Eleris EM303B User manual

User Manual

EM303B General Purpose Inverter

1

Preface

Thank you for purchasing EM303B series inverter.

Document No.: 31010032

Version No.:104

Issue Date: 11/2015

EM303B is a general purpose vector control inverter. An induction motor with the help of

EM303B canpossess fast speed response and torque control ability as a DC motor which

makes the motion control system stable, precise,and quick.

Main Features:

1. SVC (Sensorless vector control):Torque control accuracy: 5% rated torque. Speed

control accuracy: ±0.2% rated synchronous speed.

2. VVF (Vector decoupling based VF control): The steady performanceis the same as that

in SVC.

3. Wide speed regulation range, load capacity at low frequency: SVC/0.5Hz/150% rated

load, VVF/1.0Hz/150% rated load.

4. Optimized current and voltage protection algorithm ensures that motor can

accelerate/deceleratein 0.1S.

5. AVR function makes output voltage stable at grid voltage fluctuation.

6. Load disturbance compensation ensures failure-free operation of motor.

7. Auto-searching motor speed at restart smoothes thestart of motor without current

over-shoot.

8. 2 acceleration/deceleration modes: linear and S curve.

9. The performance and stability are improved significantly with dual- CPU.

It is the duty of any user to perform the appropriate, correct installation or configuration of

the optional parameters of the devices. Neither SINEE nor its distributors shall be responsible

or liable for misuse of the information contained herein or mismatching the inverter with the

motor.

In the interests of commitment to a policy of continuous development and improvement,

SINEE reserves the right to update the specification of the product or its performance, or the

content herein without notice.

www.eleris.ru

www.eleris.ru

User Manual

EM303B General Purpose Inverter

2

Contents

PREFACE ............................................................. 1

CONTENTS............................................................ 2

SAFETY INFORMATION ................................................. 4

SAFETY PRECAUTIONS ..................................................... 4

1OVERVIEW ........................................................... 8

1.1 EM303B MODEL LIST AND TECHNICAL SPECIFICATIONS......................... 8

1.2 DEFINITION OF EM303B OPERATION STATUS ................................ 10

1.3 EM303B OUTLOOK ................................................... 13

2INSTALLATION ...................................................... 14

2.1VERIFYING PRODUCT .................................................. 14

2.2 OVERALL AND INSTALLATION DIMENSIONS .................................. 15

2.3 CONSIDERATIONS OF INSTALLATION SITE.................................... 17

2.4 DIRECTION AND SPACE OF INSTALLATION ................................... 17

2.5 DISASSEMBLY AND ASSEMBLY OF KEYPAD .................................. 19

2.6 FLUSH MOUNTING .................................................... 21

3WIRING ............................................................. 22

3.1 CONNECTIONS TO PERIPHERALS .......................................... 22

3.2 WIRING MAIN CIRCUIT TERMINALS ....................................... 23

3.3 WIRING CONTROL CIRCUIT TERMINALS .................................... 31

3.4 EXTENDING KEYPAD WIRE .............................................. 39

3.5 WIRING CHECK....................................................... 40

4KEYPAD OPERATION ................................................. 41

4.1 TYPE AND FUNCTION OF KEYPAD ......................................... 41

4.2 LED KEYPAD OPERATION MODE ......................................... 42

5TRIAL OPERATION ................................................... 49

5.1 TRIAL OPERATION PROCEDURES .......................................... 49

5.2 TRIAL OPERATION PRECAUTIONS ......................................... 50

6PARAMETER TABLE .................................................. 52

6.1 FORMAT OF PARAMETER TABLES .......................................... 52

6.2 PARAMETER TABLE .................................................... 52

SECTION 1GENERAL PARAMETERS ........................................... 52

SECTION 2ADVANCED PARAMETERS.......................................... 66

7PARAMETER DESCRIPTION ........................................... 81

SECTION 1GENERAL PARAMETERS ........................................... 81

7.1 F0 GROUP:GENERAL PARAMETERS........................................ 81

7.2 F1 GROUP:MOTOR PARAMETERS ......................................... 92

7.3 F2 GROUP:INPUT/OUTPUT TERMINAL PARAMETERS ........................... 95

7.4 F3 GROUP:PRESET SPEED OPERATION PARAMETERS.......................... 105

7.5 F4 GROUP:GENERAL PARAMETERS OF PID................................. 110

7.6 F5 GROUP:GENERAL PARAMETERS OF VECTOR CONTROL...................... 116

7.7 C0 GROUP:PARAMETERS OF MONITORING FUNCTION ......................... 121

www.eleris.ruwww.eleris.ruwww.eleris.ru

www.eleris.ru

User Manual

EM303B General Purpose Inverter

3

SECTION 2ADVANCED PARAMETERS......................................... 122

7.8 F6 GROUP:SIMPLE PLC FUNCTION....................................... 122

7.9 F7 GROUP:ADVANCED PARAMETERS OF OPERATION .......................... 128

7.10 F8 GROUP:INPUT/OUTPUT BIAS ........................................ 133

7.11 F9 GROUP:SPEED SETTING OPTIONS..................................... 137

7.12 FA GROUP:ADVANCED PARAMETERS OF VECTOR CONTROL ................... 145

7.13 FC GROUP:PARAMETERS OF OPERATION CONTROL.......................... 146

7.14 FD GROUP:AUXILIARY PARAMETERS .................................... 155

7.15 FE GROUP:USER DEFINED TERMINAL FUNCTION PARAMETERS ................ 158

8AUTOTUNING MOTOR PARAMETERS ................................. 162

8.1AUTOTUNING MOTOR PARAMETERS ...................................... 162

8.2 PRECAUTIONS BEFORE AUTOTUNING ..................................... 162

8.3AUTOTUNING PROCEDURE ............................................. 163

9TROUBLESHOOTING ................................................ 164

9.1 FAULTS ............................................................ 164

REFERENCE OF LED CHARACTERS .......................................... 166

9.2 FAULT ANALYSIS..................................................... 167

10MAINTENANCE AND INSPECTION ................................... 170

10.1 MAINTENANCE AND INSPECTION ........................................ 170

10.2 DAILY INSPECTION .................................................. 170

10.3 PERIODIC MAINTENANCE ............................................. 170

10.4 PERIODIC MAINTENANCE AND REPLACEMENT OF PARTS ...................... 171

10.5 OUTLINE OF WARRANTY .............................................. 171

11ACCESSORIES ..................................................... 172

11.1 KEYPAD EXTENSION WIRE ............................................ 172

11.2 REMOTE CONTROL CASE.............................................. 172

11.3 BRAKING RESISTOR ................................................. 173

11.4 BRAKING UNIT ..................................................... 174

11.5 CONNECTING CABLE................................................. 174

11.6 CHASSIS FOR FLOOR MOUNTING ........................................ 174

11.7 EXTENDED COPPER BAR .............................................. 176

12MODBUS COMMUNICATION PROTOCOL.............................. 177

12.1APPLICATION SCOPE ................................................. 177

12.2 PHYSICAL INTERFACE ................................................ 177

12.3 PROTOCOL FORMAT ................................................. 177

12.4 EXPLANATION OF COMMAND .......................................... 177

12.5 DESCRIPTION OF PROTOCOL FORMAT .................................... 179

12.6 DESCRIPTION OF CONTROL COMMAND ................................... 182

12.7 EXAMPLE ......................................................... 183

12.8 TROUBLESHOOTING OF COMMON COMMUNICATION .......................... 184

www.eleris.ru

User Manual

EM303B General Purpose Inverter

4

Safety Information

Danger: The addition of this symbol to a Danger or Warning safety label

indicates that an electrical hazard exists, which will result in personal injury if

the instructions are not followed.

Caution: This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this symbol

to avoid possible injury or a risk of damage to the products or other devices.

Safety Precautions

Before Installation

Danger

1. Do not install the product if the package is with water, or component is missing or

broken.

2. Do not install the product if the label on the package is not identical to that on the

inverter.

Danger

1. Be careful of carrying or transportation. Risk of devices damage.

2. Do not use damaged product or the inverters missing component. Risk of injury.

3. Do not touch the parts of control system with bare hands. Risk of ESD hazard.

Installation:

Danger

1. Installation base shall be metal or other non-flammable material. Risk of fire.

2. Do not unscrew the fixing bolts, especially the bolts with red mark.

Caution

1. Do not leave cable strips or screws in the inverter. Risk of inverter damage.

2. Install the product at the place with less vibration and no direct sunlight.

3. Consider the installation space for cooling purpose when the inverter is installed in a

cabinet.

www.eleris.ru

User Manual

EM303B General Purpose Inverter

5

Wiring:

Danger

1.Wiring must be performed by authorized and qualified personnel. Risk of danger.

2.Circuit-breaker should be installed between inverter and the mains. Risk of fire.

3.Be sure that the power supply is off before wiring, and ground inverter as per standard

wiring. Risk of electrical hazard.

4.Grounding terminal must be grounded. Risk of electrical hazard and fire.

5.Dual keypad is not recommended. Risk of unexpected danger.

Caution

1.Never connect input power supply cable to output terminals U, V, and W of inverter. Pay

attention to the terminal symbols, connect them correctly. Risk of inverter damage.

2.Be sure that the wiring meets EMC requirements and local safety standard. Cables

should be in recommended sizes. Risk of accident.

3.Do not connect braking resistor to DC bus terminal & . Risk of fire.

4.Tighten terminals with screw drivers of specified torque. Risk of fire.

5.Do not connect phase-shifting capacitor and LC/RC noise filter to output circuits.

6.Do not connect the solenoid switch and electromagnetic contactor to output circuits.

Otherwise, it will trigger overcurrent protection, or damage inverter.

7.Do not disconnect internal wires of inverter. Risk of inverter damage.

Before Power-on

Caution

1. Verify that the input voltage is identical to the rated voltage of product, correct wiring of

input terminals R, S, and T and output terminals U, V, and W, wiring of inverter and its

peripheral circuits, and all wires should be in good connection. Risk of inverter damage.

2. Never perform voltage withstanding test on inverter, it has been done at ex-works. Risk

of accident.

Danger

1. Inverter shall be power-on only after the front cover is assembled. Risk of electrical

hazard.

2. Wiring of all peripherals should abide by the guide of this manual. Risk of accident.

www.eleris.ru

User Manual

EM303B General Purpose Inverter

6

After Power-on

Danger

1. Do not touch the inverter and its peripheral circuits with wet hands. Rick of electrical

hazard.

2. Do not touch any input/output terminals of inverter with bare hands. Rick of electrical

hazard.

3. After power is on at the first time, inverter will detect external circuit automatically.

Meanwhile, do not touch wiring terminals U, V, and W of inverter, or wiring terminal of

motor with bare hands. Rick of electrical hazard.

Danger

1. If autotuning is required, be careful of personal injury when motor is running. Risk of

accident.

2. Do not change the defaults of parameters. Risk of devices damage.

Trial Operation

Danger

1. Only after the front cover is installed, power can be turned on. Never take off the front

cover when power is on.

An electric shock may occur.

2. Do not come close to the machine at power failure if fault reset function is active. The

inverter will restart automatically when power is on.

An injury may occur.

3. Install an emergency switch for a quick brake in case of abnormal conditions. (

STOP

RESET

is

only enabled in keypad control mode.)

An injury may occur.

Caution

1. Never touch braking resistor. It will be very hot and with high-voltage when running.

Otherwise, an electric shock and a burn injury may occur.

2. Reconfirm the motor and machine are within the applicable ranges before starting

operation.

Otherwise, an injury may occur.

3. Do not check signals while the inverter is running.

Otherwise, the inverter will be damaged.

4. Be careful when editing inverter settings. The inverter is in factory default.

Otherwise, the inverter will be damaged.

User Manual

EM303B General Purpose Inverter

7

During Operation

Danger

1. Do not touch cooling fans, heat sink, metal panel, or discharge resistor with bare hands.

Risk of burning.

2. Non-professionals shall not detect signals during operation. Risk of personal injury or

device damage.

Caution

1. Prevent any foreign items from being left in the devices during operation. Risk of device

damage.

2. Do not control start/stop of inverter by ON/OFF of contactor. Risk of device damage.

Maintenance

Danger

1. Maintain and inspect devices after power is off. Risk of electric hazard.

2. Maintain and inspect inverter only after the voltage is lower than DC 36V between DC

bus terminals & , and power is off for 5 minutes. The residual charge on capacitor

may cause personal injury.

3. Maintenance and inspection can only be performed by professionals. Risk of personal

injury.

4. Parameter setting is required if inverter has been replaced. Plug-in& plug-out should be

performed after power-off.

User Manual

EM303B General Purpose Inverter

8

1Overview

1.1 EM303B Model List and Technical Specifications

Rated voltage: 3-phase, 380VAC

Applicable motor: 3-phase induction motor, power range: 0.75~400kW.

Output voltage: 3-phase, from 0 to Usupply.

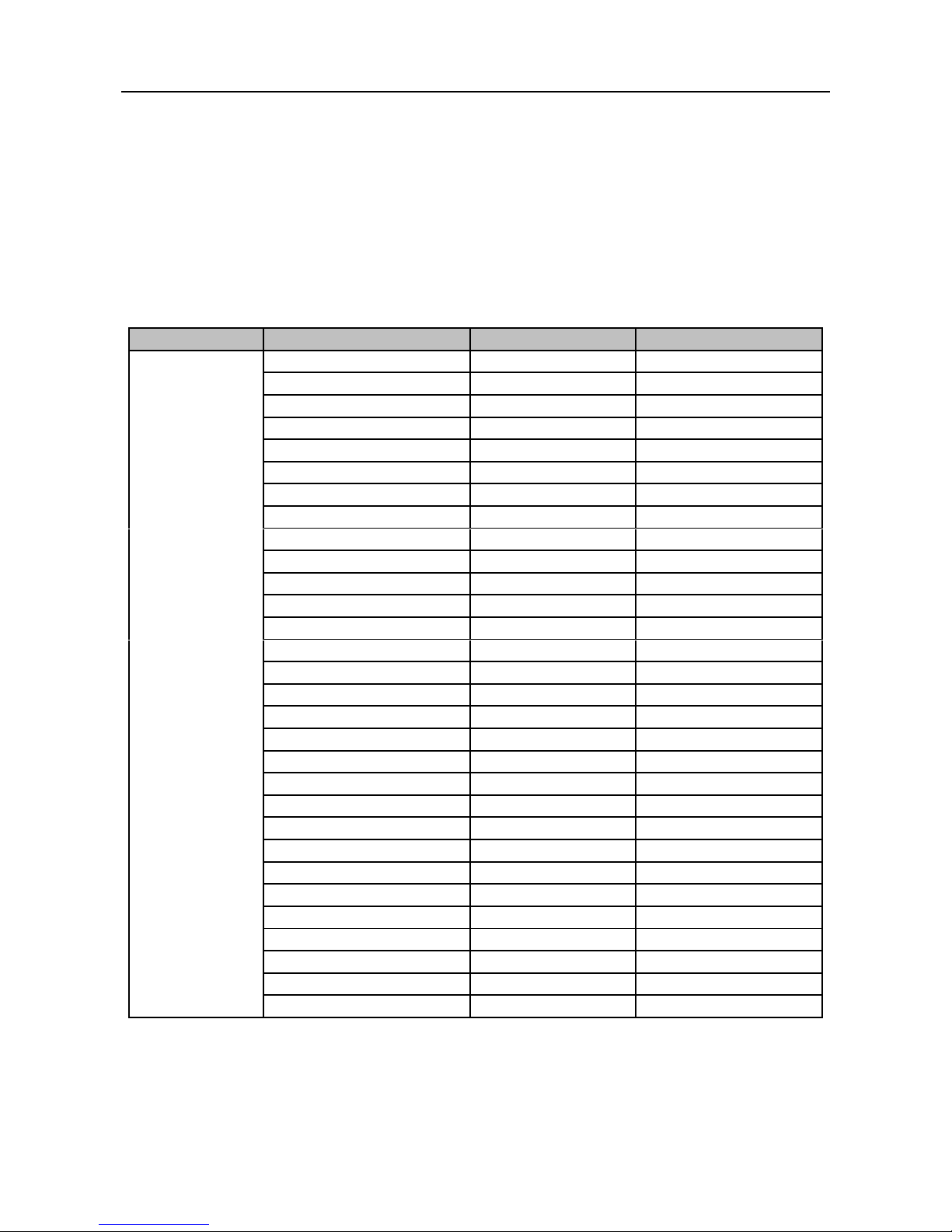

1.1.1 EM303B Model and Rated Output Current

Table 1-1 Model List of EM303B

Rated Voltage

Model No.

Motor Power(kW)

Rated Output Current(A)

3-phase,

380VAC

±20%

EM303B-0R7G/1R1P-3B

0.75/1.1

2.8/3.7

EM303B-1R1G/1R5P-3B

1.1/1.5

3.7/4.8

EM303B-1R5G/2R2P-3B

1.5/2.2

4.8/6.2

EM303B-2R2G/3R0P-3B

2.2/3.0

6.2/8.0

EM303B-3R0G/4R0P-3B

3.0/4.0

8.0/10.0

EM303B-4R0G/5R5P-3B

4.0/5.5

10.0/13

EM303B-5R5G/7R5P-3B

5.5/7.5

13/17

EM303B-7R5G/9R0P-3B

7.5/9.0

17/20

EM303B-9R0G/011P-3B

9.0/11

20/26

EM303B-011G/015P-3B

11/15

26/34

EM303B-015G/018P-3B

15/18.5

34/41

EM303B-018G/022P-3

18.5/22

41/48

EM303B-022G/030P-3

22/30

48/60

EM303B-030G/037P-3

30/37

60/75

EM303B-037G/045P-3

37/45

75/90

EM303B-045G/055P-3

45/55

90/115

EM303B-055G/075P-3

55/75

115/150

EM303B-075G/090P-3

75/90

150/180

EM303B-090G/110P-3

90/110

180/220

EM303B-110G/132P-3

110/132

220/265

EM303B-132G/160P-3

132/160

265/310

EM303B-160G/185P-3

160/185

310/360

EM303B-185G/200P-3

185/200

360/380

EM303B-200G/220P-3

200/220

380/420

EM303B-220G/250P-3

220/250

420/470

EM303B-250G/280P-3

250/280

470/530

EM303B-280G/315P-3

280/315

530/600

EM303B-315G/355P-3

315/355

600/660

EM303B-355G/400P-3

355/400

660/740

EM303B-400G/450P-3

400/450

740/820

Remarks:

EM303B is an integrated model with G (fixed torque) and P (square torque) in one. The data

listed above is of Model G. When applied to square torque like blower, water pump and etc.,

the power ratings of applicable motor can be one grade higher. See inverter’s nameplate for

details.

User Manual

EM303B General Purpose Inverter

9

1.1.2 EM303B Technical Specifications

Table 1-2 EM303B Technical specifications

Items

Specifications

Input

Rated Voltage

3-phase 380VAC±20%, 50~60Hz±5%,

voltage imbalance rate <3%

Output

Output Voltage

3-phase, from 0 to Usupply.

Rated Output Current

100% rated current non-

stop output

Max. Overload Current

Model G: 150% rated current for 1 minutes, 180% rated

current for 10 seconds

Model P: 120% rated current for 1 minutes, 150% rated

current for 10 seconds

Basic

Control

Functions

Control Mode

V/F, SVC0, SVC1

Input Mode

Frequency (Speed) input, torque input

Start/Stop Control Mode

Keypad, control terminals (2-wire sequence, 3-wire

sequence), RS485

Frequency Control Range

0.00~600.00Hz

Input Frequency Resolution

Numeric input: 0.01Hz, analog input: 0.1% of maximum

frequency

Governor Deflection

1:50(V/F), 1:100(SVC)

Speed Control Accuracy

±0.2% rated synchronous speed

Acceleration/Deceleration Time

0.01~600.00 seconds/minutes

V/F Features

Rated output voltage: 20%~100% adjustable

Frequency base :20Hz~600Hz adjustable

Torque Boost

Automatic torque boost, fixed torque boost curve,

customer defined V/F curve scaling

Start Torque

150%/1Hz(V/F),150%/0.5Hz(SVC)

Torque Control Accuracy

±5% rated torque (SVC1)

AVR

AVR is active while output voltage remains unchanged if

input voltage is varying.

Automatic Current Limit

Automatically limit output current, avoid tripping

overcurrent

frequently

DC Brake

Brake frequency:0.1~60Hz, brake time:0~30S,

brake current:0~150% rated current

Signal Input Source

Communication, analog voltage, analog current, preset

speed, simple PLC and their combinations

Special

Function

Control

Textile Wobbulation

Achieve textile wobbulation functions like wobbulation

range, time and jump

Function of

Input and

Output

Reference Power Supply

10V/20mA

Terminal Control Power Supply

24V/150mA

Numeric Input Terminals

7 programmable numeric input terminals

Analog Input Terminals

4 analog inputs:2 voltage inputs (0~10V), and 2 current

inputs(0~20mA)

Numeric Output Terminals

2 OC outputs and 1 relay output are programmable.

Maximum output current of OC: 50mA. Relay contact

capacity: 250VAC/3A or 30VDC/1A. When relay acts,

EA-EC is on, and EB-EC is off.

Analog output Terminals

2 programmable analog output terminals can output 0~10V

or 0~20mA

Keypad

Display

LED

Human interactions with displays and control actuators

Parameter Copy

Upload and download parameter information of the

inverter, copy parameters rapidly.

Protections

Protections

Short circuit, overcurrent, overload, overvoltage,

undervoltage, phase loss, overheating, external fault, and

etc.

Application

Conditions

Installation Site

Indoor, with altitude less than 1000 meters, free from dust,

corrosive gas, and direct sunlight

Ambient Temperature

-10℃~+40℃. In the temperature range +40 °C…+50 °C,

the rated output current is decreased by 1% for every

additional 1 °C. 20%~90%RH (no condensation)

Vibration

<0.5g

Storage Temperature

-25℃~+65℃

Installation Method

Wall mounting, floor mounting, flush mounting

Degree of Protection

IP20

Cooling Method

Forced air cooling

www.eleris.ru

User Manual

EM303B General Purpose Inverter

10

1.2 Definition of EM303B Operation Status

1.2.1 Operation Status of Inverter

Parameters setting status

After power is on, inverter finishes initialization and enters standby status without fault

or start-up command. Meanwhile, it does not output.

Normal running status

After receiving active start command through keypad, control terminal or RS485, the

inverter drives motor in accordance with the requirements of setting input.

JOG running status

Set by keypad, external terminal or RS485 to make motor run as per JOG input speed.

JOG stop status

Refer to the process that the output frequency drops to zero in JOG deceleration time

after JOG running command is not active.

Autotuning status

Set by keypad to autotune motor’s parameters in stationary or rotational autotuning.

Stop status

Refer to the process that the output frequency drops to zero in given deceleration time

after running command is not active.

Fault status

Status of inverter at protections, all kinds of faults and failures.

1.2.2 Control Modes of Inverter

The control modes of inverter refer to that the inverter controls motor rotation as per required

speed and torque with open loop or close-loop control mode. The control modes include:

General open loop space vector control——V/F control

Applicable to the applications of low speed changes and low speed stability accuracy

demand, and meet needs of most ofAC motor drives.

SVC 0—— Open-loop vector control without PG feedback

Only estimate speed in real-time, but no feedback control. Output current is under

real-time close-loop control, output of motor reaches 150% of rated torque at 0.5Hz, and

inverter automatically traces load variables and limit output current to make it not exceed

the maximum value. Even if there is sudden load change, quick acceleration or

deceleration, inverter will not trip overcurrent, short-circuit, and etc., and keep high

performance and reliability.

SVC1—— Torque control(Close-loop vector control without PG feedback)

Not only estimate speed in real-time, but also conduct feedback control. Speed and

current are under real-time close-loop control. Not only speed control but also torque

control can be realized. A regular AC induction motor can perform as an AC variable

speed motor and an AC torque motor by adopting this control mode. It is a genuine

sensorless vector control.

User Manual

EM303B General Purpose Inverter

11

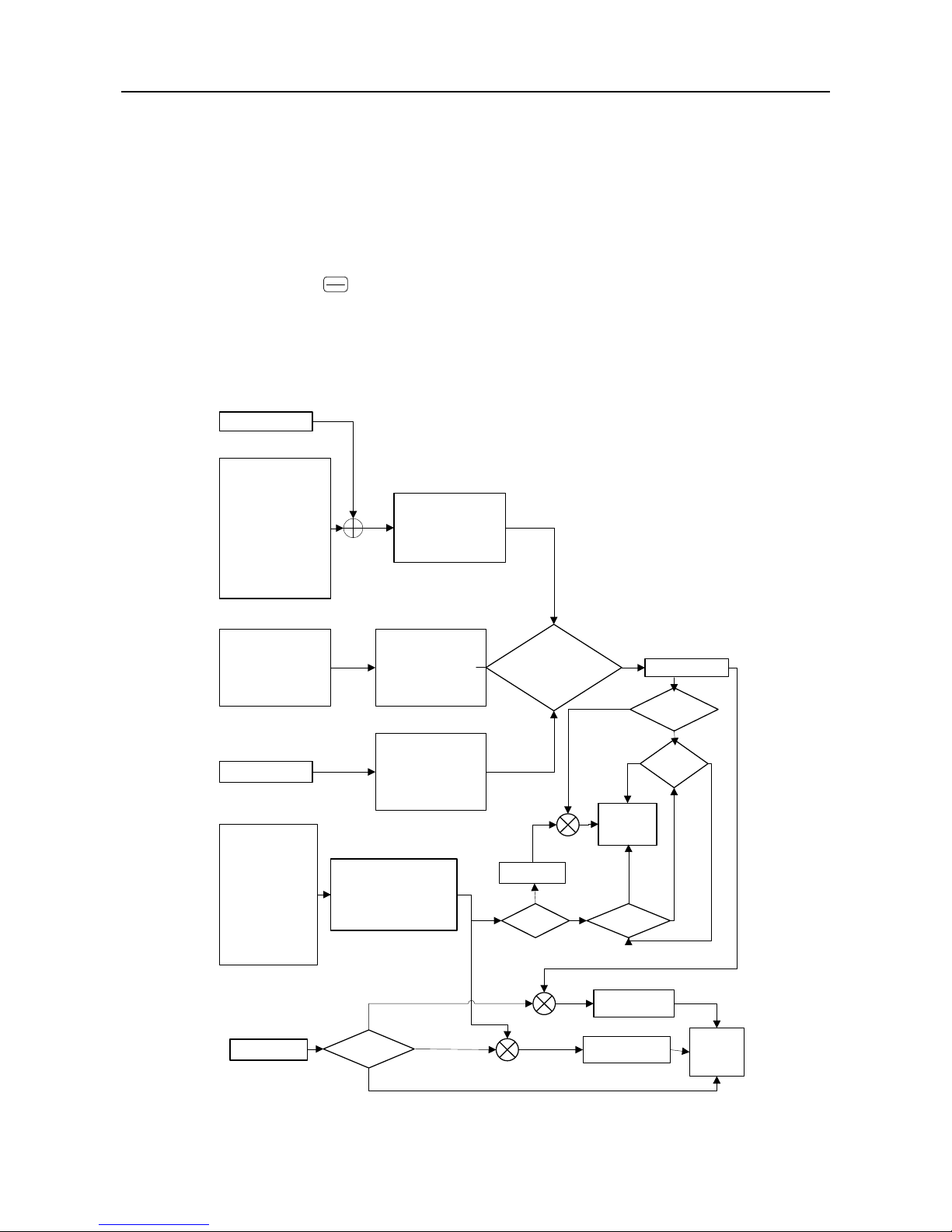

1.2.3 Setting Modes of Inverter

The setting mode of inverter refers to that what kind of physical quantity inverter is taken as

control object when driving motor.

Speed setting mode is to take motor speed as the control object

Torque setting mode is to take motor torque as the control object.

Set through various and flexible methods such as numeric setting, analog voltage, and analog

current or other mathematical combinations. Jog speed setting mode is prior to other setting

modes, i.e. when pressing

JOG

+/-

on keypad or turning control terminals FJOG and RJOG on, no

matter what the present setting mode is, the inverter will automatically switch to jog speed

setting, or the combination of jog speed+primary speed or jog speed+auxiliary speed setting .

See Figure 1-1 and Figure 1-2 for the details of all speed setting modes of EM303B.

F9-04

F9-05

Prior

F9-08: the hundreds place

F0-06

F0-11

F9-08: the ones place

F9-08: the tens place

Regular

Speed

Setting

Mode

Preset Speed1

~Preset Speed 15

0: Primary Numeric Frequency

1: VP Keypad Potentiometer

2: VS

3: IS

4: Not used

5: K3*VS+K4*IS

6: K3*VS+K5*VF

7: K4*IS+K6*IF

8: MAX{K3*VS,K5*VF}

9: MAX{K4*IS,K6*IF}

10:

K1*VP+K2*(K3*VS+K4*IS+

K5*VF+K6*IF-K8*5V)

0: Auxiliary Numeric Frequency

Setting

1: VP Keypad Potentiometer

2: VS

3: IS

4: Not Used

5: K3*VS+K4*IS

6: K3*VS+K5*VF

7: K4*IS+K6*IF

8: MAX{K3*VS,K5*VF}

9: MAX{K4*IS,K6*IF}

10:

K1*VP+K2*(K3*VS+K4*IS+K

5*VF+K6*IF-K8*5V)

0: Program running

1: Wobbulation Running

2: Stepping mode0

3: Stepping mode1

4: Stepping mode2

5: Stepping mode3

6: Stepping mode4

0: Present Setting Value

1: VS*Present Setting Value

2: VF*Present Setting Value

3: IS*Present Setting Value

4: IF*Present Setting Value

0: Present Active Setting Value

1: VS*Present Active Setting Value

2: VF*Present Active Setting Value

3: IS*Present Active Setting Value

4: IF*Present Active Setting Value

0: Present Setting Value

1: VS*Present Setting Value

2: VF*Present Setting Value

3: IS*Present Setting Value

4: IF*Present Setting Value

Jog Speed +

Auxiliary Speed Setting

Jog Speed +

Primary Speed Setting

Jog

Speed

Setting

Result of Process PID

Operation

Regular speed

setting mode is

disabled when

preset speed is

enabled.

Jog Running

Setting Frequency ++

++

F9-08 sets analog signals(VS/VF/IS/IF/VP)

*Speed setting value.

The analog signals here stand for:

Analog signal voltage/10*100%

Analog signal current/20*100%

OR

0: Present Setting Value

1: VS*Present Setting Value

2: VF*Present Setting Value

3: IS*Present Setting Value

4: IF*Present Setting Value

5: Auxilary Setting*Present

Setting Value

F9-08: the thousands place

=0

F0-26

+

Primary Speed Setting

0:Positive setting

1:Negative setting

Integral

Speed

Setting

F9-03:

the hundreds

place

F3-00~F3-14

F0-07 is the

setting value of

primary numeric

frequency.

F9-03:

The ones place=2

F9-03: The

ones place=2 F9-03:

The ones place =1

F9-03:

The ones

place=0

+

YES

NO

YES

NO

YES

NO

YES

NO

0: Regular Speed Setting

1: Special Speed Setting

2:Process PID Setting

Setting value of

F9-03 tens place =2

=1

F9-06 is the setting

value of auxiliary

numeric frequency.

Special

Speed

Setting

Mode

Auxiliary

Speed

Setting

Mode

Figure 1-1 Speed Setting Modes

User Manual

EM303B General Purpose Inverter

12

0:Present Setting Value

1:VS*Present Setting Value

2:VF*Present Setting Value

3:IS*Present Setting Value

4:IF*Present Setting Value

F5-11

F5-12 is the setting value of primary numeric torque.

FA-06: the ones place

Torque Setting

0: Primary Numeric Torque Setting

1: VP Keypad Potentiometer

2:VS

3:IS

4:VF

5:IF

6:Not used

7: K1*VP+K2*(K3*VS+K4*IS+

K5*VF+K6*IF-K8*5V)

FA-06 sets analog signals

(VS/VF/IS/IF/VP)*torque setting value.

The analog signals here stand for:

Analog signal voltage/10*100%

Analog signal current/20*100%

Figure 1-2 Torque Setting Mode

1.2.4 Start/Stop Control Mode of Inverter

The start/stop control mode of inverter refers to the modes to start/stop control of inverter.

There are 3 control modes: keypad control mode, terminal control mode, and RS485

communication control mode. Terminal control mode is categorized as 2-wire sequence, and

3-wire sequence. See Figure 1-3 for the control logic of terminal control mode.

24V

PLC

RUN

Xi

COM

F/R

K1

K2

Run

Command

K2

K1

0 0

0 1

1 0

11

Reverse

Forward

Stop

Stop

24V

PLC

RUN

Xi

COM

F/R

K1

K2

Run

Command

K2

K1

0 0

0 1

1 0

11

Stop

Forward

Reverse

Stop

0: On 1:Off 0:On 1:Off

(a) 2-wire sequence 0 (F0-05=0) (b) 2-wire sequence 1 (F0-05=1)

Forward

Button

RUN

Stop

Button

24V

PLC

RUN

Xi

COM

F/R

Run

Button

RUN

Xi

F/R

1

0

Stop

Button

Forward

Reverse

0: On 1: Off

( c ) 3-wire sequence 0 (F0-05=2) (d) 3-wire sequence 1(F0-05=3)

F/R

Xi

Reverse

Button

24V

PLC

RUN

Xi

COM

F/R

Figure 1-3 Control Logic of Terminal Control Mode

User Manual

EM303B General Purpose Inverter

13

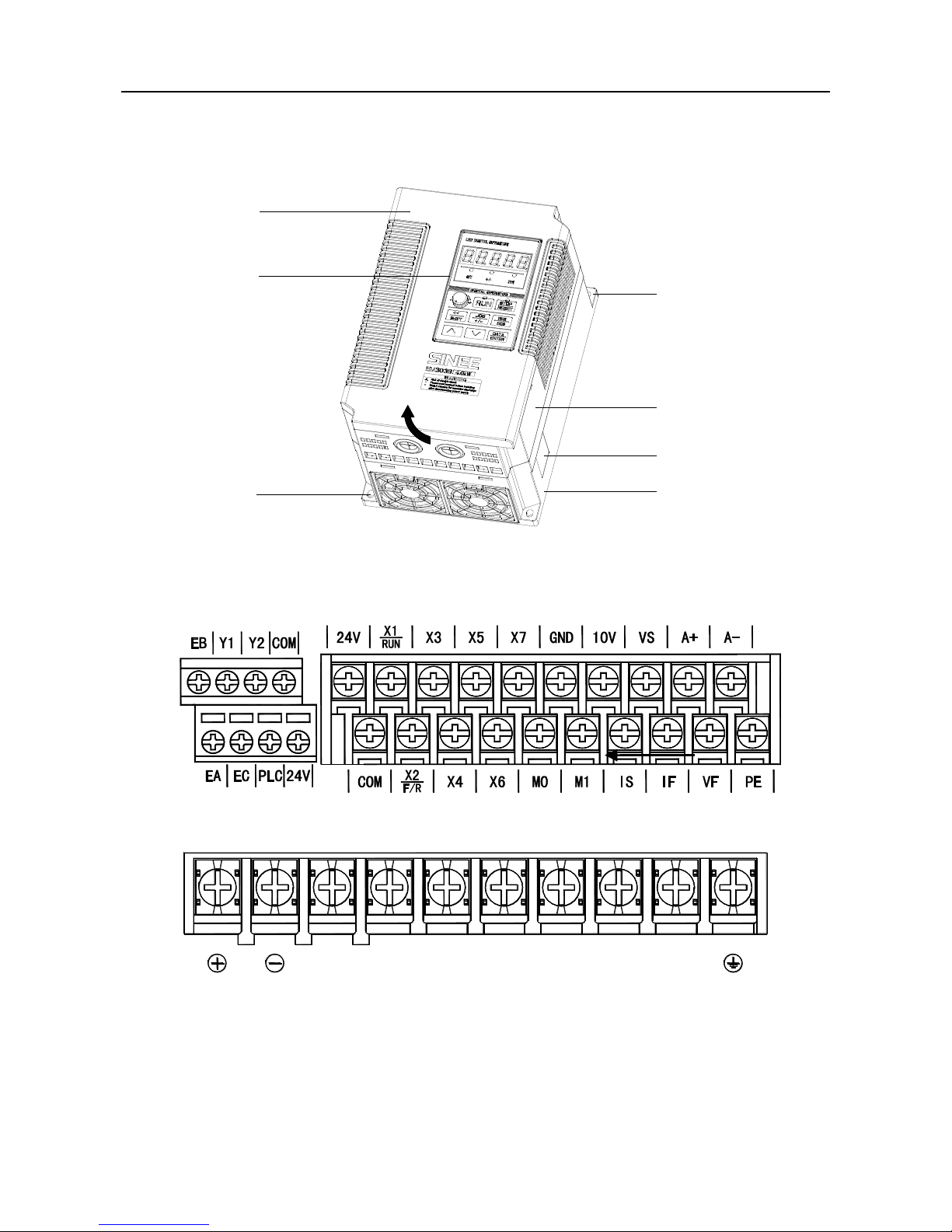

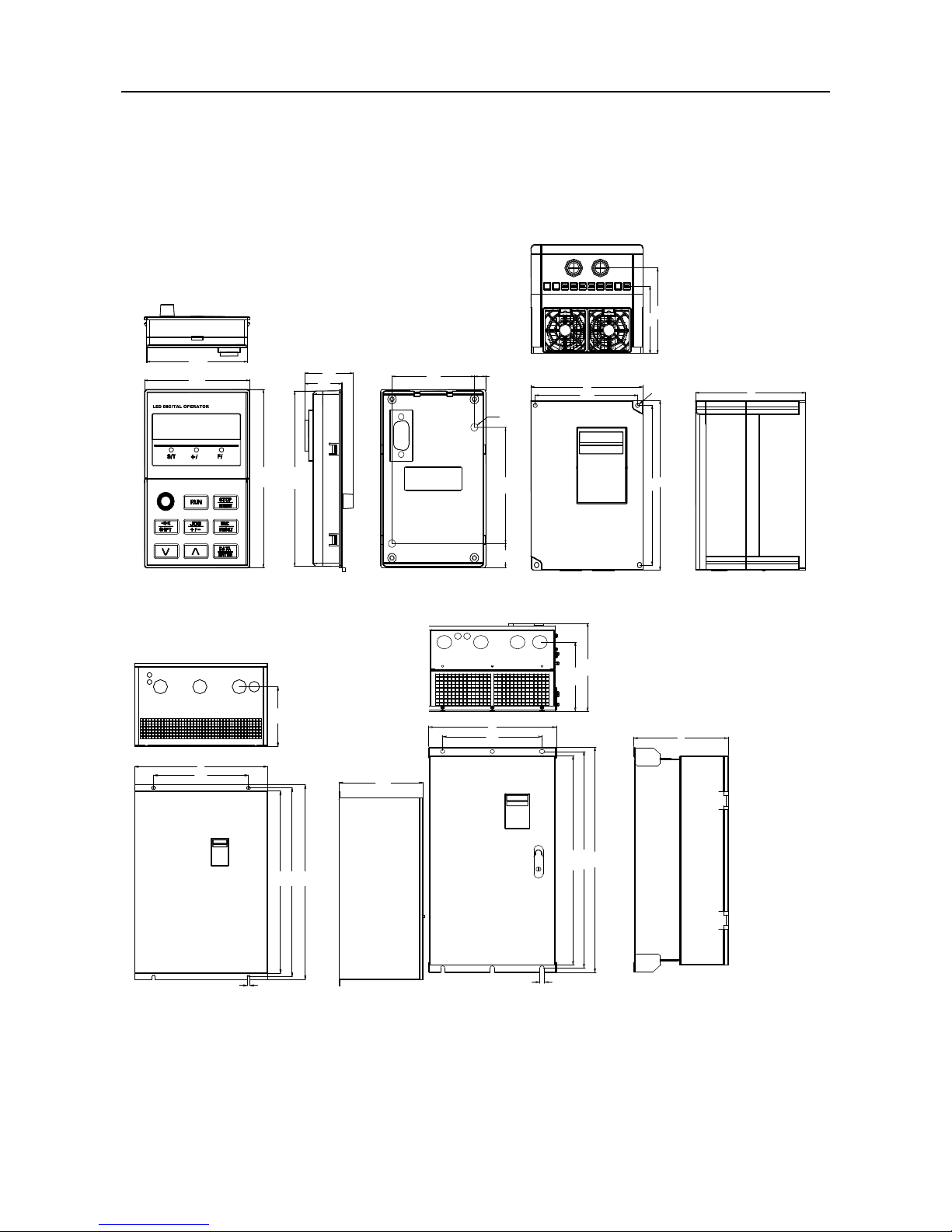

1.3 EM303B Outlook

See Figure 1-4 for the outlook of EM303B (Instance: EM303B- 4.0kW).

Keypad

Housing Upper

Nameplate

Housing Base

Mounting Hole

Housing Middle

Mounting Hole

Figure1-4 EM303B Outlook

The housing upper can be disassembled by following the arrow shown in Figure1-4.

See Figure 1-5 for control circuit terminals and main circuit terminals.

Control Circuit Terminal Block

Main Circuit Terminal Block

Figure 1-5 Control Circuit Terminal Block and Main Circuit Terminal Block

S VU W PBR T

User Manual

EM303B General Purpose Inverter

14

2Installation

2.1 Verifying Product

Refer to Table 2-1, and check and verify the EM303B.

Table 2-1 Check List

Item

Action

If the products are identical to the purchase

order.

Check the devices reference marked on the

label.

Any part damaged.

Check the outlook if any damages.

Any screw loosened.

Check with a screwdriver if necessary.

Contact the distributor or SINEE directly for quality issue.

Nameplate

Model No. :EM303B-4R0G/5R5P-3B

Rated Power :4.0kW/5.5kW

Input Voltage:380VAC

Rated Current:10.0A/13.0A

Serial No. :

Shenzhen Sine Electric Co., Ltd.

Model Numbering Scheme

Product Category

EM:Inverter

Product Series:

303B:Open Loop Vector Control System

3-phase 380V, 303B is an integrated model with G&P in one.

G: General purpose P: Blower, water pump(Omitted if not specified)

Power Ratings:

0R7

0.75kW

5R5

5.5kW

……

……

018

18.5kW

……

……

EM 303B –4R0G/5R5P –3 B

B:Integrated Braking Unit

None: No Braking Unit

Voltage Class:

1: 1-phase 220V

2: 3-phase 220V

3: 3-phase 380V

User Manual

EM303B General Purpose Inverter

15

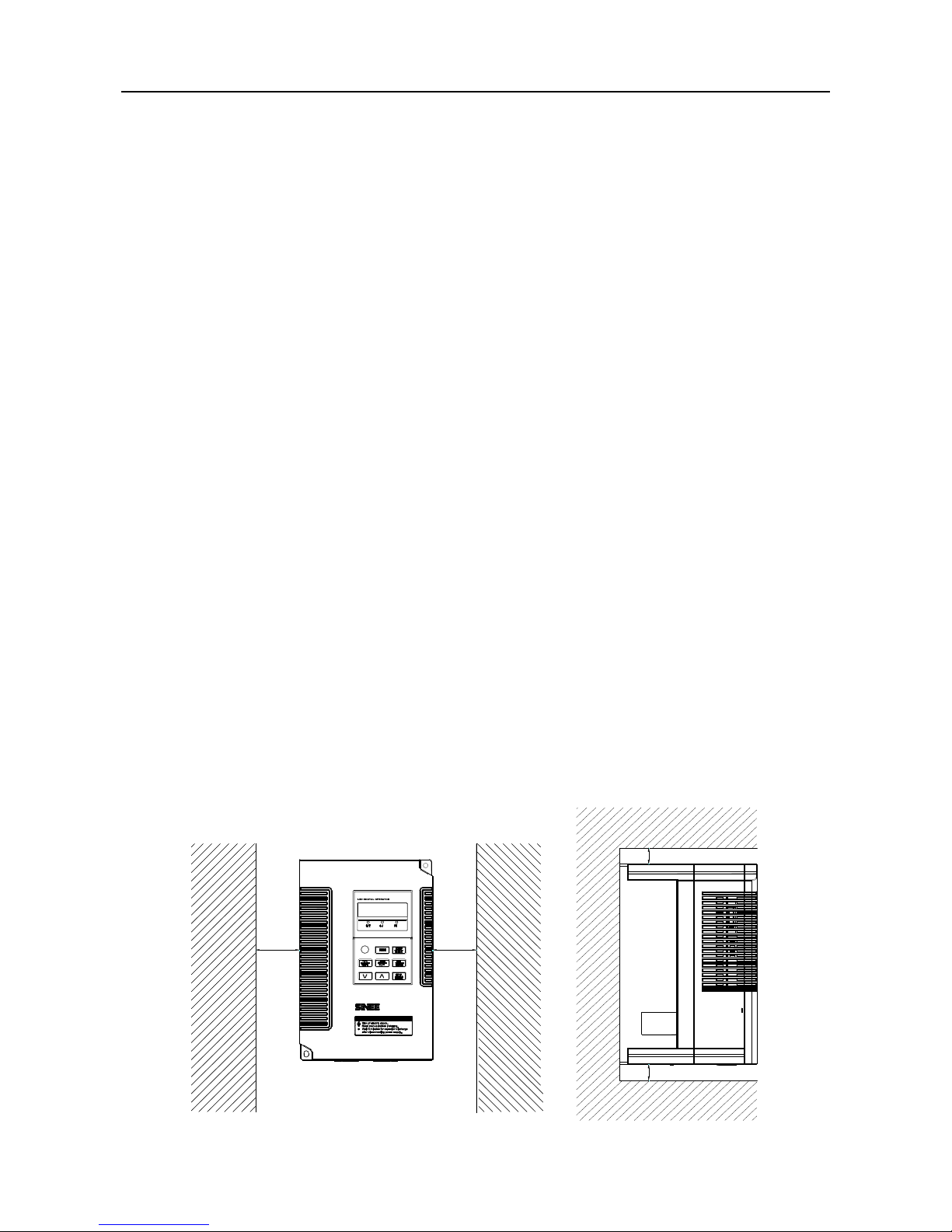

2.2 Overall and Installation Dimensions

EM303B can be classified to 10 sizes for total 30 models. See Figure 2-1 and Table 2-2 for

installation dimensions.

The keypad can be installed on the metal panel separately with a hole size of

116.5±0.1(L)*71.5±0.1 (W)mm, and applicable metal panel thickness:1.2~2.0mm.

-R

2-M3

71

74

118

26

34

116

8

58

77

16

W1

W

H

H1 D1

D2

D

2-<d>

(a) (b)

D1

W1

H

H1

H2

2-d

D

W

D

H2

H1

H

W1

W

D1

D2

3-d

(c)( d)

Figure 2-1 Overall and Keypad Dimensions of EM303B

User Manual

EM303B General Purpose Inverter

16

Table 2-2 OverallInstallation Dimensions of EM303B

Model No.

W

W1

H

H1

H2

D

D1

D2

d

Frame

EM303B-0R7G/1R1P-3B

140

125

220

205

--

152

120

161

6

(b)

EM303B-1R1G/1R5P-3B

EM303B-1R5G/2R2P-3B

EM303B-2R2G/3R0P-3B

EM303B-3R0G/4R0P-3B

EM303B-4R0G/5R5P-3B

EM303B-5R5G/7R5P-3B

165

148

250

235

--

161

126

170

6

(b)

EM303B-7R5G/9R0P-3B

EM303B-9R0G/011P-3B

215

150

352

335

317

215

172

224

7

(c)

EM303B-011G/015P-3B

EM303B-015G/018P-3B

EM303B-018G/022P-3

270

200 470 450

424

245

187

254

10 (c)

EM303B-022G/030P-3

EM303B-030G/037P-3

EM303B-037G/045P-3

335

240 550 530

500

245

190

254

10 (c)

EM303B-045G/055P-3

EM303B-055G/075P-3

390

300 695 665

635

250

200

259

12 (c)

EM303B-075G/090P-3

EM303B-090G/110P-3

386

300 753 724

700

287

231

295

13 (d)

EM303B-110G/132P-3

416

300 855 825

793

302

246

310

13 (d)

EM303B-132G/160P-3

EM303B-160G/185P-3

497

397

1107

1076

1036

335

285

343

13

(d)

EM303B-185G/200P-3

EM303B-200G/220P-3

EM303B-220G/250P-3

656

450

1348

1314

1261

383

232

390

13

(d)

EM303B-250G/280P-3

EM303B-280G/315P-3

EM303B-315G/355P-3

801

680 1417 1383

1330

383

190

390

13 (d)

EM303B-355G/400P-3

EM303B-400G/450P-3

Remarks:

1. 6modes, EM303B-055~075, EM303B-090, EM303B-110~132, EM303B-160~200,

EM303B-220~280,and EM303B-315~400,can be floor-mounted with a chassis which is

in the same width as the inverter. Heights of optional chassis: 120mm, 253mm,

253mm,308mm, 308mmand 355mm. Please order the extra chassis if needed, and see

Section 11.6 for details.

2. EM303B-090~400: power input terminals are on the top, and power output terminals are

at the bottom of the inverter.

User Manual

EM303B General Purpose Inverter

17

2.3 Considerations of Installation Site

2.3.1 Installation Site

Considerations for installation site:

Good ventilation indoor

Ambient temperature: -10C~+40C

No high temperature and high moisture, humidity:<90%RH, no water drops or any

other condensation

Never install on flammable materials

No direct sunlight

No flammable, corrosive gas or liquid

No dust, floating fiber or metal particles

Firm and steady installation base

No electromagnetic interference, and keep away from interference source.

2.3.2 Ambient Temperature

Install inverter in a place with good ventilation to improve the reliability of inverter operation.

When inverter is mounted inside a cabinet, cooling fan or air conditioner is a must. Keep the

ambient temperature below +40C.

2.3.3 Precautions

Please take protective measures during installation to prevent foreign matters like metal

particles or dust from entering the inverter when drilling. After installation, please take off

the protective devices.

2.4 Direction and Space of Installation

Cooling fan(s) installed inside EM303B is for forced air cooling. For good cooling

circulation, please mount inverter vertically, and leave sufficient space between the inverter

and wall or other objects. See Figure 2-2.

Vent

Vent

>120mm

>120mm

>150mm >150mm

R

-

EM303B4.0kW

Figure 2-2 Direction and Installation of Inverter

User Manual

EM303B General Purpose Inverter

18

Table 2-3Table of Heat Dissipating Capacity (HDC), Mass Airflow(MAF), Noise and Net

Weight(NW) of Single EM303B

Model No.

Frame

MAF

(CFM)

MAF

(m3/h)

HDC

(W)

Noise

(dB/A)

N.W.

(kg)

EM303B-0R7G/1R1P-3B

Size 1

13

22

65

40

3.15

EM303B-1R1G/1R5P-3B

74

EM303B-1R5G/2R2P-3B

80

EM303B-2R2G/3R0P-3B

110

EM303B-3R0G/4R0P-3B

135

EM303B-4R0G/5R5P-3B

163

EM303B-5R5G/7R5P-3B

Size 2

27

45

185

40

4.3

EM303B-7R5G/9R0P-3B

300

EM303B-9R0G/011P-3B

Size 3

59

100

325

45

12.3

EM303B-011G/015P-3B

385

EM303B-015G/018P-3B

525

EM303B-018G/022P-3

Size 4 80

135

515

56

19.5

EM303B-022G/030P-3

640

EM303B-030G/037P-3

870

EM303B-037G/045P-3

Size 5 165

280

1025

56

30.5

EM303B-045G/055P-3

1158

EM303B-055G/075P-3

Size 6 247

420

1525

56

51.3

EM303B-075G/090P-3

1800

EM303B-090G/110P-3

Size 7

335

570

2120

62

80.2

EM303B-110G/132P-3

Size 8

403

684

2636

62

93.8

EM303B-132G/160P-3

3216

EM303B-160G/185P-3

Size 9

424

720

3881

62

154.8

EM303B-185G/200P-3

4272

EM303B-200G/220P-3

4568

EM303B-220G/250P-3

Size 10

706

1200

4915

73

240

EM303B-250G/280P-3

5442

EM303B-280G/315P-3

6152

EM303B-315G/355P-3

Size 11

706

1200

8098

73

290

EM303B-355G/400P-3

8830

EM303B-400G/450P-3

9418

Remarks:

1. The values listed in the table refer to that the HDC and MAF required when single

EM303B is mounted in an enclosed place.

2. The HDC is calculated based on the rated voltage, rated current and preset carrier

frequency of each model.

3. 3. If more than one EM303B have to be installed in an enclosed place, please add HDC

and MAF.

www.eleris.ru

User Manual

EM303B General Purpose Inverter

19

2.5 Disassembly andAssembly of Keypad

Generally it is unnecessary to disassemble the keypad, and just remove the cover to assemble

and wire. On special occasions, disassemble the keypad by following steps.

Remove the front cover: For EM303B-0R7~7R5, push the cover vertically from the

bottom with two hands, and then lift up outwards. See Figure 2-3.

①

②

R

-

①

②

R

-

Figure2-3 Remove the Front Cover

Disassemble the keypad: Put your figures in the insert on the top of keypad, press down

slightly, and pull outwards, then the keypad can be removed. See Figure 2-4.

User Manual

EM303B General Purpose Inverter

20

Figure 2-4 Disassemble the Keypad

Assemble the keypad: Place the bottom of keypad in the slot and then press the top to

push until it clicks into right place. See Figure 2-5.

Figure 2-5 Assemble the Keypad

Table of contents

Popular Inverter manuals by other brands

Tektronix

Tektronix TG8000 Declassification and security instructions

EG4

EG4 6000EX-48 user manual

Power Innovations

Power Innovations INVB Series Technical description

Generac Portable Products

Generac Portable Products 1654-0 owner's manual

ABB

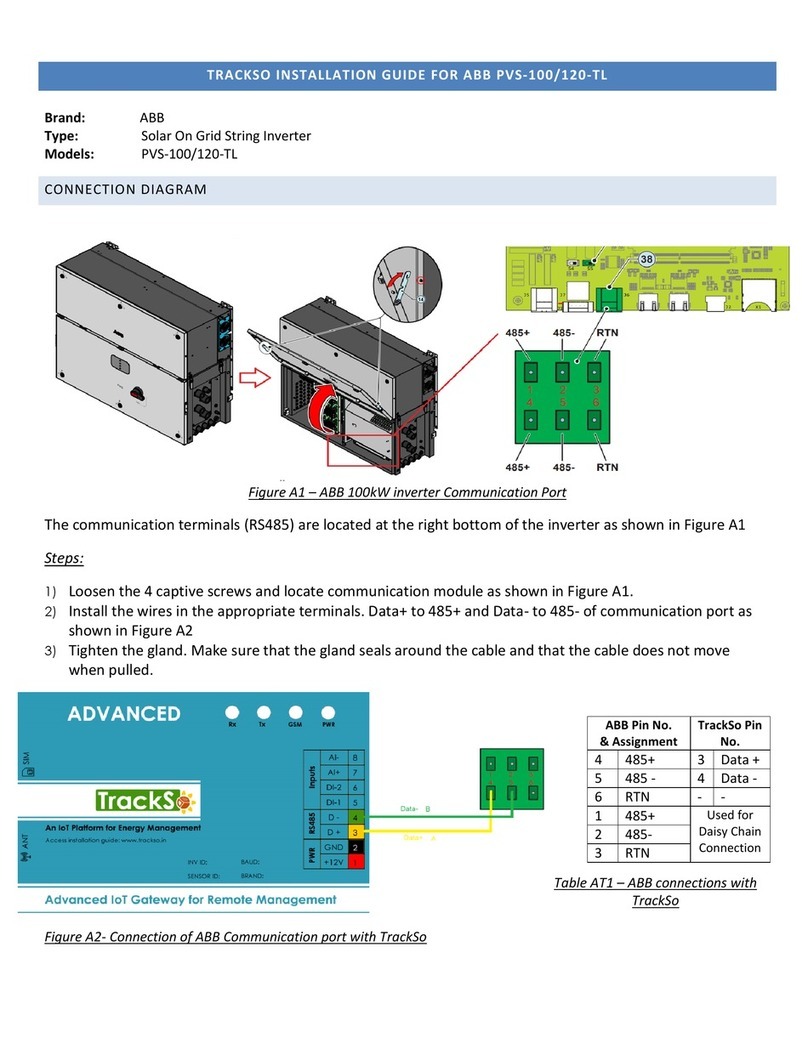

ABB PVS-100-TL installation guide

Generac Power Systems

Generac Power Systems 2.4L owner's manual