Fluke Calibration 6054 User manual

6054

Calibration Bath

User Manual

October 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Via Acquanera, 29 22100 Como

tel. 031.526.566 (r.a.) fax 031.507.984

info@calpower.it www.calpower.it

WARNING

To ensure the safety of operating personnel, and to avoid damage to this unit:

DO NOT operate this unit without a properly grounded, properly polarized power cord.

DO NOT connect this unit to a non-grounded, non-polarized outlet.

DO use a ground fault interrupt device.

WARNING

HIGH TEMPERATURES PRESENT

in this equipment.

FIRES and SEVERE BURNS

may result if personnel fail to observe safety precautions.

WARNING

HIGH VOLTAGE

is used in the operation of this equipment.

SEVERE INJURY or DEATH

may result if personnel fail to observe safety precautions.

Before working inside the equipment, turn power off and disconnect power cord.

WARNING

Fluids used in this bath may produce

NOXIOUS OR TOXIC FUMES

under certain circumstances.

Consult the fluid manufacturer’s MSDS (Material Safety Data Sheet).

PROPER VENTILATION AND

SAFETY PRECAUTIONS MUST BE OBSERVED.

c

d

TABLE OF CONTENTS

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Two Modes of Temperature Control . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 The Temperature Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 The Temperature Drift Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.3 The Fluid system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Description Of Features and Controls . . . . . . . . . . . . . . . . . . . . . 12

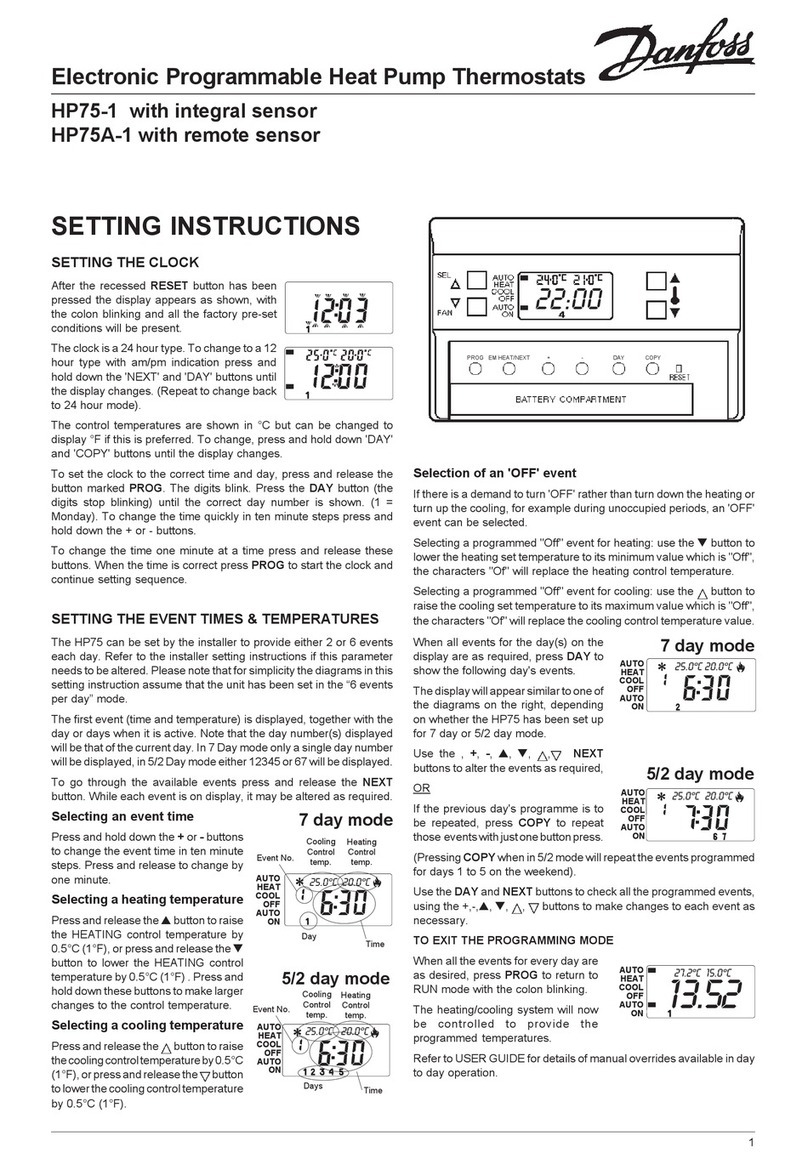

3.2.1 The Controller Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 The Power Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.3 The Rear Panel: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Installation Location Requirements . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.1 Filling the Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.1.1 Filling the Bath With Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2 Draining the Oil from the Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Bath temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Reset Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Temperature Set-point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.1 Programmable Set-points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.2 Set-point Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.3 Set-point vernier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 Temperature Scale Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 Secondary Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6 Heater Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.7 Proportional Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.8 Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

v

6.9 Controller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.10 Probe Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.10.1 R0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.10.2 ALPHA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.11 Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.11.1 Cutout Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.11.2 Stirrer Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.11.3 Stirrer set-point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.12 Serial Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.12.1 BAUD Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.12.2 Sample Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.12.3 Duplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.12.4 Linefeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.13 IEEE-488 Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.13.1 IEEE-488 Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.14 Calibration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.14.1 CTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.14.2 CO and CG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.14.3 H and L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.15 Operation Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Digital Communication Interface . . . . . . . . . . . . . . . . . . . 28

7.1 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2.1 BAUD rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2.2 Sample Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2.3 Duplex Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1.2.4 Linefeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1.3 Serial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 IEEE-488 Communication (optional) . . . . . . . . . . . . . . . . . . . . . . 29

7.2.1 Setup and Address Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.2 IEEE-488 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.3 Interface Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.4 Power Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 Heater Settings for Control. . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Bath Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1 Calibration Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Measuring the Set-point Error . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Computing R0 and ALPHA . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.4 Calibration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9 Bath Heat Transfer Fluid . . . . . . . . . . . . . . . . . . . . . . . 35

vi

9.1 Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.2 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.3 Specific heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.4 Thermal Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.5 Thermal Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.6 Electrical Resistivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.7 Fluid lifetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.8 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.9 Cost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.9.1 Commonly used fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.9.2 Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.9.3 Ethylene Glycol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.9.4 Mineral Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.9.5 Silicone oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.9.6 Heat Transfer Salt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.10 Fluid Characteristics Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.10.1 Limitations and Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.10.2 About the Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.1 The Heater Indicator LED Stays Red But The Temperature Does Not In-

crease. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2 The Controller Display Flashes “CUT-OUT” And The Heater Does Not Oper-

ate. 41

10.3 The Display Flashes “CUT-OUT” And An Incorrect Process Temperature. . . 41

10.4 The Displayed Process Temperature Is In Error And The Controller Remains In

The Cooling Or Heating State At Any Set-point Value. . . . . . . . . . . . . . . . . 42

10.5 The Controller Controls Or Attempts To Control At An Inaccurate Tempera-

ture. 42

10.6 The Controller Shows That The Output Power Is Steady But The Process Temper-

ature Is Unstable.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.7 The Controller Alternately Heats For A While Then Cools. . . . . . . . . . . 42

10.8 The Controller Erratically Heats Then Cools, Control Is Unstable. . . . . . . . 42

vii

1 Introduction

The Hart Scientific Model 6054 Calibration Bath is a

highly stable constant temperature liquid bath. It has

been designed for calibrating liquid and glass ther-

mometers or other types of long thermometers

against a known temperature standard such as a

Standard Platinum Resistance Thermometer

(SPRT).

The 6054 calibration bath provides the following fea-

tures:

•A deep fluid tank (test well is 7.5 inches in di-

ameter and has 24 inches of fluid depth).

•It provides a highly temperature stable low gra-

dient environment typically a nominal stability

of ±0.005°C with oils. The fluid is well stirred

and environmentally protected to minimize

gradients.

•The fluid level is near the top of the test well to

facilitate calibration of liquid and glass ther-

mometers without needing to compensate for

stem effect.

•The bath provides two calibration modes. An

electronically controlled mode uses a hybrid

digital and analog PI controller with lock in am-

plifier design. The temperature and other func-

tions are selected with the four button keypad

to a hundredth of a degree and finer with a digi-

tal vernier adjustment. The Drift mode by-

passes the controller with heater power

manually controlled with variable transformer.

Introduction

9

2 Specifications

Specifications

10

Power Required . . . . . . . . . 230 VAC; 60 Hz; 15 Amps max.

Bath Temperature Range . . . . 50°C to 325°C

Temperature Stability. . . . . . . ±0.005°C to 200°C, ±0.010°C to 325°C

Temperature Uniformity . . . . . ±0.005°C max

Controller Accuracy . . . . . . . ±0.5°C

Test Well Area . . . . . . . . . . 7.5-inches dia X 24-inches deep

Heater . . . . . . . . . . . . . . Electrical, 5 positions; 1=off, 2=250, 3=500, 4=750 & 5=1,000 watts at

240 VAC line

Boost Heater . . . . . . . . . . . 750watts

Heat Transfer Liquid . . . . . . . Fluids compatible with stainless steel may be used. (e.g. oils such as

Dow Corning 710 and 210H or Hart Salt)

Exterior Dimensions . . . . . . . Height 56" X Width 31" X FB 23"

Weight . . . . . . . . . . . . . . 156 Lbs.

Table 1

Specifications

3 Theory of Operation

The components, features and operational theory of

the Model 6054 calibration bath are described in this

section.

3.1 Two Modes of

Temperature Control

Two modes of temperature control are available with

the model 6054. The TEMPERATURE CONTROL

mode or the TEMPERATURE DRIFT mode may be

selected by a switch on the front panel.

3.1.1 The Temperature Control Mode

The control mode uses a hybrid digital/analog PI tem-

perature controller with lock-in-amplifier. The bath

stability is very high with this controller. The tempera-

ture is selected using a four button keypad on the front

panel. Temperatures from 0.00 to 325.00°C may be

selected directly to a hundredth of a degree. Finer ad-

justment is available using the vernier adjustment.

Accuracy of the setting is typically ±0.5°C or better.

The controller pulses AC current to the control heat-

ers in a time modulated fashion to compensate for

heat gains and losses to the system. A two color LED

on the control panel glows red when the heaters are

on and glows green when they are off and cooling is

taking place. (Note: The cooling required for control is

supplied through heat loss to ambient.)

The Temperature control probe uses a 100 ohm PRT.

It is a totally separate unit for ease of replacement. It is

inserted into the top of the bath near the stirring motor

as shown and plugs into the rear of the control unit.

The heaters are external to the tank. They are ar-

ranged electrically to provide the 4 control heating po-

sitions plus an off position. The additional boost

heating position is accessed from a separate switch

on the control panel.

3.1.2 The Temperature Drift Mode:

In the Temperature Drift mode the heater may be set

manually to allow the temperature to drift very slowly

(a few milli-°C per minute) over the desired range.

This allows the control noise to be eliminated al-

though greater skill is required in making calibrations.

The heater power is adjusted by means of a variable

transformer located on the control panel. It allows po-

sition one of the heater selection switch to be continu-

ally variable from 0 to 100% Positions 2, 3, 4 and

Boost add their full value of heat incrementally to the

adjusted value of position 1.

3.1.3 The Fluid system

The fluid system consists of the insulated tank, the

stirrer assembly, the condensate drain, the overflow

test well, and the fluid itself. The heaters and probe,

which are part of the control system, are physically

external to the tank.

The tank and other wetted parts are made of stainless

steel for compatibility with most practical

thermostating fluids.The stirrer is attached to the tank

top plate of the bath and its motor receives additional

cooling from a fan to keep from overheating and in-

crease lifetime at high bath temperatures. The stirrer

directly drives four 2-inch diameter stirring propellers.

The down draft from the propellers forces the bath

fluid through the overflow test well. The stirring motor

plugs into the rear of the control unit. (See Figure 3 on

page 14.)

The over-flow test well serves to provide a constant

depth of fluid at an essentially constant height near

the well opening. Variations in fluid volume due to

thermal expansion and volatilization will not effect

measurements within reasonable volume ranges.

The fluid expelled from the tank is controlled to flow

past the control heaters first before entering the main

tank for thermal management.

A drain is provided for convenience in changing the

bath fluid. (See draining the tank.)

The condensate drain collects condensed oil vapor

and oil that has expanded over the top of the tank

walls.Tubes on either side of the drain at the bottom of

the bath allow the liquid to be collected into a pan. Be

sure this pan is in place at all times to prevent oil from

draining onto the floor The condensate pan must be

Theory of Operation

11

EXIT — Used to exit from a menu. When EXIT is

pressed any changes made to the displayed value will

be ignored.

3) The control indicator is a two color light emitting di-

ode (LED). This indicator lets the user visually see the

ratio of heating to cooling. When the indicator is red

the heater is on, and when it is green the heater is off

and the bath is cooling.

3.2.2 The Power Panel

The Power Panel (Figure 2) controls include; 1) The

Mode Select switch and indicators, 2) the Drift Ad-

just control 3) the control Heating select switch, 4)

the Power switch and indicator, and 5) the Boost

Heater and indicator.

1) The MODE SELECT switch selects between the

Temperature Control and Drift Adjust modes. Lights

show which mode is functioning. The Temperature

Control position selects the temperature controller to

operate and the desired temperature is selected on

the controller panel. In the Temperature Drift mode

heater control is via the Drift Adjust control and the

Heating select switch.

2) The DRIFT ADJUST control is a variable trans-

former that adjusts the Low control heater through 0

to 100% of its power range. The additional power re-

quired for higher temperatures may be added in steps

by selecting heating positions Medium, Medium High,

and High, as required.

3) The control HEATING switch selects control heater

power positions 1 through 5. Select the lowest rea-

sonable value for normal control conditions depend-

ing on bath temperature. The switch simply adds

more heaters into the circuit until the desired power is

attained. Position 2 is variable using the Drift Adjust

control.

4) The POWER (On-Off) switch powers up the bath.

The switch is a DPST type that opens both legs of the

230 volt power source. A red indicator light shows that

power is on.

5) The BOOST HEATING provides an additional 750

watts for slewing between temperatures. The Boost

Heating Indicator shows whether the boost heater is

on or off. The boost heater is powered through the

Theory of Operation

13

50

60

70

80

90

100

40

30

20

10

0PERCENT

DRIFT ADJUST

MODE SELECT

TEMPERATURE CONTROL

TEMPERATURE DRIFT

HEATINGPOWER

LOW

HIGH

ON

OFF

BOOST

HEATER

OFF

OFF

Boost Heating

Indicator

Power

Indicator

Power

Switch

Heating

Switch

Temperature Control

Mode Indicator

Boost Heating

Switch

Mode Select

Switch

Temperature Drift

Mode Indicator

Drift Adjust

Control

12

3

4

5

Figure 2

Power panel

Theory of Operation

14

F

U

S

E

F

U

S

E

F

U

S

E

F

U

S

E

1

2

3

4

5

6

7

8

Figure 3

Back panel

temperature controller triac to prevent exceeding the

desired set temperature. The boost heater indicator

will flash when the set temperature has been reached

as a reminder to turn it off for control.

3.2.3 The Rear Panel:

The Rear Panel has many features (see Figure 3). 1)

The PROBE connector, 8) STIRRER POWER outlet,

7) FUSES, 6) Power Connection, 5) ELECTRONICS

FUSE INTERNAL notation, 2) Unit SERIAL NO. no-

tation, 3) optional SERIAL PORT and, 4) optional

IEEE-488 PORT.

1) The PROBE connector on the back panel is used

for the temperature controller probe.

2) The unit SERIAL NO. is located at the top right cor-

ner of the back panel. When consulting with the fac-

tory, refer to the serial number.

3) SERIAL PORT (optional)

4) IEEE-488 PORT (optional)

5) The ELECTRONICS FUSE is located inside the

cabinet and is a 1/4 amp fuse. To replace the elec-

tronic fuse, remove the cover over the controller.

6) The POWER CORD connector

7) The SYSTEM FUSES are 15 amps slow blow (one

fuse for each leg of the 230 VAC). The heater fuses

are located internally and are 10 amp, 250 VAC.

8) The STIRRER POWER connection provides 230

VAC to the stirring motor and its cooling fan.

Theory of Operation

15

4 Installation

The Model 6054 bath can be readily installed given

due care to the following instructions.

4.1 Receiving and Inspection

Upon receipt of the bath, inspect it to see that there is

no obvious damage from shipment. If any damage is

observed, notify the carrier at once for an inspector to

check out the damage.

Verify that all of the items ordered have been shipped.

Notify Hart Scientific immediately if there are any dis-

crepancies.

4.2 Installation Location

Requirements

4.2.1 Environment

The model 6054 bath is a precision instrument that

must be located in an appropriate environment. The

location should be free from drafts, extreme tempera-

tures and temperature changes, dirt, etc. The bath

must be level, use the levelers. Allow free air space

around the bath to allow surface heat to convect away

freely. Ventilation of oil fumes will require a fume hood.

4.2.2 Electrical Power

The bath requires 208-240 VAC single phase power.

The higher voltage is used for running the heaters and

is required to reduce the current to reasonable levels.

The power connected at the junction box on the rear

of the bath. The two hot legs are wired to the brown

and blue wires, and the ground to the green/yellow

wire according to standard convention.

4.2.3 Safety Considerations

The Hart model 6054 bath is a high temperature bath.

Although safety has been a concern in its design,

there are several installation and operational consid-

erations to prevent fire and burns.

Install the bath in an inherently fire safe area. There

should not be any material around that will ignite by

setting hot probes and thermometers on it or by spill-

age of the hot bath fluid.

The best floor surface is concrete. If concrete is un-

available, the surface should be protected in some

way from inadvertent spillage.

Do Not install the bath near flammable wall materials.

We recommend installing the bath under a fume hood

to safely remove oil fumes. It also will help to remove

excess heat. It is best to direct oil fumes away from the

user when using.

Keep all flammable liquids, fumes, gasses, etc. away

from the bath to prevent ignition.

Keep fire safety equipment specific to the type of me-

dium handy in case they are needed.

Safe handling equipment such as leather gloves

(such as welding gloves), face shields, long apron etc.

are required for reasonable safety.

4.3 Setup

Inspect the probe.It should not be bent or damaged in

any way. The probe used with the Model 6054 is a pre-

cision PRT sensor.

The probe is to be plugged into its connector on the

rear of the bath and inserted fully into the hole located

near the stirrer motor inside the motor cover.

Plug the stirrer into the receptacle located on the rear

panel of the bath marked STIRRER POWER.This re-

ceptacle is switched on with the unit’s main power.

Attach a drain line to the overflow drain tube at the

rear of the bath behind the strirer. Use a line compati-

ble with the selected fluid and maximum bath temper-

ature to be used. Run the line to a similarly adequate

sump.

4.3.1 Filling the Bath

The bath is shipped dry. Check inside of the test well

for foreign matter and remove it to avoid interference

with operation.

Installation

16

4.3.1.1 Filling the Bath With Oil

To fill the bath with oil, first be sure the drain is fully

closed off. Check the drain assembly for tight fittings.

Pour in the heat transfer fluid until it reaches a 1-inch

depth from the top of the top plate. Note: Actual depth

depends on the thermal expansion of the oil and the

anticipated temperature range. The fluid volume of

the tank is approximately 2800 cubic inches to the

level of the primary overflow. The flowing fluid level

can be adjusted somewhat by adding to or removing

fluid.The fluid level during pumping should be flowing

over the rim.

The bath is now ready for operation.

4.3.2 Draining the Oil from the Bath

Installation

17

5 Operating Instructions

Operating the model 6054 constant temperature bath

is not complex, but must be done according to the fol-

lowing instructions.

The system must be installed and the bath filled ac-

cording to the instructions in the previous section.

5.1 Quick Start

With the bath fluid in the bath and the control probe in

place, the bath is ready to be turned on. When

switched on, the stirring motor, the controller display-

ing the bath temperature, and the heater will come on.

Now set the bath to the desired temperature using the

buttons to set the temperature controller. This is ac-

complished by pressing the SET button and then us-

ing the UP and DOWN buttons to reach the desired

set temperature. Once the set-point desired is dis-

played, press the SET button to set the bath to the

new temperature and then press the EXIT button to

return to the temperature display (refer to the Temper-

ature Controller User Flow chart Figure 4). The bath

will heat to the set temperature and begin to control.

Allow several minutes for the bath to stabilize at the

control set-point.

The heater power switch should be set to the lowest

position necessary to provide adequate power to con-

trol. Obviously, higher bath temperatures will require

higher heater settings. The boost heater may be

switched on to bring the bath up to higher tempera-

tures quickly.It must be switched off when the temper-

ature is reached.

To achieve optimum control stability the proportional

band may require adjustment. The ideal proportional

band setting varies with temperature, heater setting,

and fluid type.

It is advised that you operate the 6054 bath with an

access cover or thermometer holder in place. At most

temperatures, control stability is improved with the

cover in place. At high temperatures, the use of the

cover also improves safety.

To accelerate bath cooling after operation at a higher

temperature, the access cover may be removed to al-

low greater air cooling. It also may be possible to

make use of a dip chiller or auxiliary cooling coil to de-

crease cooling times.

If the Temperature Drift mode is desired, select that

position after adjusting the Drift Adjust to 0% to elim-

inate jumps in temperature, then adjust to the antici-

pated heating position. Use a bridge and strip chart

recorder or other adequate means to establish the

desired temperature drift rate as the Drift Adjust con-

trol is adjusted upward. Select the LOW control

heater position for the minimum amount of heat and

add heat in increments with positions MEDIUM,ME-

DIUM HIGH and HIGH as needed.

Operating Instructions

18

6 Controller Operation

This Section discusses in detail how to operate the

bath temperature controller using the front control

panel. Using the front panel key switches and LED

display the user may monitor the bath temperature,

set the temperature set-point in degrees C or F, moni-

tor the heater output power, adjust the controller pro-

portional band, set the cutout set-point, and program

the probe calibration parameters, operating parame-

ters, serial and IEEE-488 interface configuration, and

controller calibration parameters.Operation of the pri-

mary functions is summarized in Figure 4.

6.1 Bath temperature

The digital LED display on the front panel allows di-

rect viewing of the actual bath temperature. This tem-

perature value is what is normally shown on the

display. The units, C or F, of the temperature value are

displayed at the right. For example,

25.00 C

Bath temperature in degrees

Celsius

The temperature display function may be accessed

from any other function by pressing the “EXIT”button.

6.2 Reset Cutout

If the over-temperature cutout has been triggered

then the temperature display will alternately flash,

Cut-out

Indicates cut-out condition

The message will continue to flash until the tempera-

ture is reduced and the cutout is reset.

The cutout has two modes — automatic reset and

manual reset.The mode determines how the cutout is

reset which allows the bath to heat up again. When in

automatic mode, the cutout will reset itself as soon as

the temperature is lowered below the cutout set-point.

With manual reset mode the cutout must be reset by

the operator after the temperature falls below the

set-point.

When the cutout is active and the cutout mode is set

to manual (“reset”) then the display will flash “cutout”

until the user resets the cutout. To access the reset

cutout function press the “SET” button.

SAccess cutout reset function

The display will indicate the reset function.

rESEt ?

Cutout reset function

Press “SET” once more to reset the cutout.

Reset cutout

This will also switch the display to the set temperature

function. To return to displaying the temperature

press the “EXIT” button. If the cutout is still in the

over-temperature fault condition the display will con-

tinue to flash “cutout”. The bath temperature must

drop a few degrees below the cutout set-point before

the cutout can be reset.

6.3 Temperature Set-point

The bath temperature can be set to any value within

the range as given in the specifications with a high de-

gree of resolution. The temperature range of the par-

ticular fluid used in the bath must be known by the

operator and the bath should only be operated well

below the upper temperature limit of the liquid. In ad-

dition, the cutout temperature should also be set be-

low the upper limit of the fluid.

Setting the bath temperature involves three steps: (1)

select the set-point memory, (2) adjust the set-point

value, and (3) adjust the vernier, if desired.

6.3.1 Programmable Set-points

The controller stores 8 set-point temperatures in

memory. The set-points can be quickly recalled to

conveniently set the bath to a previously programmed

temperature.

To set the bath temperature one must first select the

set-point memory. This function is accessed from the

temperature display function by pressing “SET”. The

number of the set-point memory currently being used

Controller Operation

19

Controller Operation

20

SET/EXIT

Calibration

Menu

CTO

Adjust CTO

C0

Adjust C0

CG

Adjust CG

H

Adjust H

L

Adjust L

SET/EXIT

IEEE-488

Interface

Menu

Device

Address

Adj. Device

Address

UP UP UP UP

DOWN DOWN DOWN DOWN

SET SET SET SET

SET/EXIT

Operating

Parameters

Menu

SET

EXIT EXIT EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

SET SET SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET/EXIT SET/EXIT

SET/EXIT SET/EXIT SET/EXIT SET/EXIT

SET/EXIT

SET/EXIT

SET/EXIT

SET/EXIT

SET/EXIT

Probe

Menu

R0

ALPHA

Adj. R0

Adj. ALPHA

SET/EXIT

Serial

Interface

Menu

BAUD

Rate

Adjust

BAUD Rate

Sample

Period

Adj. Sample

Period

Duplex

Mode

Adj. Duplex

Mode

Linefeed

Adjust

Linefeed

EXITEXITEXIT EXIT EXIT

EXIT

EXIT

EXIT

EXIT

EXIT

SET +

Display Power

Set Proportional Band

Set Cutout Temp.

EXIT

EXIT

EXIT

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

Reset Cutout

Select Setpoint

Adjust Setpoint

EXIT

EXIT Adjust Vernier

Set Scale °C/°F

Cutout Active

Display

Temperature

Cutout

Reset Mode

Stirrer

Mode Select

Stirrer

Setpoint

Adj. Cutout

Reset Mode

Adj. Stirrer

Mode

Adj. Stirrer

Setpoint

X5

DO NOT CHANGE THESE VALUES. SEE MANUALDO NOT CHANGE THESE VALUES. SEE MANUAL

Configuration Menu

Secondary Functions

IEEE-488

Option Installed

Interface

Option Installed

Figure 4

Controller Operation Flowchart

is shown at the left on the display followed by the cur-

rent set-point value.

25.00 C

Bath temperature in degrees

Celsius

SAccess set-point memory

1. 25.0

Set-point memory 1, 25.0°C

currently used

To change the set-point memory press “UP” or

“DOWN”.

UIncrement memory

4. 40.0

New set-point memory 4,

40.0°C

Press “SET” to accept the new selection and access

the set-point value.

SAccept selected set-point memory

6.3.2 Set-point Value

The set-point value may be adjusted after selecting

the set-point memory and pressing “SET”. The

set-point value is displayed with the units, C or F, at

the left.

C 40.00

Set-point 4 value in°C

If the set-point value need not be changed then press

“EXIT” to resume displaying the bath temperature. To

adjust the set-point value press “UP” or “DOWN”.

UIncrement display

C 42.50

New set-point value

When the desired set-point value is reached press

“SET” to accept the new value and access the

set-point vernier.If “EXIT” is pressed instead then any

changes made to the set-point will be ignored.

SAccept new set-point value

6.3.3 Set-point vernier

The set-point value can be set with a resolution of

0.01°C. The user may want to adjust the set-point

slightly to achieve a more precise bath temperature.

The set-point vernier allows one to adjust the temper-

ature below or above the set-point by a small amount

with very high resolution. Each of the 8 stored

set-points has an associated vernier setting. The ver-

nier is accessed from the set-point by pressing “SET”.

The vernier setting is displayed as a 6 digit number

with five digits after the decimal point. This is a tem-

perature offset in degrees of the selected units, C or F.

0.00000

Current vernier value in°C

To adjust the vernier press “UP” or “DOWN”. Unlike

most functions the vernier setting has immediate ef-

fect as the vernier is adjusted. “SET” need not be

pressed.This allows one to continually adjust the bath

temperature with the vernier as it is displayed.

UIncrement display

0.00090

New vernier setting

Next press “EXIT” to return to the temperature display

or “SET” to access the temperature scale units selec-

tion.

SAccess scale units

6.4 Temperature Scale Units

The temperature scale units of the controller may be

set by the user to degrees Celsius (°C) or Fahrenheit

(°F). The units will be used in displaying the bath tem-

perature, set-point, vernier, proportional band, and

cutout set-point.

The temperature scale units selection is accessed af-

ter the vernier adjustment function by pressing “SET”.

From the temperature display function access the

units selection by pressing “SET” 4 times.

25.00 C

Bath temperature

SAccess set-point memory

1. 25.0

Set-point memory

Controller Operation

21

Table of contents

Popular Thermostat manuals by other brands

Heatit Controls

Heatit Controls Z-TRM6 installation manual

EUROSTER

EUROSTER 2026TXRXG Installation and operation manual

Honeywell

Honeywell T8000 installation instructions

White Rodgers

White Rodgers 1D56 installation instructions

Netatmo

Netatmo S+ARCK Quick installation guide

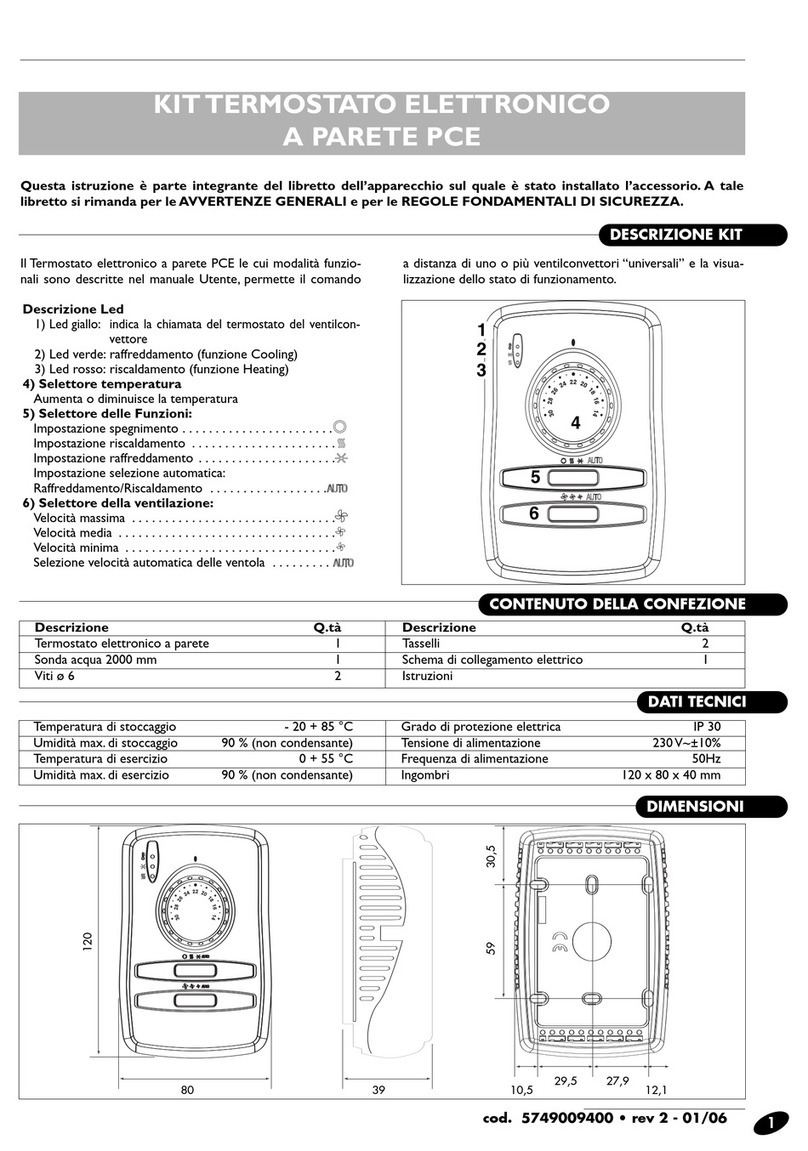

CLIMAVENETA

CLIMAVENETA PCE manual