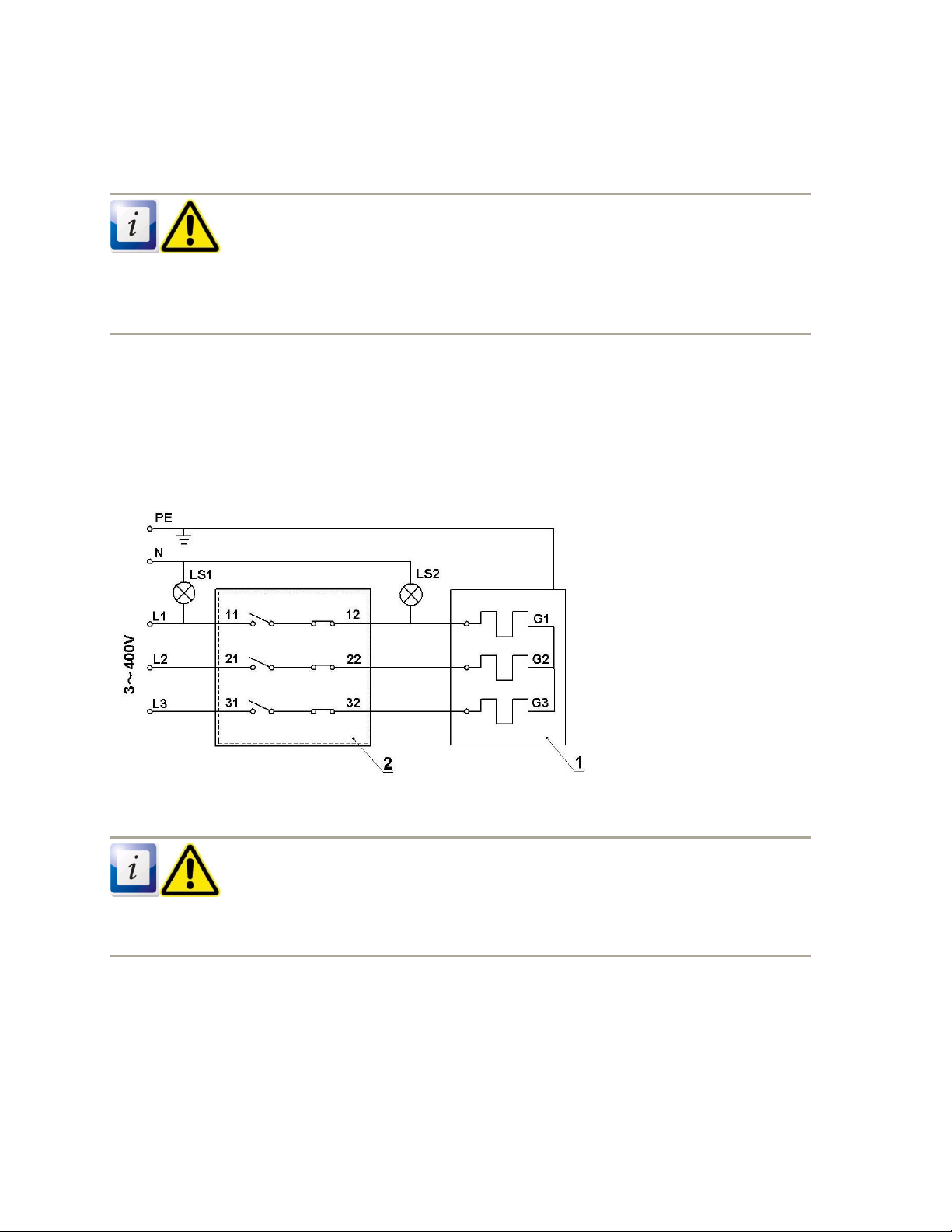

Connecting to the wiring system

The heater PANNEX DUO COMBI VVB 160L is additionally equipped with the

so-called “dry” electric heater with the heating power of 3000 W supplied with the

three-phase electric current of ~400 V. The wiring diagram of the heater is

presented in picture 2. It is recommended not to turn the heater on before filling the

tank up with water as it may cause damage to the heating elements and the

necessity of their replacement.

1- heating element

2 –thermostat with the

temperature switch regulator

LS1, LS2 –signaling lamps

Picture 2. The wiring diagram of the PANNEX DUO COMBI VVB 160L heater

Connecting to the power supply system may be performed only by a qualified

person.

Connecting to the circulation system

When the supplying sources are far away from the heater it is recommended to

use the circulating water connection pipe situated in the top end cap and. A

circulating pump should be installed on the circulation line and the pipes delivering

water to the supplying sources should be thermally insulated. In case there is no

circulation the connection pipe should be plugged.

ver.01/2 PANNEX DUO COMBI VVB 160L

7

Start up

After installation the heater must be filled up with water. In order to do that perform

the following:

–open one of the hot usable water supplying sources and the valve on the cold

water inlet to the heater (water-supply system)

–fill the tank up to the moment when water appears in the open hot usable water

supplying source and close the open hot usable water valve.

–check the tightness of the installed connection to the heater

–fill the heating water network, paying attention to deaeration of the coil pipe (it may

be performed by using a suitable circulating pump or a special vent installed on the

heating water inlet pipe)

–check the tightness of the connection between the heating network and the heater

–switch the central heating boiler on

After connecting to the wiring system and switching the electric supply on (the

green signalling lamp switches on) the desired temperature of water should be

adjusted with the use of the thermostat knob. When the heater is on, the red

signaling lamp is on. When the temperature of water reaches the required level the

thermostat switches off the heater and the lamp turns off.

Description of the heater knob settings:

1 - approx. 25°C

2 - approx. 50°C

3 - approx. 75°C

ECO - setting between 1 and 2 in which the tank was tested for energy class,

the most economical setting (approx. 45°C).

When the temperature exceeds 87°C the safety switch cuts off the power

supply to the electric heater. Before switching the power supply on again the

temperature must go down below 87°C and the safety switch must be reset by

pushing the button on the temperature limit control. In order to do that the power

must be shut off and the cover of the control panel must be removed.When the

power shut off performed by the safety switch happens too often it may indicate that

the thermostat or the temperature limit control is out of order and needs to be

replaced by a qualified person. To limit the risk of electric shock all the metal

elements of the heater are connected to the protection wire.

3. MAINTENANCE AND USAGE

Operation of the heater connected to a boiler

The temperature sensor which controls the work of the boiler supplying the

heating system of the heater should be placed in the thermometer pipe situated

under the cover of the control panel in the lid of the stub pipe of the bottom end cap.

To get access to the pipe the lower control panel or the insert should be removed. In

case of the heater with the electric heater there are also capillary pipes of the

thermostat and the temperature limit control in the pipe (when removing capillary

pipes violent twists of the cables connecting capillary pipes to the thermostat and

safety switch should be avoided)

Maintenance tips

1. The proper functioning of the safety valve should be checked periodically, at least

once a month and each time before first start-up after a period of shutdown.

2. During the work of the heater the magnesium anode rod slowly depletes so its

condition should be checked periodically, at least once every 18 months and it

ver.01/2 PANNEX DUO COMBI VVB 160L

8

should be replaced if necessary. It is recommended to replace the anode rod

every two years.

Magnesium anode rod replacement

The magnesium anode rod is situated in the top end cap of the tank and can be

accessed after the upper panel has been removed, picture 1.

To inspect or replace the anode rod perform the following:

–turn off the supply of the cold usable water and turn on the hot water using any of

the taps (the best one is the tap situated under the level of the top end cap of the

heater) in order to drain some amount of water out and reduce the overpressure in

the tank

–unscrew 4 positioning pins from upper panel and take it off

–remove the element of insulation that covers the insert with the attached anode rod

–using s60 socket wrench unscrew (1 ¼” twist) the plug together with the attached

anode rod

–screw the new anode rod with the insert in, paying attention to the tightness of the

connections (it is also advised to replace the seals)

The magnesium anode rod plays an important role in the process of the heater

maintenance as it protects the enameled tank against corrosion and its regular

inspection, replacement and proper installation are the conditions which

should be fulfilled in order to get the warranty of

Before performing any maintenance or repair works, please make sure that the

power supply to the heater is shut off.

4. WARRANTY TERMS AND CONDITIONS

1. The warranty of the enameled tank is valid for 60 months

2. The warranty of the other heating elements is valid for 24 months

3. The period of warranty is valid from the date of purchase. The date must be

specified in a Warranty Card and confirmed by a proof of purchase (receipt) written

and stamped by the vendor.

4. The guarantor guarantees a faultless operation of the heater on the condition that

it is installed and used in accordance with this Instructions for Use.

ver.01/2 PANNEX DUO COMBI VVB 160L

9

Zakład Urządzeń Grzewczych

„ELEKTROMET”

Gołuszowice 53

48-100 Głubczyce

tel. +48 / 077 / 485 65 40

DEKLARACJA ZGODNOŚCI

(DECLARATION OF CONFORMITY)

Pan Wojciech Jurkiewicz

(Mr) ……………………………………………………………………

(Imię, Nazwisko / Surname, Name)

reprezentujący firmę ZUG “ELEKTROMET” Gołuszowice 53 48-100 Głubczyce

(legal representative of) ……..……………………………………………………………

(Nazwa i adres producenta / Manufacturer’s Name and Address)

DEKLARUJE / DECLARES

z pełną odpowiedzialnością, że wyrób:

(with all responsibility, that the product):

Elektryczny pojemnościowy podgrzewacz wody użytkowej typu

PANNEX DUO COMBI VVB 160L

…………………………………………………………………………………………

(nazwa, typ lub model / name, type or model)

został zaprojektowany, wyprodukowany i wprowadzony na rynek zgodnie z następującymi

dyrektywami:

(has been designed, manufactured and placed on the market in conformity with directives):

-Dyrektywa Urządzeń Ciśnieniowych (PED): 2014/68/UE

-Pressure Equipment Directive (PED): 2014/68/UE

-Dyrektywa niskonapięciowa 2014/35/UE;

the safety principles of the “Low voltage” Directive 2014/35/UE

-Dyrektywa kompatybilności elektromagnetycznej “EMC” 2004/108/WE

the protection requirements of „EMC” Directive 2004/108/EC

-Dyrektywa Prostych Zbiorników Ciśnieniowych 2014/29/UE

- The Simple Pressure Vessels Directive 2014/29/UE

i niżej wymienionymi odpowiednimi normami:

and that the following relevant Standards:

- PN - EN 60335 - 1

- PN - EN 60335-2-21

- PN - EN 61000-3-2

- PN - EN 61000-3-3

- PN - EN 55014-1

Gołuszowice, 06. lipiec. 2017r.

…………………………………………………….….. …………………………………………………

(miejsce i data wystawienia) (imię i nazwisko oraz podpis)

(place and date) (Name, Surname and Signature)

ver.01/2 PANNEX DUO COMBI VVB 160L

10

ver.01/2 PANNEX DUO COMBI VVB 160L

11

ver.01/2 PANNEX DUO COMBI VVB 160L

12

Table of contents

Popular Water Heater manuals by other brands

andrews

andrews CSC39 Installation guide, operation & service manual

Bosch

Bosch Tronic 1000 T installation instructions

Zelmer

Zelmer CK2320 user manual

Radiantec

Radiantec Solar Water Heater owner's manual

STIEBEL ELTRON

STIEBEL ELTRON HSBB 180 Plus Operation and installation

STIEBEL ELTRON

STIEBEL ELTRON DEL 18 SLi Operating and installation instructions

STIEBEL ELTRON

STIEBEL ELTRON Accelera 300 OPERATING AND INSTALLATION Manual

Bradford White

Bradford White U65L155E N Series Service manual

Ariston

Ariston 45 Assembly and operation instructions

Air Venturi

Air Venturi EZ Fill system manual

Dux

Dux DN15DS Installation and owner's guide

Haier

Haier ES30V-A3 instruction manual