Elin EBG ELVOvert SX User manual

8074667.02/02

ELVOvert SX

Operating, Service

Projecting, Mounting & Connecting

Voraussetzung für eine erfolgreiche Inbetriebnahme sind eine

korrekte Geräteauswahl, Projektierung und Montage. Sollten Sie

in diesem Zusammenhang weitere Fragen haben, so wenden Sie

sich bitte an Ihre Vertriebsstelle oder direkt an den Lieferanten

des Gerätes.

Kondensatorentladung !

Vor Arbeiten am Gerät ist nach dem Freischalten vom Netz die

Kondensatorentladezeit von mindestens 5 Minuten abzuwarten

(Ladekontroll-LED auf der Platine !!), um sicherzustellen, daß das

Gerät völlig spannungsfrei ist.

Automatischer Wiederanlauf !

Bei bestimmten Parametereinstellungen kann es vorkommen,

daß der Frequenzumrichter nach einem Ausfall und anschließen-

der Netzzuschaltung automatisch wiederanläuft. Stellen Sie

sicher, daß dadurch weder Personen noch Einrichtungen gefähr-

det sind.

Inbetriebnahme und Service !

Arbeiten am Gerät dürfen nur von dafür qualifizierten Personen

unter Beachtung der gültigen Bedienungsanleitung und

Vorschriften erfolgen. Im Fehlerfall können auch betriebsmäßig

potentialfreie Kontakte und/oder Baugruppen gefährliche

Spannungen führen. Um eine Gefährdung auszuschließen, sind

die Vorschriften ”Arbeiten unter Spannung” zu beachten.

Lieferbedingungen:

Unseren Lieferungen und Leistungen liegen die ”Allgemeinen

Lieferbedingungen der Elektro- und Elektronikindustrie Öster-

reichs” neuester Ausgabe zugrunde.

Angaben in dieser Anleitung:

Es ist unser Bestreben, unsere Erzeugnisse ständig zu verbessern

und jeweils dem neuesten Stand der technischen Entwicklung

anzupassen. Änderungen der Angaben in dieser Anleitung, ins-

besondere von Maßen und Abmessungen, bleiben daher jeder-

zeit vorbehalten. Die Projektierungshinweise und

Anschlußbeispiele sind unverbindliche Vorschläge, für die wir ins-

besondere deshalb keine Gewähr übernehmen können, da die

anzuwendenden Bestimmungen von Art und Ort der Installation

und Verwendung der Geräte abhängen.

Vorschriften:

Der Anwender hat sicherzustellen, daß das Gerät sowie

zugehörige Komponenten nach den jeweils gültigen Vorschriften

verwendet werden. Der Einsatz dieser Geräte in Wohngebieten

ist ohne besondere Maßnahmen zur Funkfrequenzentstörung

nicht zulässig.

Schutzrechte:

Wir bitten zu beachten, daß keine Gewähr dafür übernommen

wird, daß die hier beschriebenen Schaltungen, Geräte und

Verfahren frei von Schutzrechten sind.

Bewahren Sie diese Anleitung in

Gerätenähe jederzeit griffbereit auf !

The requirements for a successfull commissioning are a correct selection

of the unit, projection and mounting. In case of further questions, please

contact the supplier or call the manufacturer of the unit directly.

Capacitor discharge !

Before any work on or in the unit, disconnect from the mains and wait at

least 5 minutes until the D.C.link capacitors have been fully discharged.

Check that the device is no longer alive by measuring the voltage at the

D.C.link capacitor.

Automatic restart !

In case of certain parameter adjustments it may happen that the fre-

quency inverter starts up automatically after switching on the mains

again. You have to guarantee, that no person and no other equipment

is in danger.

Commissioning and service:

Works on or in the unit must only be undertaken by properly qualified

staff in full compliance of the appropriate instructions and pertinent

regulations. Note that a fault may cause potential-free contacts and/or

PCBs to carry mains potential. To avoid any risk to humans, obey the

regulations concering ”Work on Live Equipment” explicitly.

Delivery conditions:

Our deliveries and services are based on the ”General Terms of Delivery

of the Austrian Electrical Industries” latest edition.

Specifications in this instruction:

We are constantly striving to improve our products and adapt them to

the latest state of technical development. We therefore reserve the right

to modify the specifications given in this instruction at any time, particu-

lary those refering to measures and dimensions. All planning hints and

connecting samples are non-binding suggestions, for which we are una-

ble to assume any liability, particulary since the regulations to be com-

plied with depend on the type and location of the plant and on the use

of the instruments.

Regulations:

It is the users responsibility to ensure that the instrument and its compo-

nent parts are used in compliance with applicable regulations.

It is not permitted to use these instruments in residential areas without

special measures to supress radio frequency interferences.

Patent and Trade Marks:

Please note that we do not guarantee any connections, instruments or

processes described herein to be free from patent or trademark right of

third parties.

Keep this instruction near the unit to

hand !

Sicherheitshinweise

Folgende Symbole werden Sie durch die Anleitung begleiten:

Allgemeiner Hinweis, Unbedingt beachten !

Gefährliche Spannungen ! Lebensgefahr !

Messung, Kontrolle !

Hinweis, Tip !

Bedienung über das Bedienfeld !

Beispiel !

General information, note exactly !

Dangerous voltages ! Danger of life !

Measurement, control !

Advise, tip !

Keypad operation !

Example !

Safety instructions

The following symbols should assist you in handling the instruction:

SX - Operating- & Service instruction - 8 074 667.02/02 - page 1

Operating & Service

Projecting, Mounting & Connecting

ELVOvertELVOvert SXSX

5,5(7,5) to 15(22) kW, 3 AC 380 to 460 V

8 074 667.02/02 / December 1998

ThemeTheme PagePage

Operating & ServiceOperating & Service 3 - 263 - 26

Projecting, Mounting & ConnectingProjecting, Mounting & Connecting 27 - 5027 - 50

Commissioning protocolCommissioning protocol A1 - A2A1 - A2

This documentation covers themes on operating, service, projecting, mounting and connecting.

It consists of the two main parts operating & service and projecting, mounting & connecting.

Regulations for the observance of the CE-directive and the new Power-Drive-Standard (EN 61800-3) are

described in the instruction manual „Additional installation regulations PX, SX“ (Cat.no. 8074578).

In case of damage or incomplete delivery, please inform the supplier or the insurance company.

The manufacturer declines responsibility for faults occurring during transport or unpacking.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 2

Notes

SX - Operating- & Service instruction - 8 074 667.02/02 - page 3

Operating & Service instruction

ELVOvert SX

5,5(7,5) to 15(22) kW, 3 AC 380 to 460 V

ThemeTheme PagePage

Operation via the built-in keypad 4

Overview: actual value display 5

Overview: 1st level of operation 5

Overview: 2nd level of operation 6

Commissioning 7

Actual value displays d0 - d3, d10, d11 8

1st level of operation

F2, F4 9

F6, F7, F8, F9, F10 10

F11, F14 11

2nd level of operation

A0 12

A1 - A4 13

A5, A6 14

A7 - A14 15

A23 - A25 16

A26, A27, A34 17

A38 - A40, A44, A47, A48 18

A49, A54, A58, A59 19

A61 - A64 21

A80, A81, A86, A90 - A92, A94 - A96 22

A97 23

A98, C0 - C7 24

C10, C11, C20, C21 25

Notes 26

This documentation covers themes on operating, parameter setting and service. Themes on projecting, mounting

and connecting can be read in the projecting, mounting & connecting instructions starting on page 27.

Regulations for the observance of the CE-directive and the new Power-Drive-Standard (EN 61800-3) are

described in the instruction manual „Additional installation regulations PX, SX“ (Cat.no. 8074578).

In case of damage or incomplete delivery, please inform the supplier or the insurance company.

The manufacturer declines responsibility for faults occurring during transport or unpacking.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 4

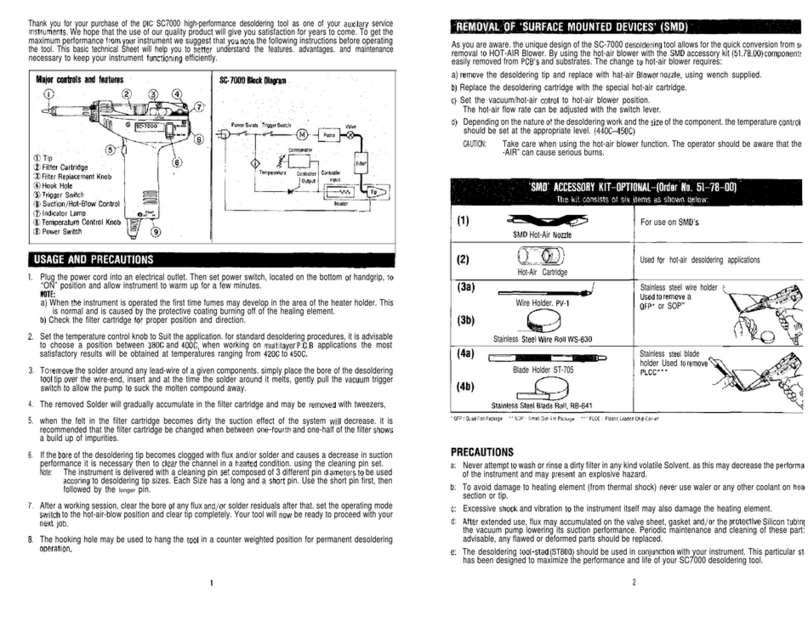

Operation via the built in operator panel

Example for the input of data

LED Display:

Shows frequency, motor cur-

rent, DC-link voltage, motor

rotation direction and type.

FUNC-key:

Selects a basic parameter or

saves a changed parameter

value.

RUN-key:

Starts the inverter (only in

the keypad mode); not func-

tional if the RUN-terminal is

activated.

STOP/RESET-key:

Stops the inverter or resets an existing trip.

Operates in the manual and in the terminal

mode but does not operate if parameters in

the 2nd level of operation are selected.

UP/DOWN-key:

Changing of parameter values or

increasing/decreasing of the output

frequency.

POWER-LED:

Shows if the electronic is working;

Attention: Use the charging LED

(right-sided to the connection termi-

nals) to check the charging condition

of the DC-link.

Programming example for adjusting the frequency and starting of the inverter

There are 3 levels of operating the inverter:

1. The level of display of values is used to display operating parameters like e.g. actual-frequency and motor current.

2. In the 1st level of operation the frequency inverter can be programmed by usage of a few selected parameters.

3. The 2nd level of operation offers a lot of additional parameters which altogether can be modified only during standstill.

Overview of the actual value display and the 1st level of operation

Selecting and changing parameters in the 1st level of operation

Assuming that parameter d0 is selected (after mains-on often 0.00):

1) Switch to the parameter mode by pressing the FUNC-key.

2) Go through the parameter list by using the UP/DOWN-keys.

3) Select the parameter by pressing the FUNC-key.

4) Change it´s value by using the UP/DOWN-keys.

5) Confirm the change by pressing the FUNC-key.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 5

Selecting and changing parameters in the 2nd level of operation

Assuming that parameter d0 is selected (after mains-on often 0.00):

1) Switch to the parameter mode by pressing the FUNC-key.

2) Select parameter F14 using the UP/DOWN-keys.

3) Select the 2nd level of operation by pressing the FUNC-key.

4) Go through the parameter list by using the UP/DOWN-keys.

5) Select the parameter by pressing the FUNC-key.

6) Change it´s value by using the UP/DOWN-keys..

6) Confirm the change by pressing the FUNC-key.

7) Go back to the 1st level of operation (F14) by pressing the FUNC-key once more.

Remark:Remark:

After switching on the mains the parameter which was activated before switching off is displayed again.

Parameter

Overview of the actual value display and the 1st level of operation

Parameter nameParameter name No.No. RangeRange FDFD (Factory default)(Factory default) see pagesee page

Display of the output frequency d0 read only read only 8

Display of the motor speed x 100 d1 read only read only 8

Display of the motor current d2 read only read only 8

Display of the converted frequency d3 read only read only 8

Display of the last trip message d10 read only read only 8

Display of the trip memory d11 read only read only 8

Frequency reference & preset speeds F2 00.0- A63 Hz 0.00 9

Running direction selection F4 F or r F 9

Acceleration time F6 0.01-999 s 30 10

Deceleration time F7 0.01-999 s 30 10

Voltage boost F8 00-99 11 10

Operating mode (reference, start/stop) F9 00-15 03 10

Analogue meter adjustment F10 00-250 172 10

Nominal motor voltage F11 380,400,415,440,460 V 400 11

2nd level of operation F14 all parameters of the 2nd

level of operation *) 11

*) Only in the factory default setting (FD) and only if selected the first time, F14 will show A0.

In all other cases the last adjusted parameter is displayed under F14.

Overview of the 2nd level of operation

Parameter nameParameter name No.No. RangeRange FDFD see pagesee page

Operating methode A0 0-5 0 12

Motor capacity setting A1 4.0- 160 kW Nominal power 13

Pole number A2 2, 4, 6, 8 poled 4 13

Speed response A3 0.00-100 2.00 13

Starting frequency A4 0.10-9.99 Hz 0.50 13

f-MAX limitation A5 00.0- A63 Hz 0.0 14

f-MIN limitation A6 00.0- A63 Hz 0.0 14

Skip frequency 1 A7 00.0- 400 Hz 0.0 15

Skip frequency 2 A8 00.0- 400 Hz 0.0 15

Skip frequency 3 A9 00.0- 400 Hz 0.0 15

Carrier frequency A10 2.0-16.0 kHz 16 8) 15

Frequency command sampling A11 1-8 8 15

Preset speed 1 A12 00.0- A63 Hz 0.0 15

Preset speed 2 A13 00.0- A63 Hz 0.0 15

Preset speed 3 A14 00.0- A63 Hz 0.0 15

Elektronic motor protection A23 20-120% 100 16

Motor protection characteristic A24 0, 1, 2 0 16

Motor pole number for d1 A25 02, 04, 06, 08, 10, 12...48 04 16

Ext. f-ref limitation: start value A26 00.0- A63 Hz 0.0 17

Ext. f-ref limitation: end value A27 00.0- A63 Hz 0.0 17

Restart selection A34 0-3 0 17

Braking unit: usage ratio A38 0.0-100% 1.5 18

Signal „Frequency arrival“: On-level A39 00.0- A63 Hz 0.0 18

Signal „Frequency arrival“: Off-level A40 00.0- A63 Hz 0.0 18

Analogue output f/I/T A44 0-3 0 18

Calculation factor n A47 0.0 - 99.9 1.0 18

Frequency reference selection A48 0, 1 1 18

„Frequency arrival“ characteristic A49 0, 1, 2 0 19

Speed search function A54 0, 1 1 19

Start with reduced voltage A58 0-06 6 19

Mode of operation A59 0, 1, 2 0 19

JOG-frequency A61 0.00-9.99 Hz 1.00 21

Base frequency A62 30- A63 Hz 50 21

End frequency A63 30-120(400)Hz 50 21

Maximum frequency A64 120, 400 Hz 120 21

Calibration of f-reference. voltage A80 0...255 pre-adjusted !! 22

Calibration of f-reference. current A81 0...255 pre-adjusted !! 22

Reset input performance A86 0, 1 0 22

PID-controller: P-gain A90 0.1 - 5.0 1.0 22

PID-controller: I-gain A91 0.0 - 15.0 s 1.0 22

PID-controller: D-gain A92 0.0 - 100.0 0.0 22

PID-controller: selection A94 0 - 4 0 22

PID-controller. reference A95 0, 1 0 22

PID-controller: internal reference A96 0.0 - 200 % 0.0 22

Auto-Tuning A97 0 - 2 0 23

Motor data selection A98 0 - 2 0 24

Input phase supervision A99 0, 1 0 = ON 24

Setting for input 1 C0 0...28 18 24

Setting for input 2 C1 0...28 16 24

Setting for input 3 C2 0...28 5 24

Setting for input 4 C3 0...28 11 24

Setting for input 5 C4 0...28 9 24

Setting for input 6 C5 0...28 2 24

Setting for input 7 C6 0...28 1 24

Setting for input 8 C7 0...28 0 24

Setting for output terminal 11 C10 0-2 0 25

Setting for output terminal 12 C11 0-2 1 25

Inputs 1-4: Inversion C20 00-09, 0A-FF 08 25

Outputs 11,12 & relay: inversion C21 00-07 04 25

SX - Operating- & Service instruction - 8 074 667.02/02 - page 6

SX - Operating- & Service instruction - 8 074 667.02/02 - page 7

Commissioning

Before start of commissioning please notice the following items:

1. Check the correct connection of mains- and motorlines.

2. Check if the control lines are connected with the correct terminals.

3. Check if the frequency inverter is correctly grounded according to regulations and mounted vertically to a wall.

4. Remove all stray pieces of wire, solderless terminals or other objects left from wiring work.

5. Check if all screws and terminals are fixed.

6. Check if the motor is specified for the defined frequency range in particular for the maximum speed.

7. For optimum adaptation of the frequency to the motor see parameter A97, Auto-Tuning.

Factory default setting (Initialisation)

At delivery all frequency inverters of the series ELVOvert SX are preset to factory default. The devices can be reset to this

basic setting any time.

To do so, proceed the following steps:

1. Switch the power on (display 0 0 0) and press the FUNC-key once (display d 0).

2. Select parameter F14 by repeatedly pressing the arrow keys.

3. Press the FUNC-key once. Parameter A0 is displayed.

4. Select one of the parameters C0 - C7 (corresponding to the terminals 1- 8, e.g. C1 = input 2) via repeatedly pressing

the arrow keys and press key FUNC once.

5. Put in parameter 7 under this parameter by usage of the arrow keys (terminal function STN = factory default setting)

and store the input via pressing the FUNC-key once.

6. The terminal which is selected by this procedure is now used to activate setting to factory default. Connect this terminal

to terminal P24 and switch off power. Wait as long as the LED which monitors the link voltage is switched off.

7. Switch on power again and wait for appr. 6 sec.

8. Disconnect the link between the terminal for factory default setting and terminal P24.

9. Switch off power again and wait until the LED which monitors the link voltage is switched off.

Commissioning via built-in keypad

Remark:Remark:

The inverter needs “Pulse unlocked“ to rotate the motor. Terminal 4 is from manufacturing preset with “Pulse unlocked“

and therefore has to be connected with P24 via a linking wire. Additionally a wire to link PLC with CM1 is required.

1. Switch on the power; the power-LED on the operator panel is then on (display shows value of d 0).

2. Select parameter F4 by repeatedly pressing the arrow keys. Press the FUNC-key. Now you can select the required

direction of rotation by usage of the arrow keys (F = forward, r = reverse). Store the input by pressing the key FUNC.

3. Select parameter F9 via pressing the arrow keys and put in 00 on this parameter position (see parameter F9).

4. Now selecet parameter F2 and adjust the set frequency by usage of the arrow keys.

5. Start the inverter via the RUN key.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 8

Description of the actual value display area

The level of “Display of the actual values“ offers the user important operating data (e.g. motor current, link voltage, ...). In

addition it supports the analysis in case of a failure.

d 0 Output frequency Hz read only

The parameter shows the actual output frequency in Hz. Display during stand-still: 0.00

In the range from 0,01 to 9,99 Hz the display cycles in 0,01 Hz steps, between 10 and 99,9 Hz in 0,1 Hz steps

and from 100 Hz to 400 Hz in 1 Hz steps.

d 1 Motor speed x 100 rpm read only

The parameter shows the calculated motor speed. As the frequency inverter cannot measure the actual speed of

the slipping motor, if no speed feedback is used, this value is theoretical.

Display during stand-still: 0.00. Pay attention to the adjustment of parameter A25 „Motor pole

number for d1“ !

Speed range Display Steps

1 to 999 rpm 0,01 to 9,99 0,01 rpm

1000 to 9990 rpm 10,0 to 99,9 0,1 (10 rpm)

10000 to 60000 rpm 100 to 600 1 (100 rpm)

d 2 Motor current A read only

The parameter shows the output current of the inverter (=motor current) with an accuracy of +/- 10%

according to the upper limit value. Display during stand-still: 0.0

From 0,1 to 99,9 A the display cycles in 0,1 A steps and from 100 to 999 A in 1 A steps.

d 3 Converted frequency read only

The parameter shows the result of the output frequency d0 multiplied by the value of A47.

Anzeige Werte

0.0 - 9.99 0.0 - 9.99

10.0 - 99.9 10.00 - 99.99

100. - 999. 100.00 - 999.99

100 - 999 1000.00 - 9999.99

10 - 39 10000.00 - 39960.00

d10 Last trip message read only

The last trip, the relevant output current and the link voltage (x10) are stored under this parameter and can be

read out with the FUNC-key.

Display:_ _ _ Up to now no trips have occurred and the trip memory is erased.

Display: 0.00 Display after reset

d11 Trip memory read only

The 2nd and 3rd last trip message are stored under this parameter. With pressing the FUNC-key they can be

displayed in turn. The trip memory can be erased with the external control unit BE-4.

Display :_ _ _ In this storage position no trip message is stored.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 9

Description of the 1st level of operation

F2 Frequency ref. value, 00.0 - A63 Hz FD: 00.0 Hz

Preset speeds

At any time Parameter F2 displays the frequency set value as an actual value which is adjustable, if F9 is

programmed in a suitable way, via the keys of the operator panel.

The inverters of the ELVOvert SX series offer the following choices to define a frequency reference value:

Set value definition via the keys of the built in operator panel.

Adjustment of this set-value by the use of motorpotentiometer up or motorpotentiometer down dig. inputs

Manual set value via the analogue input 0 ...10 V

Automatic set value via analogue input 4 ... 20 m A

3 or 7 preset speeds

(Set value definition via the key of the external control unit BE-4)

(Analogue or digital definition of set-value via one of the option boards)

Frequency reference value via keypad (F9 and F2)

For the definition of the frequency set value via the keys of the built in operator panel under parameter F9 = 00

or 02 has to be set.

Frequency range Steps

0,01 to 9,99 Hz 0,01 Hz

10 to 99,9 Hz 0,1 Hz

100 to 400 Hz 1 Hz

Permanently pressing one of the arrow keys results in continuous increase or decrease of the set value.

Preset speeds (C0 to C7; as an alternative for adjusting A12, A13 and A14)

In factory setting the digital inputs 6 and 7 (dedicated to the terminal functions CF1 and CF2) are defined to sel-

ect the pre-set speeds 1 - 3. (For the pre-set speeds 4 - 7 the terminal function CF3 is required; for program-

ming of this please see parameter C0 - C7.)

Function CF1 CF2 CF3

1. preset speed ON OFF OFF

2. preset speed OFF ON OFF

3. preset speed ON ON OFF

4. preset speed ON OFF ON

5. preset speed OFF ON ON

6. preset speed ON ON ON

7. preset speed OFF OFF ON

Adjustment of the preset speeds during operation:

After selection of the relevant preset speed by use of the terminal function CF1-CF3 the desired frequency can

be adjusted via the UP/DOWN-keys (factory default setting 000).

Store the frequency which was set by pressing the FUNC-key.

Alternatively the pre-set speeds 1 - 3 also can by defined via the use of the parameters A12, A13 and A14.

Remark:Remark:

Frequencies above 120 Hz can be only adjusted if the parameter A64 „Maximum frequency“ is set to 400 Hz !!

F 4 Running direction select. F (FWD) , r (REV) FD: F

After pressing the RUN key the motor starts with the direction of rotation which is defined by this parameter.

This parameter does not influence the control inputs.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 10

F 6 Acceleration time 0.01 - 999 s FD: 30

F 7 Deceleration time 0.01 - 999 s FD: 30

The acceleration- or deceleration time references to the defined end frequency (parameter A63).

Remarks:

The 2nd acceleration and deceleration time is set by F6 and F7, if the function CH1 (2nd ramps) is selected

The acceleration and deceleration time for the 2nd set of parameters is set by F6 and F7, if the function SET

Means that behind the parameters F6 and F7 three independently adjustable ramp times are hidden.

F 8 00 - 99 FD: 11

torque is boosted. Care has to be taken that the motor is not overloaded. A voltage boost which is adjusted to a

too great level may cause a trip (overcurrent) of the inverter.

Remark:Remark:

Voltage boost does not operate in SVC-mode (A0 set to 4 or 5) !!

F9 Operating mode 00 - 15 FD: 03

(reference, start, stop)

This parameter defines in which way the set value or the start/stop-signal is presented to the inverter.

Value Start/Stop-Signal Reference

00 Keypad Keypad*)

01 Keypad Terminals

02 Terminals Keypad*)

03 Terminals Terminals

04 Keypad Option1

05 Option1 Keypad*)

06 Option1 Option1

07 Keypad Option2

08 Option2 Keypad*)

09 Option2 Option2

10 Terminals Option1

11 Option1 Terminals

12 Terminals Option2

13 Option2 Terminals

14 Option1 Option2

15 Option2 Option1

*) One of these adjustments must be selected to use the motorpotentiometer function !!!

F10 Analogue meter adjust. 00 - 250 FD: 172

Adjustment of the analogue signal on terminal FM (frequency set-value, output current, torque).

An adjustment of the pulse signal (frequency actual value) is not possible.

The value which is put in by this parameter is maintained during reset to factory defaults (terminal function STN).

The max. output voltage (10 V) of the terminal means:

- at display of the frequency the end frequency (parameter A63)

- at display of the current 200% of the inverter´s nominal current

- at display of the torque 200 % of the motor’s nominal torque

SX - Operating- & Service instruction - 8 074 667.02/02 - page 11

F11 Nominal motor voltage 380/400/415/440/460 V FD: 380

Select the nominal voltage of the connected motor.

F14 2nd level of operation Parameters of the 2nd level FD: A0 *)

If the application requires more advanced parameters F 2 - F11 then by the use of F14 the 2nd level of operati-

on can be selected. The 2nd level of operation offers a range of further parameters (A0 - A 65) and also the

choice to program inputs and outputs according to the requirements (C 0 - C21). With the key FUNC you may

return from every parameter of the 2nd level of operation to F14. After input of data has been completed pres-

sing of key FUNC once stores the new data and another function can be selected.

Remark:

All parameter changes in the 2nd level of operation can only be performed during stand-still after releasing a

stop command.

Scheme:Scheme:

*) Only in the factory default setting and only if selected the first time, F14 will show A0.

In all other cases the last adjusted parameter is displayed under F14.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 12

Description of the 2nd level of operation:

A0 Operating methode 0 - 5 FD: 0

Frequency inverters of the ELVOvert SX series offer three different control methods:

V/f-characteristics for standard torque requirements and multi motor operation.

Sensorless Vector Control (SVC) for great torque especially at low frequencies (<5 Hz) and dynamic

compensation of slip with the usage of speed feedback. Using the operating data (output current, cos ϕ)

the frequency inverter for every load condition calculates the optimum output voltage or output frequency.

Vector Control (V2) with speed feedback using a pulse sensor or an incremental sensor for applications

which demand absolute accuracy of speed and angle (only with option board).

Remark:Remark:

At the choice of 1, 2 or 3 the inverter automatically is switched to increased output power “P“.

Value Parameter V/f-characteristic

0V/f -characteristic,

constant torque

„C“

1 V/f-characteristic

reduced torque

V/f VP1, M =n1,5

„P“ for fans, pumps, ...

(2) V/f-characteristic

reduced torque

V/f VP2, M = n1,7

„P“

(3) V/f-characteristic

reduced torque

V/f VP3, M = n2

„P“

4 Sensorless Vector Control SVC

„C“ for conveyors, chassis drives,...

5 Vector Control with feedback V2

(with optinal PCB only

„C“

For pos. 4 and 5 the correct adjustment of A1, A2 and A3 is essential !

The frequency inverter should be adapted optimally to the motor independent of the selected control method.

See parameters F11, A1, A2, A10, A97, A62, A64.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 13

A 1 Motor capacity setting 4.00 - 160 kW FD: Nom. „C“

A 2 Pole number 2, 4, 6, 8 pole FD: 4

Put in the nominal power and number of poles of the motor to achieve great motor efficiency. If the data stored

under this parameters do not comply with the actual motor data then especially in the case of the control

method SVC the drive cannot be utilised optimally.

Remarks:Remarks:

About optimum adaptation to the motor see parameter A64 !!

To show the correct speed in d1 it is necessary to set parameter A25 to the correct value !!

A 3 Speed response 0.00 - 100 FD: 2.00

This parameter is only valid for the control method SVC. It caters for the dynamic stabilisation this means that

speed remains constant even during changing of motor load.

An increase of the parameter value causes increased time to react, decreasing reduces the time to react on

changes of the slip or load.

A 4 Starting frequency 0.10 - 9.99 Hz FD: 0.50

The start frequency can be adjusted between 0.12 Hz and 9.99 Hz in Steps of 0.01 Hz.

An increase of the start frequency results in a decrease of the acceleration- or deceleration time.

An increase of the start frequency may be required e.g. to overcome remarkable friction of the drive or of the

attached machine.

Remark:Remark:

Too great setting of start frequency may cause overcurrent trips.

A

usgangsspannung

/

Output voltage [V]

Ausgangsfrequenz /

Output frequency [Hz

]

0

0.1

9

.

99

SX - Operating- & Service instruction - 8 074 667.02/02 - page 14

A 5 f-MAX limitation 0.0 - A63 Hz FD: 0.0

A 6 f-MIN limitation 0.0 - A63 Hz FD: 0.0

The frequency range which is defined by the values stored under parameter A4 (start frequency) and A63 (end

frequency) can be reduced via the parameters A5 and A6. The frequency inverter in this case only accepts set

values via the set value inputs or via the built in operator panel or the external control unit BE-4 which are within

this frequency range. As soon as the inverter gets a start command it runs to the frequency which is set via A6.

Remarks:Remarks:

At input of 0 Hz for A5 and A6 or A5 < A6 the relevant parameter is not active.

Frequencies > 120 Hz can only be adjusted if parameter A64 „Maximum frequency“ is set to 400 Hz !!

F-Sollwert [Hz] /

f-reference [Hz]

Ausgangsfrequenz /

output frequency

A5

A6

2

0

4

0

EingestellterFrequenzbereich/

adjustedfrequencyrange

0

0

[Hz]

SX - Operating- & Service instruction - 8 074 667.02/02 - page 15

A 7 Skip frequency 1 0.0 - 400 Hz FD: 0.0

A 8 Skip frequency 2 0.0 - 400 Hz FD: 0.0

A 9 Skip frequency 3 0.0 - 400 Hz FD: 0.0

To avoid resonances eventually occurring in the drive system there is the possibility to program 3 lock out

frequencies.

Remarks:Remarks:

Locked out ranges are not skipped but crossed following the ramps.

Frequencies > 120 Hz can be only adjusted if parameter A64 „Maximum frequency“ is set to 400 Hz !!

The lock out width (+/- 0.5 Hz) can be varied with the external control unit BE-4 within 0.5 Hz to 9.9 Hz.

A10 Carrier frequency 2.0 - 16.0 kHz FD:16(8) *)

Adjusts the switching frequency in steps of 0,1 kHz in the range of 2 kHz up to 16 kHz.

*) 16 kHz at „C“-applications (A0=0, 4 or 5) The parameter is automatically set to the lower value but

8 kHz at „P“-applications (A0=1, 2 or 3) will not be set back to the higher value if A0 is changed.

This must be done manually.

Remarks:Remarks:

With lower switching frequencies in the control method SVC - especially in the case of frequencies <5Hz - a

greater speed accuracy of the motor can be achieved than with great switching frequencies!

Great switching frequencies cause less motor noise and decreased losses in the motor.

To decrease the interferences which are caused by the motor cables, the switching frequency should be kept

as low as possible.

A11 Freq. command sampling 1 - 8 FD: 8

Via the usage of the parameter A11 the sample rate of the set frequency inputs can be adjusted.

(Presentation as voltage input via terminals O-L, presentation by current value via OI-L).

The parameter may be varied between 1 and 8.

1 means a short time constant (great sample rate) which of course is coupled with quick variations of the signal

which may be not acceptable. The maximum value 8 in contrary means slow speed of reaction but on the other

hand a stable output frequency.

A12 Preset speed 1 0.0 - A63 Hz FD: 0.0

A13 Preset speed 2 0.0 - A63 Hz FD: 0.0

A14 Preset speed 3 0.0 - A63 Hz FD: 0.0

Adjustment of up to 7 preset speeds (alternatively to F2).

Each of them can be seperately activated by linking one of the terminals CF1 to CF3 with P24:

PresetPreset CF1CF1 CF2CF2 CF3CF3 Remarks:Remarks:

1 ON OFF OFF To use the preset speeds 4 to 7 it is necessary

2 OFF ON OFF to assign the function CF3 to one of the programmable

3 ON ON OFF digital inputs 1-8.

4 ON OFF ON The values for the preset speeds 4-7 can be only

5 OFF ON ON adjusted via the operating unit BE-4 (parameter F-11).

6 ONONON Preset speeds will always overrule the actual reference

7 OFF OFF ON value independent of the adjustment of F9.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 16

A23 Electron. motor protection 20 - 120 % IN FD: 100

The frequency inverters of the ELVOvert SX series can monitor the connected motor thermally via the usage of an

electronic model. The electronic motor protection is adjusted according to the nominal current of the motor.

(See also parameter A 24).

If the parameter A0 is set to 1, 2 or 3 (means higher continuous power „P“),

the maximum adjustable value is 113 % !!

The input value is calculated as follows:

Motor nom. current x 100

Inverter nom. current

For the inverter´s nominal current according to the setting

of A0 the “C“ or the “P“-nominal current has to be used.

Remark:Remark:

The electronic motor protection will be reset in case

of mains switch-off.

A24 Motor protec. charact. 0 - 2 FD: 0

For the improvement of the thermal monitoring of the motor in the lower speed range the electronic motor pro-

tection can be adapted to the reduced cooling of the motor. The external control unit BE-4 offers the possibility

to program the protection characteristic on demand.

0Constant motor protection within the whole frequency range for motors with forced cooling

1 Reduced loading at low speeds for motors with built in fan

2 Protection characteristic free programmable (with optional external control unit BE-4)

A25 Motor pole number for d1 02, 04, 06, 08, 10 ... 48 FD: 04

Adjustment of the number of motor poles for the correct calculation of d1.

SX - Operating- & Service instruction - 8 074 667.02/02 - page 17

A26 Ext. f-ref limit: start value 0.0 - A63 Hz FD: 0.0

A27 Ext. f-ref limit: end value 0.0 - A63 Hz FD: 0.0

By the usage of the parameters A26 and A27 an additional individual adaptation of the external set-value

(0...5V, 0....10 V, 4...20 mA) is possible. Associated with the minimum and maximum set value (e.g. 0 V or

10 V) there is a minimum and maximum frequency value which means that the whole set value range (0...5 V,

0...10 V, 4...20 mA) corresponds with an individually selectable

frequency range.

Example: A26 = 30 Hz, A27 = 50 Hz

0 - (5)10 V corresponds to 30 - 50 Hz,

4 - 20 mA corresponds to 30 - 50 Hz

Remarks:Remarks:

Deactivated via A26 and A27 = 0.

In the case of special applications it might be required at

minimum set value (e.g. 0 V) to drive maximum frequency or

at maximum set value (e.g. 10 V) to drive minimum freq-

uency. To achieve this via A26 maximum frequency and via

A27 minimum frequency has to be put in.

If the V/f-relation (A0) is changed after adjusting A26 and

A27 both parameters A26 and A27 must be

adjusted once more.

A34 Restart selection 0 - 3 FD: 0

Influences the reaction of the frequency inverter in case of a trip occuring:

Trip Reaction

Overcurrent 3 times autoreset in 10 minutes

Overvoltage 3 times autoreset in 10 minutes

Undervoltage 3 times autoreset in 10 minutes

Short mains interruption 16 times autoreset in 10 minutes

0After every trip the inverter stops operation and displays the trip message.

1 Autoreset, at the occurence of one of the mentioned trips, the inverter catches the rotating

motor and stops it in accordance with the defined deceleration time.

2 Autoreset, at the occurence of one of the mentioned trips, the inverter catches the rotating

motor and drives it to the set value using the defined acceleration time.

3 Autoreset, at the occurence of one of the mentioned trips , the inverter restarts after the

defined timeout (factory default setting 1.0 s, adjustable via an external control unit BE-4).

Remark:Remark:

Attention! Synchronisation to the motor speed is only possible if the speed is not less than 40% of the nominal

speed and if the remanent motor voltage has not decreased too much (app. 2-3 sec).

A27

60

A26

0

0

4

10 V

5 V

20 mA

fSOLL / fACT

f [Hz]

SX - Operating- & Service instruction - 8 074 667.02/02 - page 18

A38Braking unit: Usage ratio0.0 - 100 %FD: 1.5

The mentioned types of the ELVOvertSX series are equipped with a built in braking unit and a

braking resistor (80 Ω; 120 W). The usage ratio should not exceed 1.5% if the internal

braking resistor is used.

At the usage of an external braking resistor (minimum

70 Ω)in connection with the built in braking unit the

usage ratio can be increased according to the power

dissipation of the resistor.

The usage ratio of the built in braking unit with

reference to 100 sec can be adjusted in the range

of 0% to 100%. If this usage ratio is exceeded the braking unit is switched off and the inverter trips.

At the usage of an external braking unit the input value has to be set to 0.0 and the internal and also the

external braking resistors of the built in braking unit have to be disconnected.

Remarks:Remarks:

mThis parameter is only used at the ELVOvert SX 5.5 kW and 7.5 kW. In case of the inverter types

11 kW and 15 kW this parameter is set to 0.0 %.

mThe frequency inverters ELVOvert SX 400/11C15P and 15C22P do not have a built in braking unit.

A39 Signal „Frequency arrival“0.0 - A63 HzFD: 0.0

On level

A40 Signal „Frequency arrival“0.0 - A63 HzFD: 0.0

Off level

Via the parameter A49 the characteristic of the “Frequency arrival“-signal can be programmed. The relevant

frequencies (for the settings 1 and 2 at A49 ) are put in by the parameters A39 and A40 .

Remarks:Remarks:

mThe frequency can be adjusted in 0.1 Hz steps up to 100 Hz, above in 1 Hz steps.

mFrequencies > 120 Hz are only possible if A64 is set to 400 Hz.

A44 Analogue output f/I/T0 - 3FD: 0

The terminal FM can be programmed to display different operating data.

0Output frequency, analogue 0...10 V (10 V at arrival at the maximum voltage frequency)

1Output current, analogue 0...10 V (10 V at 200 % of nominal current)

2Torque, analogue 0...10 V (use only with SVC; with V/f only an estimated value with an accuracy of

+/- 20 % is available). (10 V at 200% of the nominal torque).

3Output frequency as pulse signal

A47 Calculation factor n0.0 - 99.9FD: 1.0

Adjustment of a factor for calculating the drive speed d3.

A48 Frequency ref. selection0 / 1FD: 1

Program the set value input (terminal 0 - L ) for 0...5 V (input 0) or 0...10 V (input 1).

If the set value is adjusted by the use of a potentiometer and the internal reference voltage (terminal H - L, 10 V)

the set value input has to be put to 10 V.

Remark:Remark:

The switching of the set value definition to 4...20 mA is by a digital control input according to the

“MANUAL/AUTOMATIC“ switching (Control input 2 = 16 “Automatic-set value“).

t1t2

t3

A38 =

(t1 + t2 + t3)

100 secx 100

Table of contents