elem Energy 2 User manual

11

11

1 ❏❏

❏❏

❏

Index

Soldering point.

Male connector.

Female connector.

M/F faston connector.

Test point.

Supply voltage. Logic supply ground.

Analog supply ground.

Chassis ground.

Earth ground.

Flag joined with one or more flags

GENERALMUSICS.p.A.SalesDivision:47842S.GiovanniinMarignano(RN)ITALY-ViadelleRose,12-tel.0541/959511-fax0541/957404

GENERALMUSIContheNET:http://www.generalmusic.com

TechnicalSpecifications,Introduction,TestProcedures&Adjustments

2

Top&BottomAssemblyViews

5

ResponseCurves

7

8

WiringConnectionsDiagram

9

BlockDiagram

10

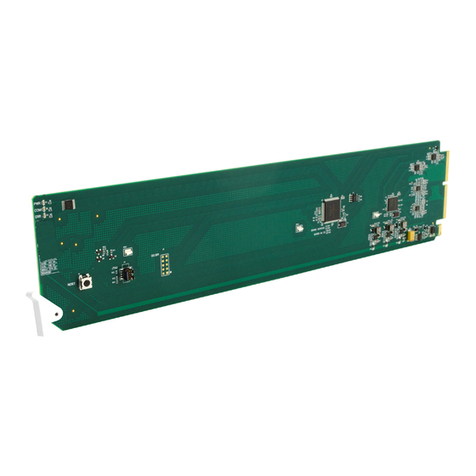

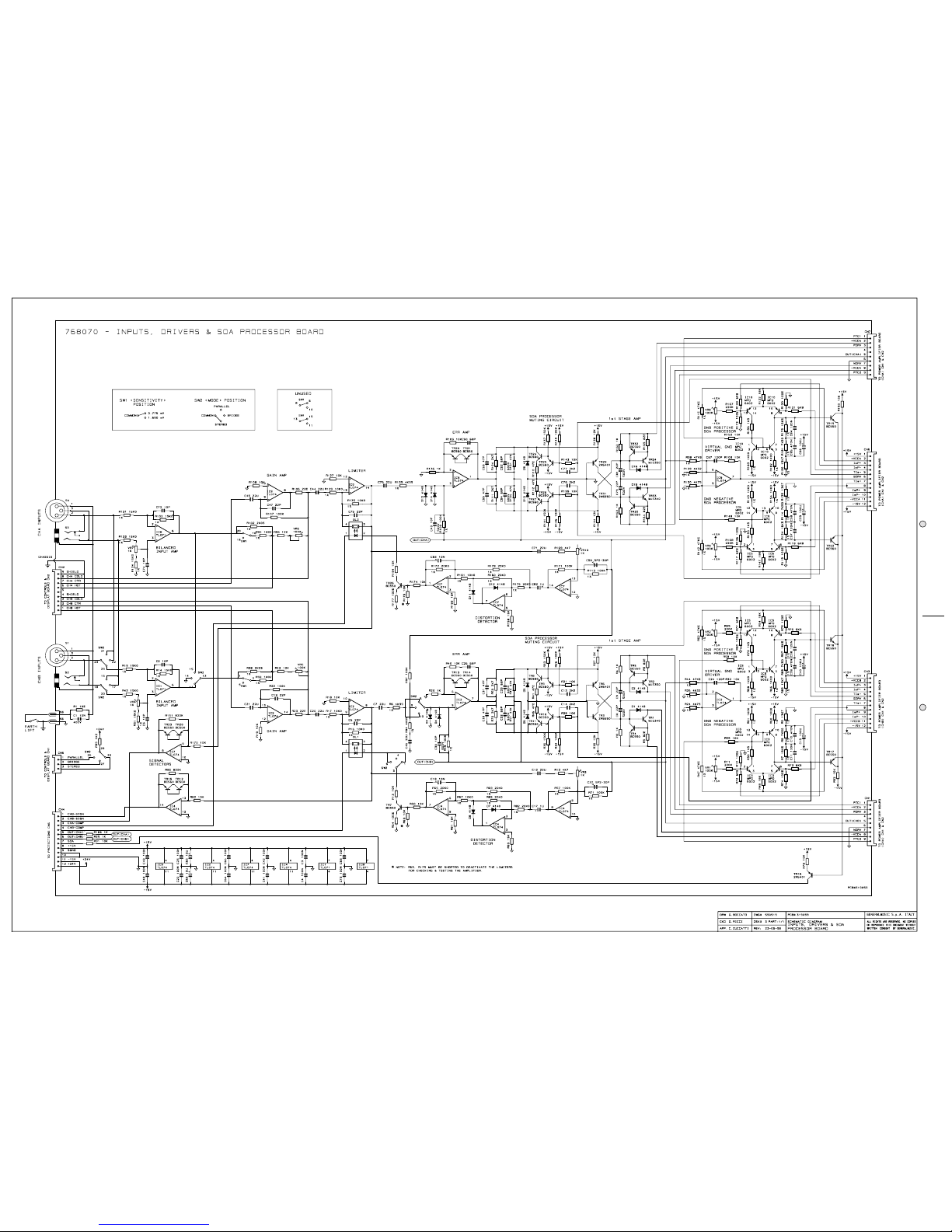

Inputs,Drivers&SOAProcessorBoard

11

SparePartList

12

ProtectionsBoard,Controls&DisplayBoard

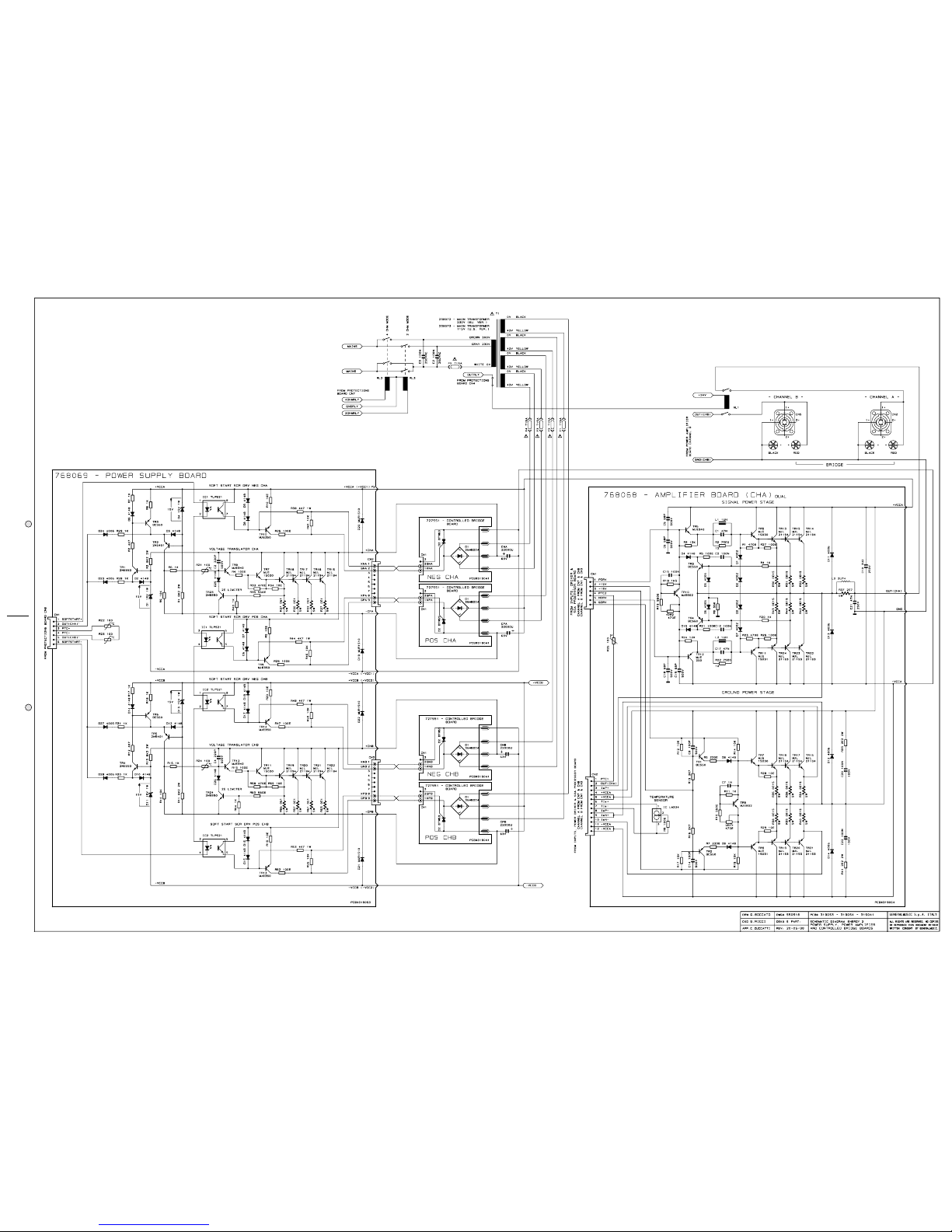

PowerSupplyBoardandAmplifierBoard

6

SERVICE MANUAL

CODE:277287

Warnings

with the same signal name inscribed.

Address

ATTENTION

Observe precautions when handling electrostatic sensitive devices.

Notice

Service must be carried out by qualified personnel only.Any tampering carried out by unqualified personnel during the guarantee period

will forfeit the right to guarantee.

For a correct operation of the instrument, after having switched off, be careful to wait at least 3 seconds before switching on again.

To improve the device's specifications, the schematic diagrams may be subject to change without prior notice.

All components marked by this symbol have special safety characteristics, when replacing any of these components use only

manufacturer's specified parts.

The (µ) micro symbol of capacitance value is substituted by U.

The (

Ω

) omega symbol of resistance value is substituted by E.

The electrolytic capacitors are 25Vdc rated voltage unless otherwise specified.

All resistors are 1/8

Ω

unless otherwise specified.

All switches shown in the "OFF" position. All DC voltages measured to ground with a voltmeter 20KOhm/V.

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

HIGH PERFORMANCE POWER AMPLIFIER

ENERGY 2

❏ ❏

❏ ❏

❏ 22

22

2

TECHNICAL SPECIFICATIONS

Dimensions: (WxHxD) 483x88x507mm (2U)

Weight: 23 Kg - 50.6 lbs

Power Requirements: 230Vac±10% 50/60Hz 2000VA

or 115Vac±10% 50/60Hz 2000VA

Load selector: * 2Ω ** 4Ω

Output Power: (2Ωstereo/parallel)* 900Watts

(4Ωstereo/parallel)** 1000Watts

(8Ωstereo/parallel)** 500Watts

(4Ωbridge)* 1800Watts

(8Ωbridge)** 2000Watts

(16Ωbridge)** 1000Watts

Max. Undistorted Out: (2Ωstereo/parallel)* 120±2Vpp

(4Ωstereo/parallel)** 180±5Vpp

Input Sensitivity: (constant sensitivity) 0.775Vrms (0dB)

(constant gain) 1.65Vrms (+6.5dB)

Input Impedance: (balanced) 30KΩ

(unbalanced) 15KΩ

Voltage Gain: (constant sensitivity) 38±0.5dB

(constant gain) 32±0.5dB

Slew Rate: 23V/µS

Damping Factor: (8Ωstereo/parallel) >400

Frequency Response (-0.2dB) 20Hz÷20KHz

at Full Power: (-3dB) 10Hz÷80KHz

IMD: (SMPTE 60Hz/7KHz 4:1) <0.02%

THD: (THD+N) <0.02%

S/N Ratio: (unweighted) >100dB

Crosstalk: (1KHz) >90dB

INTRODUCTION

Power Performances

The amplifier Energy 2 operates in AB class using the last BJT generation in

plastic package, it has been designed using a Floating Bridge Configuration: this

configuration, making the most from the double stage power supply, enables to

obtain very consistent power with very high dynamics and low distortion even

at low impedances.

Double Stage Power Supply

For each amplifier section in the Mains Transformer there are two secondary

windings which are connected in parallel or in series according to the effective

power requirements. In this manner the amplifier only receives the necessary

voltage when there is an effective demand of power with a considerable

reduction of dissipated heat.

Protections

Loudspeaker protection: in case of the breakdown of the output BJTs or other

fault condition, a DC Sensor on power output circuit is able to interrupt the

amplifier circuit avoiding that current peaks reach the load. Moreover a Soft

Start circuit delays the connection of the speakers by the Output Relay every

time the amplifier is turned on, when it is turned off the relay disconnect the load

immediately.

Thermal protection and cooling system: Inside the amplifier there is an

highly sophisticated cooling system able to protect it from overheat and to

ensure the upmost efficiency and reliability. The cooling system has two

separate heat sink structures (for positive and negative rails) for each channel

constructed with tinplated copper, instead of alluminium, for more efficiency. Air

flow thru the unit is ensured by two variable speed fans controlled by the SOA

circuit, if the temperature rise again the control circuit gradually reduces the

power supply to the final stage and at the same time enables the input limiter.

As soon as the temperature reaches the normal level , the amplifier gradually

returns to normal operation. The amplifier protect itself, by entering in a

complete muting status, only in extremely abnormal operating condition

(e.g.obstruction of the air vents) and in case of temperature rising further.

SOA processors: In conjunction with the thermal protection the SOA processors

constantly detect the power dissipation of the output BJT ensuring that they

always remain in their Safe Operating Area. In this particular amplifier the SOA

processors are three per channel, the first and most important checks the signal

output stage, the second SOA circuit checks the ground output stage and the

third circuit checks the voltage translator stage, all three circuits operate

accordly.

Current Limiters: These circuits detect the current on final and translator

stages, accordly with SOA processors limiting the excessive current on the

load, and finally enable the Input Limiter.

Transformer Thermal Protection: This protection disconnects the load (muting

the amplifier) until the cooling restores the normal temperature.

Anti-Clipping Limiter: The input signal is constantly checked to instantly

recognize a possible amplifier clip, this circuit is an efficient limiter that operate

without an excessive dynamic compression to obtain the better listening, it

operates accordly the protection circuit.

TEST PROCEDURES & ADJUSTMENTS

Precaution

➭To prevent short circuit during any test, the oscilloscope must be

EARTH insulated, this occurs because some test require to connect its

probe to the amplifier output, non-compliance may cause damages to

oscilloscope inputs circuitry.

➭Before removing or installing any modules and connectors, disconnect

the amplifier from AC MAINS and measure the DC supply voltages

across each of the power suppliy capacitors. If your measurement on any

of the caps is greater than 10Vdc, connect a 100Ω50W resistor across

the applicable caps to discharge them for your safety. Remember to

remove the discharge resistor immediately after discharging caps. Do not

power up the amplifier with the discharge resistor connected.

➭Read these notes entirely before proceeding to any operation. These

notes are not comprehensive of all damages that possibly occur, but

includes some specifically advices, checks and adjustments relative to

this amplifier.

Visual Check

➭Remove top and bottom covers from the amplifier chassis.

➭Use compressed air to clear dust in the amplifier chassis.

➭Before proceed to supply the amplifier check visually the internal assem-

bly, if appears an evident damage find the most possible reasons that

cause it.

➭Check the wiring cables for possible interruptions or shorts.

➭If the damage has burnt a printed circuit board don’t try to repair it,

replace with a new one.

Test Instruments

➭Audio Generator

➭Dual Trace Oscilloscope

➭Digital Multimeter

➭2Ω1000W, 4Ω2000W, 100Ω50W resistors

➭1 Mains cord terminated with insulated Faston

➭Variac (0÷250Vac)

➭Temperature Meter

Initial Setup

➭Turn the amplifier on bottom side.

➭Disconnect the Power Switch from the amplifier internal mains line and

reconnect it directly to the Mains Line with the other cord.

Set the Variac at zero voltage and connect it between the amplifier mains

socket and the Mains Line.

➭Set the amplifier controls as follows:

MODE on parallel (PAR),

MINIMUM LOAD on 4Ω,

EARTH selector on grounds attached,

SENSITIVITY on 0.775V

and turn full clockwise the level potentiometers.

➭Short R63 and R175 on the Inputs, Drivers & SOA Processor Board to

de-activate the limiters on each channel.

➭The procedures that follow must be executed subsequently in the order

specified.

➭The procedures are divided in two phases: the first initial test is intended

to locate the most probably faults, the second final test is intended to

verify and to adjust the amplifier with load connected.

Protections & Ac Supply Check

➭Turn the amplifier on top side.

➭Remove the Main Transformer secondary fuses (4 x16A) and then check

them with the Multimeter.

➭Turn on the amplifier, the relais on the Main Transformer primary winding

must be turn on one a time, the fans go immediately to the max. speed

and after some seconds return to the slow speed, and also the output

relay must turn on. During this time the protect red led lights.

➭If somethings goes different, the amplifier has probably some problem on

33

33

3 ❏❏

❏❏

❏

the Protections Board, first of all check its supplies:

CN4 pin 6 = +24Vdc

CN4 pin 9 = -24Vdc

CN6 pin 8 = +15Vdc

CN6 pin 11 = -15Vdc

➭If the fans don't start or go only to the max. speed, you must check the

Fan Driver circuit (TR1,2,4,6).

If all the circuit is good, you must check on the Inputs, Drivers & SOA

Processor Board the TR16,17,18,19,22 and the SOA Processor circuits

preceding the transistors; to check them quickly disconnect CN3 and CN6

the fan must go only at slower speed.

➭If the Primary Tranformer Relais don't start (also selecting 2Ω or 4Ω

minimum load switch) check their driver circuits, the fault must be prob-

ably in the Transformer Relais Driver circuit on the Protections Board ,

refer to schematics.

➭If the Outputs Relay doesn't start the fault must probably located in the

relay driver or in Soft Start circuit on the Protections Board , refer to

schematics.

➭Turn off the amplifier and check with the multimeter if the SCR on Con-

trolled Bridge Boards are shorted. If one or more are shorted, replace it

with a new one, check also the bridges.

➭Set the oscilloscope CH1 to 10V/div. 5mS and connect its probe to R48

side TR19(c) on Protections Board, turn on the amplifier: a series of

pulses appear on the screen that will became stable about +15Vdc, these

pulses activate the SCR on the Controlled Bridge Boards to slowly charge

the capacitors. If the pulses aren't displayed your amplifier has probably

some fault on Soft Start circuit, refer to schematics.

➭Set the Variac at the nominal mains voltage, measure with the Multimeter

the AC supply voltages between the secondaries: 43±3Vac

➭Switch to 2Ωminimum load and measure again the voltages: 33±3Vac.

➭Re-set the minimum load at 4Ωand the Variac at zero voltage, turn off

the amplifier and put the fuses back on its holders.

Dc Supply Initial Check

➭SETUP:

Connect the audio generator to a channel input and set it to 1KHz

775mVRMS (0dB) sinusoidal signal.

Connect the CH1 scope GND clip to the output GND and connect the

oscilloscope probe tips CH1/2 to the channel outputs before the relay, set

both to DC 20V/div. 200µS/div.

➭Turn on the amplifier and afterwards increase the Variac slowly monitor-

ing the Outputs with the oscilloscope CH1/2 connected, it should display

the sinusoidal input signal amplified with no distortions, if a distortion or a

protection trip occur, turn off the amplifier, wait some minutes and discon-

nect the supplies from the Power Amplifier Board that doesn't work

properly, to do this you must disconnect the red and the blue wires from

capacitors, continue to check the supplies.

➭CAUTION: Before re-connecting the Power Amplifier Boards to the

supplies, you must have the capacitors discharged for your safety:

connect a 100ΩΩ

ΩΩ

Ω50W resistor across the caps and remove the resis-

tor just after they are discharged.

➭Finally verify the DC supplies at the capacitor terminals: 58±2Vdc

➭If one or more voltages don’t correspond:

Check the SCR located on Controlled Bridge Board and its driver transis-

tor (TR9,10,13,14) located on Power Supply Board, particularly check the

insulation from the heating and the driver transistors and the diodes D19,

20, 21, 22.

Re-check the rectifiers, capacitors and transformers disconnecting them

from circuitry, refer to schematics.

Channels Initial Check

➭Re-set the Variac at zero voltage and eventually re-connect the damaged

Power Amplifier Board that you have previously disconnected from

supply.

➭Set up the Variac slowly and check on the oscilloscope display the output

of the damaged channel:

➭If a dc voltage is present, turn off the amplifier and check all the output

transistors TR13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, their drivers

TR5, 7, 9, 11 and all active and passive components interested with the

signal path, particularly also include TR29, 30, 31, 32, 33, 34 and D15,

16 for channel A or TR1, 2, 3, 4, 5, 6 and D1, 2 for channel B mounted

on Inputs, Drivers & SOA Processor Board.

➭If appears a simmetrical clipping before the maximum output voltage

(refer to technical spec.), the supply translator circuit of the channel

under test, located on Power Supply Board doesn't work properly: check

its driver circuit refer to schematics.

➭If appears an asimmetrical clipping before the maximum output voltage

(refer to technical spec.), the grounding power amplifier doesn't work

properly; this fault can also be checked measuring the dc voltage be-

tween output ground and the +Vcc and the voltage between output

ground and -Vcc for the channel under test, all measures must be

simmetrical near 28Vdc without input signal, if not, check the virtual

ground driver (R115/R142 ch.A or R52/R47 ch.B) located on Inputs,

Drivers & SOA Processor Board, refer to schematics.

➭If no signal appears: try to disconnect R41,46 to deactivate the signal

deletion caused by SOA circuit, then checked the right operation of the

channel, check the cable connections of SOA circuits, check its active

and passive components and verify its adjustments. If also the signal

doesn't appear check the input circuits, refer to schematics.

➭Note: If one or more of described faults appear only with the load

connected (see the following checks) may be that one or more

output, ground or voltage translator transistors is interrupted.

Dc Supply Final Check

➭These procedures are intended for one channel at a time, repeat these

operation for the other channel.

➭SETUP:

Connect the CH1 scope GND clip to the output GND.

Connect the CH1 probe tip to the CHA amplifier output before the relay.

Connect the CH2 probe tip to the red wire (+Vcc1).

Set both to DC 20V/div. 200µS/div.

Insert the temperature meter through two transistor cases interstice

located at centre of heatsink of CHA on the Power Supply Board .

Connect the 4Ω2000W load to CHA out.

Connect the audio generator to the channel input CHA and set it to 1KHz

775mVRMS (0dB) sinusoidal signal, and set the amplifier to Stereo mode.

Connect the Mains Line as described in the initial setup section.

Set the LEVEL potentiometers at zero.

Set the Variac at zero voltage.

➭Increase slowly the Variac to reach the mains voltage: check that the

supply circuit operate correctly measuring +28±2Vdc on the red wire

(+Vcc1) and -28±2Vdc on the blue wire (-Vcc1) respect the CHA GND

output.

➭Increasing the CHA input level check the right operation of the Supply

Voltage Translator: verifying that the CH2 voltage level remain the same

until the CH1 signal reach 26Vp, afterwards increasing the input level the

voltage of CH1 must envelope externally the CH2 signal with an offset of

10÷12V.

➭Increasing the level of input signal the envelope is stopped more about

100±5Vdc and the signal clip must occur at 180±5Vpp. Decrease the

level and connect the CH2 probe to the blue wire (-Vcc1), repeat the test

for the negative supply.

➭Connect the 2Ωinstead 4Ωload and verify that the output signal must be

limited at 64±2Vp. If it doesn't happen check the limit circuit (TR23 for

CHA, TR24 for CHB) on Power Supply Board.

➭Disconnect the fan and wait until the temperature reaches 110±5°C: the

primary transformer relais switch to 2Ωminimum load and the fan, re-

connecting it, goes at maximum speed (23Vdc).

➭Turn off the Amplifier and the Variac. Connect CH1 scope GND tip to R38

terminal side CN2 (SCR cathode) and its probe tip to R41 side CN2 (SCR

gate), set it to 200mV/div. 1mS/div.

➭Turn on the Amplifier and the Variac simultaneously and verify that the

voltage on the SCR gate shift from 0 to 0.8Vp in less than one second.

➭Repeat the last test after moving the CH1 GND tip to R44 side CN2 and

its probe tip on R46 side CN2 to check the second SCR.

➭Repeat all these tests for CHB, where Vcc1 become Vcc2, CN2, R38,

R41, R44, R46 become CN3, R48, R50, R53, R55 respectively.

Channel Final Check

➭These procedures are intended for one channel at a time, repeat these

operation for the other channel.

➭If you have already repaired the channel under test:

Verify, with the Multimeter, the insulation between the heatsink and the

TR8,10 transistors collectors.

Turn the trimmer VR1 full clockwise and VR2 full counter-clockwise to re-

adjust the Bias current.

➭SETUP:

Connect the scope CH1 and the amplifier as described in Dc Supply Final

Check section.

Connect the CH2 probe tip to the heatsink of the channel under test.

Insert the temperature meter through the PTC R27 (for CHB) or through

the TR15,16 (for CHA) interstice located on the Power Amplifier Board at

centre of heatsink.

Set the LEVEL potentiometers at maximum.

➭INITIAL TEST:

Increase slowly the Variac. The channel output signals must be symmetri-

cal respect the GND without visible distortion and oscillation. If there is a

distortion read the section ADVICES and proceed to check the other

channel.

Increasing the level of input signal the signal clip must occur at 180±

5Vpp.

➭BANDWIDTH CHECK:

Decrease the level to obtain a 50Vp output signal, sweep the generator

❏ ❏

❏ ❏

❏ 44

44

4

frequency from 20Hz to 20KHz, the output level must have not detectable

level changes.

Set back the frequency at 1KHz.

➭BIAS ADJUSTMENT:

Disconnect the fan and wait until the temperature reaches 50°C, set the

input level at zero, measure with the Multimeter the voltage across the

tips of R34 and the tips of R40, adjust VR1 trimmer to read 1±0.05mVdc.

Verify that the temperature is not changed and adjust VR2 trimmer to

read 1±0.05mVdc across the tips of R30 and the tips of R43.

Set the CH1 an CH2 scopes at 0.2V/div. 200µS/div., adjust the input level

until the sinewave reach 0.5Vp, no crossover distortion must be detect-

able: if necessary re-adjust VR2 until the distortion disappears without

exceed 6mVdc between R30 and R43 terminals.

Re-connect the fan.

➭OUTPUT CURRENT CHECK (GROUND AMPLIFIER):

Connect the ground clip of CH1 scope at the CHA amplifier ground out,

and its probe tip to the emitter of TR16 and CH2 probe tip to TR21 emit-

ter.

Vary the input level to obtain 0.5Vp on output and verify that the differ-

ence of their peaks are less than 0.1V.

Verify the correct division of the output current between the output tran-

sistor, connecting alternatively CH2 probe tip to the TR17 and TR18

emitters checking that their peak levels are within 10% themselves.

Moving the CH1 probe tip on TR21 emitter, repeat the measure with the

CH2 tip connected alternatively to TR19 and TR20 emitters.

➭OUTPUT CURRENT CHECK (SIGNAL AMPLIFIER):

Connect the ground clip of CH1 scope at the CHA amplifier output, and

its probe tip to the emitter of TR13 and CH2 probe tip to TR24 emitter.

Vary the input level to obtain 0.5Vp on output and verify that the differ-

ence of their peaks are less than 0.1V.

Verify the correct division of the output current between the output tran-

sistor, connecting alternatively CH2 probe tip to the TR14 and TR15

emitters checking that their peak levels are within 10% themselves.

Moving the CH1 probe tip on TR24 emitter, repeat the measure with the

CH2 tip connected alternatively to TR22 and TR23 emitters.

➭SHORT CIRCUIT SENSOR CHECK:

Short the load temporarely and verify that the current protection sensor

(TR3, TR4) limits simmetrically the signal at 0.8±0.1Vp.

Input Circuit Check

➭These procedures are intended for one channel at a time, repeat these

operation for the other channel.

➭SIGNAL/CLIP SENSOR CHECK:

Set the LEVEL pot to minimum, then increase the level and check the

SIGNAL/CLIP led activity: it must turn on (green light) when the amplifier

output is higher than 0.5Vp.

➭CMRR ADJUSTMENT:

Temporarily disconnect pin 3 from pin 1 and short the pin 2 (positive

input) and pin 3 (negative input) of XLR or Jack plug.

Adjust the trimmer VR7 (CHA) or VR4 (CHB) on Inputs, Drivers & SOA

Processor Board to obtain the minimum output level. Re-set the genera-

tor plug with the input signal at pin 2 (positive input) and pin 3 (negative

input) short with pin 1 (GND).

➭GAIN ADJUSTMENT:

Set the input signal to 0dB. Connect the Multimeter on the output of the

channel under test, set it in dB scale if available, set the input SENSITIV-

ITY at 1.65VRMS, adjust the trimmer VR6 (CHA) or VR5 (CHB) to obtain

32dB (30.8VRMS) on the output.

Set the SENSITIVITY to 0.775VRMS and verify that the Multimeter show

38.5 dB (84.1VRMS).

➭LIMITER ADJUSTMENT:

Remove the shorts from R175 (CHA) and from R63 (CHB) on Inputs,

Drivers & SOA Processor Board, connect CH2 probe tip to IC7 pin 14

(CHA) or to IC4 pin 8 (CHB) and set it at 5V/div. 2mS/div., change the

generator frequency to 100Hz, increase the signal to obtain about 40Vp

on output and adjust the VR10 (CHA) or VR3 (CHB) for the minimum

signal on CH2 trace without CH1 trace attenuation.

Change the frequency to 10KHz and adjust the C56 (CHA) or C37 (CHB)

to minimize the signal on CH2 scope without CH1 attenuation.

Re-set the generator at 1KHz, increase the signal and verify that the

clipping remain costant with the limiter intervention indicated by the red

colour of the SIGNAL/CLIP led.

➭SOA ADJUSTMENT:

Set the scope sensitivity at 5V/div. (both channels).

Connect the CH1 GND clip to S6 and its probe tip to IC6 (CHA) or IC3

(CHB) pin 8, connect CH2 probe tip to IC10 (CHA) or IC5 (CHB) pin 8 set

both at 5V/div. 200µs/div..

Insert the temperature meter through the PTC R27 (for CHB) or through

the TR15,16 (for CHA) interstice located on the Power Amplifier Board at

the centre of heatsink.

Verify that the two scope traces are located about 11±0.5Vdc.

Short temporarely the load, verify that both the traces move to the scope

screen centre and the fans turn to maximum speed.

Disconnect the fan and leave the temperature increasing until reaches

70°C disconnect the load and adjust:

VR8 (CHA) VR2 (CHB) to have the scope negative trace at 10.5Vdc.

VR9 (CHA) VR1 (CHB) to have the scope positive trace at 11.5Vdc.

Short again the load, verify that the scope traces move more about 2V

from the screen centre when the temperature reach 100±5°C; re-active

the fans, they would go at the max. speed, decrease the input level at

zero and verify that the voltage remains at 28±2V until the temperature

reaches 85±2°C on the heatsink, then change the load back to 4Ω.

➭AMPLIFIER BRIDGE MODE CHECK:

Set the amplifier in BRIDGE mode (input signal to channel A) and MINI-

MUM LOAD at 2Ω, connect the CH2 probe to the bridge output: the

output voltage must be 120±2Vp.

➭SIGNAL TO NOISE RATIO CHECK:

Disconnect the audio generator and short the input (pin 1,2,3 of XLR plug

shorted) the output signal (noise) must be less 1mV.

➭OFFSET SENSOR CHECK:

Set the Variac to zero voltage output, disconnect the load. Turn on the

amplifier, connect temporarily (by means of a suitable 100KΩresistor

with a conductor wire) the positive terminal of C4 (CHA) or C5 (CHB) to

+15Vdc supply (CN6 pin 8): the PROTECT led must turn on in 3 seconds

approx., the output relay must switch off.

Remove the connection, wait until the leds turn off and after some sec-

onds repeat the check with -15Vdc supply (available on CN6 pin 11), the

led PROTECT must turn on again.

➭SLEW RATE CHECK:

Set the scope sensitivity to 10V/div. 1µS/div. and set the generator to

1KHz square wave mode. Check the output square wave rising and falling

edge slopes: both must be 20V/µS or more.

Advices

➭Check the channels one at time to determine which is right (note: if you

have a spare amplifier module that you know as right, use it).

➭If you have determinate that the problem is a short on a rail, you must

check the output transistors.

To determine which transistor devices are bad, use a soldering iron to lift

one leg of each emitter pin and measure the emitter-collector resistance

on each device. Unsolder and lift one leg of each base pin and check the

base-collector resistance of each transistor and replace any that measure

as a short.

➭If all the transistors are OK, unsolder and lift one leg of each diode and

check them.

➭Check the circuit board for open foil traces.

➭Use the Multimeter as Ohm-meter to check the resistors, particularly the

base and emitter resistors of damaged transistor.

➭Check all active components (transistor and diodes) on the signal path

before a faulted component.

➭Check all active components (transistor and diodes) connected to the

output net when a output transistor has been faulting.

➭If the input sinewave appears to be distorted during the negative cycle,

you can assume that the problem is located somewhere in the circuitry of

the positive rail.

If the positive cycle appears distorted, you can assume that the problem

is in the circuitry of the negative rail. Refer to the schematics.

Transistor Packages

TO92

BC337, BC550, BC560

1=Collector

2=Base

3=Emitter

2N5550, 2N5401

1=Emitter

2=Base

3=Collector

TO126

MJE340, MJE350, MJE802

1=Emitter

2=Collector

3=Base

TO220

TIP127, MJE15030, MJE15031

1=Base

2=Collector

3=Emitter

4=Collector TO264

MJE21193, MJE21194

1=Base

2=Collector

3=Emitter

BTW69

1=Kathode

2=Anode

3=Gate

55

55

5 ❏❏

❏❏

❏

GENERALMUSIC S.p.A. Italy

SCHEMATIC DIAGRAM ENERGY 2

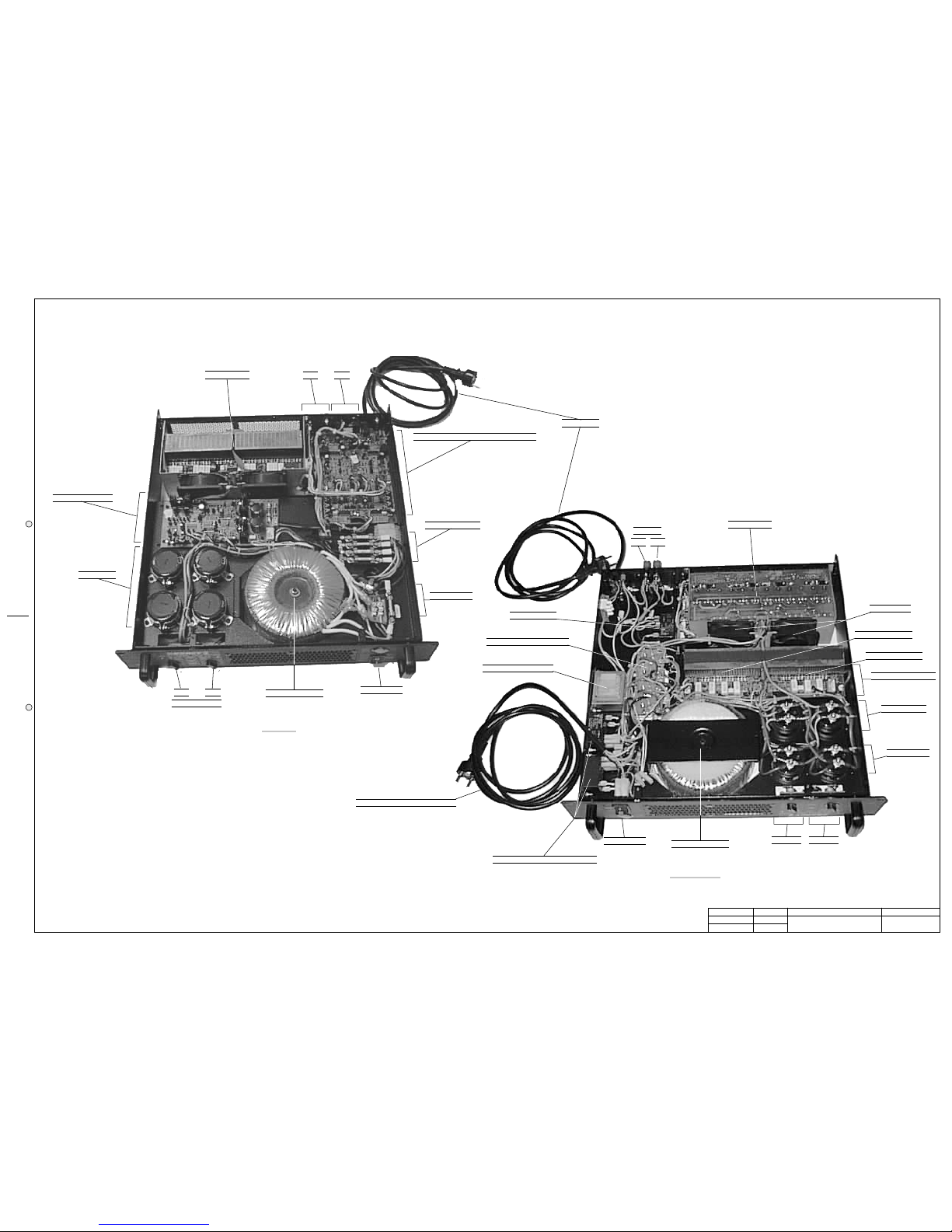

TOP & BOTTOM VIEWS

DRW: BOCCATO

APP: REV: 19-05-98

DISK: PART: 1/1CKD:

ALL RIGHTS ARE RESERVED, NO COPIES OR

REPRODUCE THIS DOCUMENT WITHOUT

WRITTEN CONSENT BY GENERALMUSIC.

TOP VIEW

CHA AMPLIFIER

BOTTOM VIEW

DWG:

CHA CHB

INPUTS, DRIVERS & SOA PROCESSORS BOARD

SECONDARY FUSES

PRIMARY FUSE

MAINS SWITCH

MAIN TRANSFORMER

CHA CHB

LEVEL CONTROLS

CAPACITORS

PROTECTIONS BOARD

MAINS CORD

OUTPUTS

CHACHB

CHB AMPLIFIER

COOLER FANS

POWER SUPPLY CHB

POWER SUPPLY CHA

POWER SUPPLY BOARD

NEGATIVE CAPs

POSITIVE CAPs

CHB CAPsCHA CAPs

MAIN TRANSFORMER

MAINS SWITCH

2

Ω

/4

Ω

PRIMARY TRANSFORMER RELAIS

SERVICES TRANSFORMER

CONTROLLED BRIDGE BOARDS

OUTPUTS RELAY

2ND MAINS CORD (FOR SERVICE ONLY)

❏ ❏

❏ ❏

❏ 66

66

6

GENERALMUSIC S.p.A. Italy

SCHEMATIC DIAGRAM ENERGY 2

MEASUREMENT

DRW: BOCCATO

APP: REV: 19-05-98

DISK: PART: 1/1CKD:

ALL RIGHTS ARE RESERVED, NO COPIES OR

REPRODUCE THIS DOCUMENT WITHOUT

WRITTEN CONSENT BY GENERALMUSIC.

DWG:

Frequency Response

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Output Power: 5W

Frequency Response

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Output Power: 500W

Distortion (THD+Noise) vs Frequency

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Output Power: 500W

Distortion (THD+Noise) vs Output Power

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Crosstalk

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Output Power: 500W

Signal to Noise Ratio

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Damping Factor

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

Output Power: 500W

CMRR

STEREO configuration

Both channels

Input level: 0dB

Load Impedance: 8Ω

GENERALMUSIC - AMPRESP &vs

-4.000

-3.500

-3.000

-2.500

-2.000

-1.500

-1.000

-.5000

0.0

.50000

1.0000

AMPL(dBr)

-50.0

-40.0

-30.0

-20.0

-10.0

0.0

10.00

20.00

30.00

40.00

50.00

PHASE(deg)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - AMPRESP &vs

-4.000

-3.500

-3.000

-2.500

-2.000

-1.500

-1.000

-.5000

0.0

.50000

1.0000

AMPL(dBr)

-50.0

-40.0

-30.0

-20.0

-10.0

0.0

10.00

20.00

30.00

40.00

50.00

PHASE(deg)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - THD-FREQ vs

0.005

0.010

0.1

1

THD+N(%)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - CROSSTLK vs

-140.0

-130.0

-120.0

-110.0

-100.0

-90.00

-80.00

-70.00

-60.00

-50.00

-40.00

-30.00

-20.00

-10.00

0.0

BANDPASS(dBr)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - NOISE vs

-140.0

-120.0

-100.0

-80.00

-60.00

-40.00

-20.00

0.0

BANDPASS(dBr)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - DAMPING vs

10

100

1k

RLOAD/R0(%)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - CMRR vs

-140.0

-130.0

-120.0

-110.0

-100.0

-90.00

-80.00

-70.00

-60.00

-50.00

-40.00

-30.00

-20.00

-10.00

0.0

BANDPASS(dBr)

10 100 1k 10k 50k

FREQ(Hz)

GENERALMUSIC - THD-PWR vs

0.005

0.010

0.1

1

THD+N(%)

110 100 1k

AMPL(W)

20KHz

1KHz

20Hz

77

77

7 ❏❏

❏❏

❏

❏ ❏

❏ ❏

❏ 88

88

8

99

99

9 ❏❏

❏❏

❏

❏ ❏

❏ ❏

❏ 1010

1010

10

1111

1111

11 ❏❏

❏❏

❏

❏ ❏

❏ ❏

❏ 1212

1212

12

Spare Part List

abbreviation explanation

(EU) = specify Europe version

(US) = specify U.S. version

Code Description

Accessories

277286 Owner's Manual

Assembly

778072 Mains & Outs Cables Assembly

778071 Cables Assembly

778048 Supply Cables Assembly

667671 Filter Front Panel

667624 Rear Panel

667623 Front Panel

667542 Bottom Cover

667541 Top Cover

667539 Chassis

657232 Level Knob

340186 Adhesive Cable Fixing

238072 Main Transformer 230Vac 2100W (EU)

238073 Main Transformer 115Vac 2100W (US)

237060 Service Transformer 230Vac 60W (EU)

237061 Service Transformer 115Vac 60W (US)

210249 Air Foam Filter

210216 Adhesive Rubber Foam 20x5mm (Specify mt)

210215 Adhesive Rubber Foam 10x1.9mm (Specify mt)

190224 Lateroid Air Redirector

190222 Lateroid Cover

177542 Handle

130285 Mains Cable (EU) (US)

110317 Relay 24V / 1 Switch no 30A 250V

110291 Power Switch

110120 Fuse Clip 6,3x32mm

110115 Fuse Clip 5x20mm

110038 T15A Fuse 6.3x32mm (US)

110004 T400mA Fuse 5x20mm (EU)

030895 22000u 20% 63V Electrolytic Capacitor

Controls & Display Board

768035 Controls & Display Board (Pcb#319045)

141060 * 12 Contacts Vert Male Connector

141059 * 9 Contacts Vert Male Connector

080734 * Led 2.5x5mm Rect Diff Red-Grn

080732 * Led 2.5x5mm Rect Diff Yellow

080731 * Led 2.5x5mm Rect Diff Red

074570 * 5K 31steps Linear Potentiometer

Protections Board

768077 Protections Board (Pcb#319024)

141060 * 12 Contacts Vert Male Connector

141059 * 9 Contacts Vert Male Connector

141058 * 6 Contacts Vert Male Connector

141056 * 3 Contacts Vert Male Connector

140068 * 3 Contacts Terminal Block

110305 * Relay 12V / 2 Switch 1A 250V

110119 * Fuse Clip 10A max (EU) (US)

110012 * T1.6A Fuse 5x20mm (EU)

100929 * TLP521-2 Dual Optocoupler

100921 * LM339 Quad Voltage Comparator

100060 * 7815 +15V 1A Voltage Regulator

100049 * 7915 -15V 1A Voltage Regulator

090920 * MJE802 TO126 Npn Darl Transistor

090558 * TIP127 TO220 Pnp Darlington Transistor

090200 * 2N5550 TO92 Npn Transistor

090194 * BC560 TO92 LN Pnp Transistor

090183 * BC550 TO92 LN Npn Transistor

090152 * BC337 TO92 Npn Transistor

080302 * 20V 1W 5% Zener Diode

080293 * 15V 1W 5% Zener Diode

080168 * W02M 1.5A Rectifier Diodes Bridge

080156 * 1N4002 1A 100V Rectifier Diode

080103 * 1N4148 100mA 75V Signal Diode

Inputs, Drivers & SOA Processor Board

768070 Inputs, Drivers & SOA Processor Board (Pcb#319059)

757942 * Manufacturer Analog Optoisolator

141184 * Hor Female XLR Socket (NC3FPRH Neutrik)

141060 * 12 Contacts Vert Male Connector

141059 * 9 Contacts Vert Male Connector

141056 * 3 Contacts Vert Male Connector

140220 * Jack Slim H F APJ678 Adimpex Socket

110299 * 4sw 2pos Horizontal Slider Switch

110255 * 6sw 3pos Vertical Slider Switch

100937 * MPQ6002 Quad Compl Pair Trans

100084 * TL074 Quad J-Fet Operational Amplifier

100019 * TL071 LN J-Fet Operational Amplifier

090917 * MJE350 TO126 Pnp Transistor

090916 * MJE340 TO126 Npn Transistor

090201 * 2N5401 TO92 Pnp Transistor

090200 * 2N5550 TO92 Npn Transistor

090194 * BC560 TO92 LN Pnp Transistor

090183 * BC550 TO92 LN Npn Transistor

080103 * 1N4148 100mA 75V Signal Diode

070241 * 100K 20% Horizontal Linear Trimmer

070121 * 1K 20% Horizontal Linear Trimmer

042725 * 100K 1/4W 1% Metalized Film Resistor

042685 * 47K5 1/4W 1% Metalized Film Resistor

042634 * 20K0 1/4W 1% Metalized Film Resistor

042628 * 16K5 1/4W 1% Metalized Film Resistor

042625 * 15K0 1/4W 1% Metalized Film Resistor

042616 * 13K7 1/4W 1% Metalized Film Resistor

042605 * 10K0 1/4W 1% Metalized Film Resistor

042586 * 7K50 1/4W 1% Metalized Film Resistor

042565 * 4K99 1/4W 1% Metalized Film Resistor

042564 * 4K75 1/4W 1% Metalized Film Resistor

042557 * 4K32 1/4W 1% Metalized Film Resistor

042515 * 2K05 1/4W 1% Metalized Film Resistor

042513 * 1K82 1/4W 1% Metalized Film Resistor

042485 * 1K00 1/4W 1% Metalized Film Resistor

010602 * 5p2-30pF N750 Ceramic Capacitor Trimmer

Controlled Bridge Assembly

727551 Quad Controlled Bridge Assembly (Pcb#319041 x4)

340078 * TO220 Insulated Bush

177587 * Heatsink

141061 * 3 Contacts Hor Male Connector

120857 * Vertical Male Faston 6.3mm

080608 * 36MB20A 35A 200V Rectifier Diode Bridge

080553 * BTW69 40A 200V TO3 Scr Diode

Power Supply Assembly

727547 Power Supply Assembly

768069 * Power Supply Board (Pcb#319054)

778074 ** Supply Cables Assembly

141059 ** 9 Contacts Vert Male Connector

141058 ** 6 Contacts Vert Male Connector

100929 ** TLP521-2 Dual Optocoupler

090201 ** 2N5401 TO92 Pnp Transistor

090200 ** 2N5550 TO92 Npn Transistor

090194 ** BC560 TO92 LN Pnp Transistor

080293 ** 15V 1W 5% Zener Diode

080158 ** 1N4006 1A 800V Rectifier Diode

080103 ** 1N4148 100mA 75V Signal Diode

060591 ** 8K2 2W 10% Resistor

060560 ** 4K7 1W 5% Resistor

060034 ** 0E15 5W 5% Wire Resistor

667545 * Heatsink

558006 * Quadruple MJL21194 Selection

090924 ** MJL21194 TO264 Npn Transistor

340079 * TO220 Mica Washer

340078 * TO220 Insulated Bush

090918 * MJE15030 TO220 Npn Transistor

090917 * MJE350 TO126 Pnp Transistor

090916 * MJE340 TO126 Npn Transistor

080821 * Ptc 90 PTH59F04BE222TS

080172 * MUR1510 15A 100V Ultrafast Recovery Diode

Amplifiers Assembly

737065 Dual Amplifiers Assembly with Fans

727548 * Fan Assembly

141055 ** Female Crimping Contact

141050 ** 3 Contacts Female Connector Housing

110363 ** 24Vdc (80x32cm) Fan

727546 * Amplifier Assembly

768068 ** Amplifier Board (Pcb#319053)

778073 *** Amplifier Cables Assembly

230578 *** 2u7H Vert Coil For Amplifier

230530 *** 1uh 10% 630ma Rf Coil

141065 *** 12 Contacts Hor Male Connector

141063 *** 6 Contacts Hor Male Connector

090194 *** BC560 TO92 LN Pnp Transistor

090183 *** BC550 TO92 LN Npn Transistor

080158 *** 1N4006 1A 800V Rectifier Diode

080156 *** 1N4002 1A 100V Rectifier Diode

080103 *** 1N4148 100mA 75V Signal Diode

070106 *** 470E 20% Horizontal Linear Trimmer

060174 *** 2E7 5W 10% Wire Resistor

060171 *** 2E2 2W 10% Resistor

042345 *** 75E0 1/4W 1% Metalized Film Resistor

667543 ** Heatsink

558005 ** Triple Selected Kit of MJL21194

090924 *** MJL21194 TO264 Npn Transistor

558004 ** Triple Selected Kit of MJL21193

090923 *** MJL21193 TO264 Pnp Transistor

340750 ** TO126 Mica Washer

340079 ** TO220 Mica Washer

340078 ** TO220 Insulated Bush

190225 ** Lateroid Air Redirector

100925 ** LM334 Adjustable Current Source TO92

090920 ** MJE802 TO126 Npn Darl Transistor

090919 ** MJE15031 TO220 Pnp Transistor

090918 ** MJE15030 TO220 Npn Transistor

090917 ** MJE350 TO126 Pnp Transistor

090916 ** MJE340 TO126 Npn Transistor

080821 ** Ptc 90 PTH59F04BE222TS

190223 * Lateroid Protection

Note:

Each spare part is single quantity unless otherwise specified.

Asterisk prefix explanation:

Omitted = First level spare part.

One asterisk = Second level, part of previous listed first level part.

Two asterisk = Third level, part of previous listed second level part.

Three asterisk = ............

Any request for not above mentioned part must encompass specific description including:

1) Model name,

2) Section name,

3) Module code,

4) Reference name,

5) Quantity number.

Table of contents