Elseta IOMOD 4RTD User manual

IOMOD 4RTD is used for temperature data monitoring over Modbus or IEC-60870-103 using resistance temperature

detector (RTD) platinum sensors. Up to 4 RTD temperature sensors can be connected at once.

● Temperature sense with ±0.5 °C accuracy over all operating conditions;

● Selectable PT100 ar PT1000 RTD temperature sensor for every channel (2, 3 or 4 wire);

● 2.5kV(rms) isolated RTD inputs;

● Configurable temperature and sensors’ fault detection for every channel;

● Temperature sensing range from -200 up to 800 °C when using platinum RTD sensors;

● Configurable Modbus or IEC-60870-103 settings: Slave ID, baud rate, parity and stop bits, RS485 terminating

resistor, etc.

● Firmware upgrade over USB.

IOMOD uses Modbus (RTU) or IEC-60870-103 protocols over RS485 connection, which can be used for cable lengths up

to 1500 meters and connect up to 30 devices on one line. Default Modbus and IEC-60870-103 settings are: 9600

bauds/s baudrate, 8N1, Slave (Link) address - 1.

To read temperature using Modbus (RTU) protocol user can use device with default settings without configuring it. To

read temperature from RTD sensor, send 04 Modbus command (Read Input Registers) with resolution of two registers

from 0 to 7. Odd numbers represent least significant words, even numbers represent most significant words. For

example, to read temperature measured by first RTD, read register 0 and 1, where register 0 is least significant word.

Two words read by Modbus represent a float type (IEEE-754 compatible) variable.

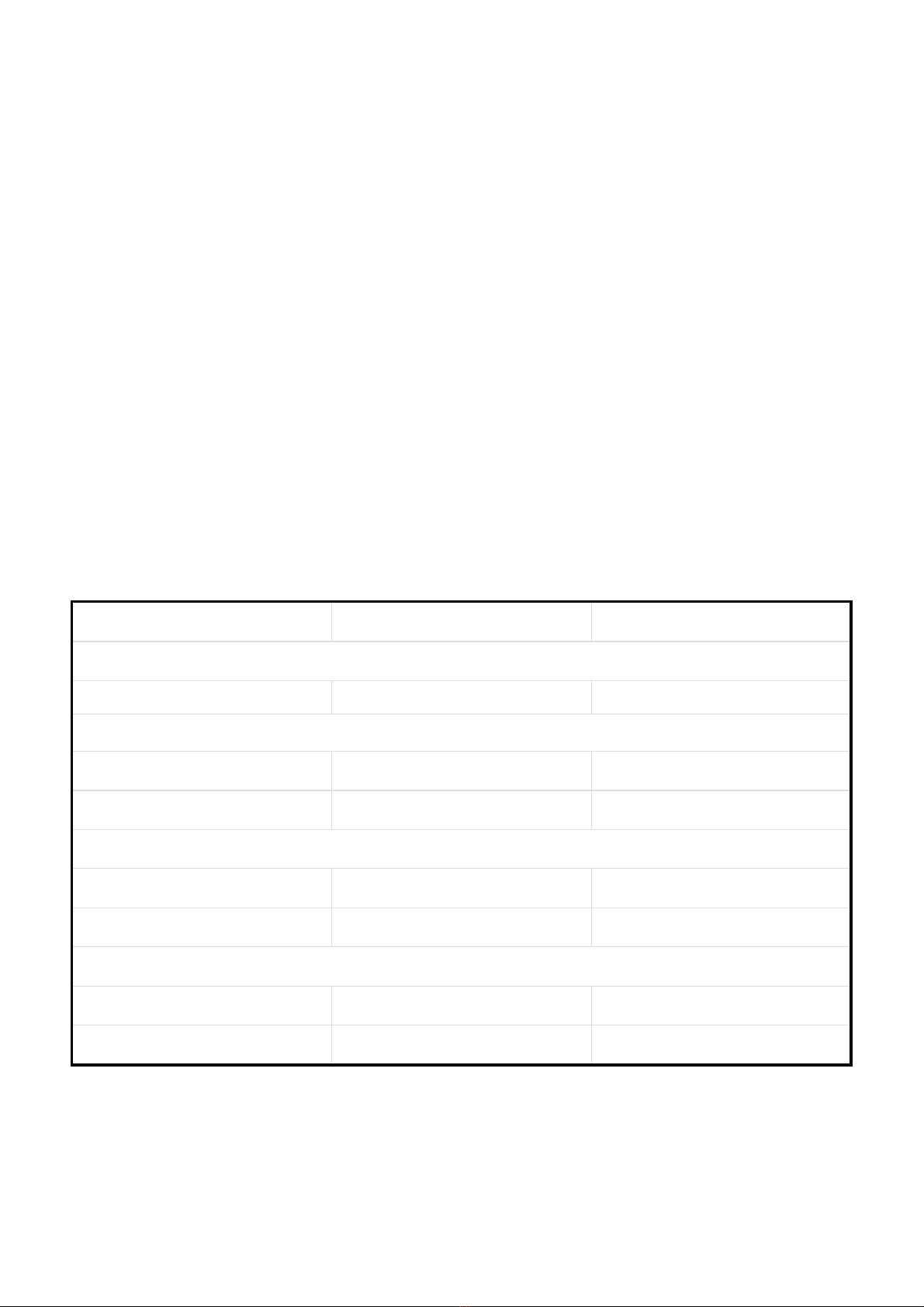

For further information regarding setting temperature parameters and configurable options please refer to table shown

below, also supported MODBUS functions described in paragraphs described below.

CONFIGURABLE OPTIONS

OVER USB

OVER MODBUS

Slave Address

Yes

No

Baudrate

Yes

No

Data, Stop and Parity bits

Yes

No

RS485 Terminating Resistor

Yes

No

RTD parameters

Yes

No

Default settings

Yes

No

Setting temperature limits

Yes

Yes

Fault configuration

Yes

Yes

Status LED can be in 2 colors :

Blue - Device connected to USB.

Green - Normal operation.

The RX/TX LED on the IOMod flashes when data is either being transmitted or received via the RS485 port.

IOMOD 4RTD User Manual Modbus

Introduction

Features

Operational Information

Status LED

Rx/Tx LED

01 (0x01) Read Coil Status

Used to read fault flags. Fault is implemented as high logic level if any configured fault has occurred, zero otherwise.

Fault flags are cleared automatically if possible.

03 (0x03) Read Holding Registers

May be used to read holding registers containing temperature limits defined by user in degrees Celsius, fault mask

register.

Temperature limits are defined as 16-bit integer values. Values that are below or above the predefined limits are

ignored. These limits are described in Modbus register mapping table below. If upper limit value is lower than lower

limit value, these values are switched between them.

Fault mask registers contain information about fault bits that would be lifted in fault register if any particular fault for

particular RTD has occurred. Its values for every four RTDs are kept at holding register of addresses 11 to 14.

04 (0x04) Read Input Registers

May be used to read current temperature values and faults.

As temperature is kept as a 4-byte wide float value, two neighboring register are used to keep it. RTD values are kept

at registers 0 to 7, least significant word first. Values read can be easily converted using any converter capable of

converting floats based of IEEE-754 standard.

Fault register values are read as 16-bit input registers on addresses 16 to 19. Meanings of individual bits are explained

below, in subsection Fault registers.

06 (0x06) Preset Single Register

Used to set holding registers one by one described when explaining 03 Modbus function. That means that arbitrary

value may be written to set up different temperature limits and faults masks.

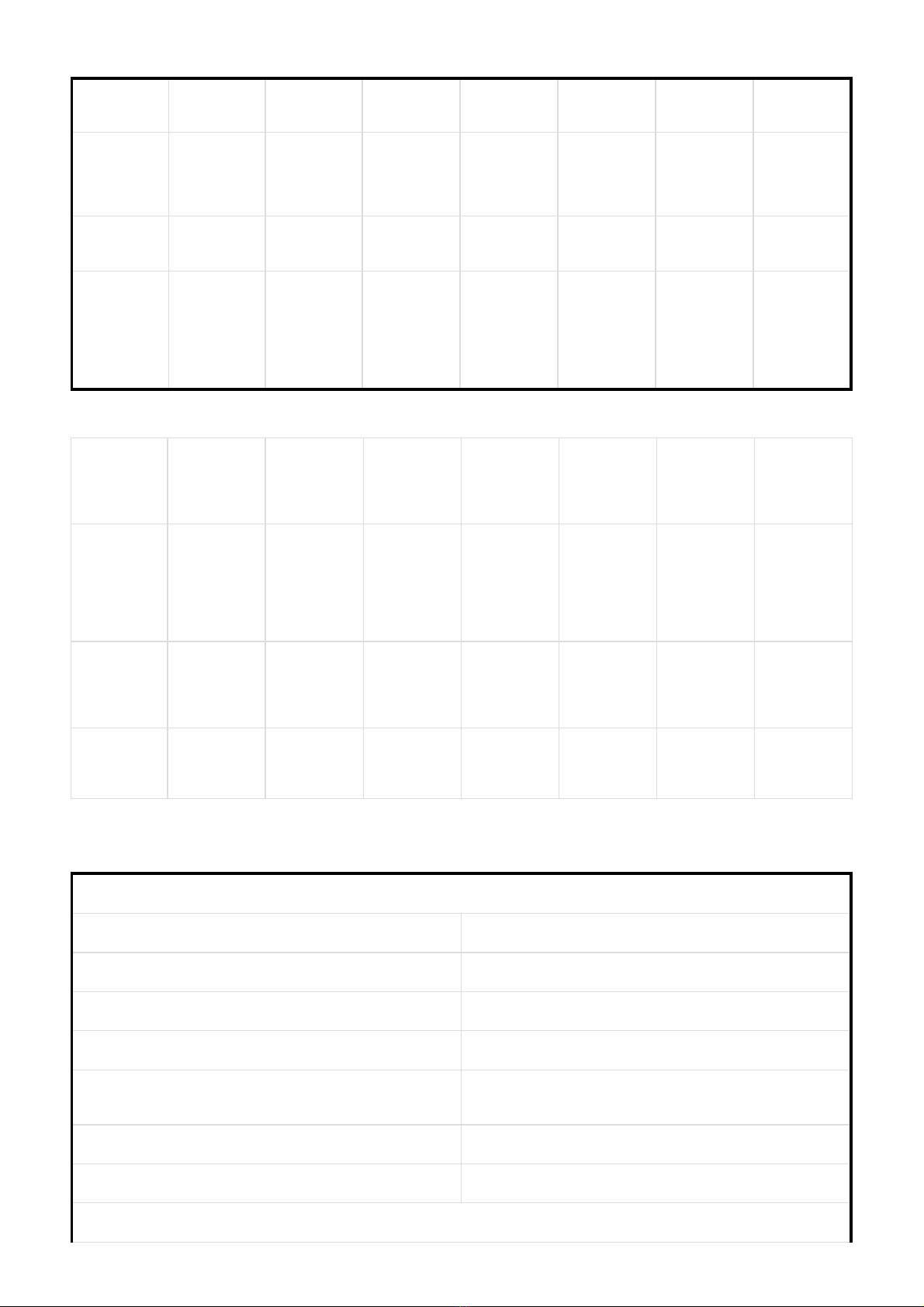

Register (decimal)

Description

Value range

Read coil status (01)

00010-00013

Reading fault flags

0-1

Read holding register (03)

00000-00007

Get temperature limits (lower limit first)

-200-800

00011-00014

Fault Mask registers for RTDs

0-57836

Read input registers (04)

00000-00007

Temperatures from RTD sensors, LSW first

0-65535

00016-00019

Fault registers for RTD sensors

0-57836

Preset Single Register (06)

00000-00007

Set temperature limits (lower limit first)*

-200-800

00011-00014

Set Fault Mask register for RTDs

0-65535

Fault registers (Modbus addresses - 16-19) are read-only. They represent faults that occurred during operation of

device. To enable showing desired fault user should set appropriate bits in Fault mask register (Modbus addresses - 11-

14) or via USB interface, entering Advanced Settings Tab in RTD parameters menu. Fault registers and fault masked

registers are different for different temperature channels. Default values are shown in brackets below.

Fault register[15:14] shows flags that are lifted if temperature limits are exceeded. Bits[7:5,3:2] inform about faults

that were detected by RTD reading chip. These faults are usually lifted if unsuitable settings are set or RTD is faulty or

not connected.

Supported MODBUS functions

Modbus register table

Fault registers

Fault register

15

(R-0)

14

(R-0)

13

(R-0)

12

(R-0)

11

(R-0)

10

(R-0)

9

(R-0)

8

(R-0)

RTD

Temperature

Hi Threshold

RTD

Temperature

Lo Threshold

-

-

-

-

-

-

7

(R-0)

6

(R-0)

5

(R-0)

4

(R-0)

3

(R-0)

2

(R-0)

1

(R-0)

0

(R-0)

RTD Code Hi

Threshold

RTD Code Lo

Threshold

RTD REFIN- >

0.85 x VBIAS

-

RTD FORCE

Open

RTD

Overvoltage/

Undervoltage

-

-

Fault mask register

15

(R/W-0)

14

(R/W-0)

13

(R/W-0)

12

(R/W-0)

11

(R/W-0)

10

(R/W-0)

9

(R/W-0)

8

(R/W-

RTD

Temperature Hi

Threshold Fault

Enable

RTD

Temperature Lo

Threshold Fault

Enable

-

-

-

-

-

-

7

(R/W-1)

6

(R/W-1)

5

(R/W-1)

4

(R/W-0)

3 (R/W-1)

(R/W2 -1)

1 (R/W 0) -

0 (R/W 0)

RTD Code Hi

Threshold

RTD Code Lo

Threshold

RTD REFIN-

> 0.85 x

VBIAS Fault

-

RTD FORCE

Open

RTD

Overvoltage/Un

dervoltage

-

-

System

Dimensions

17.5 (H) x 101 (W) x 119 (L), mm

Case

ABS, black

Working environment

Indoor

Working temperature

-40 | +80°C

Recommended operating

conditions

5 – 60°C and 20 – 80% RH;

Configuration

USB

Firmware upgrade

USB – mass storage device

Electrical characteristics

Technical information

Termination resistor

Selectable, 120Ω

Power

Power Supply

9-33 VDC

Current consumption

40mA @ 12VDC, 20mA @ 24VDC

IOmod 4RTD can be powered through main power connector +12/24 VDC or through USB. Apply +12/24VDC to V+

and 0 V to V-. The device has a built-in reverse voltage polarity, overcurrent and overvoltage protection.

IOMod 4RTD has one RS485 connector. Connect RS485 cable pair to contacts marked RS485/A and RS485/B.

Connections should be made with minimum possible cable stub.

IOMOD 4RTD has integrated 120Ω termination resistor which can be enabled or disabled over USB configuration. It is

recommended to use termination at each end of the RS485 cable. See typical connection diagram on Fig. 5.1.

Fig. 5.1. Typical IOMod connection diagram

IOMOD 4RTD has 1/8 Unit load receiver which allows to have up to 256 units on line (compared to standard 32 units).

To reduce reflections, keep the stubs (cable distance from main RS485 bus line) as short as possible when connecting

device.

IOMOD 4RTD devices has indications that help user easily debug possible problems. Light emitting diodes can show if

RTD fault has happened on any of four RTD measuring channels (FLT1-FLT4). STAT LED indicates if proper power

Device Connection

Power connection

RS485 serial interface

Status indication

connection is made - this LED is always on if device has a power connection. Blue light means device is only powered

via USB, green light indicates proper power connection is made and there is no fault condition on printed circuit board

, red light indicates there is something wrong with either power connection or RTD channels. RX/TX status LED

indicates if RS- 485 transmission is happening at a moment.

Fig. 5.3. RTD sensor colour codes

IOmod 4RTD accepts 2-wire, 3-wire or 4-wire connection types of RTD sensors (PT100, PT1000). Firstly, select a sensor

type (PT100 or PT1000) using a USB terminal. Secondly, use the following instructions depending on the number of

wires of a selected RTD sensor.

2-wire RTD sensor: connect red wire to RTD+ and white wire (or black) to RTD- contacts. The connection between

RTD+ and F+, RTD- and F- must be shorted.

3-wire RTD sensor: connect one red wire to RTD+, second red wire (compensating lead wire) to F+ and white (or black)

wire to RTD-. The jumper between RTD- and F- must be shorted.

4-wire RTD sensor: connect red wires to RTD+ and F+ contacts, white (or black) wires to RTD- and F- contacts. No

contacts shall be shorted.

IOmod 4RTD USB interface is used for configuration, diagnostics and firmware updates. IOmod 4RTD is powered

through USB when connected, no extra power connection needed for operation. Use a USB mini B cable for connection.

Device requires USB drivers to work as a Virtual COM port. First-time connection between device and computer could

result in “Device driver software was not successfully installed” error such as one shown in Fig.6.1.

Fig. 6.1. Unsuccessful device software installation error

A user then should manually install drivers by selecting a downloaded driver folder:

RTD sensor connection

USB interface

Configuration over USB

Driver installation

Go to Control Panel -> Device Manager;

Select a failing device;

Press “Update driver software”; screen as in Fig. 6.2. should appear:

Fig. 6.2. Device driver software update message

Select “x86” driver for a 32-bit machine or x64 for a 64-bit machine. If not sure, select a root

folder (folder in which x64 and x86 lay inside, as in Fig. 6.3).

Fig. 6.3. Device driver folder content

Configuration of IOMOD device is done through CLI (Command Line Interface) on virtual COM port. Drivers needed for

MS Windows to install VCOM will be provided. To open up CLI simply connect to specific VCOM port with terminal

software (it is advised to use PuTTY terminal software. If other software is being used, user might need to send

<return> symbol after each command). When connected user should immediately see main screen similar to one in

Fig.6.4.

IOMod 4RTD configuration via PuTTY terminal

Fig. 6.4. The main menu for IOMod 4RTD

Navigation is performed by pressing number connected to its function. User then should proceed by following further

on-screen instructions. For example, to set desired slave address, press [1] to enter Slave Address screen; enter new

configuration; press [RETURN] to save, or [ESC] to cancel changes. When done, press [0] (exit) before disconnecting

device. Default values are set by pressing [7] on main screen, and later confirming these changes by pressing [1].

If terminal window is accidentally closed without exiting, user can connect to terminal again, and press any key on

keyboard to show up main menu once again.

Configuration of device is not possible when USB Simulation Mode is entered. To access configuration menu again user

should reset device and then try again.

Modbus Main menu

Menu Name

Function

Values

Default Values

1.

Slave Address

Modbus Slave address / ID

1-247

1

2.

Communication settings

[1] Baud rate,

[2] Data, Stop and

Parity Bits,

[3] RS485

Terminating resistor

[1] 100 - 256000,

[2] 8 Data bits + 1/2

Stop bits,

Even/None/Odd

Parity

[3] Enabled/Disabled

[1] 9600,

[2] 8N1,

[3] Enabled

6.

RTD parameters’

configuration*

Configuring Callendar-Van

Dusen coefficients,RTD

wire count, type, etc.

PT100, 2 wires, coefficients

according to IEC-751

7.

Set Default Settings

Sets Default Settings

(1 to confirm, 0 to cancel)

-

8.

Firmware Upgrade

Mass Storage Device

Firmware Upgrade

(1 to confirm, 0 to cancel)

-

9.

Diagnostics

Input / Output states

-

-

0.

Exit

Exit and disconnect

-

-

To update device firmware user must enter main configuration menu.

Enter Firmware update screen by pressing [8];

Confirm update by pressing [1];

Device now enters Firmware Upgrade mode. Device reconnects as mass storage device (Fig 6.10.).

It is recommended to close terminal window after entering firmware upgrade mode.

Firmware upgrade over USB

Fig. 6.10. Mass storage device warning

User then must delete existing file “firmware.bin”, and simply upload new firmware file by drag and drop. (Fig 6.11.)

Fig. 6.11. Dragging and dropping new firmware file

Reconnect device and check firmware version. It should now represent the one it was updated to.

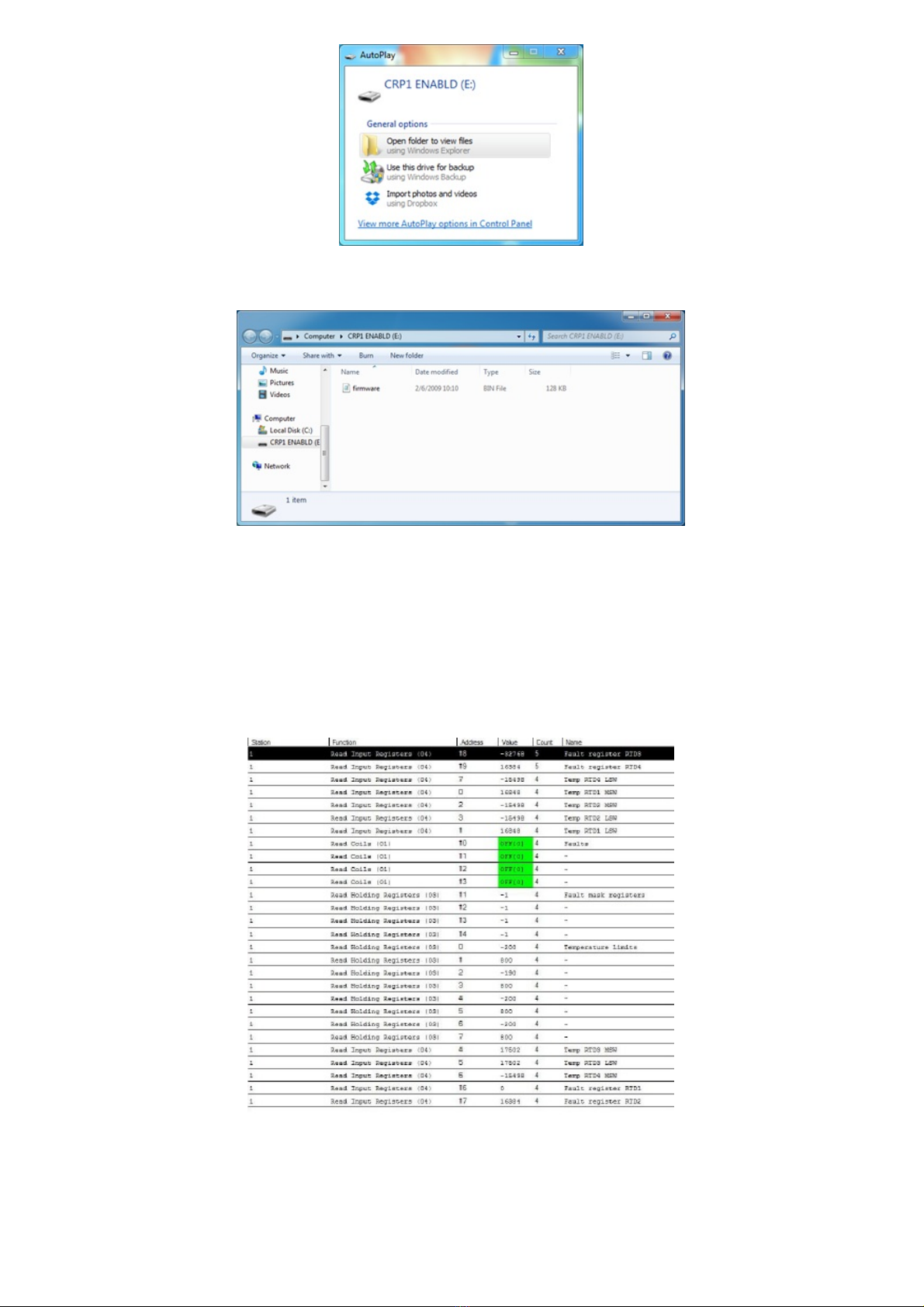

To test IOMOD 4RTD with default settings, user can connect device through RS485 to Modbus or IEC-60870 (depending

on firmware) master or using USB Simulation Mode. Example will show The Vinci Expert as serial interface converter

and adapter to PC with The Vinci software. Default settings – 9600 baud; 8 data, no parity, 1 stop bit. When opening

The Vinci software, choose Modbus serial – Master mode. In Settings tab, choose station number (default – 1);

configure tags (as described in section 2. Device operational information); press Start and go to Statistic tab:

Fig. 6.7. Example of results of Modbus testing

Testing With “THE VINCI” software

Fig.6.8. Representing temperature as float when using Modbus

Fig. 6.8. represents how The Vinci software should be configured to represent temperature in IEEE- 754 standard float

type when using Modbus communication.

Revision #4

Created 1 December 2021 13:47:53 by Tautvilis

Updated 3 May 2022 08:26:01 by Simas

Table of contents

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics Triaxial ICP 339A31/NC Installation and operating manual

Endress+Hauser

Endress+Hauser CleanFit P CPA 471 operating instructions

Kusam-meco

Kusam-meco CA-1000 manual

GHM

GHM GREISINGER GIA 20 EB Mounting and operating manual

Elvaco

Elvaco CMi4110 user manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ECOSCAN CON TDS 5 CONDUCTIVITY PORTABLE... Mode d'emploi