Elk M1XSP Manual

Page 1 M1XSP Supplementary Instructions and Release Notes

Table of Contents

M1XSP Installation and Setup ..................................................................................................................................... 2

ELK-M1 Data Bus E.O.L. Termination .......................................................................................................................... 3

Carrier Infinity HVAC System “Thermostats” ............................................................................................................. 4

Updating/Replacing Firmware in the ELK-M1XSP ..................................................................................................... 6

Firmware Release Notes .............................................................................................................................................. 6

Version 40.0.6 released September 13, 2010 ....................................................................................................... 6

PO Box 100 • Hwy. 70W • Hildebran, NC 28637 • USA • 828-397-4200 • http://www.elkproducts.com

Firmware and/or bootware releases contain enhancements and/or resolutions for issues found in previous releases.

For the latest Updates refer to the Elk Website. http://www.elkproducts.com

Copyright 2012, Elk Products, Inc. No portion of this document shall be copied or distributed without the express written permission of Elk.

2/9/2012

ELK-M1XSP Serial Port Expander

Supplementary Instructions & Release Notes

for

Firmware Version 40.X.X

This version provides M1 Integration to:

Carrier Infinity HVAC Systemst.

Page 2 M1XSP Supplementary Instructions and Release Notes

M1XSP Diagnostic LED indicator

Slow blink (1/2 sec.) = Normal communication with M1.

Fast flicker = Communicating with other equipment (Thermostat, Lighting Controller, PC, etc.)

No blink = No communication with M1. Unit might be unplugged or powered off.

M1XSP Installation and Setup

1. The M1XSP operates on the M1 Keypad data bus and may therefore be remoted near the equipment being interfaced.

2. Before making any wiring connections, turn Off the M1 Master Power Switch.

3. Connect terminals +12V, A, B, and Neg from the M1XSP to the M1's Keypad Data Bus (terminals +VKP, Data A, Data B, &

Neg). NOTE: Refer to the M1 Installation Manual and the M1DBH information in this manual about proper

connections of data bus devices with multiple homerun cables.

4. There are 4 address switches, each with a position of OFF or ON (binary value 0 or 1) and a decimal equivalent value of

(1, 2, 4, or 8). The total decimal value of the "ON" switches equates to the data bus address. As a rule, the first M1XSP

should be set to address 1. If more than 1 M1XSP is installed, set each one to a unique (sequential) address (2, 3, etc).

5. Set the "Mode", "Baud", and other necessary jumpers according to the Installation diagrams on previous pages.

6. After all connections are complete, turn On the M1 Master Power Switch.

7. Enroll the M1XSP into the M1 Control. From the Keypad access the Installer level programming and select Menu 01-Bus

Module Enrollment. Press the right arrow key to start the enrollment. Onceenrollment has completed, press the right

arrow key to view results. Enrolled M1XSPs will show up as type 5 (T5) followed by the specific address number.

RS-232 (DB9) 9 Pin

Partner Port

INSTALL UNIT * SET ADDRESS AND OPTION JUMPERS * ACTIVATE M1 BUS ENROLLMENT PROCESS

RS-485

M1 Data Bus

RS-485

Partner Port

Data Bus

Address

Switches

Jumpers

S1,S2,S3 select

BAUD rate

Jumpers

S4,S5,S6,S7,S8

select Interface

MODE

J1 -Factory

Use ONLY!

JP3 - Jumper selects

between RS-232 or

RS-485

JP5 - Jumper Selects

+12VDC to DB9 Pin 4

(MUST be in-place for

HAI Thermostats)

JP1 - Jumper selects

termination of M1

RS-485 Data Bus

JP2 - Jumper selects

termination of

other Mfg. RS-485

Table 1: Data Bus Address Switch Settings

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Address 1

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Address 2 Address 3 Address 4

Address 5 Address 6 Address 7

LEGEND

ON

OFF

M1XSP Data Bus Terminating Jumper

JP1 Used to engage a 120 Ohm resistor for

terminating the M1 RS-485 Data Bus. See

Data bus wiring instructions before use.

For an M1XSP the only valid Data Bus

Addresses are 1 thru 7 since the max.

number of M1XSPs is 7.

Page 3 M1XSP Supplementary Instructions and Release Notes

VERY IMPORTANT!

The control uses a RS-485 “differential” data bus operating at 38,400 bits per second. This is relatively high speed by industry standards

and ensures fast, accurate communications. EOL data bus terminating resistors are strongly suggested to eliminate the possibility of

reflection errors due to varying cable lengths. Every device; keypad, expander, etc. and the control has a built-in bus terminating resistor

(120 Ohm) which can be activated via a 2 pin jumper (2 Gold Pins). Two black shorting caps are included in the hardware pack. When one

of the shorting caps is placed on the two gold pins, it activates the 120 Ohm terminating resistor across Data Lines A & B. Terminating

resistors are marked JP2 on the keypads and JP1 on the expanders. From the factory, no terminating resistors are installed (activated).

WARNING! The RS-485 Data Bus must NEVER have more than 2 terminating resistors header/jumpers installed.

The M1 should have no more than 2 home run cables but devices can be daisy chained along each. The last device on each home run

SHOULD be terminated via the gold 2 pin terminating header/jumper. Placing a shorting cap on the pins will engage a 120 Ohm resistor across

data lines A & B. If there is only 1 data bus home run cable then place shorting cap on JP3 of Main Board. See other hookups below.

The optional ELK-M1DBH † Data Bus Hub is suggested if the job must have more than 2 home runs. The M1DBH accepts CAT5 or CAT6 cable

with RJ45 plugs. It keeps wires more organized while also providing easy bus termination. Essentially, the M1DBH circuit board daisy chains

the devices by series connecting the DATA lines A & B. An plug-in RJ45 terminator is supplied for use in the first unused jack.

Another option for wiring multiple home runs is with 6 conductor cable. This allows devices to daisy chained by making an in and out

connection, basically a 3 way splice of the data A (Green)wire to 2 wires of the 6 conductor cable (designated A and A1). Do the same for the

data B (White) wire. At the control splice the A1 and B1 wires to the A and B wires going to the next device. Terminate the last wired device

and the control JP3 ONLY! The data wires will be in series, but the POS (+) and Neg (-) power wires should be parallel wired to the +VKP and

Neg terminals or to an auxiliary Power Supply if the combined current draw exceeds the rated current available from the Control.

BLACK

WHITE

GREEN

RS-485 Data Bus (Max. length is 4000 ft.

Max. bus devices vary by control.)

RED

Jumper

Terminate

these two

devices.

DO NOT Jumper

Terminate these devices.

Keypad 1

Data Bus Devices e.g. Keypads, Expanders

Keypad 3

Daisy Chain Connection of Data Bus Devices Using Two (2) Home Run Cables

+VKP

DATA B

DATA A

NEG

RS-485 DATA BUS

Install Teminating

Jumper on this last

device AND on the

control JP3.

6 conductor cable

DATA

A1 A

B1 B

DATA

A1 A

B1 B

Optional Output and Zone Input - See Keypad Instructions

Connect each device to the 6 conductor cable as shown above

Daisy Chain Connection of Data Bus Devices Using 6 Conductor Cables

Keypad

RS-485 DATA BUS

+VKP

DATA B

DATA A

NEG

Keypad

RED

GREEN

BLACK

WHITE

To 12VDC

To 12VDC

BLUE

BROWN

6 Wire

Cable

Keypad

RED +12

+

BLACK (-)

-

GREEN

WHITE

A

A1

B

B1

TO CONTROL

Keypad

ELK-M1DBH Data Bus Hub †

Mount M1DBH inside control. Connect it to the M1

Data Bus terminals using a 4 conductor cable.

J2 J4 J6 J8

J1 J3 J5 J7 J9

RJ45 Terminating Plug Insert in first unused jack and terminate the

control at JP3. DO NOT TERMINATE AT ANY OF THE DEVICES!

CAT5 Cables

Daisy Chain Connection using the ELK-M1DBH and CAT5 Cables.

RS-485 DATA BUS

Keypad

Refer to

Keypad

Instructions

for more info

about Output

and Zone Input

+

-

A

A1

B

B1

TO CONTROL

8 - Brown

7 - Wht/Brn

6 - Orange

5 - Wht/Blue

4 - Blue

3 - Wht/Org

2 - Green

1 - Wht/Grn Pin1

RJ45 Plug

Blue pair

is unused

COLOR CODE for CAT5 or CAT6 Data Bus Cable

to RJ45 Plugs for ELK-M1DBH Data Bus Hub.

Pin1

Front

view

Optional programmable Zone Input

Optional programmable Output

-

+

N.C. N.O.

2200

Ohm

EOL

To BLACK (Neg)

To BLACK (Neg)

Wht/Blue

Brown

Wht/Brn

Orange

Wht/Org

Green

Blue Wht/Grn

RED +12V

BLACK (-)

GREEN

WHITE

BROWN

BLUE

Keypad

CAT5

or

CAT6

Cable

To

+ 12V

Load (50mA max)

I.E. LED, Relay

+ VKP

DATA A

DATA B

NEG

ELK-M1 Data Bus E.O.L. Termination

Page 4 M1XSP Supplementary Instructions and Release Notes

Carrier Infinity HVAC System “Thermostats”

A Carrier Infinity HVAC System can be SERIALLY interfaced to ELK-M1G or M1EZ8 Controls using an M1XSP Serial

Port Expander flash programmed with firmware version 40.0.6 (or later 40.0.x revision). See Firmware Release Notes for

any new releases. Integration involves the connection of the ELK-M1XSP to the RS232 port (Home Automation

Connection) on the Carrier Infinity System Access Module “SAM” model # SYSTXCCSAM01. The SAM actually

supports up to two (2) Carrier Infinity HVAC systems, with each system supporting eight (8) zones. The ELK-M1XSP

can communicate with up to 16 Thermostats total. Refer to LIMITATIONS AND NOTES BELOW.

The firmware in the M1XSP MUST be manually updated to version 40.0.6 or greater. Firmware updates may be

obtained from the Elk website.

Components required:

- ELK-M1 or ELK-M1EZ8 Controller.

- ELK-M1XSP Serial Port Expander. Requires firmware version 40.0.6 to support Carrier Infinity

- Carrier Infinity System Access Module (SAM) model # SYSTXCCSAM01

Setting up the M1XSP and the M1 to communicate with the SAM

1. Install the ELK-M1XSP and set its data bus address per instructions on page 2.

2. Set the M1XSP BAUD jumpers for 38,400 Baud S1=1, S2=1, S3=1

3. Set the M1XSP MODE jumpers to: S5=1, S6=1, S7=1, S8=1 Note: If the M1XSP has a jumper S4 then

set it to 1.

4. Set jumper JP3 to the “232” position. If there is a shorting plug on JP5 then remove it and discard.

5. Connect a standard 9-pin serial cable between the M1XSP and the Carrier Infinity System Access Module (SAM).

6. Power up all the devices and enroll the M1XSP into the M1. VERY IMPORTANT!

7. Update the firmware in the M1XSP to version 40.0.6 (or the latest 40.x.x version). This firmware can be downloaded

from the Elk website.

ElkRP Configuration for Carrier Infinity

10. Use the ELK-RP Software to program a name (see Automation > Thermostats) for each Thermostat being controlled.

The mapping for M1 Thermostats is fixed as follows:

Elk Thermostat 1 is assigned to Carrier System 1, Zone 1 Elk Thermostat 09 is assigned to Carrier System 2, Zone 1

Elk Thermostat 2 is assigned to Carrier System 1, Zone 2 Elk Thermostat 10 is assigned to Carrier System 2, Zone 2

Elk Thermostat 3 is assigned to Carrier System 1, Zone 3 Elk Thermostat 11 is assigned to Carrier System 2, Zone 3

Elk Thermostat 4 is assigned to Carrier System 1, Zone 4 Elk Thermostat 12 is assigned to Carrier System 2, Zone 4

Elk Thermostat 5 is assigned to Carrier System 1, Zone 5 Elk Thermostat 13 is assigned to Carrier System 2, Zone 5

Elk Thermostat 6 is assigned to Carrier System 1, Zone 6 Elk Thermostat 14 is assigned to Carrier System 2, Zone 6

Elk Thermostat 7 is assigned to Carrier System 1, Zone 7 Elk Thermostat 15 is assigned to Carrier System 2, Zone 7

Elk Thermostat 8 is assigned to Carrier System 1, Zone 8 Elk Thermostat 16 is assigned to Carrier System 2, Zone 8

Page 5 M1XSP Supplementary Instructions and Release Notes

It is Elk's understanding that different models of SAM modules are available and that each model retains the Home Automation Connection (RS232) regardless of the

interface technology. However, it is ultimately the responsibility of the Installer to make sure the correct SAM module is selected and that it includes the RS232

connection.

LIMITATIONS & SPECIAL NOTES:

· The M1XSP and M1 supports the following Carrier system commands: Set Mode (Heat, Cool, Auto, Off, EHeat),

Set Fan (Auto, Med), Set Hold (Hold On, Hold Off), Set Current Heat Setpoint, Set Current Cool Setpoint, Set

Current Day, and Set Current Time

· The M1XSP and M1 DOES NOT support Low, High, or any variable speed Fan functions.

· The M1XSP and M1 DOES NOT support any Humidity functionality.

· The M1XSP and M1 DOES NOT support and Outside Temperature Probes.

Page 6 M1XSP Supplementary Instructions and Release Notes

The M1XSP stores it’s operating firmware in “Flash” memory. This state-of-the-art memory allows electronic field updates

and eliminates the old fashion method of changing IC chips or shipping boards back to the factory. As new firmware updates

become available, they will be posted on ELK’s website found at www.elkproducts.com. NOTE: Firmware updating can only

be done through the M1 Control using a Direct to PC Com port connection or an optional Ethernet Network connection.

Dial-up connections cannot be used to perform firmware updates.

How to Update:

1. Physically connect the Computer and Control using either the RS-232 Serial Port 0 or the M1XEP Ethernet Interface.

2. Open ElkRP and the account belonging to the control. Click on the Connection menu icon and establish a connection.

Use either the Direct using Com_ OR Network options.

3. On the Send/Rcv menu icon there is a selection that allows the firmware to be updated.

4. Select the device to be updated. In this case it is a Serial Expander. Select the update firmware option.

5. Display will show: Device name, current Firmware, Hardware, and Bootware version, and a pull down window for selecting

the update firmware. NOTE: All update (.bin) files downloaded or received should be stored in a directory on your

computer. Refer to the Options tab under the Setup menu in RP. It will indicate what directory is used for the update files.

6. Click on the check box for “Update”. If “Reprogram” or “Rollback” is displayed the firmware file is the same as OR older

that what is in the control. Reprogramming with the same firmware is a waste of time but was included for factory testing

purposes. Rollback is not recommended except under the guidance of Elk Technical Support.

Updating/Replacing Firmware in the ELK-M1XSP

Firmware Release Notes

Version 40.0.6 released September 13, 2010

This is the first version of firmware released to support Carrier Infinity System Thermostats

Other manuals for M1XSP

1

Table of contents

Popular Thermostat manuals by other brands

TCS Basys Controls

TCS Basys Controls SZ1041A product manual

wirsbo

wirsbo WT1 user manual

LiquoSystems

LiquoSystems iFerm Nano Terminal operating instructions

Honeywell

Honeywell TB7600 Integration manual

Neptronic

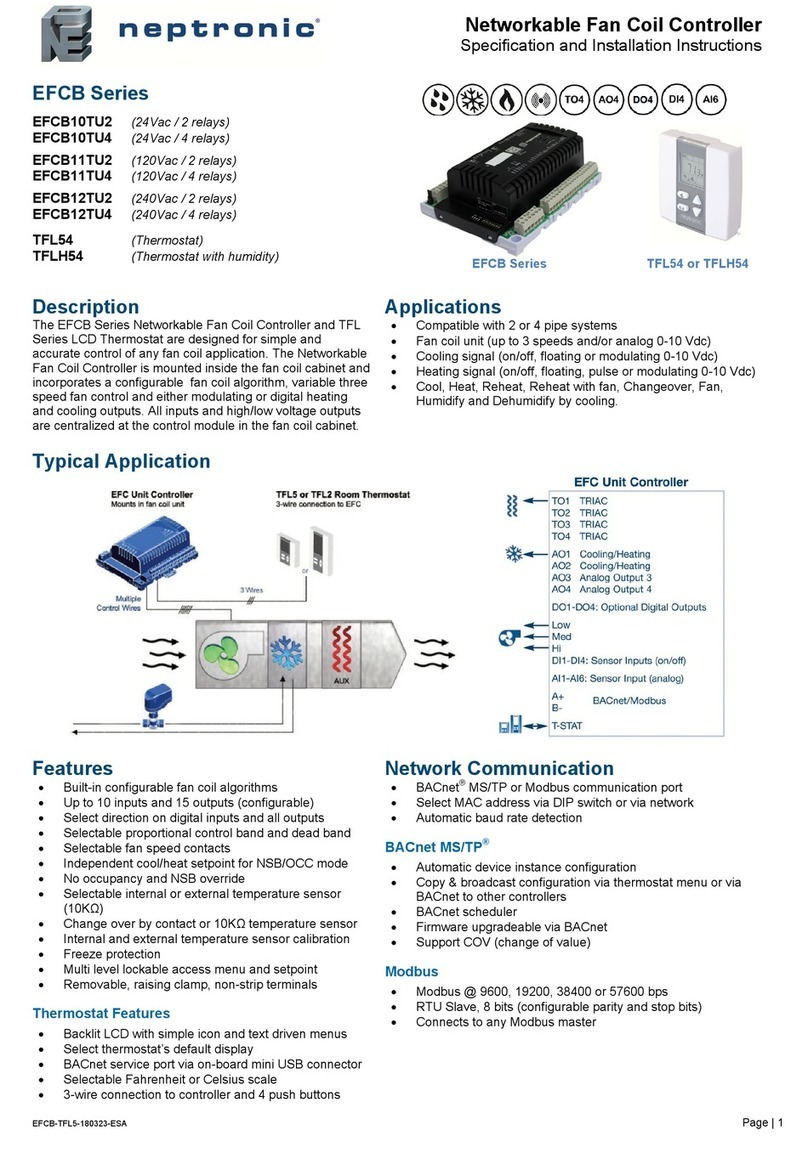

Neptronic EFCB10TU2 Specification and installation instructions

meitav-tec

meitav-tec ETN24-PM-HP-SUPER-BL Owner's manual & technician settings