Emcee TTU500FA User manual

Broadcast Products

P.O. Box 68, White Haven, PA 18661 Phone: (570) 443-9575 FAX: (570) 443-9257

MDS

MMDS

ITFS

LPTV

North America

South America

Europe

Asia

Australia

Africa

Since 1960

6) USERS MANUAL

TTU500FA

SOLID STATE LDMOS

500W UHF TRANSMITTER

TTU500FA

SOLID STATE LDMOS

500W UHF TRANSMITTER

05/01

IMPORTANT

Transient Overvoltage Protection

Transient overvoltageof micro- andnano-secondsdurationspresentonAC lines

are a continuous threat to all solid-state circuitry. The resulting costs of

equipment repairs and system downtime make preventative protection the best

insurance against thesesuddensurges. Types ofprotection rangefrom isolation

transformers and uninterruptible power supplies to the more cost effective AC

power line protectors. As transientsare most often caused by lightning induction

and switching surges, AC power line protectors are the most practical solution.

An effective AC power line protector is one capable of dissipating impulse

energy at a low enough voltage to ensure the safety of the electronic compo-

nents it is protecting. The protection unit should be across the AC line at all

times even during periodsof total blackout. It should also reset immediately and

automatically to be 100% ready for repeated transients.

TABLE OF CONTENTS

I. THE TTU500FA TRANSMITTER

1.1 Introduction

1.2 Specifications

1.3 Installation

1.4 Operation

1.5 Warrant

y

and Parts Orderin

g

II. CIRCUIT DESCRIPTION

2.1 Modulator

2.2 EMEX1 2 Watt UHF Exciter

2.3 500 Watt UHF Power Amplifier

2.4 Output Section

2.5 Control/Meterin

g

Panel

III. MAINTENANCE

3.1 Periodic Maintenance Schedule

3.2 Recommended Test E

q

uipment

3.3 Troubleshootin

g

3.4 Ali

g

nment

3.5 Output Power Calibration

3.6 Linearit

y

Corrector Ad

j

ustment

3.7 Remote Monitor Si

g

nal Levels

3.8 Spare Modules and Components

3.9 S

y

nthesizer Pro

g

rammin

g

IV. DATA PAK

V. SCHEMATIC DIAGRAMS

i

SECTION I

THE TTU500FA TRANSMITTER

1.1 INTRODUCTION ....................................................... 1

6

1

1.2 SPECIFICATIONS ..................................................... 1

6

1

1.3 INSTALLATION ........................................................ 1

6

3

1.4 OPERATION ........................................................... 1

6

4

1.5 WARRANTY AND PARTS ORDERING ................................... 1

6

5

1

6

1

SECTION I

THE TTU500FA TRANSMITTER

1.1 INTRODUCTION:

The EMCEE TTU500FA LPTV Transmitter is a remarkably compact design rated to provide

500 watts peak visual and 25 watts average aural power on any FCC specified channel extending

from 470 to 806MHz. The TTU500FA is completely solid-state supplying maximum performance

and reliability through the liberal utilization of Laterally Diffused Metal Oxide Semiconductors

(LDMOS). Comprised of a modulator, an EMEX1 2 Watt UHF Exciter, one 500 Watt UHF Amplifier

drawer, an Output Section for filtering and power measurement, and panels for power distribution

and metering/control, the TTU500FA is easy to service and maintain with RF alignment practically

nonexistent. A number of controls and indicators, furnished on the transmitter’s Control/Metering

panel and the EMEX1 Exciter front panel, provide convenient operation while displaying the results

of the transmitter's diagnostic circuitry.

The TTU500FA is designed for the express purpose of broadcasting as authorized by the U.S.

Federal Communications CommissionunderPart 74, Subpart G, of the FCC Rulesand Regulations.

1.2 SPECIFICATIONS:

Visual:

Output Power 500 watts peak

Emission 5M75C3F visual

Color Transmission NTSC, PAL, or SECAM

Output Frequency 470-806MHz

(FCC - Ch.14-69)

(CCIR - Ch.21-62)

Frequency Stability Visual Carrier ±500Hz

Output Power Stability ±0.5dB

Spurious Products

60dB below peak sync

Harmonics

60dB below peak sync

In-band Intermodulation (IM3)

52dB below peak sync

Differential Gain ±5%

Differential Phase ±3

(

1

6

2

Low Frequency Linearity 5%

Frequency Response ±0.5dB

Sideband Response Better than FCC 73.687(a)(1)

Envelope Delay Better than FCC 73.687(a)(3)

Output Impedance/Connector 50 ohms / 7/8" EIA flange

Video Signal to Noise

55dB

Video Input Level 1 volt peak-to-peak nominal

Video Input Impedance 75 ohms unbalanced

Aural:

Output Power 25 watts average

Emissions 250KF3E

Frequency Stability ±200Hz re. visual

Audio Input Level 0dBm nominal

Audio Input Impedance 600 ohms balanced

Audio Distortion <1%

FM Noise <

55dB

General/Mechanical:

Ambient Temperature

30

(

C to +50

(

C

Power Requirements 230Vac ± 15%, 1 phase, 50/60Hz, 4kW

Power Consumption: 2kW w/black picture

Power Factor 0.9

Mechanical Dimensions 48"H x 22"W x 31"D

Weight 300 lb.

1

6

3

1.3 INSTALLATION:

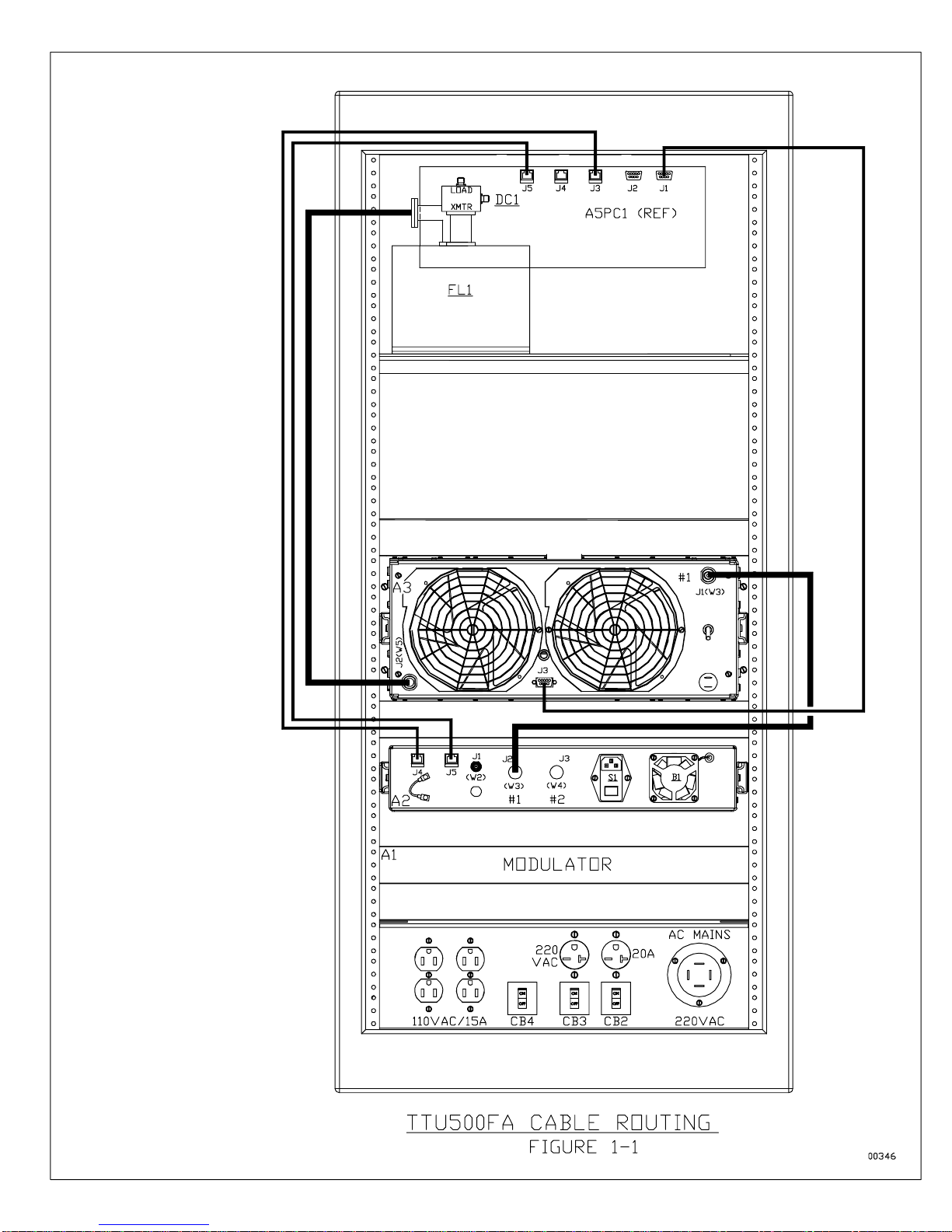

Except where otherwise noted, the connectors mentioned in the following instructions are located

on the rear of the transmitter.

1. After unpacking the transmitter, a thorough inspection should be conducted to reveal any

damage which may have occurred during shipment. If damage is found, immediately notify

the shipping agency and advise EMCEE Broadcast Products Customer Service or its field

representative. Also check to see that any connectors, cablesor miscellaneous equipment,

which may have been ordered separately, are included.

2. Place the transmitter in a clean, weatherproof environment providing adequate ventilation

for the exhaust fans at the rear of the transmitter drawers. It is important to maintain the

transmitter's ambient temperature within the

30

(

C and +50

(

C limits. Cooler ambient

temperatures will provide increased reliability.

3. Place the transmitter in its permanent location near a single-phase receptacle that supplies

230Vac at 50/60Hz. The ac source should have a minimum power capacity of 4kW.

IMPORTANT

Do not apply ac power to the transmitter at this time since its RF output must be

properly loaded before being placed in operation.

4. Set all circuit breakers, including the customer's incoming ac line breaker, to the OFF

position. Ac breakers can be found on the transmitter’s AC Distribution Panel, at the rear of

the amplifier and Exciter drawers, and on the front AC Power panel. Place an appropriate

power line protector (surge suppressor) across the ac line that supplies the transmitter.

5. Connectthebasebandvideoandaudiocables(customersupplied)tothetransmitter's VIDEO

and AUDIO connectors located on the upper panel at the rear of the transmitter cabinet.

6. Connect the transmitting antenna cable (or a 1kW, 50 ohm dummy load) to the 7/8" EIA

flange connector marked RF OUTPUT located through the center rear of the cabinet’s top

cover.

7. Verify that the power cords of the Modulator (110V/15A), Exciter (110/15A) and 500W Power

Amplifier drawer (220V/20A)are plugged into the receptacles at the bottom of the transmitter

cabinet. Also check to see that any ancillary equipment included in the cabinet (i.e. Video

Detect Switch, Stereo Generator, etc.) are connected to the appropriate ac sockets.

8. Check to see that all RF cables and wire harnesses are properly connected and secure.

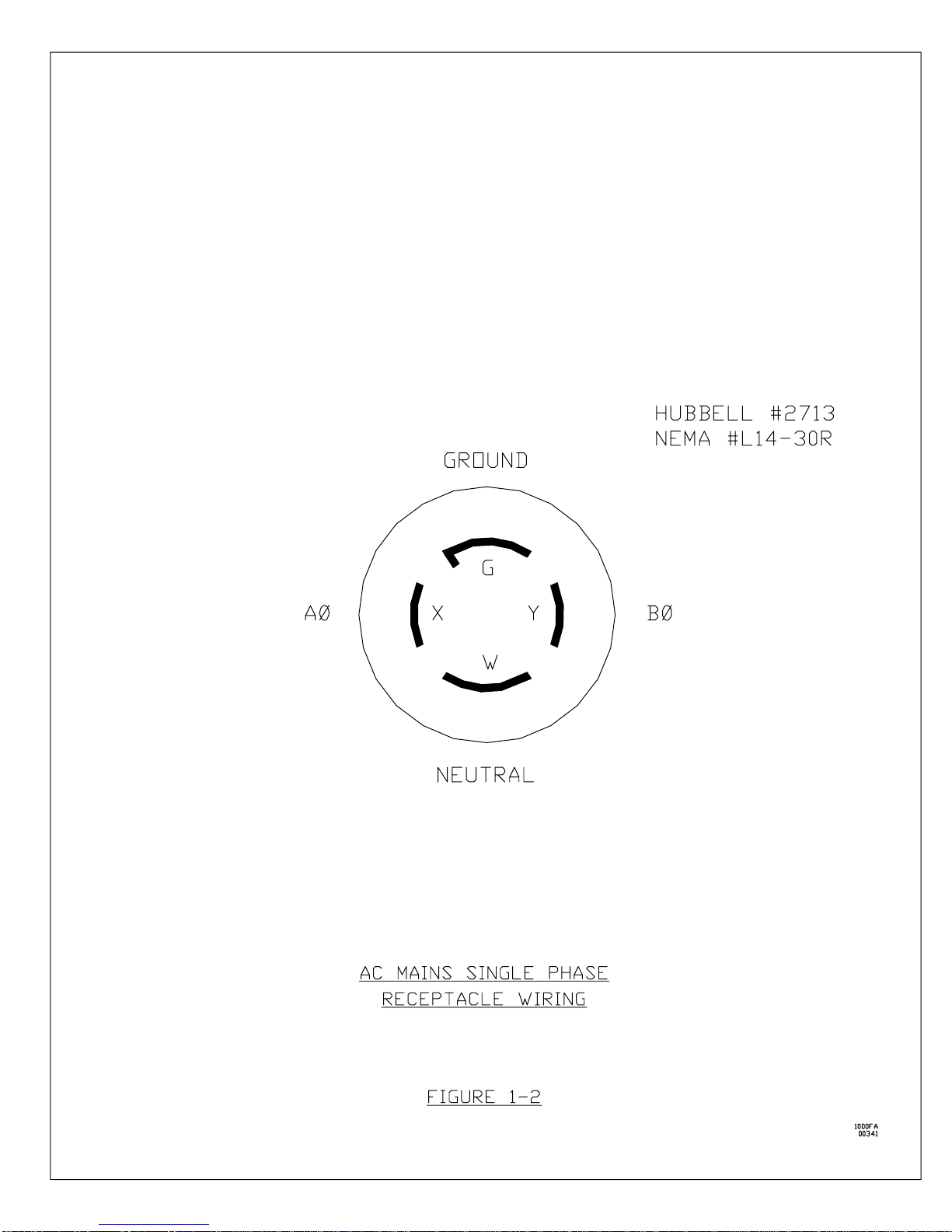

9. Usingthe4-prong, twist-lock, femaleplugsuppliedwiththetransmitter,fabricateanac power

cord (Figure 1

6

1) and plug it into the transmitter's AC MAINS connector at the bottom rear

of the transmitter cabinet. Open the incoming ac mains wall breaker and connect the other

end of the power cord into an appropriate 220Vac electrical outlet.

1

6

4

1.4 OPERATION:

Assuming the installation instructions of Section 1.3 have been completed and the transmitter is

receivingbasebandvideo and audiosignals, proceed with the following steps to place the transmitter

in operation. Except where otherwise noted, the controls, switches, and indicators mentioned in

these steps are located on the front of the transmitter.

1. Open the AC POWER circuit breaker located on the bottom front panel of the transmitter and

close the incoming ac mains breaker. Insure that the EMEX1 Exciter OPERATE/STANDBY

switch is in the off/out (STNDBY) position and the AGC/MANUAL button is in the off/out

(MANUAL) position. Place the transmitter’sControl/Metering panel FWD/REFL meter switch

to the FWD/out position.

2. Place the three AC Distribution Panel breakers (CB2, CB3, CB4), located at the lower rear

of the cabinet, to the on position. Also switch the Exciter and amplifier drawer rear panel

breakers to on.

3. Move the AC POWER circuit breaker located on the bottom front panel of the transmitter to

the ON position.

4. If applicable, place the Modulator's power switch to ON and verify that it is providing 87.5%

video modulation. If necessary, adjust the Modulator for the proper video depth of

modulation asdescribed in its instruction manual. Also check to see that the audio peaks are

not overmodulating the aural carrier.

5. Verify the following transmitter responses:

a. The fans at the rear of each drawer should be operating.

b. The Exciter’s green LED indicators should react as follows:

SYNTHESIZER LOCK – on

IF STATUS – on

AMPLIFIER STATUS – on

LINEARITY CORRECTOR – on

AGC ACTIVE – off

SWEEP MODE – off

OPERATE/STANDBY – off

VSWR RESET – off

AGC voltmeter – 1 segment lit at approximate center

RF POWER meter – 0%

c. The green LED indicators on the transmitter’s Control/Metering panel should respond

as follows:

AMPLIFIER TEMP – off

AMPLIFIER – on

POWER SUPPLY – off

RF POWER meter – 0%

FWD – on

REFL – off

1

6

5

6. Turn the Exciter's OUTPUT LEVEL ADJUST two or three turns counterclockwise and press

the OPERATE/STANDBY switch in to place the transmitter in OPERATE. Then verify the

following responses of the transmitter:

a. The Exciter’s OPERATE/STANDBY switch indicator is now lit green.

b. The POWER SUPPLY Control/Metering panel indicator is now lit green.

c. The status of all other indicators previously mentioned is the same.

7. Check to see that the Control/Metering panel’s meter switch is in the FWD/out position and

then slowly turn the Exciter’s OUTPUT LEVEL ADJUST clockwise until a 100% indication

appears on the Control/Metering panel’s RF POWER meter. The Exciter’s RF POWER

meter should also be displaying a 100% indication.

8. After 10 minutes of operation press the Exciter’s AGC/MANUAL switch in to engage the

transmitter’s output automatic gain control. If necessary and with a small tuning tool, slowly

turn the AGC LEVEL ADJUST to bring the transmitter’s RF POWER meter reading back to

100%.

9. Place the Control/Metering panel's meter switch to REFLD and verify that the RF POWER

meter indicates no more than 10% returned power. If the reflected power is more than 10%,

shutdownthe transmitter andcheck theVSWR of thetransmittingantenna anditsassociated

cable.

10. Place the Control/Metering panel's meter switch to FWD for constant monitoring of the

transmitter's final output power.

The transmitter is now in operation. Check its coverage area for clean, sharp television reception.

If the reception or picture quality is unsatisfactory, examine the amount of power delivered to the

transmitting antenna (see Section 3.5) and, if necessary, examine the antenna orientation and

antenna transmission line VSWR to insure maximum radiation in the proper direction.

1.5 WARRANTY AND PARTS ORDERING:

Warranty – EMCEE warrants its equipment to be free from defectsin material and workmanship for

a period of one year after delivery to the customer. Equipment orcomponents returned as defective

(prepaid) will be, at our option, repaired or replaced at no charge as long as the equipment or

component part in question has not been improperly used or damaged by external causes

(e.g., water, ac line transients or lightning). Semiconductors are excepted from this warranty and

shall be warranted for a period of not more than ninety (90)daysfrom date of shipment. Equipment

or component parts sold or used by EMCEE, but manufactured by others, shall carry the same

warranty as extended to EMCEE by the original manufacturer.

Equipment Returns – If the customer desires to return a unit, drawer, or module to EMCEE for

repair, follow the procedure described below:

1. Contact EMCEE Customer Service Department by phone or fax for a Return Authorization

Number.

1

6

6

2. Provide Customer Service with the following information:

Equipment model and serial numbers.

Date of purchase.

Unit input and output frequencies.

Part number (PN) and Schematic Diagram designator if a module is being sent.

Detailed information concerning the nature of the malfunction.

The customer shall designate the mode of shipping desired (e.g., Air Freight, UPS, Fed Ex, etc.).

EMCEE will not be responsible for damage to the material while in transit. Therefore, it is of utmost

importance that the customer insure the returned item is properly packed.

Parts Ordering – If the customer desires to purchase parts or modules, utilize the following

procedure:

1. Contact EMCEE Customer Service by phone or fax indicating the customer's purchase order

number. If thepurchaseorder number isprovidedbyphone, writtenconfirmation of theorder

is required.

2. Also provide:

The equipment model and serial number.

The unit input and output frequencies.

The quantity, description, vendor, number, and designation of the parts needed as found in

the Parts Lists subsection of this manual.

If a module is required, give the part number (PN) and Schematic Diagram designator

(e.g., 30404029).

Designate the mode of shipping desired (e.g., Air Freight, UPS, Fed Ex, etc.).

Shipping and billing addresses.

Spare and Replacement Parts – The Spare Modules and Components section of this manual

provides a detailed listing of the modules and some discrete components contained within the

transmitter. The listing contains those modules or components considered to be essential

bench-stock items and should be available to the technician at all times. The Schematic or

Interconnection Diagram isthegoverning document of this manual. Should there be a discrepancy

between a modules or components list and a diagram, the diagram takes precedence. Such a

discrepancy is possible since manufacturing changes cannot always be incorporated immediately

into the instruction manual.

Component Referencing – A transmitter may consist of a modulator or receiver, a number of

modules and components mounted in drawers, and components or modules mounted to panels or

directly to the cabinet. Components mounted in a module which is included in a drawer take the

drawer number and the module number in addition to a component number. Thus the reference

designator A2A1Q1 means transistor Q1 in module A1 of drawer A2. Components mounted in a

drawer takeonly the drawer number and a component number (e.g., A2M1 designates meter M1 of

drawer A2). Components mounted directly to a panel take only the panel number and a component

number. Components and modules mounted directly to the cabinet take only a component or

module number.

1

6

7

For EMERGENCY technical assistance, EMCEE offers atoll free,24-hour, 7-day-a-week

customer service hot line: 1-800-233-6193.

ii

SECTION II

CIRCUIT DESCRIPTION

2.1 MODULATOR ......................................................... 2

6

1

2.1a Video Detector Switch ............................................... 2

6

1

2.2 EMEX1 2 WATT UHF EXCITER ......................................... 2

6

1

2.2a Linearity Corrector .................................................. 2

6

2

2.2b IF/Converter ....................................................... 2

6

3

2.2c UHFSynthesizer ................................................... 2

6

6

2.2d Reference Oscillator ................................................. 2

6

7

2.2e UHF Bandpass Filter ................................................ 2

6

7

2.2f 2WattUHFAmplifier................................................ 2

6

7

2.2g Metering Coupler ................................................... 2

6

9

2.2h MeteringDetector................................................... 2

6

9

2.2i Control/Interface Board .............................................. 2

6

9

2.2j Display/MonitorBoard .............................................. 2

6

20

2.2k 28V/15V/5V Power Supply ........................................... 2

6

24

2.3 500 WATT UHF POWER AMPLIFIER DRAWER ......................... 2

6

24

2.3a PowerSplitter..................................................... 2

6

25

2.3b 300W UHF Power Amplifier .......................................... 2

6

25

2.3c PowerCombiner................................................... 2

6

27

2.3d AmplifierStatusInterface............................................ 2

6

27

2.3e Power Supply/Thermal Interface ....................................... 2

6

27

2.3f 32V Power Supply ................................................. 2

6

28

2.4 OUTPUT SECTION ................................................... 2

6

29

2.4a UHF Bandpass Filter ............................................... 2

6

29

2.4b Directional Coupler ................................................. 2

6

29

2.4c MeteringDetector.................................................. 2

6

29

2.5 CONTROL/METERING PANEL ......................................... 2

6

30

2.5a Control/Monitor Board .............................................. 2

6

30

2

6

1

SECTION II

CIRCUIT DESCRIPTION

2.1 MODULATOR:

EMCEE EM1 / Scientific Atlanta 6340 / RF Comm. 2000

t

A1

IF OUT

8dBm peak visual typical

The modulator processes baseband video and audio signals to provide a composite IF output

composed of a visual carrier at 45.75MHz with 5M75C3F modulation, and an aural carrier at

41.25MHz with 250KF3E modulation. Any of these modulators can be used to drive the EMEX1

2 Watt Exciter drawer (A2). The optional video sense circuit provides an indication of whether the

modulator is receiving a baseband video signal. The output of the video sense is either a logic

high (

+5Vdc) with video present or a logic low (

0Vdc) when video is not present. This logic

signal is used by the Exciter Control/Interface Board (A2PC1) to place the transmitter in standby

if the video signal is lost.

2.1a Video Detector Switch:

Burst VDS

t

A9

For those modulators which do not contain a video sense alarm, the Burst Electronics Video

Detector Switch (Model VDS) will be installed in the transmitter cabinet. The VDS detects the

presenceofcompositevideo connected toitsA INPUT directly from the VIDEO connector mounted

on the Video/Audio/Remote Panel (A8J2). If a loss of video is detected, then the unit switches to

the B INPUT, lights its red LED and energizes an internal TALLY relay. Through this relay, a

ground is sent to the Exciter Control/Interface circuit via the transmitter’s Control/Monitor board

(A5PC1) placing the transmitter in a nonradiating condition.

2.2 EMEX1 2 WATT UHF EXCITER:

Interconnection Diagram 40404001/Rev 55

t

A2

Composite IF IN (J1)

8dBm peak visual

21dBm average aural

RF OUT (J2 & J3)

+18dBm typical peak visual

+5dBm typical average aural

The EMEX1 Exciter drawer converts the composite IF signal from the modulator to the desired

UHFfrequency while amplifyingthisRF signal to the appropriateoutputlevel. TheExcitersupplies

approximately 200mW of peak visual power to drive the 500W UHF Power Amplifier drawer (A3).

Power control, automatic gain control (AGC) and heterodyne conversion are performed by the

IF/Converter module (PC1). Utilizing the composite IF signal, the Linearity Corrector furnishes

performance improvements for the transmitter’s ICPM, differential phaseand gain, syncamplitude

2

6

2

andintermodulation. The UHFSynthesizersuppliesaprogrammableLOtotheIF/Converter mixer

where the LO and IF signalsare combined to create the desired UHF frequency. The UHF signal

from the Converter module is then passed through the UHF Bandpass Filter (FL1) to remove the

unwanted LO and sum products from the conversion process while passing and amplifying the

desired difference signals. The signal is then amplified approximately 25dB by the 2 Watt UHF

amplifier (A1) and passed through the Metering Coupler (CP1). Here, a forward RF sample is

provided for useby the Metering Detector (A3) while the main signal is passed to the output of the

drawer.

Metering and control functions are provided by the Metering Detector, the Display/Monitor board

(PC3) and the Control/Interface Board (PC4). The Display/Monitor Board has several status and

diagnostic LED indicators which are presented on the Exciter’s front panel. The Control/Interface

board provides for various controls and logic circuits for proper operation of the transmitter. Dc

powerforthe Exciterissupplied by asmall, efficient multioutput switchingpowersupplyPS1which

furnishes ±28, ±15 and ±5 volts.

2.2a Linearity Corrector:

Schematic Diagram 40404011/Rev 55

t

A2PC2

IF IN (J1)

11dBm typical

IF OUT (J2)

12dBm typical

Gain with S1 ENABLE/DISABLE (J1-J2) 0 to

2dB typical

Current Draw 610mA @ +15Vdc

TheLinearityCorrectorisasix-stage, unitygaincircuitwhichcompensatesfor nonlinear distortions

generated inthetransmitter'sClassAB500 Watt Power Amplifier drawer. Whenproperly adjusted,

it provides correction to the transmitter’s output signal for sync amplitude, differential gain,

differential phase, ICPM and intermodulation. Corrector amplifiers U1 through U8 are all

monolithic amplifier stages providing approximately 12dB of gain per device. A phase correction

network is centered around amplifiers U2 through U5 while the circuitry surrounding U7 and U8

corrects for differential gain and sync compression. When properly adjusted, the phase and gain

correction networks will collectively reduce intermodulation distortion.

Input amplifier U1 is biased through resistor R1 and inductor L1 which acts as an RF choke.

Capacitor C2 is utilized as a B+ bypass with coupling capacitors C1 and C3 advancing the input

signal to the matching T-attenuator made up of resistors R2, R3 and R4. At hybrid splitter DC1,

the IF carrier is divided into two equal amplitude signals which are 90

(

out of phase. At the

splitter’s

90

(

port, a negative phase-shift network composed of inductor L3 and capacitors C15

through C18 adds another

22.5

(

shift to the signal (

112.5

(

total) before amplification by U3.

Conversely, connected to the 0

(

port of the splitter is a positive phase-shift network comprised of

inductor L2 and capacitors C4 throughC7. Here the 0

(

signal is shifted in the positive direction by

22.5

(

resulting in a 135

(

total difference between the two signals. In order to keep the amplitude

of each signal similar, the circuits surrounding amplifiers U2 through U5 are essentially identical

with the same biasing, bypassing and coupling described for U1. Transformers T3 and T4 on the

negative shift side of the circuit are 2:1 step-up types identical to T1 and T2, but necessary to

efficientlydrivegain expansiondiodesCR1andCR2. Throughadjustment of slopepotentiometers

R15 and R25 and threshold (cut-in) pots R21 and R30, the amplitude of the negative shifted signal

can be varied to add to or subtract from the positive shifted signal at in-phase combiner CP1.

When adjusted properly, this circuit can then correct the differential phase, intermodulation and

ICPM distortions created by the transmitter’s power amplifier. At the output of combiner CP1 the

2

6

3

IF signal passes through a matching pi-attenuator comprised of resistors R35, R36 and R37 before

amplification by U6, U7 and U8. Transformers T5 and T6 again double the signal voltage to

properly drive the gain expansion diodes CR3 and CR4 which compensate for differential gain and

sync compression created in the 500 Watt Power Amplifier (A3).

Thevariablegainexpansionnetworks,whichprovidelinearitycorrection,arecenteredarounddual

diodes CR1 through CR4, slope potentiometers R15, R25, R41, R57, unity gain dc amplifiers U9,

U10, U11, threshold potentiometers R21, R30, R47, R55 and ENABLE/BYPASS switch S1. The

threshold (cut-in) potentiometers determine the point on the IF waveform where the correction, or

gain expansion, willoccurandtheslope potentiometersdictate theamount of correction/expansion

to be used at that breakpoint. With S1 in the ENABLE position, the four diode pairs form nonlinear

circuits where each diode is reverse biased and the amount of reverse bias dictates the point at

which the diode turns on during the positive and negative cycles of the visual IF carrier envelope.

Eachdiodeisbiasedusingvoltagesestablishedby thethresholdpotentiometersin conjunction with

dc amplifiers U9, U10, U11 and U12. L4 through L6 and L9 through L12 isolate the IF signal from

the diode threshold biasing circuitry. When the positive and negative peaks of the visual signal

envelope are sufficient to forward bias a diode pair, the pair turns on placing the resistance of its

respective slope potentiometer in parallel with the series arm of its L-pad (R14, R24, R40, R50).

As a result, the attenuation of the visual IF carrier is reduced during this period causing the

waveform to stretch. Slope control R41 is typically used to correct differential gain while R57

primarily adjusts sync amplitude.

With S1 in the BYPASS position, ground is applied to FET switches Q1 and Q2 placing each diode

pair in hard reverse bias preventing conduction throughoutthe positive and negative cycles of the

IF carrier envelope. Due to the high reverse resistance provided, each diode network essentially

represents a resistive L-pad (R14/R16, R24/R31, R40/R42, R50/R58) with the IF signal attenuated

by a fixed amount in each location. As a result, no linearity correction is provided.

2.2b IF/Converter:

Schematic Diagram 40404021/Rev 53

t

A2PC1

IF INPUT (J1) 0dBm to

30dBm peak visual

CORRECTOR LOOP Out (J3)

11dBm peak visual typical

CORRECTOR LOOP In (J4)

12dBm peak visual typical

RF OUT

10 to

18dBm

LO INPUT (J5) +13dBm minimum

Current Draw 42mA @ +15V

31mA @

15V

185mA @ +5V

The IF/Converter performs three tasks in this transmitter. With thefirst AGC loop it furnisheslevel

control for the incoming signal from the modulator, upconverts the IF signal to the desired UHF

channel and then controls the transmitter’s output power through a second gain control loop.

The modulator’s IF input, provided at J1, is amplified or attenuated by variable gain amplifier U1.

This integrated circuit, controlled by the output of integrator U4 via switch S1, (U1) can produce

wide variations in gain ranging from +30dB to

10dB. At the output of U1 is coupling capacitor C3

and 2:1 step-down transformer T1 required for proper impedance matching between U1 and in-

phase splitter CP1. At the output of CP1, twoequal amplitude IF signals are delivered for differing

applications. The signal at pin CP1-3 is used to provide a reference for the input AGC loop, while

2

6

4

the second signal at pin CP1-4 is fed to the Linearity Corrector (PC2) connected to output J3. Both

signals pass through attenuators (3dB and 7dB respectively) which are connected to identical

monolithic amplifiers, U7 and U8. Thesedevices, offering approximately 14dB of signal gain, are

furnished bias through resistors R15/R22 and RF chokes L1/L2. The output of amplifier U8 is

connected, through coupling capacitor C19, to a variable PIN attenuator composed of diodes CR7

and CR8. This diode array forms a pi-attenuator operated by buffer U9 whose input (pin 5) is

supplied control voltage from the Exciter’s front panel OUTPUT LEVEL ADJUST. With maximum

voltage from U9 (+15V) the attenuator will exhibit minimum attenuation of approximately 2dB.

With minimum voltage the attenuator can provide more than 50dB of loss to the signal. This

attenuator is utilized as the main power control and standby mechanism for the transmitter.

At the output pin 3 of U7 is the second IF signal required by the input AGC circuit as a power

referencerepresenting the incoming modulator signal level. Thissignal is passedthrough coupling

capacitor C16 to integrated circuit U6, an RMS detector. At pin 7,U6 outputs the video component

of the IF visual carrier while C11 rolls off the aural energy contained in the signal. The amplitude

of the video is then doubled using op-amp U5A and then sent to peak detector CR3 via pins 1 and

2 of jumper JP1. (Pins 2 and 3 of JP1 are utilized for average digital power detection only.)

Capacitor C9 and resistor R10 filter the peak video component from diode CR3 and this dc voltage

is sent to unity gain buffer U5B. The dc level at the output of U5B (pin 7), which is now

proportional to the peak power of the visual signal entering the IF/Converter, will be approximately

+3V when the modulator level into the Converter board is at the midpoint of its input AGC window

(

15dBm peak). This potential then appears at pin 6 of integratorU4B where it is compared to the

voltage on pin 5 (

+3V) generated by divider R7/R8. When the values of each voltage at pins 5

and 6 are equal, the output of U4B at pin 7 will be zero, holding variable gain amplifier U1 at the

center of its gain extremes (+10dB) via pins 8 and 1 of electronic switch S1. (The gain of U1 can

also be set to its center by applying a low to the INPUT AGC CONTROL line which is connected

to pin 6 (IN) of switch S1. This low, supplied by the OPERATE/SWEEP switch PC4S1 on the

Control/Interface board, will disconnect the input AGC voltage at S1-8 from S1-1 and connect the

ground at S1-2, 3 to S1-1 effectively placing a zero voltage on pin 1 of U1.) If the input level from

the modulator at J1 increases, the outputs of U7, U6, U5Aand U5B will also increase forcing pin 7

of U4B negative and proportionally reducing the gain of U1. Conversely, if the input from the

modulator were to be reduced, the output of U4B would swing positive causing U1 to increase its

gain compensating for the signal reduction. Under normal transmitter operating conditions, the

signal provided at theCORRECTORLOOP output (J3) willbeapproximately

11dBm peak visual.

However, if the IF signal is significantly reduced (

25dBm) or removed completely, the potential

at the output of U4B will exceed +2.5V causing the level at input pin 2 of U4A to exceed the

reference (2.5V) provided at pin 3 through divider R5/R6. This action would drive output pin 1 of

U4A to zero, turning off the IF STATUS light (PC3DS5) on the Exciter’s front panel and placing a

low on the LEVEL ADJUST lineattached to pin 5 of U9 increasing the attenuation of the associated

PIN diode circuit to maximum (

50dB).

After proceeding through the Linearity Corrector, the IF signal is fed to CORRECTOR LOOP input

J4 at an approximate level of

12dBm. Here the signal is furnished a 50 ohm match using

pi-attenuator R30/R31/R32. Hybrid amplifier U1, biased through resistor R33 and RF choke L3,

provides 14dB of gain and delivers the signal to in-phase2-way splitter CP2 via coupling capacitor

C29. At output pins 3 and 4 of CP2 are two equal amplitude IF signals used, respectively, to drive

the output AGC loop (U13 through U18) and to bemixed to the wanted UHF channel after passing

through the output control attenuator. Made up of PIN diodes CR9/CR10 and controlled by U18,

this attenuator is capable of 2dB to 50dB of attenuation and ultimately sets the output power of the

transmitter. From the output control attenuator the IF signal is transferred to mixer MX1 through

coupling capacitor C51 and pins 1 and 2 of jumper JP3. (Connecting pins 2 and 3 of JP3 brings

the IF signal to test point TP1.) In MX1 the IF is then upconverted to the desired UHF signal as

a result of combining with the local oscillator frequency presented at LO INPUT J5. At the output

of the mixer (pin 4) resistors R67/R68/R69 provide 5dB of attenuation and the appropriate

Table of contents

Other Emcee Transmitter manuals