elem MTBT59-CC139L User manual

Original Instructions

TILLER THERMAL

MTBT59-CC139L

S44 M11 Y2018

This machine is delivered WITHOUT OIL OR GASOLINE in the engine

Read this manual carefull before putting the unit in operation

■1. Unit

The lightweight tiller is together with a high-efficient 4 strike engine. This design is ideal for tilling

close-planted crops with semi-hard soils. When in operation, it runs steady and is quite silent.

The tiller is made of a little special wearable steel so it provides for good cost-effectiveness. A

special shape of blades provides for thrifty and efficient tilling. The turning guide wheel keeps the

tiller operation easily. tart-up system responding to a button pressing (the tiller will run upon

pressing an operation button in rest (state) improves the labor safety.

◆Scope of deliver

1. carriage

2. left-hand handle(driving lever)

3. depth limiter

4. bracket and handle

5. wheel

6. right-hand handle (on/off, speed)

7. right-hand blade

8. left-hand blade

9. Left-hand Blade protector

10. Right mudguard

11. Left mudguard

12.right-hand Blade protector

■

2. General safet instructions

Prior to the initial use of the unit, the operating instructions should be read completely. If in

doubt with regard to connection and operation of the unit, consult the manufacturer (servicing

department).This machine shall always be used in this instructions laid down in the instruction

handbook.

FOLLOW THE INSTRUCTIONS BELOW CAREFULLY IN ORDER TO SECURE A HIGH DEGREE OF

SAFETY:

CAUTION!

1. Pa attention to the conditions of the area, which ou are working in. after the engine is

started; power machine will produce poisonous flue gas. The gas may be invisible and

odorless. Hence never work with the machine closed or poorly ventilated areas. Provide for

good lighting when cutting. Provide for stability when cutting in wet, snow or icy weather

conditions on slopes or rough ground.

2. Do not let an unauthorized person approach the machine. The visitors and viewers

primarily the children, the ill and infirm persons should not have any access to the working

area. Prevent other person from any contact with the machine.

3. Make provision for the tools storage. The machines not in current use should be kept in a

dry place, elevated or locked where practicable so that any access to them is prevented.

4. Alwa s use a correct tool for the job to be done. E.g. avoid using small tools and accessories

for work that should be actually done with a heavy tool. Use the tools only for the purposes

they were designed for.

5. Pa attention to adequate clothing. The clothing should fit the purpose and should not put

any limits to you when working.

6. Use personal protection equipment. Wear safety shoes with steel toes and antiskid or rough

sole.

7. Wear goggles. Object may be thrown against you.

8. Wear ear protectors. Wear personal protective equipment to protect your ears, such as ear

protectors.

9. Hand protection. Wear hard gloves-gloves of chrome tanned side leather give a good

protection.

10. Transport. The tiller should be always transported with the driving wheel in transport

position. Make sure that nobody is exposed to risk when the tiller is put out of services.

ecure the unit against tilting, damage and fuel leakage.

11. Remove the wrench etc. Any wrenches/spanners etc. must be removed before the tiller is

put on.

12. Be attentive an time. Mind what ou are doing. Use common sense. Do not use the tiller

when tired. Never work with the cursed when influence by alcohol, drugs or medicaments

affecting the concentration capability.

13. Refueling. Always switch the engine off before refueling. Open the tank closure carefully for

overpressure run out slowly and the fuel ejaculation be prevented. When working with the

tiller, the unit body temperature increases. Let the unit cool down before refueling.

Otherwise, the fuel could ignite and persons get burnt. Beware of overfilling the tank. If there

is a spill, remove it and clean the unit. After finishing the refueling, make sure the screwed

closure is tight to avoid loosening in result of vibrations.

14. Watch out for an damaged parts. Inspect the machine before use. Are any parts damaged?

Ask yourself seriously when detecting slight damage whether the machine will work perfectly

and safely despite that. Watch out for proper aligning and adjustment of any moving parts.

Do the parts fit one in another properly? Are the part damaged? Is everything installed as

appropriate? Are any other prerequisites of proper working in place? Damaged protective

devices etc. must be repaired or replaced by authorized entities unless the operation manual

expressly says otherwise. Any defective switches must be replaced at an authorized servicing

centre. Do not use the machine if it can’t be put on and off with the switch. When repairs are

necessary, kindly turn to your local servicing centre :

15. Switch the engine off before an adjustment and maintenance. That applies to the blades

replacement in the first place.

16. Use approved parts onl . Use only identical spare parts for maintenance and repairs.

Request advice of an authorized servicing centre for this purpose.

1) training

a) Read the instructions carefully. Be familiar with the controls and the proper use of the

equipment;

b) Never allow children or people unfamiliar with these instructions to use the machine.

Local regulations can restrict the age of the operator.

c) Never work while people, especially children, or pets are nearby;

d) Keep in mind that the operator or user is responsible for accidents or hazards occurring

to other people or their property.

2) Preparation

a) While working. Always wear substantial footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals;

b) Thoroughly inspect the area where the equipment is to be used and remove all objects

which can be thrown up by the machine;

c) WARNING – Petrol is highly flammable;

tore fuel in containers specifically designed for this purpose

-Refuel outdoors only and do not smoke while refueling;

-add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol

while the engine is running or when the engine is hot;

-If petrol is spilled, do not attempt to start the engine but move the machine away from

the area of spillage and avoid creating any source of ignition until petrol vapor has

dissipated;

-Replace all fuel tank and container caps securely;

d) Replace faulty silencers;

e) Before using, always visually inspect to see that the tools are not worn out or damaged.

Replace worn out or damaged elements and bolts in sets to preserve balance.

3) Operation

a) Do not operate the engine in a confined space where dangerous carbon monoxide fumes

can collect;

b) Work only in daylight or in good artificial light;

c) Always be sure of your footing on slopes;

d) Walk, never run with the machine;

e) For wheeled rotary machines, work across the slopes, never up and down;

f) Exercise extreme caution when changing direction on slopes;

g) Do not work on excessively steep slopes;

h) Use extreme caution when reversing or pulling the machine towards you;

i) Do not change the engine governor settings or over speed the engine;

j) tart the engine carefully according to manufacturer instructions and with feet well away

from the tool(s);

k) Do not put your hands or feet near or under rotating parts;

l) Never pick up or carry a machine while the engine is running;

m) top the engine:

-Whenever you leave the machine;

-Before refueling;

n) Reduce the throttle setting during engine shut down and, if the engine is provided with

A shut-off valve, turn the fuel off at the conclusion of working;

4) Maintenance and storage

a) Keep all nuts, bolts and screws tight to ensure the equipment is in safe working

condition;

b) Never store the equipment with petrol in the tank inside a building where fumes can

reach an open flame or spark;

c) Allow the engine to cool before storing in any enclosure;

d) To reduce the fire hazard, keep the engine, silencer, battery compartment and petrol

storage area free of vegetative material and excessive grease;

e) Replace worn or damaged parts for safety;

f) If the fuel tank has to be drained, this shall be done outdoors.

SYMBOLS

Denotes risk of personal

injury or damage to the

tool.

Read manual before use

Wear goggles and ear

defenders when using the

device.

Wearing of protective

shoes advised

Wear gloves

Engine exhaust contains

carbon monoxide, Never

operate the product in an

enclosed area!

No naked flame

No smoking

Flammable. Do not fill fuel

tank in an enclosed area

or while unit is running.

Allow engine to cool at

least 2 minutes before

re-fueling.

Risk of injury caused by

rotating machine parts!

Clutch handle released,

unit is running in idle.

Choke, cold start setting

Maximum motor

revolutions

Minimum motor

revolutions.

Add engine oil.

Hot! Do not touch exhust

system or engine until cool

Risk of injury due to flying

parts! Always maintain a

sufficient safety distance

Risk of projections.

There is a risk of flying

objects while using the

machine.

Clutch handle pulled, tine

turns

Motor off

When repairing, please

take out the spark plug.

Then repair according to

the operation manual.

EC accordance with

European standards of

safety enforcement

Stop the engine

before refueling

Guaranteed sound

power

◆2.1 Emergenc action

Apply the first aid adequate to the injury and get qualified medical assistance as quickly as

possible. Protect the injured person from more accidents and calm him/her down.

◆2.2 Assigned use

The unit is designed only for regular use in agriculture, forestry, and horticulture and area

treatment. The manufacturer should not be held liable for any personal and material losses

due to a failure to observe these rules.

◆2.3 Residual hazards and protective action

2.3.1 Mechanical residual hazards

Hazard description protective Residual hazards

Incision, cutting Rotating blades may

cause severe incisions

or cut a part of body

off.

Always wear protection

gloves when working with

the unit. Never reach in

when the unit is running

Catching, winding

up

Cords, wires or parts of

garments may be

caught by the spud and

pulled in.

Remove any foreign objects

from the land and keep

distant from the teeth and

wear tight-fitting clothes.

2.3.2 Electrical residual hazards

Hazard Description Protective Residual hazards

Direct electrical

contact

Contact with the ignition

plug when the engine is

running may result in an

electrical shock

Do not touch the plug

socket while the

engine is running

2.3.3 Thermal residual hazards

Hazard Description Protective Residual hazards

Bums, frost bites Contact with exhaust

may cause burns

2.3.4 Noise hazard

Hazard Description Protective Residual hazards

Hearing impairment Frequent or prolonged work

with unit without wearing ear

protectors may result in

hearing impairment

Wear ear

protectors

2.3.5 Vibration hazard

Hazard Description Protective Residual hazards

Entire body

vibration

Working with the unit for

a prolonged period may

affect human organism

due to the vibrations

Have regular breaks

2.3.6 Material and other substances hazards

Hazard Description Protective Residual hazards

Contact, breathing

in

Breathing in exhaust

gases may be hazardous

for health

The unit should be

used outdoors only

Fire or explosion The unit is used with

easily ignitable mixture

that may ignite in the

course of refueling

Don’t refuel near

open fire.

Do not smoke while

filling

2.3.7 Other hazards

Hazard Description Protective Residual hazards

Thrown objects or

splashed liquids

Thrown objects or soil

may cause injury.

Pay attention to the work

area free of any persons.

Wear personal protective

equipment

2.3.8 Disposal

Disposal instructions are given by pictographs on the unit or packaging. For meaning of

individual symbols refer to chapters on unit.

◆2.4 Operator requirements.

The operator shall read the instruction manual carefully before using the unit.

2.4.1 Qualification

No special qualification is required for use of the unit except for detailed direction by a

professional.

2.4.2 Minimum age

Only persons above 16 years of age are allowed to work with unit.

Exempted from the provision is the use of the juvenile trainees if they work in the course of

their professional training with an aim to obtain the skill under trainer supervision.

2.4.3 Training

Use of the unit requires adequate lesson by a professional or the use of the manual only.

pecial training is not required.

■3.Technical data

Engine design 4 strike OHV

Max. rotational speed

n

0

:3000 min

-1

Engine displacement

2,6 kW/139cm³

Working width

590 mm Max. – 360mm Min.

pud

4 x Φ26 cm

Forward run 1

Fuel/tank volume 1.5L

Volumes of lubricating oil tank 0.6L

SAE 10W40

tarting system Reverse starter

Guaranteed sound power level 93dB(A)

Gross weight

35 kg

(L

PA

) 77.3 dB(A) (L

WA

) 93 dB(A) K 3 dB(A)

ATTENTION !

The sound power pressure may exceed 85 dB(A), in this case

individual hearing protection must be worn.

Weighted root mean square acceleration according to relevant standard : 3.548 m/s² K = 1.5 m/s²

The declared vibration total value has been measured in accordance with a standard

test method and may be used for comparing one tool with another that the declared vibration

total value may also be used in a preliminary assessment of exposure.

A warning that the vibration emission during actual use of the power tool can differ

from the declared total value depending on the ways in which the tool is used and of the need to

identify safety measures to protect the operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts of the operating cycle such as the times

when the tool is switched off and when it is running idle in addition to the trigger time).

NOTE: This product is not intended for professional use.

■4.Tansportation and storage

●The unit is allowed to be transported with the engine off only.

●Clean the unit thoroughly before putting in on storage.

●tore the unit at a dry clean place.

■5.Assembl

tructural group 1

Delivery –contained

Parts and

accessories

Fig 1 – pos.1

Fig 1 – pos.4

tructural group 2

Required structural

groups

Delivered parts and

accessories

tructural group 1

Fig 1 – pos.6

tructural group 3

Required structural

groups

Delivered parts and

accessories

tructural group 2

Fig 1 – pos.5

tructural group 4

Required structural

groups

Delivered parts and

accessories

tructural group 3

Fig 1 – pos.2

Fig 1 – pos.7

tructural group 5

Required

structural groups

Delivered parts

and accessories

tructural group 4

Fig 1 – pos.3

Flg.8

Refueling

Use only regular leadless petrol

Explosion hazard!

Refuel outdoors only!

Never refuel with engine running or while it is

still hot!

Do not smoke and do rot handle open fire.

Engine oil filling

Use only oil type 15W40!

Use oil dip rod to check the filling status.

Avoid fuel or oil splashing so that soil

contamination is avoided. Use appropriate tools

for filling(funnel)

◆5.1 safet instructions for the first putting in operation

Always make sure that the screwed parts are tight as appropriate and use only the parts

included in the delivery.

◆5.2 procedure

Assemble separate parts in the correct order as shown. Make sure that structural parts

are arranged as shown in figures.

the unit is delivered without oil and fuel. Fill in the liquids according to specifications.

■6. OPERATION

Guiding wheel in work position

Put the wheel in pos. 1 for working.

CAUTION!

Transport the unit with the wheel in pos.2

The wheel can be adjusted with engine off

only!

Cutting height setting

hifting the depth limiter shall set up the

required depth of tilling. 5 different

positions are possible.

witching unit on/off

Put the lever on the chute (fig.11).pull the

starter cable evenly. The engine should

start up after 3-5 pulls. Put the lever at the

required speed and pull the driving lever

(fig 11) against the handle (fig.12).

Notice: if the engine is heated up, it is

possible to start up in the slow/fats

position.

With the driving lever tripped, the drive

will be off but the engines works on. The

engine may be switched off with the

switch in OFF position (fig.11).

When starting up the engine, the unit

should not be titled, only on the side

reverse to the operator if necessary for the

start.

◆6.1 OPERATOR SAFETY INSTRUCTION

●Do not use the machine until you have read the instruction manual carefully.

●Observe any safety instructions included in the manual.

●Be responsible to the others.

●The unit is provided a foot-operated brake than stops the blades within 3 seconds after

the drive lever tripping. Never attempt stooping the unit or tilting the unit with blades

still rotating. Wait for the blades to come stand still by themselves.

●If the blades get in contact with foreign objects stop the engine immediately and check

the unit with blades stopped for damage. Continue working with unit undamaged only.

●Walk while working, do not run.

●Always walk forwarder only. Never pull the unit walking backwards.

●When working on a slope, always work across, never down and up. Be particularly

carefully when changing direction.

●When travelling across no-grass areas and transferring the unit from the work area to

another one, the blades must not be operating.

●Always holding tighten the clutch which allow the machine to be handle by your two

hands .

◆6.2 STEP BY STEP INSTRUCTIONS

1. Fill in the fuel (see chapter assembly and first putting in operation

2. Clear any foreign objects from the land.

3. pud the land until the soil is sufficiently loose.

4. Clean the unit thoroughly after every use.

■7. TROUBLES-CAUSES-TROUBLESHOOTING

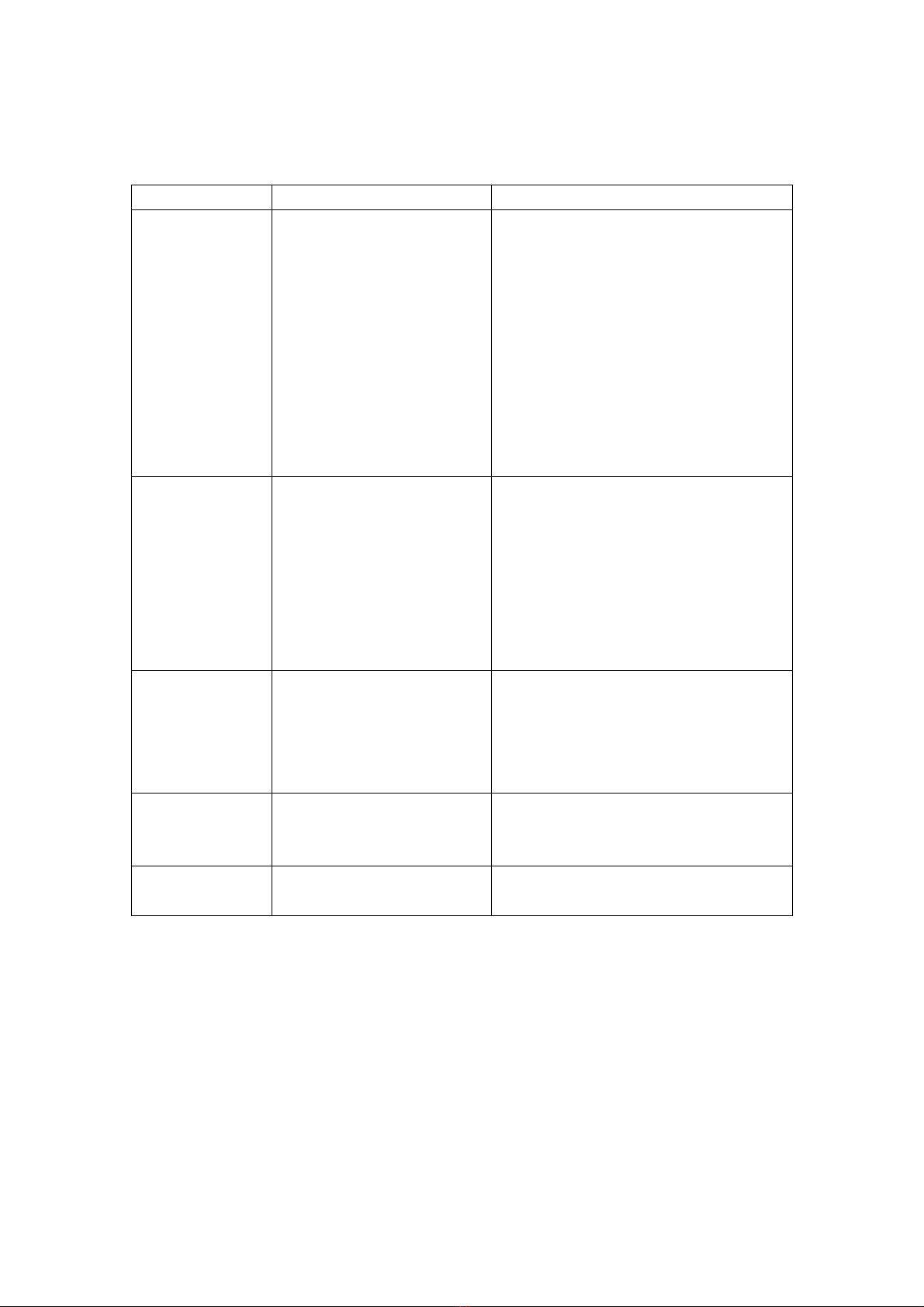

Trouble Cause Troubleshooting

Engine will not

start

1. Empty tank

2. fouled air filter

3. no ignition spark

4. flooded engine

1. fill in the tank, check the fuel in

carburetor, defecate the tank and

clean the hole in the lid with a needle

2. clean the air filter

3. clean the ignition plug or use a new

one, check the ignition cable, have the

ignition system checked in a servicing

shop

4. remove the plug, clean and wipe dry,

pull the starting cable several times

with the plug removed

Faltering engine 1. ignition cable detached

2. fuel piping clogged or

wrong fuel

3. blocked hole in the fuel

tank cover

4. water or dirt in fuel

system

5. fouled air fitter

1. push the plug, socket firmly on the

plug

2. clean fuel piping, use fresh/different

fuel replace the fuel tank cover

3. drain the fuel and refuel

4. clean the air filter

Engine often

switches off when

idling

1. too long ignition interval,

defective ignition plug

2. carburetor not set

correctly

3. fouled air filter

1. adjust/replace the ignition plug

2. set up the carburetor

Drive will not

work properly

1. check the drive lever

cable tension

2. drive does not work

1. adjust the cable tension if necessary

2. have the unit checked in a servicing

shop

Excessive

vibrations

1. loose lock screws 1. tighten the lock screws

■8. INSPECTIONS AND MAINTENANCE

◆8.1 INSPECTIONS AND MAINTENANCE SAFETY INSTRUCTIONS

The machine will serve as a sufficient aid only if maintained and care for appropriately.

Insufficient maintenance and care may result in accidents and injuries.

●Prior to an works on the unit, alwa s switch the engine off and pull the sparkle plug

socket out!

●Never use aggressive detergent for cleaning. That could result in damage or destruction

of the unit.

◆8.2 INSPECTION AND MAINTENANCE SCHEDULE

Time interval Description Other details if necessary

Before start of work Check the engine oil level

(see figure)

Check for any loosen parts

Every 25 operating hours Exchange the engine oil

Check the engine oil level

Clean the air filter (see

figure)

Remove remnants of grass

from rotation parts with a

brush or a blunt tool.

Wipe the body with a soft

cloth

When the dirt is hardened,

the unit may be cleaned with

soft cloth wetted in soapy

waters

Every 100 operating hours Check, clean or replace the

ignition sparkle plug.

SERVICE DEPARTMENT

_ Damaged switches must be replaced by our after-sales service department.

_ If replacing the power cord is necessary, it should be done by the manufacturer or his agent to

avoid a hazard.

After-sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product

as well as spare parts. Exploded views and information on spare parts can also be found

under:

www.eco-repa.com

ELEM GARDEN TECHNIC application service team will gladly answer questions concerning our

STORAGE

Risk of fire !

Store your Electric Hoe away from fuels, oils,

grease and gases.

_ Thoroughly clean the whole machine and its accessories.

_ Store it out of the reach of children, in a stable and secure position, in a cool and dry place, avoid too

high and too low temperatures.

_ Protect it from exposure to direct sunlight. Keep it in the dark, if possible.

_ Don’t keep it in plastic bags to avoid humidity build-up.

At the end of the season, perform a general inspection of the machine and remove any deposits

which may have accumulated. At the start of each season, ensure that you check the condition of the

machine. If repairs are necessary, please contact one of our customer service centers (see address on

warranty certificate).

GUARANTEE

Refer to the enclosed guarantee conditions for the terms and conditions of guarantee.

Made in China 2017

GB

Declaration of Conformity

We “ELEM GARDEN TECHNIC” hereby declare that the machine described below complies

with the relevant basic safety and health requirements of the EU Directives, both in its basic design and

construction as well as in the version put into circulation by us. This declaration shall cease to be valid if

the machine is modified without our prior approval.

Product:

TILLER THERMAL

Type: MTBT59-CC139L

SN : 2018.11 :001~396

Relevant EU Directives

2006/42/EC(MD) - 2014/30/EU(EMC)

2005/88/EC(NOISE) - 2010/26/EU(GAS)

Applied harmonized standards

EN 709 :1997/A4 :2009

AfPS GS 2014 :01 PAK

EN ISO 14982 :2009

EN ISO 3744 :1995

ISO 11094 :1991

Technical Data

Product: TILLER THERMAL

Type: MTBT59-CC139L

2,6 kW/139cm³

L

pA

: 77.3dB(A) K=3 dB(A)

L

WA

: 93 dB(A) K=3 dB(A)

3.548 m/s² K = 1.5 m/s²

ELEM GARDEN TECHNIC

81 rue de Gozée 6110 Montigny-le-Tilleul Belgique

Belgium, November 2018

Mr Joostens Pierre

Director

ELEM GARDEN TECHNIC, rue de Gozée 81,

6110 Montigny-le-Tilleul, Belgique

Tél : 0032 (0) 71 29 70 70

Fax : 0032 (0) 71 29 70 86

SN : 2018.11 :001~396

31.10.12611

Arrival date

: 21/01/2019

Production year :

2018

81, rue de Gozée

6110 Montigny-le-Tilleul

Belgique

Tél : 0032 71 29 70 70 Fax : 0032 71 29 70 86

Made in China

S.A.V

sav@eco-repa.com

Service Parts separated

32 / 71 / 29 . 70 . 83 32 / 71 / 29 . 70 . 86

Made in China 2018

Drawings, descriptions and photos are non-contractual and subject to change.

Table of contents