Emfi PISTOLET MOUSSE User manual

Product code : I0020A – Version 2 from 08-01-2021

3 rue Ettore Bugatti - 67 00 Haguenau

Tél : 03 88 90 60 00 - Fax : 03 88 73 48 38

Internet : http://www.emfi.com - EMail : [email protected]

Writer : CD

Page 1 / 3

Product code : I0020A

PISTOLET MOUSSE

DESCRIPTION

PISTOLET MOUSSE is a professional-grade manual applicator intended to e trude

polyurethane foam packed in aerosol. It is particularly suitable for the use of bombs equipped

with a standard threaded tip found in stores.

AREAS OF APPLICATIONS

PISTOLET MOUSSE allows an easy and clean application of polyurethane foam packed in

aerosol. The ability to adjust the flow of the product allows controlled spraying and adequate

filling of the joints. The secure flow adjustment screw and nylon seal adapter make the whole

gun airtight and prevent the product from hardening inside during possible interruptions in

work.

TECHNICAL DATA

Nature of the materials Handle in black plastic

Body and trigger in nickel coated aluminium

Adapter (with nylon seal) in PTFE coated aluminum

Barrel in nickel coated steel

Non-return ball in PTFE

Nozzle in nickel coated brass

Needle in brass

Weight Appro . 340 g

Technical specifications Tapered nozzle: M9 type

Adapter: NBS ALBA RT type, M14 1,5mm connection

thread

Flow adjustment screw: secured (anti-leaks)

Accessories provided: 200 mm long e tensions (conical

and cylindrical) in transparent plastic

Advantages Controlled spraying, optimal dosage

Airtight assembly for good conservation

PTFE coated adapter for easy cleaning

INSTRUCTIONS FOR USE

Make sure the gun does not have any damaged parts before using it.

Product code : I0020A – Version 2 from 08-01-2021

3 rue Ettore Bugatti - 67 00 Haguenau

Tél : 03 88 90 60 00 - Fax : 03 88 73 48 38

Internet : http://www.emfi.com – EMail : [email protected]

Writer : CD

Page 2 / 3

Use:

Shake the can vigorously twenty times, the valve upside down. Screw the can onto the gun’s adapter and press the

trigger for about 2 seconds so that the gun is filled with foam.

During application, keep the gun in an upright position.

he amount of foam can be adjusted using the adjustment screw on the back of the gun: turn it clockwise to reduce the

flow and / or obtain a thinner layer, turn counterclockwise to increase the flow and / or to obtain a thicker layer. his

setting is required to obtain optimal results.

When replacing the can, shake the new can vigorously, unscrew the empty one and immediately replace it with the new

one to prevent the foam from hardening in the adapter. Residues of hardened foam in front of the nozzle can only be

removed mechanically.

During short work interruptions, the aerosol can be left on the gun, but the screw on the back of the gun must be tight.

he can must be pressurized and at least half full, otherwise the foam will harden in the gun. During longer work

interruptions, clean the gun with NE OYAN MOUSSE (EMFI ref. G0081A) or with acetone.

Cleaning:

Any foam that may have leaked must immediately be removed from the gun with the NE OYAN MOUSSE: spray the

cleaner on a clean, dry cloth (saturate it) and clean the surface. Repeat the procedure with a clean cloth. It is also

possible to spray NE OYAN MOUSSE directly on stains caused by PU foam or on dirty surfaces sales (the adapter, for

example), then to rub firmly with a clean cloth.

Gun cleaning:

After unscrewing the PU foam aerosol from the gun, purge the gun completely by pressing the trigger until all foam is

extruded. Screw the cleaner spray with its adapter onto the gun (in vertical position). Gently press the gun trigger until

the NE OYAN MOUSSE begins to come out and then release the trigger. Leave to act for 1 to 2 minutes inside the

gun. Press the trigger again and hold it until a clean cleaner comes out of the gun. Repeat the procedure 2 to 3 times,

until the gun is completely clean. After cleaning the gun, immediately remove the NE OYAN MOUSSE from the gun.

Make sure to keep the gun clean (especially inside the body) to give it a longer life.

PACKAGING

Unit sale

he technical data contained herein is based on our present knowledge and experience and we cannot be held liable for any errors, inaccuracies, omissions or

editorial failings that result from technological changes or research between the date of issue of this document and the date the product is acquired.

Before using the product, the user should carry out any necessary tests in order to ensure that the product is suitable for the intended application. Moreover, all

users should contact the seller or the manufacturer of the product for additional technical information concerning its use if they think that the information in their

possession needs to be clarified in any way, whether for normal use or a specific application of our product.

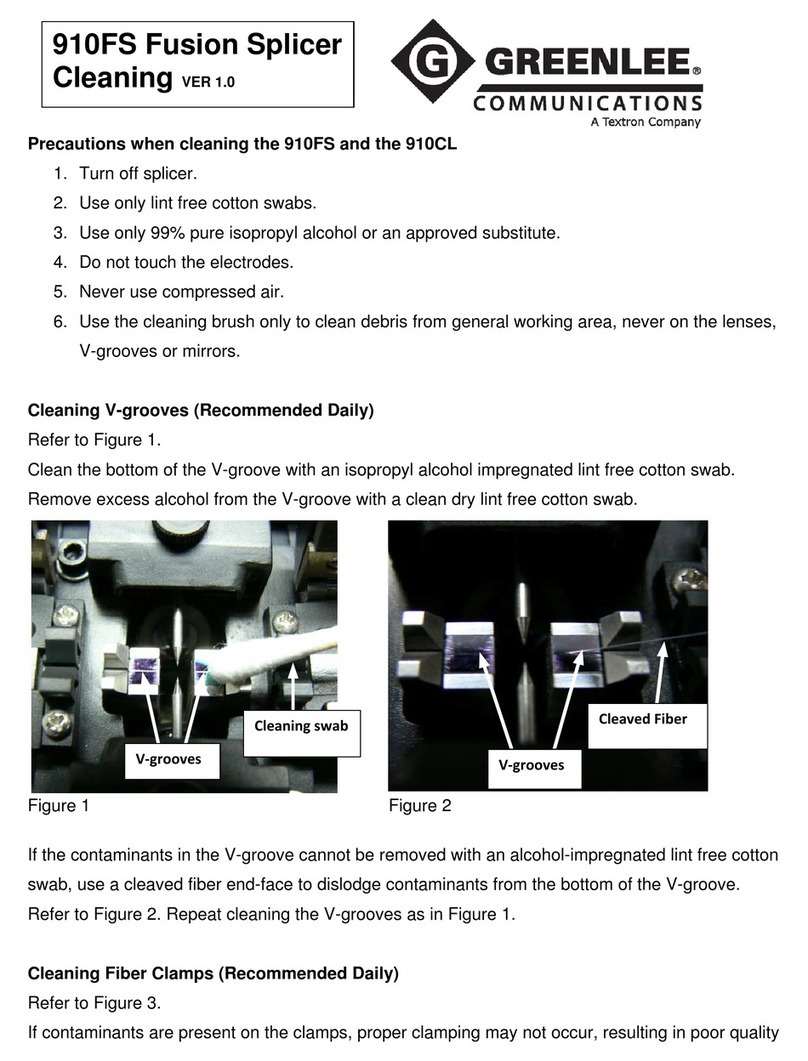

1 Body

2 Handle

3 rigger

4 Adapter (+ non-return ball)

5 Flow adjustment screw

6 Barrel

7 Nozzle

8 Needle

3

1

6

7

2

4

8

5

Product code : I0020A – Version 2 from 08-01-2021

3 rue Ettore Bugatti - 67 00 Haguenau

Tél : 03 88 90 60 00 - Fax : 03 88 73 48 38

Internet : http://www.emfi.com – EMail : [email protected]

Writer : CD

Page 3 / 3

Our guarantee applies within the context of the statutory regulations and provisions in force, current professional standards and in accordance with the stipulations

set out in our general sales conditions.

he information detailed in the present technical data sheet is given by way of indication and is not exhaustive. he same applies to any information provided

verbally by telephone to any prospective or existing customer.

This manual suits for next models

1

Table of contents

Popular Tools manuals by other brands

Urrea

Urrea 23RG250 User manual and warranty

Klutch

Klutch 49652 owner's manual

easydriver

easydriver infinity 2.5 Installation and instruction manual

MATLOCK

MATLOCK CRP130 INSTRUCTIONS & GENERAL INFORMATION

Textron

Textron GREENLINE 910FS CLEANING

microjig

microjig Matchfit DOVETAIL CLAMP PRO instruction manual