PRODUCT DESCRIPTION

Contents

1Preface...................................................................................................................... 4

2Acceptance test......................................................................................................... 5

2.1 Checking for damages........................................................................................ 5

3Installation ................................................................................................................. 6

3.1 Operational environment .................................................................................... 6

3.2 Safety requirements ........................................................................................... 7

3.3 External fusing.................................................................................................... 7

3.4 Electrical connections......................................................................................... 7

3.5 Device protection................................................................................................ 7

3.6 Grounding........................................................................................................... 7

3.7 Product description............................................................................................. 9

3.8 Control elements and connections ................................................................... 11

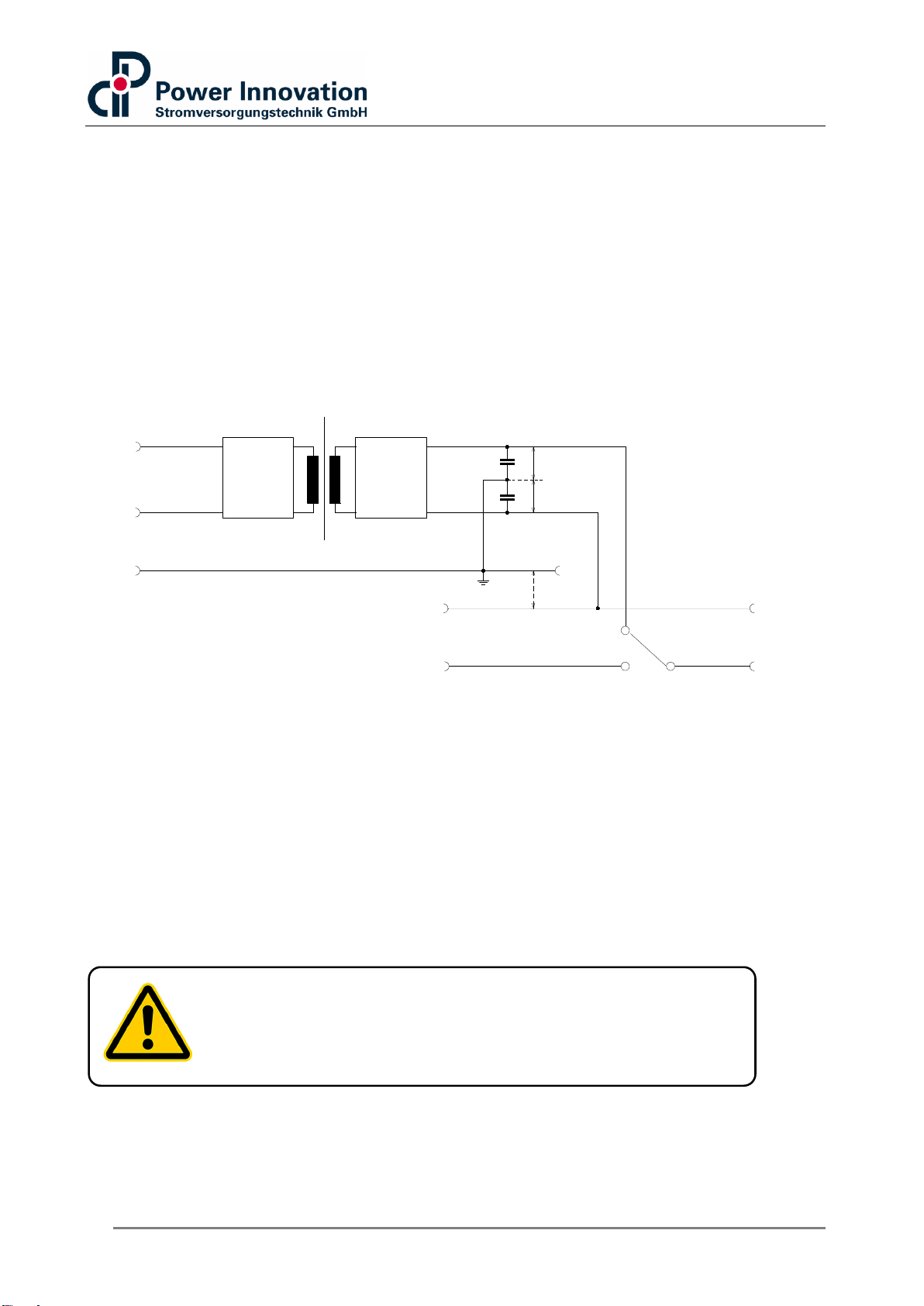

3.9 Block diagram................................................................................................... 12

3.10 Fuse ................................................................................................................. 12

3.11 Connection ....................................................................................................... 13

3.11.1 VDC input.................................................................................................. 13

3.11.2 LED display............................................................................................... 14

3.11.3 Mode Changeover..................................................................................... 14

3.11.4 Alarm contact ............................................................................................ 15

3.11.5 AC input/output.......................................................................................... 16

3.12 Operation.......................................................................................................... 17

3.12.1 Prerequisites ............................................................................................. 18

3.12.2 Operation with external commercial power line (mains)............................ 18

3.12.3 Bypass switching characteristics............................................................... 19

4Setup....................................................................................................................... 20

4.1 Enabling setup mode........................................................................................ 20

5Mechanical dimensions ........................................................................................... 22

6Exhibit...................................................................................................................... 23

A. Conversion table AWG to millimeter........................................................................... 23

B. Declaration of conformity............................................................................................ 24

C. Technical data............................................................................................................ 25

D. Fields of application.................................................................................................... 26

E. Applications................................................................................................................ 26

F. Shipping and storage.................................................................................................. 26

G. Terms of warranty...................................................................................................... 27