STAUFF PPC-06 User manual

Stauff Hydraulic Tester

PPC-06/08/12

Operating instructions

Version 2.1

Artikel-Code: 1810000112

2007-08-24

Operating Instructions Hydraulic Tester PPC-06/08/12

2

Walter Stauffenberg GmbH & Co. KG

Im Ehrenfeld 4 D-58791 Werdohl

Postfach 1745 D-58777 Werdohl

Germany

Telefon: +49 (0) 2392 / 916 – 0

Telefax: +49 (0) 2392 / 2505

E-Mail: [email protected]

Internet: www.stauff.com

Operating Instructions Hydraulic Tester PPC-06/08/12

3

Directory

1Unpacking.....................................................................................................................................5

1.1 Protection of PPC-06/08/12 ...................................................................................................5

2General remarks ..........................................................................................................................6

2.1 Instrument types.....................................................................................................................6

3Functions and settings ...............................................................................................................7

3.1 Operating the PPC-06/08/12..................................................................................................9

3.1.1 Switching on the PPC ............................................................................................................9

3.1.2 Display..................................................................................................................................10

3.1.3 Connection of sensors .........................................................................................................11

3.1.4 Operation and display control ..............................................................................................12

3.1.5 Number input........................................................................................................................14

3.1.6 Text input .............................................................................................................................16

3.2 Measurement and display....................................................................................................18

3.2.1 Display of measured values (ACT – MIN - MAX) ................................................................18

3.2.2 Deleting MIN / MAX memory ...............................................................................................21

3.2.3 Temperature.........................................................................................................................21

3.2.4 Differential values.................................................................................................................22

3.2.5 Alignment of I1 and I2 ..........................................................................................................23

3.2.6 Optional channel (combination) ...........................................................................................24

3.3 Data output...........................................................................................................................28

3.3.1 Online function .....................................................................................................................29

3.3.2 Online function with PC / Laptop..........................................................................................30

4Auxiliary sensors / current - voltage measurement ...............................................................34

4.1 Configuration of auxiliary sensors........................................................................................35

4.2 Frequency measurement .....................................................................................................37

5Additional features of the PPC-06/08/12..................................................................................39

5.1 Memory capability ................................................................................................................41

5.2 Manual recording of measured values.................................................................................43

5.3 Software-driven recording of measured values ...................................................................45

5.3.1 Edge-triggered recording .....................................................................................................46

5.3.2 Externally triggered recording ..............................................................................................50

5.3.3 Manually triggered recording ...............................................................................................54

5.3.4 Time triggered recording......................................................................................................58

5.4 Memory output .....................................................................................................................62

6Configuration PPC-06/08/12......................................................................................................65

6.1 Device Setup........................................................................................................................66

6.1.1 RS 232 interface test............................................................................................................67

6.2 Battery Service.....................................................................................................................68

6.3 System setup .......................................................................................................................69

6.3.1 System Reset.......................................................................................................................70

6.3.2 Memory setting.....................................................................................................................71

6.3.3 User identification.................................................................................................................72

7Quickstart PC-software PPC-SOFT..........................................................................................73

7.1 Installation ............................................................................................................................73

7.2 RS 232 interface test............................................................................................................74

7.3 Measurement transfer from PPC-06/08/12 to PC-Soft ........................................................75

7.4 Measurement recording by online mode..............................................................................77

7.5 Online-Help ..........................................................................................................................79

Operating Instructions Hydraulic Tester PPC-06/08/12

4

8Technical Appendix – Memory Management..........................................................................80

8.1Expressions and Definitions ........................................................................................................80

8.2Recording time, Memory -Interval and Memory capacity ............................................................81

8.3Recording a fix number of MIN/MAX-readings per channel ........................................................83

8.4Traditional Memory Concept versus PPC-06/08/12 Memory Concept.......................................84

8.5PPC-06/08/12 Setup....................................................................................................................85

8.5.1 Measuring Points .................................................................................................................85

8.5.2 Memory –Rate = storing rate ...............................................................................................86

8.6Customer’s benefits based on PPC-06/08/12 memory management (Points/Channel) .............87

Operating Instructions Hydraulic Tester PPC-06/08/12

5

1 Unpacking

Please inform the shipping department at Walter Stauffenberg GmbH & Co. KG if the

delivery package is damaged. When removing the PPC-06/08/12 out of the package make

sure that it is in good condition.

1.1 Protection of PPC-06/08/12

Do not place any objects on the PPC-06/08/12. Protect it against direct sunlight, high

humidity, heavy vibrations, extreme temperatures and chemically aggressive environments.

Operating Instructions Hydraulic Tester PPC-06/08/12

6

2 General remarks

The STAUFF PPC series of „Hydraulic Testers“ are service and diagnostic instruments to

measure pressure, flow, temperature, rotational speed (frequency), current and voltage.

Depending on the instrument type the user is able to operate with up to 6 channels (inputs),

allowing accurate hydraulic diagnostics. Measured values can be transferred to a PC or

printer via an integrated RS 232 interface. The instrument has an internal memory which can

hold up to 240 independent measurement values. Each individual data set holds all single

measured values of each of the connected sensors / inputs. It is possible to store the entire

data set as well as a single measurement (curve) under the identical name. This makes a

later measurement analysis easier. For further measurement evaluation and processing on a

PC, the software packet PPC-Soft (for Windows 95® / 98® / XP® and Windows NT®) is also

available.

The graphic LCD-display shows up to six channels in an easy-to-read form. Every

measurement can be displayed as an actual, minimum and maximum value. In the

optional line mathematical operations are displayed (hydraulic power + volume). It is

also possible to present the measured values graphically as a curve.

Attention:

Before first operation of the Hydraulic Testers

PPC-06/08/12 charge the internal battery for min. 16

hours!!

2.1 Instrument types

Depending on the application requirement, STAUFF PPC „Hydraulic Testers“ are available in

three different types:

TYPE / Model Channels MIN / Max memory

values

PPC-06 3 60.000

PPC-08 4 125.000

PPC-12 6 250.000

Operating Instructions Hydraulic Tester PPC-06/08/12

7

3 Functions and settings

Operating Instructions Hydraulic Tester PPC-06/08/12

8

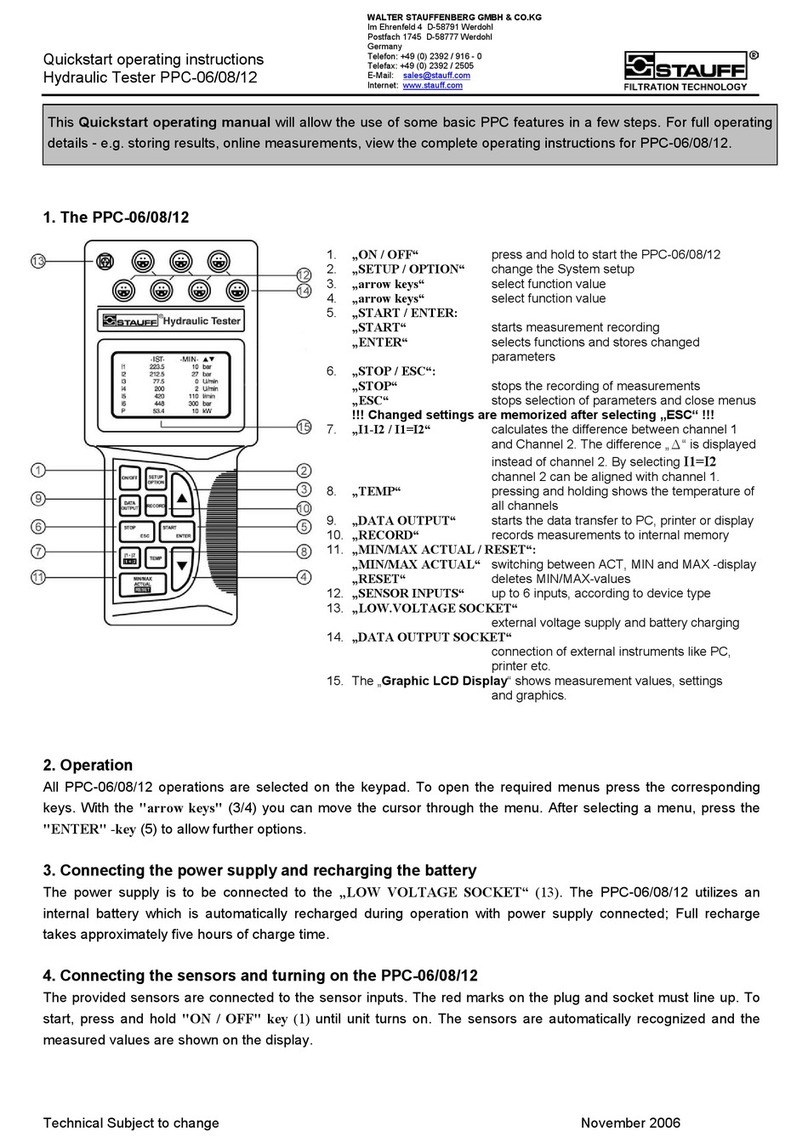

1. „ON / OFF“ is used to switch the instrument on and off.

2. „SETUP / OPTION“ is used to change system settings.

3. The „arrow“ keys are used to select lines and functions.

4. The „arrow“ keys are used to select lines and functions.

5. „START / ENTER“:

„START“ is used to start data (measurement) recording.

„ENTER“ is used to poll sub-functions and accept (memorize) changed function

values.

6. „STOP / ESC“:

„STOP“ is used to stop data (measurement) recording.

„ESC“ is used to stop the function value changing and to close sub-functions. The

previous menu is displayed.

!!! Changed settings won’t be recalled !!!

7. „I1-I2 / I1=I2“ is used for calculation of the difference between measurement channel

1 and measurement channel 2. The value displayed on channel 2 is the difference I1

– I2. It is possible to align I2 on I1. The I1=I2 key sets measurement channel 2 equal

to measurement channel 1 (balancing function).

8. After pressing and holding “TEMP“ the temperature data of all channels are shown.

9. „DATA OUTPUT“ is used to start data output to PC, printer or display.

10. „RECORD“ is used to record and store measurements.

11. „MIN/MAX ACTUAL / RESET“:

„MIN/MAX ACTUAL“ switches display to ACTUAL, MINIMUM and MAXIMUM.

„RESET“ deletes MIN/MAX-values.

12. Up to 6 sensors from the PPC 06/08/12 -program can be simultaneously connected

to the “SENSOR INPUTS“. They are automatically recognised by the instrument. An

adapter is necessary for auxiliary sensors, current and voltage measurements.

13. „LOW-VOLTAGE SOCKET“ enables external voltage supply and battery charging

via power supply unit.

14. External instruments like PC, printer, etc. are connected to the “DATA OUTPUT

SOCKET“.

15. The Graphic LCD display shows measurement values, settings and graphics.

Operating Instructions Hydraulic Tester PPC-06/08/12

9

3.1 Operating the PPC-06/08/12

The main functions of the instrument, such as measuring and displaying, recording

measurements („RECORD“), data output („DATA OUTPUT“) and changing the instrument

settings („SETUP / OPTION“) are selected directly through the keyboard. The „arrow“ keys

select the desired menu. „ENTER“ brings up the selected menu item. The menu item

accompanying function value (parameter) is highlighted.

Changing of the function values is done with the “arrow“ keys. Pressing “ENTER“ confirms

and stores the selected value.

3.1.1 Switching on the PPC

Press “ON / OFF“ for two seconds to switch on the instrument. The current battery state of

the rechargeable battery is shown on the display for a short time.

The version number indicates the internal manufacturing key.

The current battery state is given in percent and illustrated with the black section of the

battery on the display. If the battery state is lower than 40 % you will find the message “BAT.

SERVICE STATUS” on the display.

If the battery state is 0 % you have to use an external voltage supply. The rechargeable

battery will then be charged automatically.

After approx. 8 seconds the display switches to simple measured value representation and

shows the actual measurement values (ACT-values)

STAUFF TEST

PPC-12 3778R9-10101

BATT: LEVEL <=50%

In - ACT 56

1 223,6 bar

2 212,5 bar

3 77.5 U/min

4 200 U/min

5 420 l/min

6 448 bar

P 53.4 kW

Operating Instructions Hydraulic Tester PPC-06/08/12

10

3.1.2 Display

The graphic LCD-display of the instrument has a maximum resolution of 128 x 64 pixel. The

visible area is 72 x 40 mm. Using an 8-line representation (status, 6 channels (inputs),

optional line) the digit height is 4,2 mm. Indicated values are adapted to the display size

through an automatic digit height setting, for example if there are less then four channels for

the actual values the numbers on the display will have double the size.

The text mode is separated into 8 lines and 4 columns. The first column shows the selected

channel. The second and third columns show the corresponding measured values. Here it is

possible to choose between four different options:

ACT Æactual measured value (third column empty)

ACT - MIN Æactual measured value – minimum value

ACT - MAX Æactual measured value – maximum value

MIN - MAX Æminimum value – maximum value

Column four shows the UNITS of the measured values.

The first line of the display shows the status (i.e. recording, memorizing), the measured value

identifier (ACT, MIN, MAX) or the menu name. Lines 2 – 7 show the measured values. Line 8

is an optional line, in which calculated values like P (power) and V (volume) are shown.

Curves from measured values can be displayed in the graphic mode

Operating Instructions Hydraulic Tester PPC-06/08/12

11

3.1.3 Connection of sensors

The sensors are connected to the input jack of the PPC-06/08/12 via an interconnection

cable. The red points on the plugs must correspond with the red points on the sockets. The

measuring range is scaled through automatic sensor recognition and the measured value will

be shown on the display.

Attention!!

Safety Instructions for using sensors (i.e. the 1.000 bar pressure sensor):

Please pay attention to built in test points acc. to rated nominal pressure and

specified safety factors.

Operating Instructions Hydraulic Tester PPC-06/08/12

12

3.1.4 Operation and display control

The navigating and programming of the PPC-06/08/12 unit is basically done as follows.

For example look at the „SETUP“ menu:

Pressing „SETUP / OPTION“

opens the „SETUP“ –menu.

By pressing the „arrow“-keys

the Cursor can be navigated

through the menu.

By pressing „arrow“ –key up,

the cursor jumps from

„AUX.SENSOR“ to „CONTRAST (%)“

By pressing „Start / Enter“ the

-cursor jumps right to the function

value, contrast can now be adjusted

with the arrow keys.

By pressing „Start / Enter“

once again, the value will be

confirmed and the cursor jumps

back to „CONTRAST (%)“.

Depending on the menu item, after

pressing „Start / Enter“, a new menu

is opened.

The submenu „INPUT“ of the

menu item „AUX.SENSOR>“

is opened.

ESC -- SETUP -- 56

CONTRAST (%) 50

AUX. SENSOR>

COMBINATION>

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

ESC -- SETUP -- 56

CONTRAST(%) 50

AUX. SENSOR>

VERKNUEPFUNG>

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

ESC -- SETUP -- 56

CONTRAST (%) 50

AUX. SENSOR>

COMBINATION>

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

ESC -- SETUP -- 56

CONTRAST (%) 50

AUX. SENSOR>

COMBINATION >

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

ESC -- INPUT 56

ANALOGUE> I1

FREQUENCY>

ESC -- SETUP -- 56

CONTRAST (%) 50

AUX. SENSOR>

COMBINATION>

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

Operating Instructions Hydraulic Tester PPC-06/08/12

13

By pressing „Stop / ESC“ the current

menu is closed and the prior menu

is displayed.

The programming of numbers and text is described in chapter 3.1.5, and 3.1.6 respectively.

ESC -- SETUP -- 56

CONTRAST(%) 50

AUX. SENSOR>

COMBINATION >

RECORD SETUP>

DEVICE SETUP>

BATT.SERVICE>

SYSTEM SETUP>

Operating Instructions Hydraulic Tester PPC-06/08/12

14

3.1.5 Number input

When configuring auxiliary sensors (chapter 4.1) the measurement range (i.e. 0 ... 250 bar)

and the corresponding initial and end value (i.e. 0 ... 20 mA) have to be programmed.

The next example shows the number input of an auxiliary sensor.

After selecting a number, this number is highlighted. By pressing the „arrow“ keys, the

former number is deleted, the first digit is highlighted and changed. The first digit of the

number has to be confirmed by pressing „START / ENTER“ and the following digit is

highlighted.

„STOP / ESC“ terminates the input and stores the new number.

Example:

select number

confirm number

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 0

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 0

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 0

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

Operating Instructions Hydraulic Tester PPC-06/08/12

15

change first digit

confirm first digit

change second digit

confirm second digit

complete number input

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 5_ _ _ _ _ _ _

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 5 0 _ _ _ _ _ _

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 5 5 _ _ _ _ _ _

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 5 5 _ _ _ _ _ _

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

ESC -- ANALOGUE -- 56

In1

UNITS: bar

FROM: 55

TO: 600

SIGNAL: mA

FROM: 4

TO: 20

Operating Instructions Hydraulic Tester PPC-06/08/12

16

3.1.6 Text input

For functions like auxiliary sensors (chapter 4.1), data recording (chapter 5.3) and user ID

(see chapter 6.3.3), text input is mandatory.

After selecting a text line, the menu “TEXT” is displayed.

New text is shown on the bottom line next to „TEXT“ as it is entered. New character’s can be

selected by pressing the „arrow“ keys. By holding down the arrow key the cursor moves

faster through the text input field. „START / ENTER“ confirms the selected character and

highlights the next character. „_“ represents a space. The text input can be completed by

pressing „STOP / ESC“. The text displayed under the heading TEXT is stored and then the

display returns to the previous active menu.

select new character

confirm new character

select next character

-- TEXT -- 56

AaBbCcDdEeFfGgHhIiJj

KkLlMmNnOoPpQqRrSsTt

UuVvWwXxYyZz%/_

0123456789.-+

STORE = STOP/ESC

15 CHARS MAX

TEXT: MASCH3

-- TEXT -- 56

AaBbCcDdEeFfGgHhIiJj

KkLlMmNnOoPpQqRrSsTt

UuVvWwXxYyZz%/_

0123456789.-+

STORE = STOP/ESC

15 CHARS MAX

TEXT: MASCH3 _ _ _

-- TEXT -- 56

AaBbCcDdEeFfGgHhIiJj

KkLlMmNnOoPpQqRrSsTt

UuVvWwXxYyZz%/_

0123456789.-+

STORE = STOP/ESC

15 CHARS MAX

TEXT: MASCH3 _ _ _

Operating Instructions Hydraulic Tester PPC-06/08/12

17

confirm character

terminate text input and store text

Operating Instructions Hydraulic Tester PPC-06/08/12

18

3.2 Measurement and display

The following chapters describe the different presentation of measured values.

3.2.1 Display of measured values (ACT – MIN - MAX)

The measured values in the display can be shown as ACT (actual), MIN (minimum) and MAX

(maximum) values. There are several display options. The basic configuration shows the

ACT values.

When pressing “MIN/MAX ACTUAL / RESET“ the following values are shown:

This display shows the ACT value and the MIN value.

The following display shows the ACT and MAX value.

In - ACT 56

1 223,6 bar

2 212,5 bar

3 77.5 U/min

4 200 U/min

5 420 l/min

6 448 bar

P 53.4 kW

In - ACT MIN 56

1 223,6 10 bar

2 212,5 27 bar

3 77.5 0 U/min

4 200 2 U/min

5 420 410 l/min

6 448 300 bar

P 53.4 kW

In - ACT MAX 56

1 223,6 320 bar

2 212,5 220 bar

3 77.5 80,0 U/min

4 200 400 U/min

5 420 420 l/min

6 448 555 bar

P 53.4 kW

Operating Instructions Hydraulic Tester PPC-06/08/12

19

The next display shows the MIN and MAX value.

By pressing „MIN/MAX ACTUAL / RESET“ once again all actual values of channel 1 are

shown. Using the „arrow“ keys shows the values of the sensors.

select different sensor

By pressing „STOP / ESC“ all channels can be shown on the display again.

The display of all actual measured values from one sensor can be obtained by selecting the

corresponding input with “ENTER“.

select Sensor / Input I2

In - MIN MAX 56

1 10 320 bar

2 27 220 bar

3 0 80,0 U/min

4 2 400 U/min

5 410 420 l/min

6 300 555 bar

P kW

I1 56

345,6bar

Min=131 Max=434

T=55°C

I3 56

162,6bar

Min=145 Max=201

T=63°C

In - ACT 56

1 223,6 bar

2 212,5 bar

3 77.5 U/min

4 200 U/min

5 420 l/min

6 448 bar

P 53.4 kW

Operating Instructions Hydraulic Tester PPC-06/08/12

20

confirm sensor / input I2

The values of the other sensors are shown by using the “arrow“ keys.

By pressing “STOP / ESC“ the values of all sensors return on the display.

back to previous display

I2 56

212,5bar

Min=131 Max=434

T=55°C

In - ACT 56

1 223,6 bar

2 212,5 bar

3 77.5 U/min

4 200 U/min

5 420 l/min

6 448 bar

P 53.4 kW

This manual suits for next models

2

Table of contents

Other STAUFF Measuring Instrument manuals