IE-IE NICHINO IE-101 User manual

CULTIVATOR

IE –101 中耕管理機

使用保養說明書

Operation and Maintenance Manual

IE-IE CORPORATION (www.ietw.com.tw) MADE IN TAIWAN

使用前請務必詳細閱讀本說明書

2012 年1月製

1

目錄Table of Contents

一.各部位名稱----------------------------- 3~4

Machine Structure

二.安裝步驟-------------------------------- 5~8

Set up

三.潤滑------------------------------------ 9~11

Lubrication

四.作業前檢查 ---------------------------------- 12

Check before operation

五.~ 八. 調整----------------------------- 13~16

Adjustment

九. 操作使用方法 ----------------------------- 17~18

Operation Remarks

十. 安全警示 / 警告標誌 ---------------------- 19~20

Safety Warning / warning signs

十一. 保養(長期放置) ----------------------------- 21

Maintenance (long-term storage)

十二. 隨機配件-------------------------------- 22

Accessories

十三. 選購配件-------------------------------- 22

Additional accessories purchase

(附件) 產品保固卡

(Annex) Warranty Card

2

二.各部位名稱 (變速桿側)

Machine Structure (Parts Location -

Gear shift side )

Moving wheel

行走輪

駐車腳架 Packing rack

覆土側蓋 Side Cover

汽油引擎 Gasoline engine

變速桿 Gear lever

尾輪調整把手

Guide Wheel

adjustment handle

加油頭 Accelerator

handle

尾輪 Guide

3

三.安裝步驟 Set up

1. 開箱前先裝入把手

Install the handle prior to open the container.

2. 裝入把手架後抬出機體

Move out of the machine after the handle installed

4

3. 將套管及輪胎裝入行軸

Fix the wheel and the connection pipe on the shaft of the

Gearbox

4. 再將尾輪裝入,順時針轉動旋把

Install the Guide Wheel, and turn the guide wheel handle

clockwise.

雙輪式樣 Twin wheel

(八角軸心 Octagonal shaft)

單輪式樣 Single wheel

(八角軸心 Octagonal shaft)

5

5.鎖緊呼吸管(GM291/GM301 專用套件)

Tighten the respiratory tube (GM291/GM301 Special kit)

6. 雙面耕犁裝卸方法(穿過膠板)

Install Two-sided plow (Through the plastic cover)

6

7. 裝入培土刀,注意旋回方向

Install the banking up blade, check the rotating direction.

8. 裝入耕耘刀,注意旋回方向

Install the Tillage blade, check the rotating direction.

9. 插入保險桿旋緊固定螺絲

Insert the protector and tighten the screw& Nut.

旋回方向

回方向

7

四.潤滑Lubrication

1. 引擎 Engine :#30 機油 engine oil

(1) 引擎潤滑油更換時機:第 1次使用 15 小時潤滑油更換 , 之後每操作 80 個

小時更換 1次。

Engine oil periodic change schedule:Initial change for the first 15 hrs

operation, after each 80 hrs operation, the engine oil must be changed。

(2) 更換方式 : 添加時機身放平 ,放鬆洩油孔螺絲使油完全漏掉後鎖上螺絲 ,

由注油孔注入機油 , 依油尺刻度為標準。

How to change: Place the cultivator on a level surface and hold it in an upright

position. Loose the oil drain screw to drain all the oil. Add the new oil from the

oil filler cap, and then check the suitable oil level on the dipstick.

2. 空氣濾清器(油式)內加注#30 機油至油杯標示線止 , 勿注入中心圓孔內 , 進入

汽缸。注意 : 潤滑油更換時空氣濾清器須一同清洗換油。

Air cleaner (oil type): #30 engine oil. Add the oil to the oil cup level mark. Do not

put the oil into the center hole(cylinder)。Caution: When changing the engine oil, Air

cleaner should be clean and oil change.

3. 行走部及耕耘部(變速箱) Run body and tillage part (Transmission) : #90齒輪油gearoil.

(1) 行走部及耘部潤滑油更換時機 :第1次使用 15 小時潤滑油更換 , 之後每操

作200 個小時更換 1次

Engine oil periodic change schedule for Run body and tillage part : Initial change

for the first 15 hrs operation, after each 200 hrs operation, the engine oil must

8

be changed.

(2) 更換方式 : 添加時機身放平 ,放鬆耕耘及行走部本體之洩油孔螺絲使油完

全漏掉後鎖上螺絲 , 由注油孔螺栓注入至探油窗 6分滿位置即可。

How to change: Place the cultivator on a level surface and hold it in an upright

position. Loose the oil drain screw on the Run body and tillage part to drain all

the oil. Add the new oil from the oil filer cap, and then check the suitable oil level

on the oil window to 60 percent full.

9

Belt side

Gear shift side

Filter oil cup enter hole

油孔

Oil filler cap

(dipstick)

Oil drain

screw(Engine)

Oil drain screw

Tillage part

Run body

Oil filler cap

Oil check window

油孔

變速桿側

油孔

皮帶側

卸油孔

洩油孔

(引擎)

引擎 柱油孔

(油尺)

注油孔

油孔

行走部本體

油孔

耕耘部本體

油孔

探油窗

油孔

濾清器油杯

油孔

10

五. 作業前檢查 Check before operation

1. 各部位螺絲 , 螺帽等有無鬆動現象

Check all part for loose screws and nuts.

2. 把手架有無鬆動現象

Check the handle bracket for any looseness.

3. 各潤滑部位是否依照指示適時加入潤滑油

Check if each Parts for lubrication in accordance with instructions.

4. 機械稍作運轉移動 , 檢查有無異常的聲音及異常發熱的地方

Start the engine and moving the machine to check for any abnormal noise and heat.

5. 作業刀具之刀口或左右邊必需配合軸心轉向否則無法作業

The edge or left and right sides of the blade should be coordinate with the rotational

direction of the axle , otherwise will not be able to operation.

11

六. 調整Adjustment

1. 把手高低調整 Handle height adjustment

把手可作上下五段高低調整 , 將高低調整握把壓入至定位銷分離狀態 , 依個人

使用狀況調至適當操作位置 , 再將握把放鬆即可定位固定

The adjustable handle provide 5 section height adjustment, press down the Handle

height adjustment lever until the adjusting pin detached. Adjustable the handle

height to a suitable operation position, release the Handle height adjustment lever

can lock this suitable position.

2. 把手轉向移位調整 Handle Rotate adjustment

把手座可作 260 度旋轉 , 10 段定位 , 依地形狀況調至合適角度操作 , 轉向時將

旋轉調整握把壓入至定位銷分離狀態旋轉至適當角度 , 再放鬆握把使其定位銷

與定位孔接合穩固

Handle base can be turning for horizontal 260 degree in 10- section height

adjustment, press down the Handle Rotate adjustment lever until the adjusting pin

detached. Adjustable into a suitable operation degree, release the Handle Rotate

adjustment lever can lock this suitable position.

定位 lock

把手旋轉調整離合握把

Handle rotate adjustment

lever

把手架高低調整離合握把

Handle height adjustment

lever

lock 定位

分離 Detach

Detach 分離

12

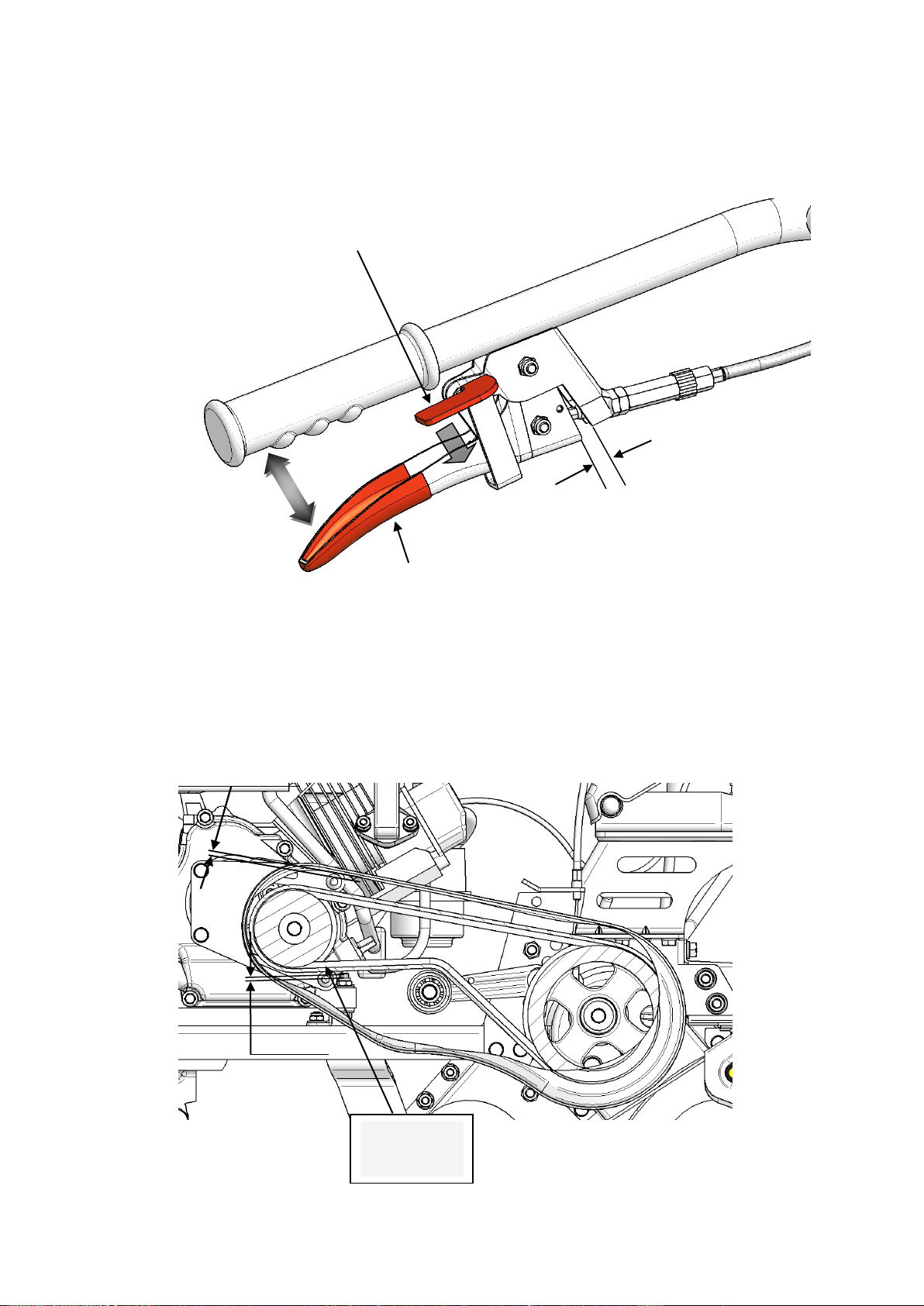

六.離合器調整 Clutch Adjustment

1. 當離合器握把放鬆時 , 使張力輪往上壓皮帶下方使皮帶壓緊產生傳動作用 , 如

圖示 A-3 引擎皮帶兩端皮帶呈平行狀態為最適當

When release the clutch lever , make the tension pulley turn upward to press the

bottom of the belt and then belt become tightly to produce transmission action .

As the Figure (A-3). The up and down of the belt should be parallel.

2. 當離合器握把壓緊時張力輪往下產生離的作用使傳動皮帶微接觸於皮帶調整滑

片上 , 如圖 A-4 所示 (離合握把放鬆須加壓握把 , 按下安全扣離合握把即可放

鬆)

When press or push the clutch handle, the tension pulley moves downward. And

then the belt is touch with the belt fastener lightly. As the Figure (A-4) (press the

clutch lever and push down the protector; the clutch lever can be released.)

3. 離合器導索之間隙必須預留約 8 ~ 15mm 避免張力輪無法壓緊皮帶產生皮帶打滑

磨損 , 如圖 A-3 所示

Keep 8 ~ 15mm gap for leading rope of the clutch wire to avoid the tension pulley

from unable tighten the belt and then sliding and wear away. As the Figure (A-3)

13

Fig

圖A-4

2~3mm2~3mm

2~3mm

離

引擎皮帶輪

Belt pulley

壓緊 ( 停止 )

Press (Stop)

放鬆 ( 傳動 )

Release (Transmission)

離合握把

Clutch lever

安全扣 Protector

圖A-3

Fig

8 ~ 15mm

14

八. 加油調整 Accelerator

加油推桿向右則引擎轉速高 , 輸出馬力 , 加油推桿向左則引擎轉速低 , 成待速狀

態, 加油座 , 加油索調整 , 須使引擎於低轉速下調整並使調速器(GOVERNOR ROD)

於低轉速時使可調整 , 如圖 A-5

Accelerator to the right for higher speed running, result in powerful operation;

Accelerator to the left for lower speed running, allow the engine in idle. When adjust the

accelerate base and wire, the engine and the governor should be at the low rotational

speed. As fig A-5

加油頭 Accelerator

高High speed

低Low speed

圖A-5

Fig

15

九. 操作使用方法 Operation Remarks

1. 行走部變速前進 2段, 後退 2段耕耘部刀具轉速 2段依作業適用選擇變速

The speed change for the Run Body has 2 forward and 2 reverse speed . The

rotational speed for the Till Part, total is 4 speeds. Depend on the operating condition

to select the speed

2. 引擎轉速之控制在把手架右側上的加油座推桿 , 向左側推為加速 , 向右側推減

速

Engine running speed can be adjust from an Accelerator which locate on the right

side of handle bracket. Accelerator to the right for higher speed running,;

Accelerator to the left for lower speed running.

3. 中耕寬度依作業需要可增減左 , 右兩側刀具 1節組最窄 22cm ,第2節連接 最寬

42cm (另有第 3節刀具組可供選配 , 耕作寬度提升至 61cm)

Tillage width can be adjusted in accordance with the operation, then add or

remove one section of blade(22cm) in the both on left and right side. The widest

blade width for second section is 42cm( 3rd section blade for option , Tillage width

can be increase to 61cm )

4. 耕作深度可調整尾輪高低來控制 , 尾輪調低可使耕作深度加深 , 尾輪調高耕作

深度愈淺 , 尾輪調整把手可旋轉微調耕作深度

Tillage depth can be adjusted via the height setting of the real wheel. Lower the real

wheel will deeper the Tillage depth;Raise the real wheel will decrease Tillage depth.

Guide Wheel adjustment handle can be turning for slightly adjusted the tillage depth.

16

5. 中耕或培土作業方式 : 將耕耘部裝上中耕刀 , 或培土刀 , 必須注意耕刀回旋

方向 (請參照三.安裝步驟 : 7 和8圖) , 將耕耘覆蓋 , 側蓋 , 塑膠擋泥板掀起 ,

依需要作落土點之調整 , 先裝上中耕刀將土翻鬆 , 拆下中耕刀裝上培土刀及培

土鐵輪 , 即可進行培土作業 , 若需要作單邊培土作業 , 請將左邊培土刀拆下裝

上單邊培土刀(刀架為紅色) , 右邊培土刀不必拆 , 使土噴向右邊,操作時人站在

把手方向 , 引擎在前面 , 請參照下圖 :

How to tillage or banking up: Install the tillage blade or banking up blade onto the

tillage part, carefully inspect the blade for correct rotating direction (Refer to 3.

Assembly; Fig 7 & 8). Depend on the operation requirement to adjust the open angle

of the rotary cover , side cover and muddy plate. Install the tillage blade first to

loosening the soil, and dissemble the tillage blade then install the banking up blade

and wheel for banking up operation. If just need to bank up single side, please

remove the left side of banking blade first, then load single banking blade(the rotary

coclor is red), keep the right side of blade to make the soil moving to right side.

Operator should stand near the handle, carefully follow the engine, Refer to the

following fig.

17

十. 安全警示 / 警告標誌

Safety Warning / warning signs

1. 作業前機器檢查 Check before operation :

檢查機器時 , 必須在引擎完全停止的安全狀況下檢查

Always check the machine while the engine is fully stopped to ensure a safety

situation.

2. 作業刀具的各部螺絲 , 螺帽必須確實鎖緊

Fully tighten each part of screw and nut for operation blade.

3. 作業中的安全事項 Safety check between operation

(1) 中耕機機體輕巧 , 轉速不高 , 扭力特別大 , 操作者不能輕忽作業安全

This cultivator with a compact body, lower engine running speed but higher

power torque, Each operator can not overlook the safety information

(2) 每次作業前檢查離合器之功效 , 離合器效果不佳時可調整導索或通知保修

人員

Check the performance of the clutch before operation. If the clutch

performance is poor, adjust the leading rope or call the mechanic.

(3) 操作者作業時 , 身體重心必須保持穩固

Each operator should keep the body center of gravity in a stable status when

18

operation.

(4) 操作者不可於刀具前進之前方操控作業 , 以確保人身安全(即嚴禁操作者以

後退行走方式操控作業) 若須使用後退檔時 , 先暫時停止刀具運轉 , 並降

低油門觀察後方及將障礙排除 , 確保後方安全無慮之後 , 再以低速檔小心

倒退(非必要時 , 勿使用後退檔)

For personal safety, the operator should not control and operation in front of

the blade when it move forward (It is strictly prohibit the way of walk back for

operation). If necessary for use of the backward speed, it should temporary stop

the blade, lower the accelerator then inspect backward and remove all the

barrier, operate the machine in lower speed after the backward direction is for

sure safety. (Unless it is necessary , do not use the reverse operation)

(5) 引擎運轉中若遇有故障或障礙需排除時 , 必須將引擎熄火再排除障礙 , 以

確保人身安全

During the engine operation, if there is any breakdown or obstacle need to

remove, should turn off the engine before the trouble shooting to protect the

operator’s safety.

(6) 引擎運轉中勿碰觸排氣筒 , 皮帶輪及任何轉動部位 , 配戴相關防護器具

Do not touch the exhaust pipe, belt pulley, and any rotary parts when the

engine is running; always wearing a suitable protection gear.

19

十一. 保養(長期放置)

Maintenance (long-term storage)

1. 各部清洗乾淨後 , 檢查各部位螺絲是否有鬆動 , 漏油 , 損壞

After cleaning all parts, to check if there is any looseness or oil leak or

damages for all parts bolts.

2. 本機易生銹部分 , 在使用後 , 清洗乾淨並必須塗抹防銹油或噴漆以防生

銹

For the easily rusted parts of the machine: after using the machine, should be

clean and wash and daub with the anti-rust oil or spray paint to prevent rust.

3. 將油箱燃料漏乾並將引擎發動至自行熄火為止(化油器及油管內均無燃料)

再將火星塞口處入機油於汽缸內 , 爾後拉引擎起動拉柄 , 使活塞往覆運

動十數次,再把火星塞鎖緊 , 並使活塞於汽缸內呈壓縮狀態

Drain away the fuel from the fuel tank and switch on the engine until the

engine stopped (no fuel in carburetor and oil pipe )and infuse the engine oil

into the cylinder from the spark plug cap and then pull the engine start handle

to move the piston back and forth for more than ten times , then lock the

spark plug to make the piston stay in compression condition in the cylinder.

Table of contents

Popular Tiller manuals by other brands

MTD

MTD 215-355AB2 Owner's operating service instruction manual

Black & Decker

Black & Decker GXC1000 manual

Troy-Bilt

Troy-Bilt Garden way 12215 owner's manual

Ardisam

Ardisam BENCHMARK 38248 owner's manual

MTD

MTD 340 Series Operator's manual

Brillion

Brillion HFC Series Assembly instructions operator's manual