Emheater EM15-SP Series User manual

Preface

Thank you for purchasing the EM15-SP series solar inverter developed by China EM Technology Limited.

Features:

⚫MPPT algorithm of fast tracking of maximum power point of PV cells, efficiency >99%.

⚫Solar battery working point voltage can be manually or automatically MPPT tracking.

⚫All weather automatic operation,can also be manually or automatically,

⚫Realize”sunrise work and sunset sleep”.

⚫35 kinds protection function. including auto detecting short circuit after power on.

⚫Auto sleep function/pump dry protect/low frequency protection/over load protection and etc.

⚫Full protections:overload,over current, overvoltage,under voltage,short circuit, dry pumping etc.

⚫Output frequency range: V/F(0~3000hz); vector control(0~300HZ).

⚫Overload capacity:60s with 150% of rated current,3s with 180% of rated current.

⚫Speed accuracy:±0.5%(SVC);±0.02%(VC).

⚫Pulse setting input:0Khz~100Khz.

⚫Remote control, support RS232/RS485 protocol, terminal control, analog control.

Before unpacking, please check carefully:

1. Whether the nameplate model of solar inverter are consistent with your order ratings. The box contains the solar

inverter, user manual.

2. Whether the solar inverter is damaged during transportation. If you find any omission or damage, please contact

us or your local supplier immediately.

First-time Use

For the users who use this product for the first time, read the manual carefully. If in doubt concerning some

functions or performances, contact the technical support personnel to ensure correct use.

Due to the continuous improvement of solar inverter, this document will be updated without prior notice.

EM15-SP series solar inverter complies with the following international standards. All products have passed the CE

certification.

IEC/EN61800-5-1: 2003 Variable speed electric drive system safety requirements;

IEC/EN61800-3: 2004 Variable speed electric drive system, Part 3: The Electro Magnetic Compatibility (EMC)

Standards of Product and its specific testing methods.

Version:V2.0.0

Contents

1. Safety Information and Precautions......................................................................................................................... 1

1.1 Safety Information......................................................................................................................................... 1

2. Product Information................................................................................................................................................. 3

2.1 Designation Rules.......................................................................................................................................... 3

2.2 Model and Technical Data............................................................................................................................. 3

2.3 ProductAppearance and Installation Dimension........................................................................................... 4

2.3.1 ProductAppearance............................................................................................................................ 4

2.3.2Appearance and Installing Dimension................................................................................................ 4

2.3.3 Installation Dimension of External Keypad (Keypad Tray) ............................................................... 5

3.Installation of Frequency Inverter............................................................................................................................. 6

3.1 Installation Environment ............................................................................................................................... 6

3.2 Installation Direction and Space.................................................................................................................... 6

3.3 Sketch and Description of Main Circuit Terminals........................................................................................ 7

3.3.1 Function and Description of Main Circuit Terminals......................................................................... 7

3.4 Control Circuit and Main Circuit Terminals Description .............................................................................. 8

3.4.1 Control Circuit and Main Circuit Wiring............................................................................................ 8

3.4.2 Control Circuit Terminal Layout......................................................................................................... 8

3.4.3 Description of Control Circuit Terminals ........................................................................................... 8

3.5 Collection Diagram For Different Motor..................................................................................................... 10

3.5.1 The Wiring of Water-Level Automatic Control .................................................................................11

4 Operation and Display............................................................................................................................................ 13

4.1 Instruction of Operation and Display........................................................................................................... 13

4.2 Function Code Table.................................................................................................................................... 14

5. Fault Diagnosis and Solution................................................................................................................................. 42

5.1 FaultAlarm and Countermeasures............................................................................................................... 42

Appendix I. Modbus Communication Protocol......................................................................................................... 44

I. About Protocol................................................................................................................................................ 44

II. Application Methods..................................................................................................................................... 44

III. Bus Structure ............................................................................................................................................... 44

EM15-SP User Manual 1. Safety Information and Precautions

1

1. Safety Information and Precautions

In this manual, the notices are graded based on the degree of danger:

Danger: Indicates that failure to comply with the notice will result in severe personal injury or even death.

Warning: Indicates that failure to comply with the notice will result in personal injury or property damage.

Read this manual carefully so that you have a thorough understanding. Installation, commissioning or maintenance

may be performed in conjunction with this chapter. EMHEATER will assume no liability or responsibility for any

injury or loss caused by improper operation.

1.1 Safety Information

Danger

⚫Do not use damaged or missing components solar inverter. Failure to comply will result in personal injury.

⚫Please use the electric motor with upper B insulation class. Failure to comply will result in personal injury.

⚫Install the solar inverter on incombustible objects such as metal, and keep it away from combustible materials.

Failure to comply may result in a fire.

⚫Wiring must be performed only by qualified personnel under instructions described in this manual. Failure to

comply may result in unexpected accidents.

⚫A circuit breaker must be used to isolate the power supply and the solar inverter. Failure to comply may result

in a fire.

⚫Ensure that the power supply is cut off before wiring. Failure to comply may result in electric shock.

⚫Connect the solar inverter to ground properly by standard. Failure to comply may result in electric shock.

⚫Cover the solar inverter properly before power-on to prevent electric shock.

⚫Do not open the solar inverter’s cover after power-on to prevent from electric shock.

⚫Do not touch the solar inverter with wet hand and its peripheral circuit to prevent from electric shock.

⚫Do not touch the terminals of the solar inverter (including the control terminals). Failure to comply may result

in electric shock.

⚫Do not touch the U, V, W terminal or motor connecting terminals when solar inverter automatically does

safety testing for the external high-voltage electrical circuit. Failure to comply may result in electric shock.

⚫Do not go close to the equipment when selected the restart function. Failure to comply may result in personal

injury.

⚫Do not touch the fan or the discharging resistor to check the temperature. Failure to comply will result in

personal injury.

⚫Signal detection must be performed only by qualified personal during operation

1. Safety Information and Precautions EM15-SP User Manual

2

Warning:

⚫When two solar inverters are laid in the same cabinet, arrange the installation positions properly to ensure the

enough cooling effect.

⚫Do not drop wire residue or screw into the solar inverter. Failure to comply will result in damage to the solar

inverter.

⚫Never connect the power supply cables to the output terminals (U, V, W) of the solar inverter. Failure to

comply will result in damage to the solar inverter.

⚫Make sure that all the connecting wires comply with the requirement of EMC and the safety standard in the

region. Use wire sizes recommended in the manual. Failure to comply may result in accidents.

⚫Never connect the braking resistor between the DC bus terminals (P+) and (P-). Failure to comply may result

in a fire.

⚫Do not perform the voltage resistance test on any part of the solar inverter because such test has been done in

the factory. Failure to comply will result in accidents.

⚫All peripheral devices must be connected properly under the instructions described in this manual. Failure to

comply will result in accidents.

⚫Note the danger during the rotary running of motor when check the parameters. Failure to comply will result

in accidents.

⚫Do not change the factory default settings of the solar inverter. Failure to comply will result in damage to the

solar inverter.

⚫Avoid objects falling into the solar inverter when it is running. Failure to comply will result in damage to solar

inverter.

⚫Do not start/stop the solar inverter by turning the contactor ON/OFF. Failure to comply will result in damage

to the solar inverter.

EM15-SP User Manual 2. Product Information

3

2. Product Information

2.1 Designation Rules

EM15 Series Frequency Inverter

Products Type: PV use

Voltage range:

1: DC 250~400V to Three phase AC 220V

3: DC 350~750V to Three phase AC 380V

Adaptable motor: 7d5: 7.5KW ;011: 11KW

Diagram 2-1 Designation rules

2.2 Model and Technical Data

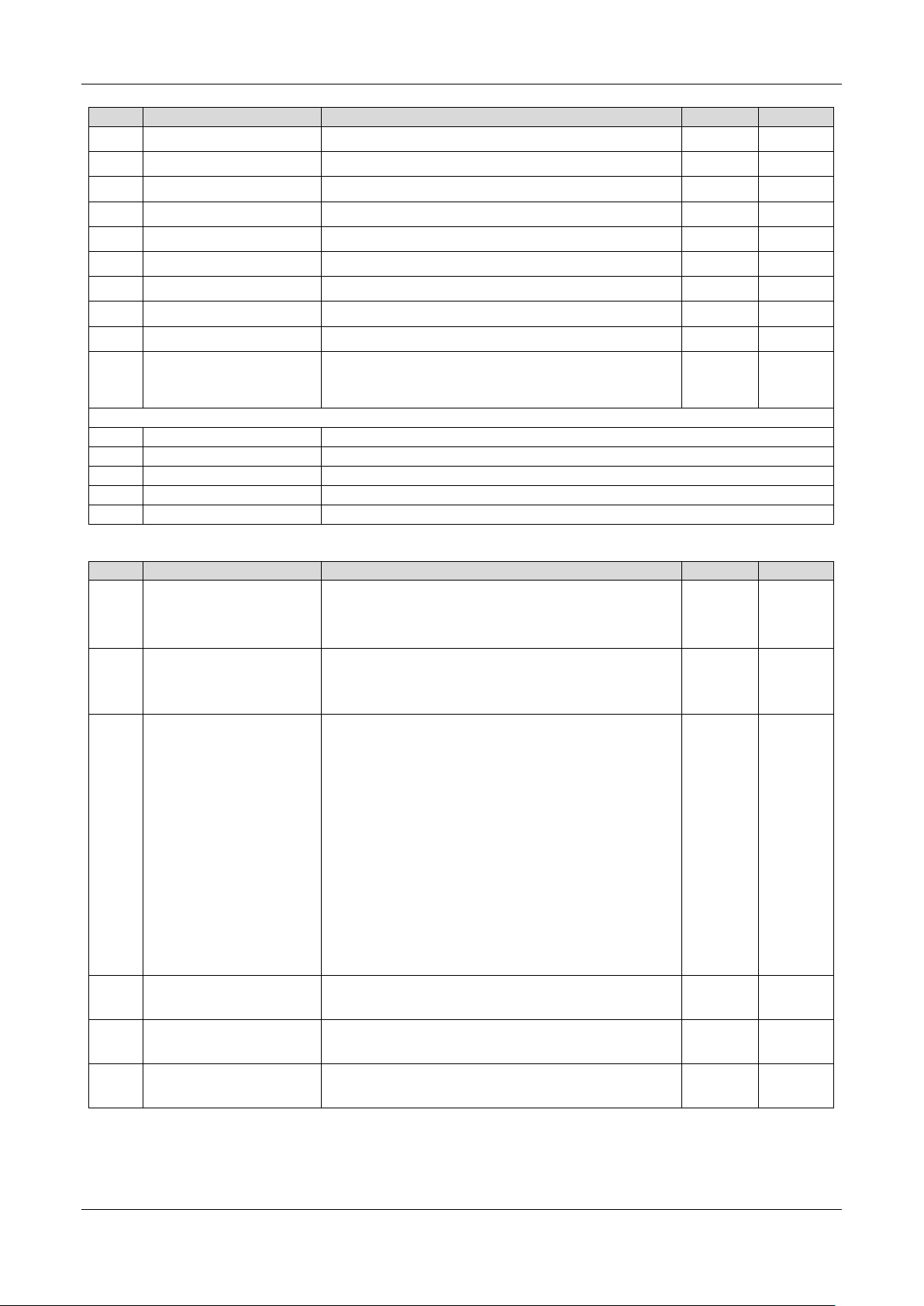

Table 2-1EM15-SP Model and technical data

EM15-SP1

Description

d75

1d5

2d2

004

5d5

7d5

011

015

018

022

030

037

045

DC input (+, -)

Rated power/KW

0.75

1.5

2.2

4

5.5

7.5

11

15

18.5

22

30

37

45

Min. DC voltage/V

120

Max.DC voltage/V

400

Recommended MPPT

range /V

250~400

AC output(U, V, W)

Output current/A

3.8

5.1

9

13

25

32

45

60

75

91

112

150

176

EM15-SP3

Description

d75

1d5

2d2

004

5d5

7d5

011

015

018

022

030

037

045

055

075

090

110

132

160

200

220

250

280

315

355

400

DC input (+, -)

Rated power/KW

0.75

1.5

2.2

4

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

160

200

220

250

280

315

355

400

Min. DC voltage/V

280

Max.DC voltage/V

750

Recommended MPPT

range /V

350~750

AC output(U, V, W)

Output current

2.1

3.8

5.1

9

13

17

25

32

37

45

60

75

91

112

150

176

210

253

304

377

426

465

520

585

650

725

Output frequency

0~50/60Hz

Power factor

>0.99

Communication mode

RS485 communication

Protection class

IP20

Ambient temperature

-10℃~ +40℃(ambient temperation at 40℃~50℃,please keep derated use)

Storage temperature

-20℃~ +60℃

Humidity

Smaller than 95%RH, non-condensation

Cooling

Forced Air cooling

Altitude

Lower than 1000 m

Humidity

Less than 95%RH, without condensing

Vibration

Less than 5.9 m/s2 (0.6 g)

2. Product Information EM15-SP User Manual

4

2.3 Product Appearance and Installation Dimension

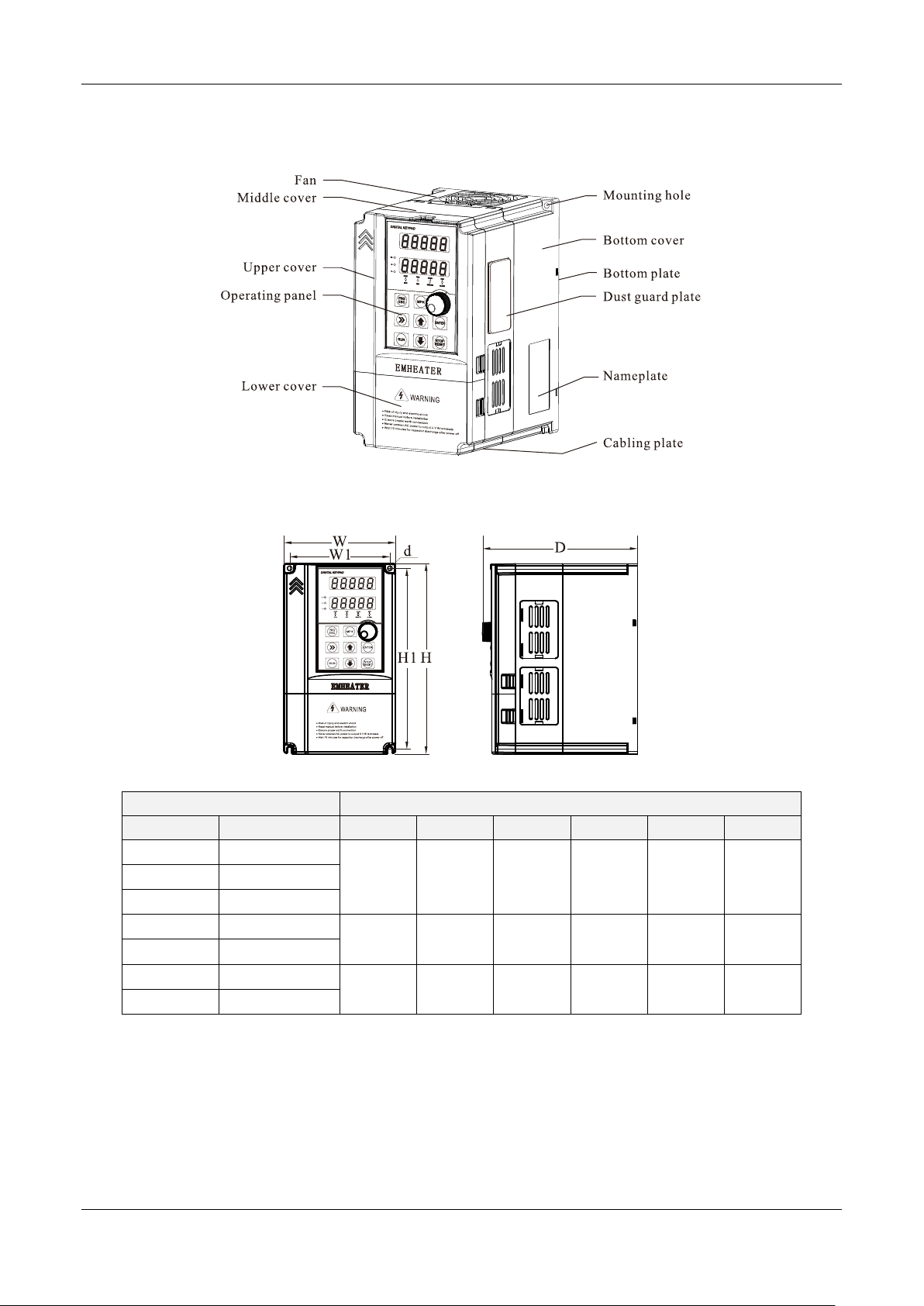

2.3.1 ProductAppearance

Diagram 2-2 Product appearance (With potentiometer)

2.3.2Appearance and Installing Dimension

Diagram 2-3 Appearance and installation dimension of EM15 series (Plastic housing structure)

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

H1

D

d

1PH 220V

0.75~2.2kW

120

108

205

195

166

Φ4.5

3PH 220V

0.75~2.2kW

3PH 380V

4~5.5kW

3PH 220V

4~5.5kW

162

148

250

238

191

Φ5.5

3PH 380V

7.5~11kW

3PH 220V

7.5~11kW

223

207

323

307

207

Φ5.5

3PH 380V

15~22kW

EM15-SP User Manual 2. Product Information

5

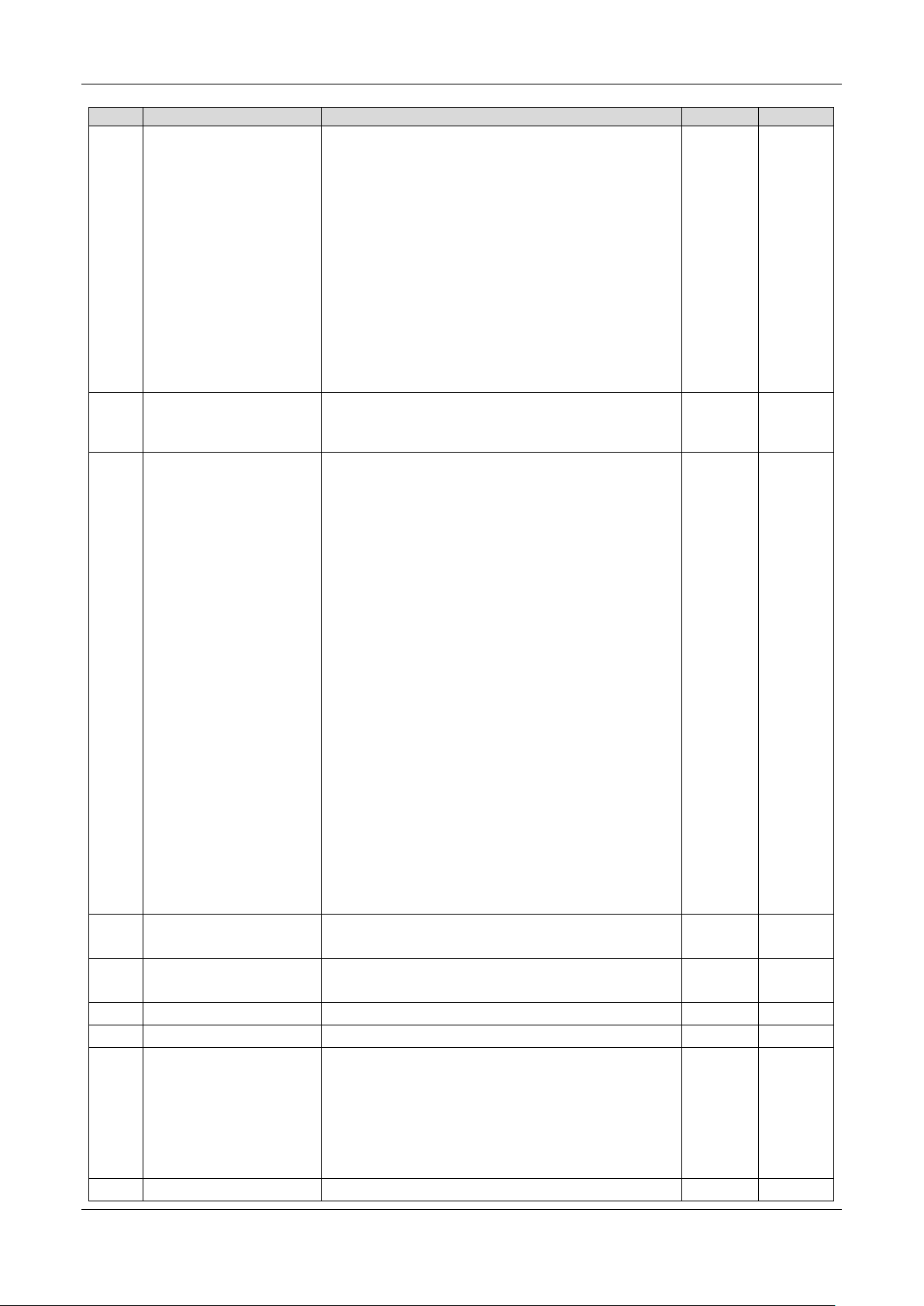

Diagram 2-4 Appearance and installation dimension of EM15 series (Metal housing structure)

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

H1

D

d

3PH 220V

15~18.5kW

300

220

540

500

240

Φ7

3PH 380V

30~37kW

3PH 220V

22kW

340

260

580

540

270

Φ10

3PH 380V

45~55kW

3PH 220V

37~45KW

410

260

610

575

280

Φ12

3PH 380V

75~90kW

3PH 380V

110~132kW

460

320

710

690

335

Φ12

3PH 380V

160~220kW

535

360

885

830

370

Φ12

3PH 380V

250~315kW

650

360

1040

985

415

Φ12

3PH 380V

355~400kW

815

600

1350

1250

445

Φ12

2.3.3 Installation Dimension of External Keypad (Keypad Tray)

Diagram 2-5 Appearance and installation dimension of external keypad (keypad tray)

3. Installation of Frequency Inverter EM15-SP User Manual

6

3.Installation of Frequency Inverter

3.1 Installation Environment

1. The place with indoor vents or ventilation devices.

2. The environment temperature shall be -10℃~40℃. If the temperature is over 40℃but less than 50℃,

better to take down the cover of frequency inverter or open the front door of cabinet to facilitate heat

dissipation.

3. Try to avoid high temperature and wet place; the humidity shall be less than 90% without frost deposit.

4. Avoid direct sunlight.

5. Keep away from flammable, explosive and corrosive gas and liquid.

6. No dust, floating fiber and metal particles.

7. Install on the place without strongly vibration. And the vibration should be not over 0.6G, Especially

pay attention to far away from the punching machine, etc.

8. Keep away from electromagnetic interference source.

3.2 Installation Direction and Space

In order to not affect the service life of frequency inverter and reduce its performance, note for its

installation direction and space and correctly fasten it.

Diagram3-1 Ventilating duct installation dimension diagram of frequency inverter

Power class

Installation dimension

A

B

≤7.5kW

≥ 20mm

≥ 100mm

11kW - 30kW

≥ 50mm

≥ 200mm

≥ 37kW

≥ 50mm

≥ 300mm

Please install the frequency inverter vertically, to send out the heat upward, and pay attention to direction of

frequency inverter to avoid inversion.

If there are several units of frequency inverter installed, please install them side by side, do not to install up

and down.

EM15-SP User Manual 3. Installation of Frequency Inverter

7

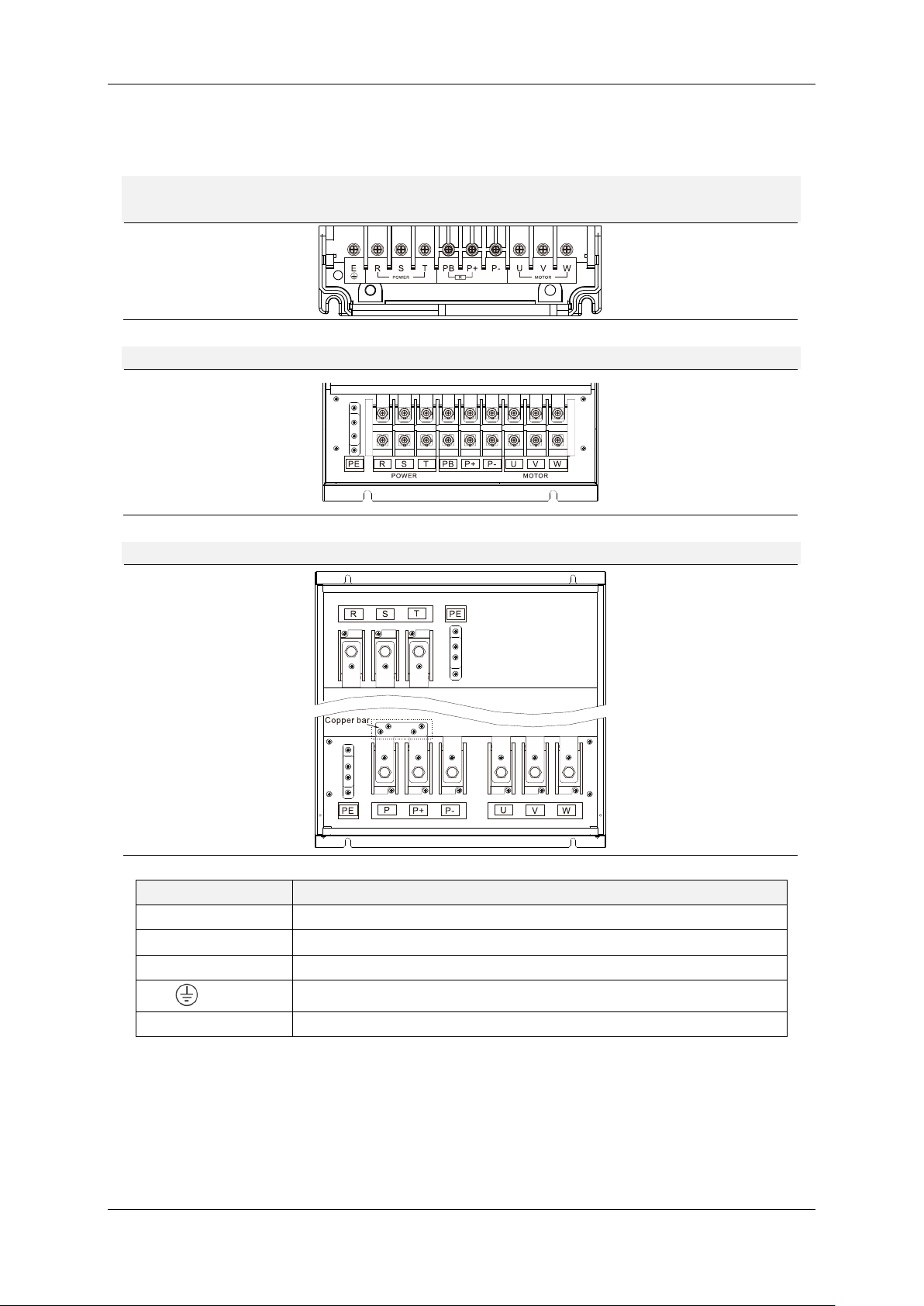

3.3 Sketch and Description of Main Circuit Terminals

3.3.1 Function and Description of Main Circuit Terminals

Three phase 220V output:EM15-SP1-d75~EM15-SP1-011

Three phase 380V output:EM15-SP3-d75~EM15-SP3-022

Three phase 380V output:EM15-SP3-030~EM15-SP3-090

Three phase 380V output:EM15-SP3-110~EM15-SP3-400

Terminal symbol

Function description

R, S, T

AC power input terminals

P+,PB

Braking resistor connectin

P+,P-

DC power input terminals

or E/PE

Grounding terminal

U,V,W

Three-phase AC power output terminals

3. Installation of Frequency Inverter EM15-SP User Manual

8

3.4 Control Circuit and Main Circuit Terminals Description

3.4.1 Control Circuit and Main Circuit Wiring

Diagram3-2 EM15-SP control circuit and main circuit wiring

3.4.2 Control Circuit Terminal Layout

Diagram3-3 EM15-SP control circuit terminal sketch diagram

3.4.3 Description of Control Circuit Terminals

Type

Terminal

Symbol

Terminal Name

Terminal function description

Power

Supply

+10V-GND

External +10V

power supply

Provide +10V power supply to external unit. Maximum

output current:10Ma

Generally, it provides power supply to external potentiometer

with resistance range of 1 kΩ~5kΩ

+24V-COM

External +24V

power supply

Provide +24 V power supply to external unit. Generally, it

provides power supply to DI/DO terminals and external

sensors.Maximum output current: 200 mA

EM15-SP User Manual 3. Installation of Frequency Inverter

9

Type

Terminal

Symbol

Terminal Name

Terminal function description

PLC

External power

supply input

terminals

It connect with +24V default

Analog

input

AI1-GND

Analog input 1

1. Input range: DC 0V~10V/ 0mA~20mA(decided by jumper

AI1/AI2 on the control board); AI3: DC -10V~+10V

2. Impedance: 22 kΩ (voltage input), 500 Ω (current input)

AI2-GND

Analog input 2

AI3-GND

Analog input 3

Digital

input

DI1-COM

Digital input 1

1. Optical coupling isolation, compatible with dual polarity

input

2.Input Impedance: 2.4 kΩ

3. Voltage range for level input: 9V~30 V

DI2-COM

Digital input 2

DI3-COM

Digital input 3

DI4-COM

Digital input 4

DI5-COM

Digital input 5

HDI-COM

High Speed

Pulse Input

Maximum input frequency: 100 kHz

Analog

output

AO1-GND

Analog output

1

Voltage or current output is decided by jumper AO1/AO2.

Output voltage range: 0V~10 V

Output current range: 0mA~20 mA

AO2-GND

Analog output

2

FMP- COM

High Speed

Pulse Output

Constrained by function code b4-00 "FMP terminal output

mode selection" as the high-speed pulse output, the highest

frequency is 100kHz; when use as an open collector output,

specifications is the same as DO.

Relay

output

TA1-TB1

NC terminal

Contact driving capacity: 250 VAC, 3 A, COSø= 0.4

DC 30 V, 1 A

TA2-TB2

TA1-TC1

NO terminal

TA2-TC2

RS485

Output

485+

Communication

port terminal

Input and output signal terminals for MODBUS protocol

communication

485-

Auxiliary

interface

PG card interface

PG cards: Open-collector, differential are selectable options.

Communications expansion

Reversed

External keypad interface

Connected to an external keypad

Jumper

PE-COM

COM grounding PE selection ,default connection.

In the case of interference, connecting PE to COM can improve

anti-interference

PE-GND

GND grounding PE selection ,default connection.

In the case of interference, connecting PE to COM can improve

anti-interference.

AI1

AI1 output selection.

Voltage or Current output, voltage output by default.

AI2

AI2 output selection.

Voltage or Current output, current output by default.

AO1/AO2

AO1/AO2 output selection.

Voltage or Current output, voltage output by default.

458

485 communication resistor selection, default connection

ON.

In the case of interference, anti-interference can be improved.

3. Installation of Frequency Inverter EM15-SP User Manual

10

3.5 Collection Diagram For Different Motor

COM

Photovoltaic cell

Water Tank

Pump

Water Pipe

+-UV W

EM15-SP

Control Term inal

DI1 DI2

Note: For the EM15-SP1S series,

U and V as single Phase 220V

output terminal.

Diagram3-4 220V three phase installed without water level sensor (PV Input)

COM

Control Term inal

Water Tank

Pump

Water Pipe

Photovoltaic cell

+-UV W

EM15-SP

DI1 DI2 DI4 DI5

Diagram3-5 Diagram of 3phsae inverter connection method (PV Input)

EM15-SP User Manual 3. Installation of Frequency Inverter

11

3.5.1 The Wiring of Water-LevelAutomatic Control

The wiring for floater water-level switch connected by cable

The common port, which using floate water-level switch connected by cable, is fed to the terminal “COM”

of EM15-SP.And then, connected to DI1.

DI1

COM

EM15-SP

Inverter

DI1

COM

EM15-SP

Inverter

High water-level

Low water-level

Diagram3-6 Diagram of Low water level and high water level

Remarks:

When the actual water-level in the wells is higher than the horizontal line of high water-level, DI1 will be

connected to the “COM”as well as controller automatically will start the pump. On the contrary, if the

actual water-level is lower than the horizontal line of low water-level, DI1 will be disconnected from

“COM”as well as controller automatically stop the pump to prevent anhydrous idling.

The wiring for floater water-level switch mounted on a side

The floater water-level switch mounted on a side is the normally open contact to output and its common

wire is connected to the terminal COM of EM15-SP inverter. At the same time, the low level-water wire is

connected to terminal DI4 and the high water-level wire is connected the terminal DI5.

EM15-SP

EM15-SP

EM15-SP

EM15-SP

DI5

Low water-level

High water-level

COM DI5 COM

DI4 COM DI4 COM

Detector switch of

high water-level

Detector switch of

low water-level

Detector switch of

high water-level

Detector switch of

low water-level

Diagram3-7 Diagram of Low water level and high water level

3. Installation of Frequency Inverter EM15-SP User Manual

12

Remarks:

When the actual water-level in the reservoir is lower than horizontal line of low water-level, DI4 and DI5

will be disconnected from the COM as well as controller automatically strat the pum. On the contrary, if the

actual water-level is higher than the horizontal line of high water-level, DI4 and DI5 will be connected to

COM as well as controller automatically stop the pump to prevent water overflow.

Notice:

1. If only use one detection signal of water-level in the reservoir, DI4 and DI5 must be connected together

by conductor.

EM15-SP User Manual 4. Operation and Display

13

4 Operation and Display

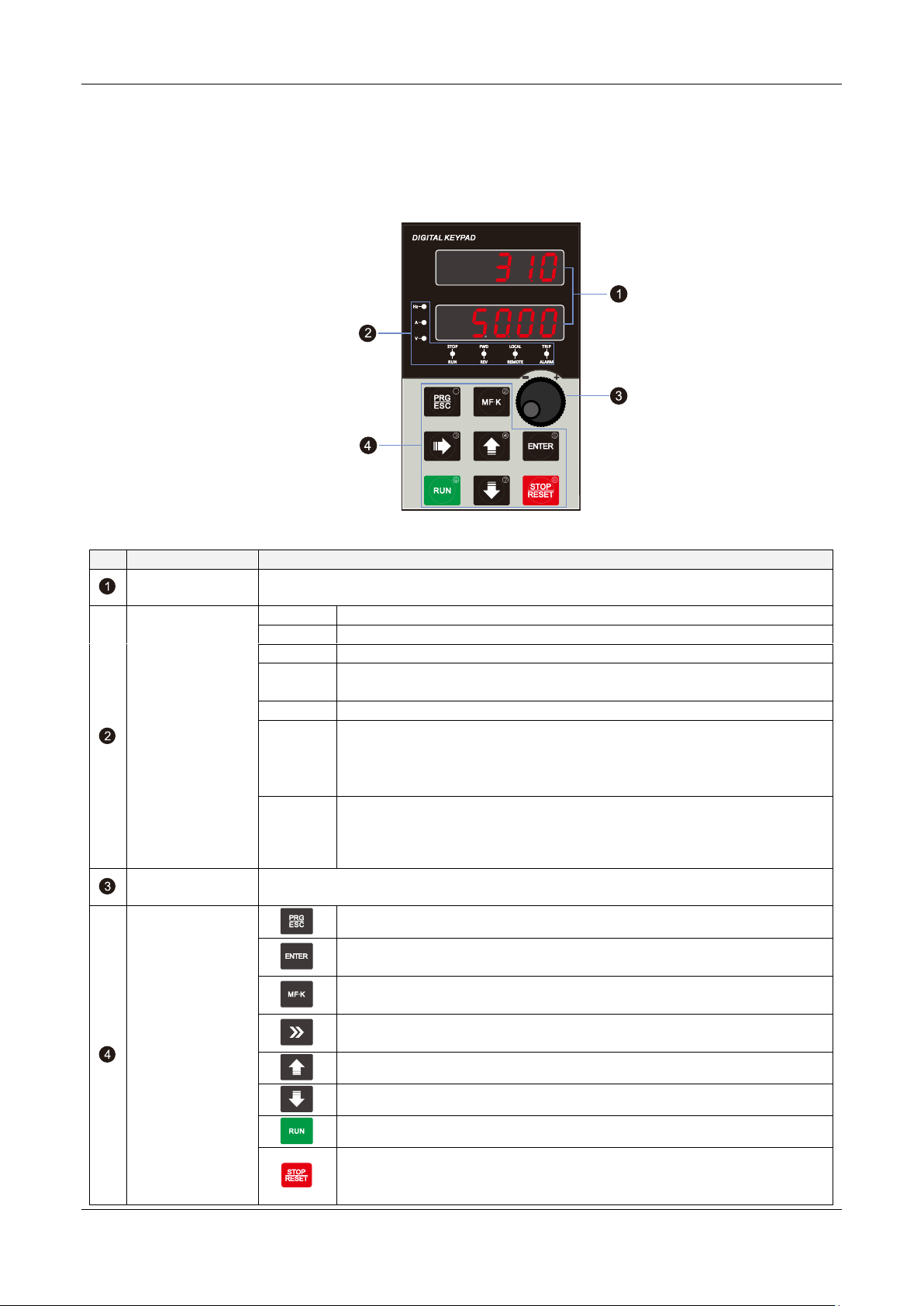

4.1 Instruction of Operation and Display

Diagram 4-1 Operating panel

No.

Name

Function

LED display area

The 5-digit LED display is able to display the set frequency, output frequency, monitoring

data and fault codes.

Unit / Status

Indicator area

Hz

Frequency unit

A

Current unit

V

Voltage unit

STOP/

RUN

OFF indicates that the frequency inverter is in the stop state and ON indicates

that the frequency inverter is in the running state.

FWD/REV

It is Forward/Reversal indicator, ON indicates Reverse rotation.

LOCAL

/REMOTE

It indicates whether the frequency inverter is operated by operation keypad,

terminals or remoter (communication). OFF indicates keypad operation

control state; ON indicates terminals operation control state; Blinking

indicates remote operation control state.

TRIP

/ALARM

Tunning/ Torque Control/Fault indicator

When the indicator is ON, it indicates torque control mode. When the

indicator is blinking slowly, it indicates the auto-tuning state. When the

indicator is blinking quickly, it indicates the fault state.

Encoder knob

Frequency, data or function code increase or decrease; the encoder knob has the

confirmation key function

Operation key area

Programming key: Enter or exit menu level I.

Confirmation key: Enter the menu interfaces level by level, and confirm the

parameter setting.

Multi-function key: Perform function switchover according to the setting of

b9-01

Shift key: Select the displayed parameters in turn in the stop or running

state, and select the digit to be modified when modifying parameters.

Increment key: Increase data or function code.

Decrement key: Decrease data or function code.

Running key: Start the frequency inverter in the keypad control mode.

Stop/Reset key: Stop the frequency inverter when it is in the running state and

perform the reset operation when it is in the fault state. The functions of this

key are restricted by b9-00.

4. Operation and Display EM15-SP User Manual

14

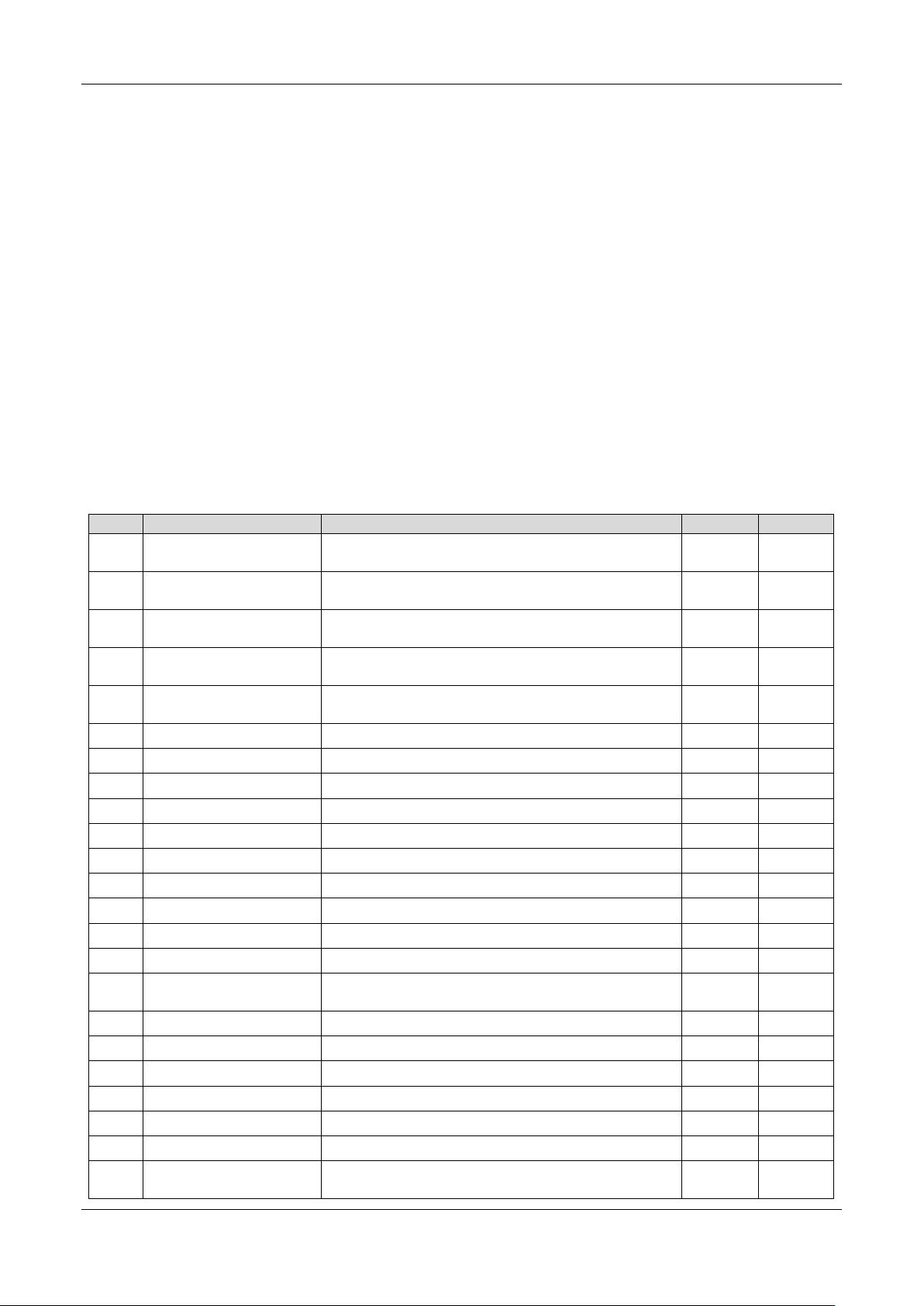

4.2 Function Code Table

Debugging specification:

1. Set A1-00 to turn on photovoltaic mode, or it’ll run in ordinary inverter mode; Set A1-01 to enable MPPT function to

search Vmpp voltage automatically; Otherwise, the default Vmpp voltage needs to be set manually;

2. Target frequency is the maximum frequency limit, and MPPT automatically controls the operating frequency and

searches for the maximum operating frequency;

3. Stability parameters A1-13, A1-14: Adjust to the stable state of bus voltage, output frequency and output current

(normal small fluctuation);

4. Light intensity detection:

5. Other protection functions: dormancy and underload

6. The operation direction of the pump is limited. If there is no water coming out, the motor wiring can be adjusted or

b0.18 can be set to change the direction;

7. Relevant Settings of A1-04, sleeping voltage, etc. should be made according to the configuration of the panel. Default

parameters are suitable for working near 500V DC voltage;

8. Power on automatic operation:

Group A1: PV Special Control Parameters

Code

Parameter Name

Functional description

Default

Property

A1-00

PV mode enable

0: Disabled

1: Enabled

1

★

A1-01

Vmpp voltage Selection

0: Manual setting

1: MPPTAutomatic algorithm tracking

1

★

A1-02

Vmpp voltage value of

manual given

0~100.0%

85.00%

★

A1-03

PV open circuit voltage

selection

0: Automatic detection of shutdown

1: Manual setting

0

★

A1-04

PV open circuit voltage

manual setting value

0.0~1000.0V

500.0V

★

A1-05

MPPT interval

0.1~100.0s

1.0s

★

A1-06

MPPT hysteresis

0.01Hz~5.00Hz

0.10Hz

★

A1-07

MPPT step size

0.01%~10.00%

0.10%

★

A1-08

MPPT voltage upper limit

0.0~100.0%

100.0%

★

A1-09

MPPT voltage lower limit

0.0~100.0%

60.0%

★

A1-10

CVT proportional gain

0.00~20.00

0.50

★

A1-11

CVT integral coefficient

0.00~20.00

0.50

★

A1-12

CVT proportional gain 1

0.00~20.00

1.00

★

A1-13

CVT integral coefficient 1

0.00~20.00

1.00

★

A1-14

CVT switching point

3.0%~15.0%

5.0

★

A1-15

Open circuit reference

voltage

0.0~6553.5V

0.0V

★

A1-16

PV DC current

0.00~655.35A

0.00A

★

A1-17

PV DC current gain

0.0~200.0%

100.0%

★

A1-18

PV DC current bias

-100.00~100.00A

0.00A

★

A1-19

Sleep voltage

0.0~1000.0V

360.0V

★

A1-20

Wake-up voltage

0.0~1000.0V

400.0V

★

A1-21

Wake up time

0~30000s

60s

★

A1-22

Light weak detection

frequency

0.00~100.00Hz

15.00Hz

★

EM15-SP User Manual 4. Operation and Display

15

Code

Parameter Name

Functional description

Default

Property

A1-23

Low light sleep delay

0~30000s

30s

★

A1-24

Light weak wake-up time

0~30000s

60s

★

A1-25

Underload detection current

0.00~300.00A

0.00A

★

A1-26

Underload detection time

0~30000s

60s

★

A1-27

Underload reset delay

0~30000s

300s

★

A1-28

Water full delay time

0~30000s

60s

★

A1-38

Water full reset time

0~30000s

120s

★

A1-39

Water shortage delay time

0~30000s

60s

★

A1-40

Water shortage reset time

0~30000s

600s

★

A1-41

MPPT selection

0: Method 1

1: Method 2

2: Method 3

1

★

Alarm Stop Code

A-LP

Low-voltage sleep

Lower than value of A1-09, will give Low-voltage sleep alarm

A-LS

Light dormancy

Meet the conditions of A1-22/23, give light dormancy alarm

A-LL1

Underload protection

Meet the conditions of A1-25/26, give Underload protection alarm

A-TF

Full protection

Define DI terminal to 52, enable ON

A-LL

Water shortage protection

Define DI terminal to 53, enable ON

Group b0: Basic Function Parameters

Code

Parameter Name

Functional description

Default

Property

b0-01

Motor control mode

0: Sensor-less vector control (SVC)

1/2:V/F control

3: Closed-loop vector control (FVC)

2

★

b0-02

Command source selection

0: Keypad control (LED off)

1: Terminal control (LED on)

2: Communication control (LED blinking)

0

★

b0-03

Main frequency source X

selection

0: Digital setting (Digital setting frequency b0-12,

UP/DOWN modifiable, no-record after power off)

1: Digital setting (Digital setting frequency b0-12,

UP/DOWN modifiable, record after power off)

2: AI1

3: AI2

4: AI3

5: Pulse setting (HDI)

6: Multi-function

7:Built-in PLC

8: PID

9: Communication setting

1

★

b0-04

Auxiliary frequency source

Y selection

The same as b0-03 (Main frequency source X selection)

0

★

b0-05

Selection of auxiliary

frequency Y range

0: Relative to maximum frequency

1: Relative to main frequency X

0

☆

b0-06

Range of auxiliary

frequency Y

0%~150%

100%

☆

4. Operation and Display EM15-SP User Manual

16

Code

Parameter Name

Functional description

Default

Property

b0-07

Frequency source selection

Unit's digit: Frequency source selection.

0: Main frequency source X

1: X and Y calculation (calculation result determined by

ten's digit)

2: Switchover between X and Y

3: Switchover between X and "X and Y calculation"

4: Switchover between Y and "X and Y calculation"

Ten's digit: X and Y calculation relationship

0: X+Y

1: X-Y

2: Maximum of them

3: Minimum of them

0

☆

b0-08

Encoder knob frequency

change unit

0:1Hz

1:0.1Hz

2:0.2Hz

0

☆

b0-09

Binding command source to

frequency source

Unit's digit: Binding keypad command to following

frequency source.

0: No binding

1: Digital setting frequency

2: AI1

3: AI2

4: AI3

5: Pulse setting (HDI)

6: Multi-function

7: Simple PLC

8: PID

9: Communication setting

Ten's digit: Binding terminal command to frequency

source.

0~9, same as unit's digit

Hundred's digit: Binding communication command to

frequency source.

0~9, same as unit's digit

Thousand’s digit: Automatically running binding to

frequency source.

0~9, same as unit's digit

0

☆

b0-10

Record of digital setting

frequency of power failure

0: not record

1:record

1

☆

b0-11

Frequency unit

1: 0.1 Hz

2: 0.01 Hz

2

☆

b0-12

Digital setting frequency

0.00 ~ maximum frequency (b0-13)

50.00 Hz

☆

b0-13

Maximum frequency

50.00~3000.00 Hz

50.00 Hz

☆

b0-14

Source of frequency upper

limit

0: Set by (b0-15)

1: AI1

2: AI2

3: AI3

4: Pulse setting (HDI)

5: Communication setting

0

☆

b0-15

Frequency upper limit

Frequency lower limit (b0-17) ~ maximum frequency

50.00 Hz

☆

EM15-SP User Manual 4. Operation and Display

17

Code

Parameter Name

Functional description

Default

Property

(b0-13)

b0-16

Frequency upper limit

offset

0.00 Hz~ maximum frequency(b0-13)

0.00 Hz

☆

b0-17

Frequency lower limit

0.00 Hz ~frequency upper limit(b0-15)

0.00 Hz

☆

b0-18

Rotation direction

0: Forward direction

1: Reverse direction

0

☆

b0-19

Base frequency for UP/

DOWN modification during

running

0: Running frequency

1: Setting frequency

0

★

b0-20

Acceleration/Deceleration

mode

0: Linear acceleration/ deceleration

1: S-curve acceleration/deceleration A

2: S-curve acceleration/deceleration B

0

☆

b0-21

Acceleration time 1

0.00s~650.00s (b0-25 = 2)

0.0s~6500.0s (b0-25 = 1)

0s~65000s (b0-25 = 0)

Model

dependent

☆

b0-22

Deceleration time 1

0.00s~650.00s (b0-25 = 2)

0.0s~6500.0s (b0-25 = 1)

0s~65000s (b0-25 = 0)

Model

dependent

☆

b0-23

Time proportion of S-curve

start segment

0.0% ~ (100.0% minus b0-24)

30.0%

☆

b0-24

Time proportion of S-curve

end segment

0.0% ~ (100.0% minus b0-23)

30.0%

☆

b0-25

Acceleration/Deceleration

time unit

0:1s

1: 0.1s

2: 0.01s

1

☆

b0-26

Acceleration/Deceleration

time base frequency

0: Maximum frequency (b0-13)

1: Set frequency

2: 100 Hz

0

★

Group b1: Start and Stop Control Parameters

Code

Parameter Name

Functional description

Default

Property

b1-00

Start mode

0: Direct start

1: Rotational speed tracking restart

2: Pre-excited start (AC asynchronous motor)

0

★

b1-01

Rotational speed tracking

mode

0: From frequency at stop

1: From zero speed

2: From maximum frequency

0

★

b1-02

Rotational speed tracking

ratio

1~100

20

★

b1-03

Startup frequency

0.00~10.00 Hz

0.00 Hz

☆

b1-04

Startup frequency holding

time

0.0s~100.0s

0.0s

★

b1-05

Startup DC braking current/

Pre-excited current

0%~100%

0%

★

b1-06

Startup DC braking time/

Pre-excited time

0.0s~100.0s

0.0s

★

b1-07

Stop mode

0: Decelerate to stop

1: free stop

0

☆

b1-08

DC braking initial

0.00 Hz ~ maximum frequency

0.00 Hz

☆

This manual suits for next models

8

Table of contents

Other Emheater Inverter manuals

Popular Inverter manuals by other brands

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

WilTec

WilTec 61897 Operation manual

Brunner

Brunner 0826089N quick start guide

Kohler

Kohler SDMO PERFORM 3000 XL TB UK C5 Instruction and maintenance manual

Sungrow

Sungrow SG60KU-M user manual

Agilent Technologies

Agilent Technologies E8247C PSG CW user guide