Elson BUSHPEX CRIMP GAS PEX-AL PIPING SYSTEM User manual

CRIMP GAS

PEX-AL PIPING SYSTEM

Product information

and installation Manual

Version 3.0

BUSHPEX Crimp Gas

Elson Australasia Pty Ltd proudly presents the BUSHPEX Crimp Gas

PEX-AL Piping System. This compliments the range of PEX and PEX-AL

Plumbing Systems / Gas Piping System offered by Elson Australasia.

BUSHPEX Pull On PEX System for Water Reticulation, 16 to 32mm.

BUSHPEX Crimp On PEX System for Water Reticulation, 16 to 25mm.

BUSHPEX Push On PEX System for Water Reticulation, 16 to 25mm.

All Three Systems For Water use the same BUSHPEX PN20 Pipe.

BUSHPEX CRIMP GAS PEX-AL PIPING SYSTEM - BUSHPEX Crimp System for

GAS, 16 to 63mm.

BUSHPEX Crimp On PEX for WATER and BUSHPEX CRIMP GAS PEX-AL

Systems use the same BUSHPEX Crimp tools and gauges. Reaming /

Calibrating tools are specific to the BUSHPEX Crimp Gas PEX-AL Piping

System.

This brochure provides specifications and

installation information relevant to the

BUSHPEX Crimp Gas PEX-AL Piping system.

The system comprises of Pipe, Fittings and Tooling.

BUSHPEX Gas PEX-AL pipe is manufactured as a composite pipe

consisting of an inner and outer layer of cross linked polyethylene which is

permanently adhered to a central core of Aluminium. The pipe is

manufactured under Strict Quality controls to Australian Standards AS4176

/ ATS 5200.478 under Licence SMKP 21859.

BUSHPEX Crimp Gas fittings are a solid brass double crimp fitting with

double “O” ring secondary seal and stainless steel crimp sleeves. The fittings

are manufactured under Strict Quality controls to Australian Standard

AS4176 under licence SMKP 21859.

BUSHPEX CRIMP Tooling comprises of both Manual Tooling for 16mm,

20mm, 25mm and Battery tooling from 16mm to 63mm. All tooling used

should be verified before use to ensure suitability for BUSHPEX Crimp

systems. BUSHPEX Crimp Gauges and BUSHPEX Crimp Gas PEX-AL Reaming

/ Calibrating tools are essential requirements for use during the installation

procedure as detailed in this Manual.

All products are fully warranted for a period of 25 years when installed as a

Proprietary Gas System in accordance with AS/NZS5601 and this BUSHPEX

Crimp Gas PEX-AL Piping System Installation Manual by a

Licenced Gas Fitter using all Pipe and Fittings with Licence Number

SMKP 21859 only , and the approved tooling.

BUSHPEX Crimp Gas

IMPORTANT NOTE

ELSON AUSTRALASIA aims to ensure all BUSHPEX Branded products are

manufactured and installed in accordance with all applicable Australian

Standards and requirements. Installation of the BUSHPEX Crimp Gas

PEX-AL Piping System MUST only be carried out by a Licenced Gas Fitter.

The Licenced Gas Fitter must also have successfully completed the

BUSHPEX Crimp Gas PEX-AL Piping SystemInduction and Training

Module. Installation must be in accordance with the Gas Installation

Australian Standards AS/NZS5601 and any other relevant and

applicable local authority codes which may take precedence. The Installer

must alsouse the installation guidelines set out in this manual.

Installation must only ever involve the use of the approved system of

BUSHPEX Gas PEX-AL pipe and fittings with Licence SMKP21859 and

Approved tooling. The Design of any Gas piping system must safely

supplyan adequate flow and velocity of gas to every appliance at the

required pressure. Please consult the Sizing tables in this Manual and the

calculation process and procedures as defined in AS/NZS5601 to ensure

conformance and suitability of this system prior toinstallation.

ELSON AUSTRALASIA Pty Ltd will log records of Licenced Gas Fitters

who have successfully completed Induction and Training. These records if

required can be accessed by TechnicalRegulators on verification if

confirmation is required for training.

Application for verification of completion of BUSHPEX Crimp Gas PEX-AL

Piping System Training should be sent to the email address below

requesting the name of the person requiring verification. ELSON

AUSTRALASIA will then reply confirming or denying training and supply

the training date, Personal details will not be supplied.

Email: sales@elson.net.au

BUSHPEX Crimp Gas PEX-AL Piping System is required and detailed in

this manual for installation conformance to AS/NZS5601.

If you require a copy of this standard it can be purchased fromthe

following Website:

http://infostore.saiglobal.com/store

If you require further assistance with purchasing this standard please

contact our office by phone (02) 9625 7899 or by email

sales@elson.net.au

BUSHPEX Crimp Gas

BUSHPEX CRIMP GAS

FEATURES AND BENEFITS

• Manufactured, distributed and supported by Elson.

• 25 Year product Warranty when installed according to detailed

requirements.

• Product manufactured by Elson to relevant Australian Standards by

our ISO9001 approved manufacturing facility with all Certification by

SAI Global.

• BUSHPEX Crimp Gas PEX-AL Piping System is a cost effective

alternative to other Gas systems.

• BUSHPEX Crimp Gas PEX-AL Piping System is fast and easy to

install.

• BUSHPEX hand crimping tools can be used for both BUSHPEX

Crimp-on Water PEX and BUSHPEX Crimp Gas PEX-AL Piping Systems.

• Light weight – easy to handle & install.

• Smooth inner core reduces pressure losses.

• Low levels of thermal conductivity and expansion.

• Strong impact resistance.

• Comprehensive size range 16mm – 63mm diameter.

• Double “O” ring is the internationally preferred system.

• Long entry stainless steel crimp sleeve.

• Double crimp seal.

• Four easy to see witness holes to confirm full engagement of fitting

onto pipe.

• Yellow retaining ring signifies “Gas” and also locates Battery tool

Jaws.

• German manufactured Battery Tools available in two sizes.

Contents

Technical Information

................................6

1. BUSHPEX Crimp Gas PEX-AL Pipe

.............6

2. BUSHPEX Crimp Gas Fittings

..................7

3. BUSHPEX Tooling

............................... 12

Warranty

............................................13

BUSHPEX Crimp Gas Tool Inspection

...........14

BUSHPEX Crimp Gas Jointing Procedure

.......15

FAQ

..................................................18

Sizing Tables for Natural Gas

....................20

Sizing Tables for LPG

..............................23

Fittings

............................................... 24

Pipe

...................................................34

Tools and Accessories

.............................35

5

BUSHPEX Crimp Gas

Technical

Information

Technical Information

6BUSHPEX Crimp Gas

BUSHPEX Crimp Gas is a complete Gas Piping

system comprising of a multi-layer composite

PE-Xb/AL-PE-Xb (PEX-AL) pipe, a comprehensive

range of Brass crimp fittings from 16mm to

63mm and tooling options in both manual and

Battery operation complete with reaming /

calibrating tools and crimp gauges to ensure

system performance.

1.

BUSHPEX Crimp Gas PEX-AL Pipe

BUSHPEX Crimp Gas composite pipe is

manufactured from an inner and outer wall of

crossed linked polyethylene material which is

bonded on both sides with a middle layer of

aluminium. The Pipe is yellow in colour and is

clearly marked at 1m intervals detailing Brand,

Type, Size, Class, Standard and Licence

Number. The pipe has been tested and

approved in accordance with the Australian

Standard AS4176 / ATS

5200 under Licence

number SMKP 21859 for gas Installation only

using BUSHPEX Crimp Gas fittings with the same

corresponding Licence number.

BUSHPEX PE-Xb/AL-PE-Xb DN20x2.2 CLASS 500 GAS AS 4176/ATS5200.478

LN SMKP21859 I >>>>I 20120112 16:18 DN20120112806807080504 EL01

NOT FOR USE IN DIRECT SUNLIGHT B018M

Technical Information

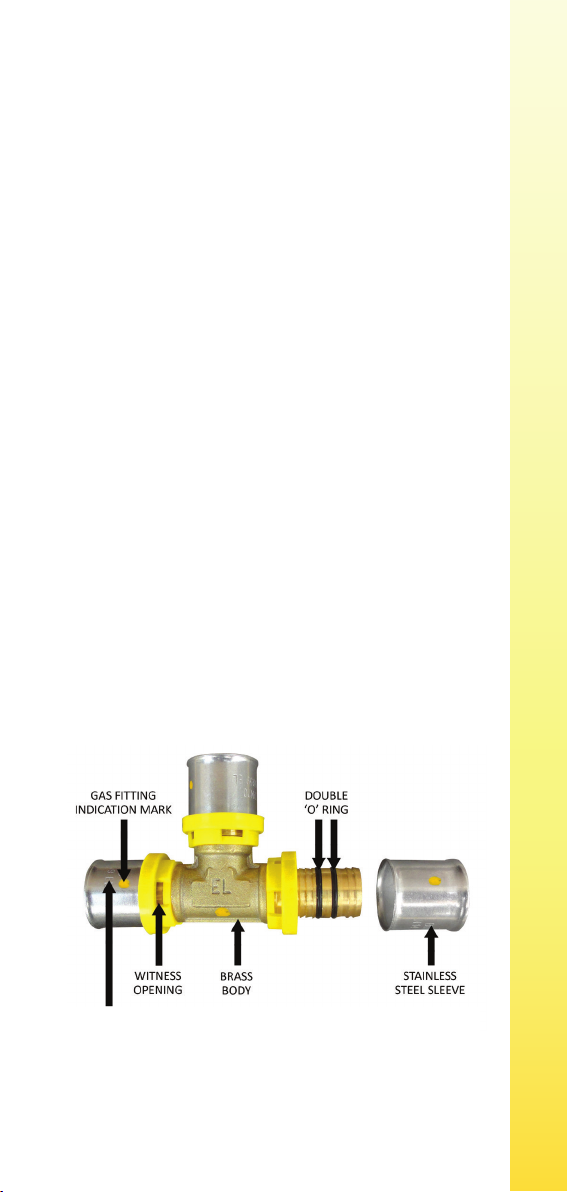

2. BUSHPEX Crimp Gas fittings

7

BUSHPEX Crimp Gas

MARKING: BUSHPEX GAS DN16 CLASS 500 AS 4176 SMKP 21859 EL

BUSHPEX Crimp Gas fittings are manufactured

to a very high standard from a solid brass forged

process. Fittings have long engagement dual

“O” ring Barbs with a Stainless Steel Crimp ring

and a yellow plastic retainer with 4 engagement

sighting holes. All fittings have stamped detail

into their Stainless Steel Crimp Rings clearly

showing Brand, Size, Class, Standard and

Licence Number. Identification Stamping also

appears on the brass fitting where possible or it

will display the letters EL. In addition all

BUSHPEX Crimp Gas Stainless Steel sleeves are

identified with a yellow dot. BUSHPEX Crimp

Gas fittings have been tested and approved in

accordance with the Australian Standard

AS4176 under licence number SMKP21859 for

gas Installation only, using BUSHPEX PEX-AL

Gas Pipe with the same corresponding Licence

number.

MARKING: BUSHPEX GAS DN16 CLASS 500 AS 4176 SMKP 21859 EL

Technical Information

8BUSHPEX Crimp Gas

Pipe & Fitting Protection and Care

during Handling and Installation:

BUSHPEX Crimp Gas PEX-AL pipe and fittings must

be protected from damage through all stages of the

process from transport to storage and installation in

accordance with AS/NZS5601. Provision for pipe

and fitting protection therefore includes but is not

limited to the following:

• Care must be taken to keep pipe free of grit, dirt,

dust and foreign matter.

• Care must be taken to ensure fittings are free of

grit, dirt, dust and foreign matter and the yellow

retainer is securely seated onto the fitting with the

stainless steel crimp ring and dual “O” rings are

seated correctly.

• Pipe must be protected from physical damage

including cuts, abrasion, dents, kinks, tears,

holes, etc.

• Pipe must be protected from long term or

permanent U.V. exposure.

• Pipe and fittings must be protected from

excessive heat or burning, (refer to maximum

operating temperature detailed in Pipe

specification section), chemical / solvent attack,

animal or rodent attack, machinery damage,

other external threats, etc.

• Chemical or corrosive environments.

1. Pipe needs to be protected.

2. Fittings must be wrapped and protected. This

includes all underground installations for all

fittings.

• Pipe support and clipping; both vertically and

horizontally to ensure conformance for

vibration, excessive tension, torsion or

compressive stresses on fittings and pipe. Refer

to pipe specification Chart for spacing.

Technical Information

9

BUSHPEX Crimp Gas

•

•

•

•

Pipe penetrations through timber and steel frames and

concrete sections need to conform and may require protection

using grommets, fire collars, sleeving or wrapping. Holes,

notches and cutouts must be accurately drilled “in-line” to

allow movement for any expansion or contraction of the pipe

and fitting so engagements are not exposed to excessive

stress. Refer to Pipe specification Chart for timber frame cut

out limitations.

Pipe Expansion and contraction needs to be accommodated

during installation to allow for movement due to thermal

Linear expansion. Failure to do so may exceed torsional

pullout allowances on fittings resulting in product failure. Refer

to Pipe specification Chart for the Thermal Expansion

co-efficient.

Pipe Bending; BUSHPEX Crimp Gas PEX-AL pipe is flexible but

requires care when bending to avoid kinks, cracks or other

permanent deformation that may restrict flow or put undue

pressure on joints. If the pipe is kinked, bent or damaged in

any way it must be cut out and replaced. BUSHPEX Crimp Gas

elbows are recommended for tight bends and larger pipe sizes

above 32mm. Refer to the Pipe specification Chart for

minimum bending radius and tools for bending.

Connecting Barbs; when soldering connecting barbs, (male or

female) first remove/dismantle the yellow plastic retainer ring,

stainless crimp ring and two “O” rings, then, solder the brass

connecting barbs – allow to cool before assembly. When

assembling the fitting, ensure the yellow plastic retainer ring,

the two “O” rings and the stainless steel sleeve are installed

correctly. (Refer to picture on Page 9 of this brochure for

assembly detail). Alternatively, use elson PRESS Crimp-On

fittings from copper to BUSHPEX Crimp Gas.

Technical Information

10 BUSHPEX Crimp Gas

Pipe Specifications & Data Sheet:

Timber Frame Plates and Studs

75mm wide timber –maximum cut-out, notch, drill diameter of 19mm

100mm wide timber –maximum cut-out, notch, drill diameter of 25mm.

Timber Joists

Refer AS/NZS5601

BUSH

Crimp Gas 16mm

Nom O.D.

20mm

Nom O.D.

25mm

Nom O.D.

32mm

Nom O.D.

40mm

Nom O.D.

50mm

Nom O.D.

63mm

Nom O.D.

Nominal O.D. (mm) 16 20 25 32 40 50 63

Colour Yellow Yellow Yellow Yellow Yellow Yellow Yellow

Class 500 500 500 500 500 500 500

Standard AS4176/ATS 5200 AS4176/ATS 5200 AS4176/ATS 5200 AS4176/ATS 5200 AS4176/ATS 5200 AS4176/ATS 5200 AS4176/ ATS 5200

Licence SMKP 21859 SMKP 21859 SMKP 21859 SMKP 21859 SMKP 21859 SMKP 21859 SMKP 21859

Maximum Supported

distance –Clipping 1.0m 1.25m 1.5m 2.0m 2.0m 2.0m 2.0m

Min Bending Radius by hand 80mm 100mm - - - - -

Min Bending Radius with

Bending Spring 50mm 60mm 110mm 150mm - - -

Coil Sizes metres 25, 50 &100 25, 50 &100 25 &50 25 &50 - - -

Straight Length metres 5m 5m 5m 5m 5m 5m 5m

Coefficient of Linear (UOM) Thermal

Expansion in mm per meter of pipe for

every 10Deg C Temperature variation 0.26 0.26 0.26 0.26 0.26 0.26 0.26

Max Operating temperature 80 Deg C 80 Deg C 80 Deg C 80 Deg C 80 Deg C 80 Deg C 80 Deg C

Max Operating Pressure 70 kpa 70 kpa 70 kpa 70 kpa 70 kpa 70 kpa 70 kpa

Technical Information

11

BUSHPEX Crimp Gas

Underground Pipe installation:

Underground installation of BUSHPEX Crimp Gas PEX-AL

Pipe must be in accordance with AS/NZS5601. The

following points should be noted and referenced for

conformance to the standard:-

Piping beneath a building and in the ground is allowed

with NO joints.

Piping embedded in Concrete is allowed with NO

joints, maximum pressure 70kpa.

Underground installation should include the provision

for a Trace Wire and Marker Tape to be installed to

assist in pipe detection.

Underground installation should comply with standard

for quality of bedding and backfill.

Underground installation must comply with the

required standards for minimum buried depth.

Underground Installation must comply with the

required standard for termination to Metallic risers.

Underground Installation must comply with the

required separation standard for Consumer Gas

Piping.

BUSHPEX Crimp Gas Fittings must be wrapped and

protected using suitable and verified processes for all

in ground installations and corrosive environments.

System Testing:

Pipe and joint system testing must be carried out in

accordance with the standard AS/NZS5601and any

other relevant and applicable local authority codes prior

to burying or concealing the BUSHPEX Crimp Gas PEX-AL

Piping system. It is the responsibility of the Licenced

Installer to ensure that all joints and fittings are inspected,

checked and tested for leaks to ensure safety and

compliance. It is recommended to incorporate a

checking procedure to ensure that each joint has been

correctly crimped by testing every joint with a crimp

gauge and marking as complete.

Proprietary Gas System Identification:

BUSHPEX Crimp Gas PEX-AL Piping system has an

identification Tag as part of its Product Range and must

be permanently attached adjacent to the gas meter or LP

Gas cylinder to identify the system installed on every

installation as detailed in AS/NZS5601. Do not attach

this signage plate to any gas cylinder or other movable

object.

•

•

•

•

•

•

•

•

Technical Information

12 BUSHPEX Crimp Gas

Provision for Pipe Reversion:

As detailed in AS/NZS5601, in certain installations

in some building types it is mandatory for the instal-

lation of reversion fittings to allow for Proprietary

Gas Piping systems like BUSHPEX Crimp Gas to be

extended or additions made for future application. A

Reversion Fitting allows for the connection of a

Proprietary system to be adapted to a standard

Thread or Copper tube. The BUSHPEX Crimp Gas

PEX-AL Piping system Product Range includes the

three variants of Reversion fittings as detailed in the

standard.

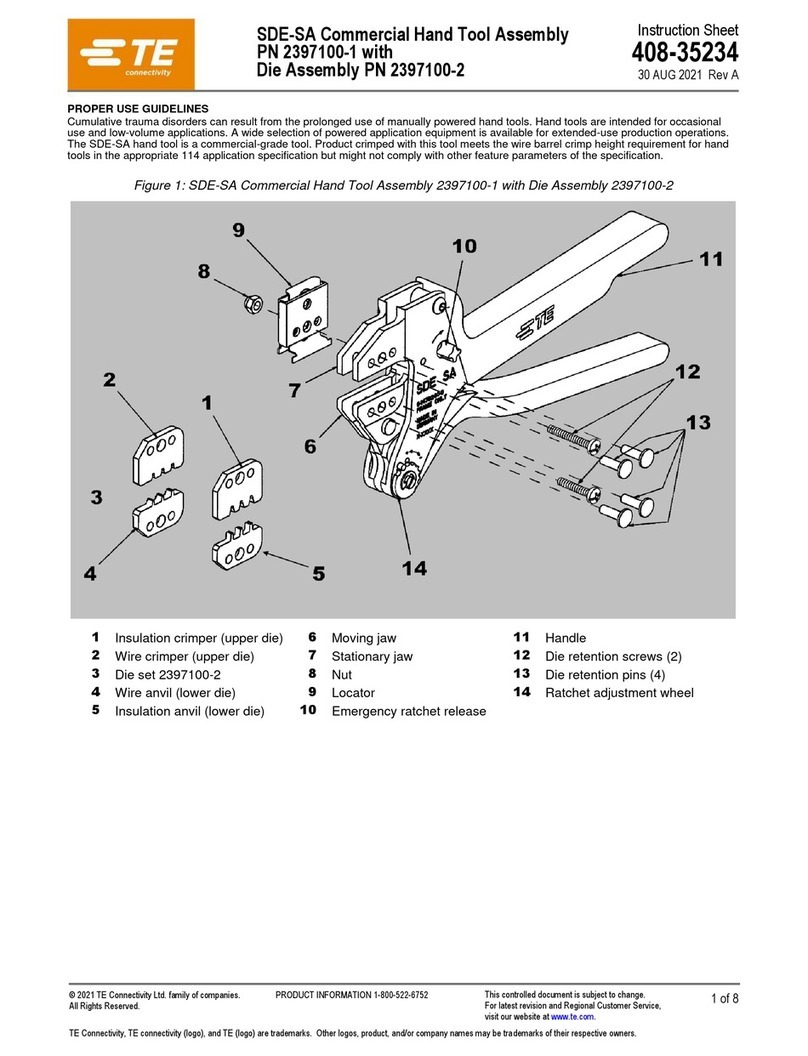

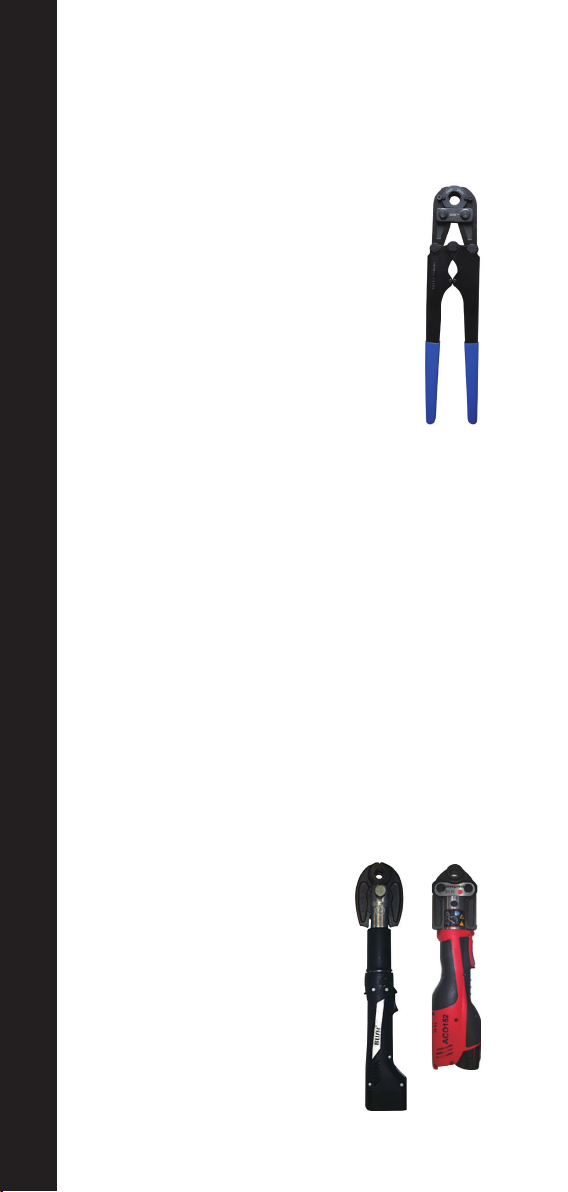

3. BUSHPEX Crimp Gas Tools

BUSHPEX Crimp Gas Tools are specifically designed

to be used with the BUSHPEX Crimp Gas PEX-AL

Pipe and Fittings System and must not be used with

other systems. BUSHPEX Crimp Gas Tools are

manufactured to precise specifications and require:

Care during operation and confirmation that

each completed crimp joint is crimped correctly.

The use of the BUSHPEX Crimp Gauge is

required to confirm crimp conformance.

Regular maintenance and cleaning after use to

avoid dirt, dust, grit or moisture damaging the

tool.

Recognition of the jointing guide procedures and

safety recommendations within this Manual and

the Handbook Instructions of the approved

BUSHPEX Crimp battery tool kit.

Specific and approved manual or battery drill

BUSHPEX Crimp Gas PEX-AL Reaming / Calibrating

tools are an essential requirement to round and

deburr every squarely cut pipe end prior to insertion

into the crimp fitting.

Use the BUSHPEX crimp gauge on each crimped

joint to ensure the joint has been sufficiently

crimped.

•

•

•

Technical Information

13

BUSHPEX Crimp Gas

System Testing

Pipe and joint system testing must be carried out in

accordance with AS/NZS5601 and any other

applicable local authority requirements prior to

burying or concealing the BUSHPEX Crimp Gas

PEX-AL Piping System.

It is the responsibility of the Licenced Installer to

ensure that all joints and fittings are inspected,

tested and checked for leaks to ensure safety and

compliance.

It is recommended to incorporate a checking

procedure to ensure that each joint has been

correctly crimped by testing every joint with a crimp

gauge and marking as complete.

Warranty

BUSHPEX Crimp Gas PEX-AL Piping System carries a

25 year warranty when the system is installed by a

Licenced Gas Fitter in accordance with

AS/NZS5601 and any other relevant and

applicable local authority codes which may take

precedence and established installation practices.

The Licenced Gas Fitter must also have successfully

completed the BUSHPEX Crimp Gas PEX-AL Piping

System Induction and Training. The Installer must

use the installation guidelines set out in this manual

and the Induction Training. Installation must only

ever involve the use of the same approved system of

BUSHPEX Crimp Gas PEX-AL pipe and fittings with

licence SMKP21859 and approved tooling.

Compliance with Australian Standards

BUSHPEX Crimp Gas PEX-AL Piping System is

licensed by SAI Global to Australian Standards

and complies with Australian Standards AS4176

(Licence 21859).

Jointing Procedure

14 BUSHPEX Crimp Gas

Jointing Procedure

Tool inspection

Manual Tools:

Inspect the tool and jaw to ensure it is in good

working order, operates properly and approved

for use with BUSHPEX Crimp Gas fittings and

BUSHPEX PEX-AL pipe. Visually inspect and

ensure the jaws align and have no gap when the

crimp tool is fully compressed and closed. The

jaws must be clean and undamaged – free of

defects, debris and corrosion. Always keep

clean and dry and lubricate after use. If a gap is

visible between the jaws then the tool must be

adjusted, (see Tool Adjustment section and

follow the instruction).

WARNING: An incompatible tool, incorrectly adjusted

tool or damaged jaws may result in a joint failure, tool

damage or both. It will also void the warranty!

Manual Tool Adjustment: The tool will require adjustment if

the jaws do not fully close when compressed OR if the crimp

gauge does not pass easily over both indentations in the

stainless steel sleeve after the crimping process. If this occurs,

follow the procedure below and re-test the tool to ensure

adjustment is correct.

1. Loosen LH and / or RH “Back Nuts” with spanner.

2. Turn LH and / or RH “Adjustment Dials” one increment at

a time.

3. Tighten LH and / or RH “Back Nuts” with spanner.

4. Confirm if the jaws now fully close? If NO – repeat

process ( 1 ) to ( 4 ). If YES – go to step 5.

5. Crimp a joint then check with the crimp gauge until the

crimp auge passes easily over both indentations in the

stainless steel crimped sleeve.

Battery Tools: Tested and approved

tools include:

1. Klauke MAP1, Klauke UAP-1.

2. Novopress ACO-152,

Novopress ACO-203.

3. KPS & KPL.

Above battery tools all require specific

BUSHPEX Jaws to suit the BUSHPEX

Crimp-On piping system.

Jointing Procedure

15

BUSHPEX Crimp Gas

Jointing Procedure:

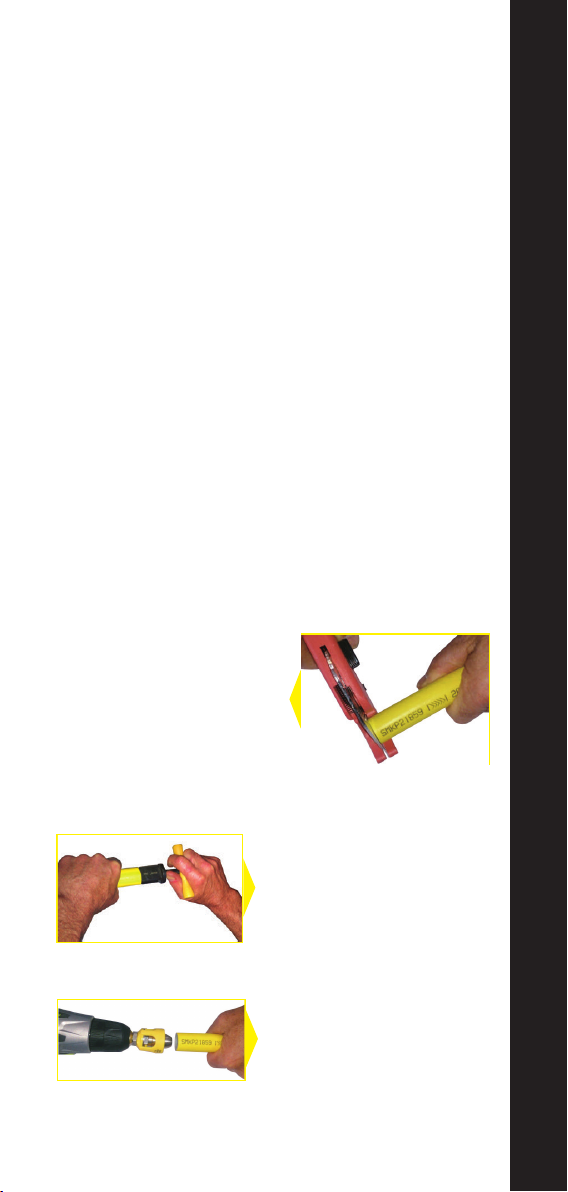

• Cut the pipe straight and

square using BUSHPEX pipe

cutters. Check for any damage

to the pipe including any surface

damage, cuts, scores, abrasion,

kinks, splits, heat damage.

Re-cut or replace and remove

any physically damaged pipe.

• Round and debur the end of the

pipe using either the specific sized

BUSHPEX Crimp Gas manual

calibrating tool or the BUSHPEX

Crimp Gas Battery drill Calibrating

tool. Match the size of the

calibrating tool to the pipe. Insert

the calibrating tool completely into

the end of the pipe with a twisting

action and rotate 2-3 full turns.

Remove all swarf from outside and

inside the pipe.

Before using the battery tool it is essential that the user reads

and recognises the instructions contained in the manual

included with every tool. Make sure you are aware of the

operating features and functions.

Ensure that only BUSHPEX compatible jaws are used to match

the tool. Check the jaw matches the diameter of the BUSHPEX

PEX-AL pipe and BUSHPEX Crimp gas fittings.

Inspect and test all tools prior to use to ensure they are

functioning properly.

Visually inspect all tools and jaws to ensure they are clean, dry,

free of dust, dirt, grit and corrosion.

It is a requirment to check every crimped joint with the crimp

gauge by passing the crimp gauge over both indentations in

the stainless steel sleeve to ensure proper crimping function.

If the battery warning light comes on or any detection of

incomplete crimping occurs you must change the battery

immediately, check the joint with a crimp gauge and re-crimp

as necessary.

If the crimping tool does not fully compress or the jaws do not

flully close, release the trigger, actuate the retract slide, check

the tool then re-crimp the joint and check with the crimp gauge

to ensure conformance.

•

•

•

•

•

•

•

Jointing Procedure

16 BUSHPEX Crimp Gas

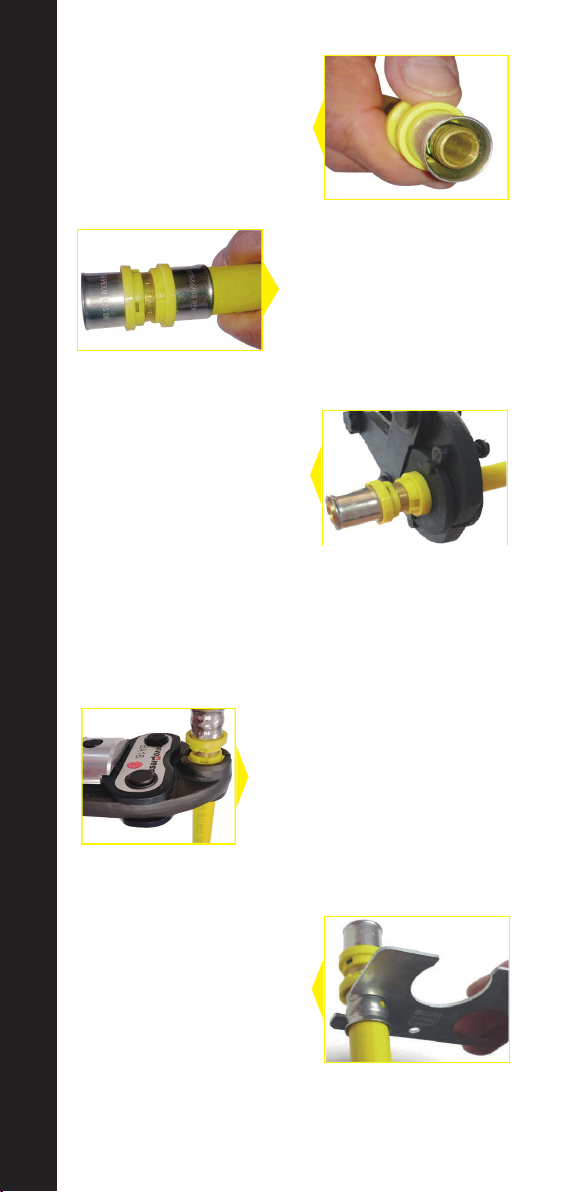

• Visually inspect the inside of

the fitting to ensure it is free of

dust, dirt and grit and confirm

the 2 “O” rings are intact and

undamaged.

• For BUSHPEX Manual

Crimping Tools: Centralise the

BUSHPEX Manual tool – sized

to suit the pipe and fitting with

jaws over the stainless steel

crimp ring and butted up

against the yellow retaining ring. Slowly bring the lever handles

together closing the jaws completely compressing the joint.

NOTE: DO NOT position the manual tool crimp jaws over the

yellow retaining ring. This will damage the fitting, destroy the

integrity of the fitting and void warranty. If this occurs you must

cut-out the fittings and replace immediately.

fitting. Activate the battery tool and compress the stainless crimp

ring completely until the jaw is closed.

according to instructions, then re-crimp and test.

• Insert the BUSHPEX PEX-AL

pipe into the BUSHPEX Crimp

Gas fitting. Ensure that the pipe

is fully inserted into the fitting by

viewing the pipe through the 4

inspection holes in the yellow

plastic retaining ring.

• For BUSHPEX approved Battery

Crimping Tool: Align the Battery

tool jaw to seat over the plastic

retaining ring at one end and cover

the stainless crimp ring. This

position locates the jaw onto the

• Check each joint has been

compressed correctly by using

the BUSHPEX Crimp Gauge. If

the BUSHPEX crimp gauge

does not pass over the crimp

indentations check tooling,

inspect and adjust the tool

BUSHPEX Crimp Gas PEX-AL Calibration Tool

Battery Drill Calibration Tool

Specific tooling for BUSHPEX Crimp Gas PEX-AL piping system.

IMPORTANT NOTES:

• Always set the drill speed no greater than 500rpm.

• Water & Gas calibrating tools are NOT interchangeable.

Calibration Procedure

BUSHPEX Crimp Gas:

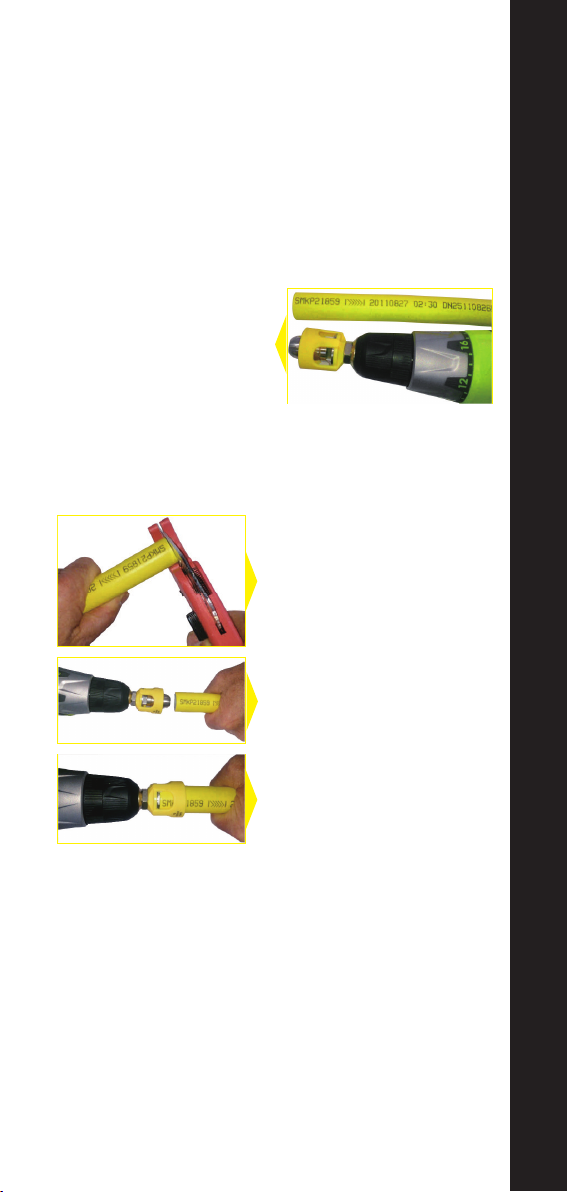

• Confirm you have all tooling to

complete the job – DO NOT

start without these:

BUSHPEX Crimp Gas Calibration

tool – sized to suit the pipe,

Battery Drill – charged,

• Cut the BUSHPEX Gas PEX-AL

pipe to length, using BUSHPEX

pipe cutter.

Calibrate the end of the BUSHPEX

Gas PEX-AL pipe using the specific

sized calibrating tool to round and

deburr the end of the pipe. Ensure

the calibrating tool has been

completely inserted into the

BUSHPEX Gas PEX-AL pipe with at

least 2-3 full turns. Remove all

swarf from outside and inside of

pipe.

• Continue as per page 18.

IMPORTANT:

This system MUST be installed by a licenced Gas Fitter in

accordance with AS/NZS5601, this procedure and using

BUSHPEX Crimp Gas PEX-AL pipe, fittings and approved tools,

otherwise warranty will be void.

It is a requirment to incorporate a visual checking system to

confirm every joint has been crimped prior to concealing joints.

This should be done with a crimp gauge test on every joint.

BUSHPEX Crimp Gauge, BUSHPEX Crimp Gas PEX-AL

pipe & fittings.

•

•

Jointing Procedure

17

BUSHPEX Crimp Gas

Frequently Asked Questions

18 BUSHPEX Crimp Gas

Is there anything I need to do before using a Manual crimp

Tool?

YES – follow all of these important steps below:

Ensure that the tool is compatible with BUSHPEX GAS

PEX-AL Pipe and BUSHPEX Crimp Gas Fittings

Ensure the tool is in good working order

Ensure that the jaws align and have no gap when closed

Ensure that the jaws are clean, free of defects and debris

Refer to the Jointing Procedure in this manual for correct

method

If the jaws of the Manual Tool do not align when closed

what must I do?

Adjust the jaws and test until the jaws align and have no

gap. Follow the process described in the section, “jointing

procedures – Tool adjustment”

Is there anything I need to do before using the approved

battery crimp Tool?

YES – follow all of these important steps below:

Ensure that the tool and jaws are compatible with BUSHPEX

GAS PEX-AL Pipe and BUSHPEX Crimp Gas Fittings

Read and recognise the instructions contained in the

manual

Ensure the correct jaws match the tool, the pipe and the

fittings

Inspect the tool to ensure it functions properly

Inspect the jaws to ensure they’re clean, dry, free of dirt grit

and corrosion

If the battery Tool does not fully compress what should I do?

Release the trigger and jaws by actuating the retract slide

Recharge the battery or replace with charged battery

Crimp the joint a second time and check with the crimp

gauge

Cut off the pipe and fitting if it fails to crimp properly

Do I need to inspect the pipe end prior to crimping?

YES, always inspect the pipe and ensure it is cut square, has

been “rounded & deburred”, has no rough edges and the

internal and external pipe is undamaged prior to crimping.

FAQ

i)

ii)

iii)

iv)

v)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Frequently Asked Question

19

BUSHPEX Crimp Gas

Do I need to “round and deburr” the pipe prior to every

crimp joint?

YES - this is a requirement for every joint – ensure that the

reaming/calibrating tool suits BUSHPEX Gas PEX-AL pipe

Do I need to inspect the crimp fitting prior to every crimp

joint?

YES - you should visually inspect each fitting to ensure it

is free of any dirt and grit, has both “O” rings intact, the

stainless crimp sleeve is properly located and all parts are

undamaged – clean/ replace/discard as required.

How can I tell if the pipe has been pushed into the fitting

properly?

Inspect the fitting to ensure the pipe is visible through

all 4 witness openings

Do I need to check every crimp joint has been

compressed properly?

YES - you should check every crimp joint has been

compressed properly by testing with the crimp gauge

Is there a procedure to follow when soldering

connecting barbs?

YES, ALWAYS:

Dismantle the fitting prior to heating and brazing

Allow to cool fully before assembly

Ensure the yellow plastic retainer rings, two “O” rings

and stainless steel sleeve are installed correctly – refer

to picture assembly detail on page 9 of this brochure.

What are the requirements for installing the BUSHPEX

Crimp Gas system?

Must only be installed by a licenced Gas Fitter

Must be installed in accordance with AS/NZS5601

Must be installed using the BUSHPEX Crimp Gas

PEX-AL Piping system procedures

Must be installed using BUSHPEX Gas PEX-AL pipe,

BUSHPEX Crimp Gas fittings and tools, licence

SMKP21859

vi)

vii)

viii)

ix)

x)

xi)

•

•

•

•

•

•

•

•

Pipe Sizing Tables

20 BUSHPEX Crimp Gas

PIPE SIZING - NATURAL GAS

The following gas pipe sizing tables were calculated using

the method described in AS/NZS

5601.

Nom diam.

(DN)

Pressure drop of 0.075 kPa

for supply pressure of 1.1 kPa on Natural Gas

Length of straight pipe m

2 4 6 8 10 12 14 16 18

16 63 44 35 30 27 24 22 21 19

20 150 103 83 71 63 57 52 49 46

25 268 184 148 127 112 102 94 87 82

32 591 406 326 279 247 224 206 192 180

40 982 675 542 464 411 373 343 319 299

50 1873 1287 1034 885 784 710 654 608 570

63 4163 2861 2298 1967 1743 1579 1453 1352 1268

20 25 30 35 40 45 50 55 60

16 18 16 15 13 13 12 11 11 10

20 43 38 35 32 30 28 26 25 24

25 77 68 62 57 53 50 47 45 43

32 170 151 136 126 117 110 104 98 94

40 283 251 227 209 194 182 172 164 156

50 539 478 433 398 370 348 328 312 297

63 1198 1062 962 885 823 772 730 693 661

Nom diam.

(DN)

Pressure drop of 0.12 kPa

for supply pressure of 1.25 kPa on Natural Gas

Length of straight pipe m

2 4 6 8 10 12 14 16 18

16 85 58 47 40 36 32 30 28 26

20 194 133 107 92 81 74 68 63 59

25 351 241 194 166 147 133 123 114 107

32 760 523 420 359 318 288 265 247 232

40 1308 899 722 618 548 496 456 425 398

50 2445 1680 1350 1155 1024 928 853 794 745

63 5440 3739 3003 2570 2278 2064 1899 1766 1657

20 25 30 35 40 45 50 55 60

16 24 22 20 18 17 16 15 14 13

20 56 49 45 41 38 36 34 32 31

25 101 90 81 75 69 65 62 58 56

32 219 194 176 162 150 141 133 127 121

40 376 334 302 278 259 243 229 218 208

50 704 624 565 520 484 454 429 407 388

63 1565 1387 1257 1156 1076 1009 954 906 864

PIPE SIZING TABLE 2 –Flow rates in units of MJ/h

PIPE SIZING TABLE 1 –Flow rates in units of MJ/h

NOTE: Allowance for fittings has been incorporated into the table listed below

which is equivalent to a 50% increase of the length of the pipe. This method is

detailed in the Standard, AS/NZS 5601 Appendix F section F1.3.

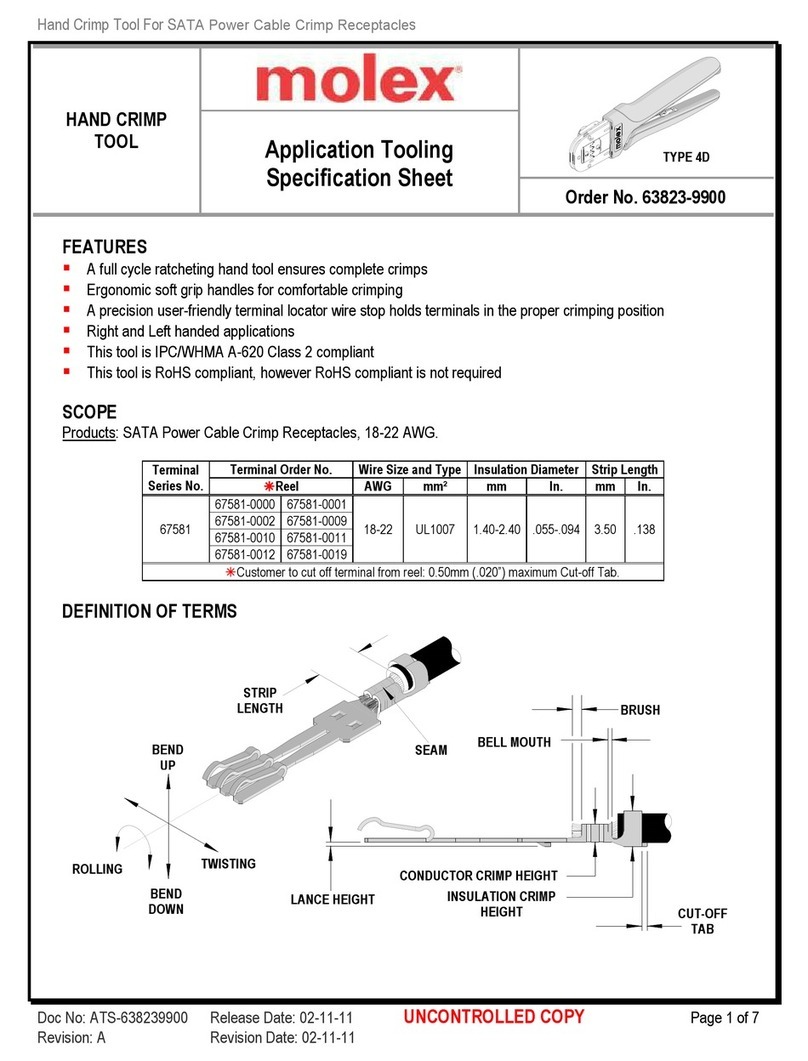

Table of contents

Popular Crimping Tools manuals by other brands

molex

molex 207129 Series manual

molex

molex 63811-5500 Specification sheet

Textron

Textron Greenlee GATOR EK12IDLT Operation manual

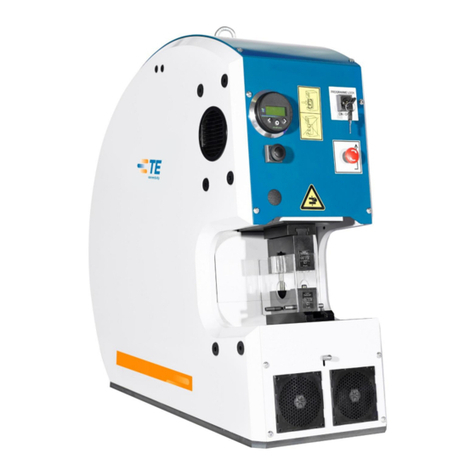

TE Connectivity

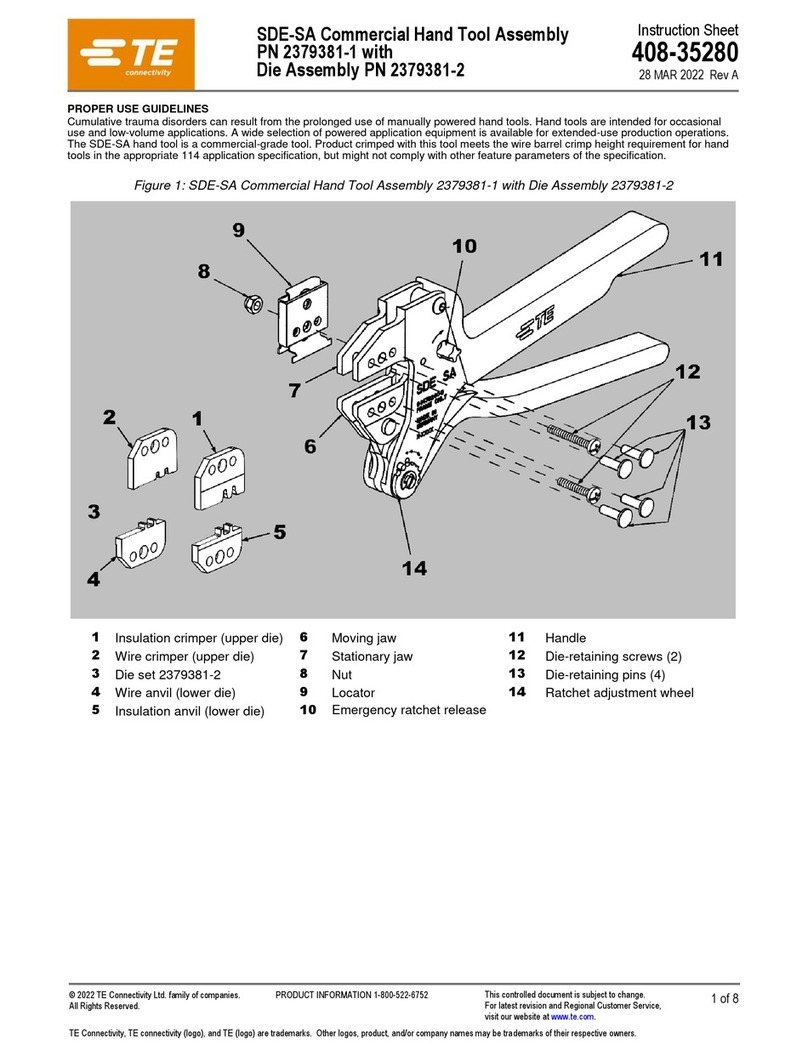

TE Connectivity 2379381-1 instruction sheet

TE Connectivity

TE Connectivity PRO-CRIMPER III instruction sheet

TE Connectivity

TE Connectivity AT-65 Operation manual