STEP AS180 Series User manual

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

AS180 Series High Performance V/F General

Purpose Inverter

Operation Manual

Publishing state: Standard

Product version: V2.02

Shanghai Sigriner STEP Electric Co., Ltd.

AS180 SERIES HIGH PERFORMANCE V/F GENERAL PURPOSE

INVERTER................................................................................................... 1

CHAPTER 1 INVERTER INSTALLATION.........................................- 1 -

INSTALLATION SITE OF THE INVERTER MUST MEET THE FOLLOWING CONDITIONS:.............................- 1-

CHAPTER 2 INVERTER WIRING.......................................................- 3 -

INVERTER AND PERIPHERAL DEVICE CONNECTION ............................................................................- 4-

INVERTER TERMINALS WIRING DIAGRAM..............................................................................................- 6-

MAIN CIRCUIT TERMINALS DESCRIPTION..............................................................................................- 8-

CONTROL CIRCUIT TERMINALS DESCRIPTION....................................................................................- 8-

CHAPTER 3 INVERTER QUICK COMMISSIONING....................- 11 -

1. INVERTER COMMISSIONING STEPS BEFORE POWER UP ................................................................- 11 -

2. INVERTER COMMISSIONING STEPSAFTER POWER UP ...................................................................- 12 -

3. PARAMETER SETTINGS:..................................................................................................................- 12 -

4. SPECIAL FUNCTIONS DESCRIPTION................................................................................................- 14 -

5. INVERTER TEST RUN PROCESS......................................................................................................- 14 -

6. PRECAUTIONS................................................................................................................................- 15 -

CHAPTER 4 FAULT CODES LIST...................................................- 17 -

APPENDIX I OPERATOR................................................................- 23 -

FUNCTIONS OF VARIOUS PARTS OF THE OPERATOR ..........................................................................- 23 -

LED INDICATOR..................................................................................................................................- 23 -

LED DIGITAL TUBE..............................................................................................................................- 23 -

LCD DISPLAY......................................................................................................................................- 23 -

KEYBOARDDESCRIPTION....................................................................................................................- 24 -

OPERATIONS OF LCD OPERATOR......................................................................................................- 24 -

Detailed description for [State Monitoring]...............................................................................- 24 -

Detailed description for [Panel Control] ...................................................................................- 25 -

Operating state of operator........................................................................................................- 26 -

V/F CONTROL QUICK COMMISSIONING...............................................................................................- 29 -

APPENDIX II FUNCTION PARAMETERS TABLE.......................- 30 -

FUNCTION CODE PARAMETER TABLE DESCRIPTION...........................................................................- 30 -

FUNCTION CODE PARAMETERS TABLE ...............................................................................................- 30 -

APPENDIX III EXAMPLES OF CONSTANT PRESSURE WATER

SUPPLY APPLICATION .....................................................................- 59 -

1. ONEDRIVES THREE APPLICATION...................................................................................................- 59 -

2. ONEDRIVES TWO SLEEP PUMP APPLICATION .................................................................................- 63 -

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

Preface

Thank you very much for purchasing Sigriner inverter. To ensure proper installation and use, please read

this operation manual carefully, and fully understand the safety precautions of the product prior to use. It shall be

operated by professional electrical engineers.

The copyright of this inverter operation manual is owned by Shanghai Sigriner STEP Electric Co., Ltd.

Without authorization of Shanghai Sigriner STEP Electric Corporation, no unit or individual is allowed to extract

or copy this manual (software, etc.) in whole or in part, or spread in any form (including data and publication). All

rights reserved.

Shanghai Sigriner STEP Electric Co., Ltd. (hereinafter referred to as “Sigriner”) has reviewed the contents

of this manual and the hardware and software described for consistency. However, there may still be

contradictions and fallacies, and it is impossible to guarantee that they are completely consistent. We will

periodically review the contents covered in this manual and make necessary corrections in future revisions. We

welcome suggestions for improvement. This manual will be supplemented and modified. Keep an eye on our

website for the updated manual. If you have any questions or problems while reading this manual, please

contact Sigriner via the website address and service hotline below. Website :

http://www.stepelectric.com/sigriner.

is a registered trademark of Sigriner.

is a registered trademark of Sigriner.

Warranty Period The warranty period of the product is within 12 months from the date of delivery to your

company or your customers, or within 18 months from the date of leaving factory. It is subject to that up first.

Fault Diagnosis The initial troubleshooting is in principle implemented by the user. However, at the request

of the user, Sigriner can provide paid services. At this time, according to the results of negotiation with the user,

if the faults are caused by Sigriner, the service is provided for free.

Trouble-shooting When it comes to repair and product replacement for the faults occurred, Sigriner can

send technicians to provide free on-site service. However, on the following occasions, services will be paid:

Shanghai Sigriner STEP Electric Co., Ltd.

1. Occasions where faults are caused by improper storage, use or design of users and their customers.

2. Occasions where faults are caused by user’s private transformation to Sigriner products without informing

Sigriner.

3. Occasions where faults are caused by use outside the product specifications of Sigriner.

4. Occasions where faults are caused by natural disasters and fires.

5. Occasions where faults are caused by other reasons for which Sigriner is not liable.

Beyond Guarantee Responsibility

Failure of Sigriner products, which causes inconvenience to the users and their customers and non-Sigriner

product damages, whether within the warranty period or not, is not the liability of Sigriner. Sigriner will not be

liable for any associated losses.

Safety Related Signs Instructions

Wrong use may cause danger and personal casualty.

Wrong use will cause danger and may cause personal mild or severe injury and equipment

damage.

Important Section to be complied with and focused by the user.。

(Customer service center) service hotline: 400-821-0325

Add.: No. 1560, Siyi Road, Jiading District, Shanghai, China

Postal code: 201801

Tel: 021-69926000

Fax: 021-69926010

Website:www.stepelectric.com/sigriner

Danger

Notice

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 1 -

Chapter 1 Inverter Installation

Please confirm carefully when unpacking: Whether there is any damage during transportation; whether the

model and specifications on the nameplate of this machine are consistent with the ordering requirements. If

you find that the model does not match or components are missing, please contact the manufacturer or

supplier. For inverters that have been stored for more than one year, the voltage should be slowly boosted

by a regulator during power-on, otherwise there is a risk of electric shock and explosion. When handling,

please focus force on the bottom of the body.

1. Do not lift the operation panel or cover when handling, otherwise there is a

danger of inverter falling and being damaged.

2. When installing, consider the bearing capacity of platform, otherwise there is a

danger of inverter falling and being damaged.

3. It is strictly forbidden to install the inverter in places where water droplets may

splash, otherwise there is danger of damage.

4. It is strictly forbidden to cause metal powder, oil, water, etc. to enter the inverter,

otherwise there is danger of damage and explosion.

5. When the inverter is damaged or parts are incomplete, please do not install and

operate, otherwise there is danger of damage to the inverter.

6. Do not install in a place exposed to direct sunlight, otherwise there is a danger

of overheating and accidents.

1. It must be installed on incombustible materials such as metal, otherwise there is a

danger of fire.

2. There must be no combustibles nearby, otherwise there is a danger of fire.

3. Do not install in an environment containing explosive gases, otherwise there is a

danger of explosion.

Installation site of the inverter must meet the following conditions:

a) A clean site without oil mist, dust, or a fully enclosed cabinet where floats cannot intrude.

b) A site without radioactive materials.

c) A site without hazardous gas, liquid, or with less salinity.

d) Asite with low vibration, the fasteners must have anti-vibration parts, such as spring washers, and the

screws of the inverter must be tightened.

e) When installing the inverter in a closed cabinet, install a cooling fan or cool the air conditioner to keep

the temperature below 40 °C.

f) Vertically install in a well ventilated area.

Figure 1.1. Installation Orientation

Notice

Danger

Vertical installation in the

cabinet: required

Horizontal installation: prohibited

Inverter

Shanghai Sigriner STEP Electric Co., Ltd.

- 2 -

g) The spacing distance requirements for installation of 45 kW and below inverters and the spacing

distance requirements for installation of 55 kW and above inverters are shown in the figure

below.

Fan

exhaust >120mm

>50mm

>50mm

>120mm

Fan

exhaust

>350mm

>100mm

>100mm

>350mm

The spacing distance requirements for installation

of 45 kW and below inverters

The spacing distance requirements for installation

of 55 kW and above inverters are shown in the

figure below.

Figure 1.2 Schematic diagram for installation distance of the inverter

h) When two inverters are installed with one over the other, a deflector should be applied in the

middle, as shown in the figure below.

In

ve

rt

er

In

ve

rt

er

Figure 1.3 Schematic diagram for installation deflector of the inverter

i)When user installs the inverter vertically, the angle between the inverter and horizontal plane

can be between 87°and 90°.

Figure 1.4 Allowable installation angle

87°(Minimum angle)

Horizontal plane

Inverter front

Electric

cabinet

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 3 -

Chapter 2 Inverter Wiring

◎Before wiring, please confirm whether the input power is completely disconnected.

Otherwise there is danger of electric shock.

◎Please request professional electrical engineers to perform wiring.

Otherwise there is danger of electric shock.

◎Be sure to ground the ground terminal PE reliably.

Otherwise there is danger of electric shock.

◎Do not touch the terminal directly with your hand. Do not touch the output line of the inverter

with its cover.

Otherwise there is danger of electric shock.

◎Do not connect power supply to the output terminals U/T1, V/T2, W/T3.

Otherwise there is a danger of damage to the inverter.

◎Do not make the terminals ○+1/○+2 and○-short connected.

Otherwise there is a danger of explosion.

◎Check that the voltage of AC main circuit power supply is consistent with the rated voltage of

the inverter.

Otherwise there is a danger of fire and personal injury.

◎Connect the braking resistor correctly according to wiring diagram.

Otherwise there is a danger of fire.

◎The main circuit terminal must be securely connected to the wire or wire crimp terminal.

Otherwise there is a danger of damage to the inverter.

Danger

Danger

Shanghai Sigriner STEP Electric Co., Ltd.

- 4 -

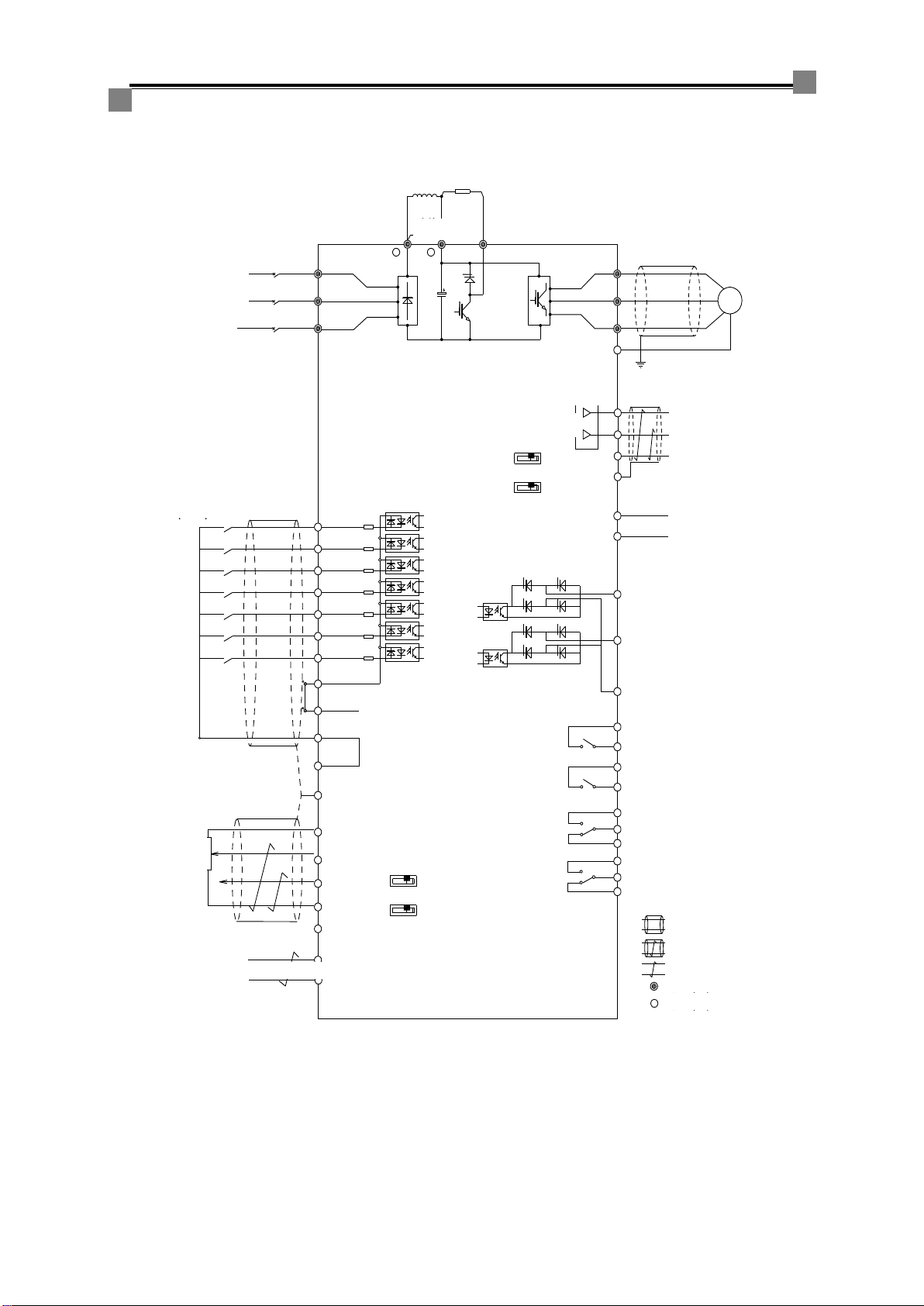

Inverter and Peripheral Device Connection

Figure 2.1 Inverter and Peripheral Device Connection Diagram

Note: The diagram is drawn taking a three-phase power input as an example.

1、Inverter input side

DC reactor: Improve the power factor of power supply at the input side and reduce the high harmonic current; a

built-in DC reactor of the ≥37kW inverters.

AC reactor: Improve the power factor of power supply at the input side and reduce the high harmonic current.

Inverter-specific filter: suppress high-frequency noise interference from the inverter.

变频器

滤波器

接触器

断路器

交流电抗器

滤波器

交流电抗器

M电机

输入侧

噪声滤波器

噪声滤波器

输出侧

制动电阻器

直流电抗器

R

S

T

PE

PE

PE

PE

PE

PE

PE

AS180

熔断器

Fuse

Circuit

breaker

AC reactor

Noise filter

Contactor

DC reactor

Input side

Filter

Noise filter

AC reactor

Output side

Motor

Filter

Inverter

braking resistor

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 5 -

2、Inverter output side

Inverter-specific filter: suppress high-frequency noise interference from the inverter.

AC reactor: If the wiring between the inverter and the motor is too long, the high-order harmonic current leakage

will increase due to the influence of the distributed capacitance of the wire, which may cause the inverter to

activate output over-current protection. Therefore, the wiring length between the inverter and the motor should

not exceed 100m. If the wiring length exceeds 100m, the reactor and output filter should be optionally

configured.

Do not connect a capacitor or a surge filter to the output side of the inverter. The inverter outputs high order

harmonics, so connecting the capacitor or surge filter to the output side may overheat and damage the inverter.

Figure 2.2 Inverter output side error connection

3、Braking resistor

Inverters of ≤30kW come with a built-in braking unit as a standard, and an external braking resistor; Inverters

of >30kW feature an optional external braking unit. An external braking resistor can be connected. It is

necessary to fully consider heat dissipation conditions of the braking resistor, and ensure that it is well ventilated.

Wiring length of the braking resistor must not exceed 5m.

4、Grounding

The grounding terminal is preferably a dedicated grounding electrode with a impedance of 10 Ω or less. Do not

share with welding machines or other power equipment. Use the grounding wire specified in the electrical

equipment technical standard, and keep it as short as possible. If the grounding wire is too long, leakage

current of the inverter will make the potential of grounding terminal unstable. It is recommended to use a special

yellow-green grounding wire. See the table below for the grounding wire specifications. When multiple inverters

are grounded, it is recommended to avoid forming loops so as to avoid circuits formed by grounding wires.

Figure 2.3 Grounding method for multiple inverters

Table 2.1 Cross-sectional area of the grounding wire

Cross-sectional area of the wire during

installation S (mm2)

The minimum cross-sectional area of the

corresponding grounding wire Smin (mm2)

S≤16

S

16<S≤35

16

35<S

S/2

V/T2

U/T1 M

W/T3

Shanghai Sigriner STEP Electric Co., Ltd.

- 6 -

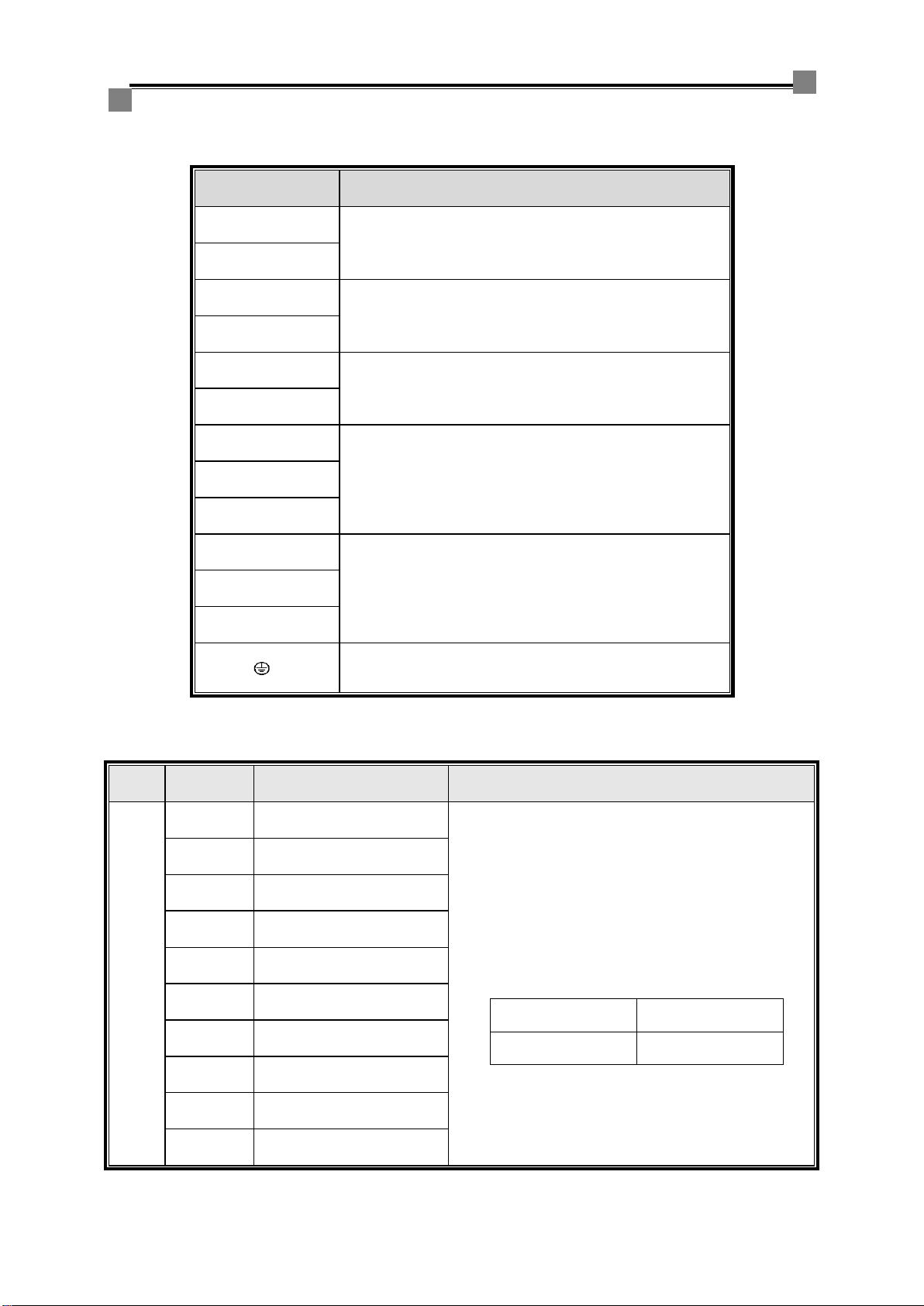

Inverter terminals wiring diagram

Applicable to models (≤30kW) that do not have a built-in DC reactor but have a built-in brake unit.

200V级220VAC

50/60Hz

X0

X1

X2

X3

X4

X5

X6

XV

24(+24V)

XC

XC

V+

A0

A1

V-

PE

Modbus通讯接口

4C

4B

4A

3C

3B

3A

YC

Y1

Y0

0V

M1

M0

A+

B-

可编程多功能输入信号

模拟量输入0

(-10V~+10V或

0~20mA可选)

模拟量输入1

(-10V~+10V或

0~20mA可选)

可编程继电器输出3

可编程继电器输出4

可编程集电极开路输出1

多功能模拟量输出1

多功能模拟量输出0

可编程集电极开路输出0

三相电源

400V级380~460VAC R/L1

S/L2

T/L3

U/T1

V/T2

W/T3 M

0V

屏蔽线

屏蔽双绞线

双绞线

PE

主回路接线端子

控制回路接线端子

+1 B

+2

短路块

制动电阻

可外接直

流电抗器

AS180高性能VF通用变频器

UI

A0/SW4

UI

A1/SW3

拨动开关

P1

P2 PTC保护点

1A

1B

2A

2B 可编程继电器输出2

可编程继电器输出1

UI

M0/SW6

U

M1/SW5

I

拨动开关

Figure 2.4 Schematic diagram for terminals wiring of AS180 inverter (30kW and below)

Note: The input power supply in the figure is given as an example of three-phase power input, and the 400V

level of input phase is 380~460V.

Three-phase power supply

400V level 380~460VAC

200V level 200VAC

Programmable

multi-function input

signal

Analog input 0

(-10V~+10V or

0~20mA optional)

Analog input 1

(-10V~+10V or

0~20mA optional)

Slide switch

Slide switch

AS180 High Performance V/F

General Purpose Inverter

Braking

resistor

External

DC reactor

Short

circuit

block

Multi-function

analog output 0

Multi-function

analog output 1

PTC protection point

Programmable Open

Collector Output 0

Programmable Open

Collector Output 1

Programmable relay

output 1

Programmable relay

output 2

Programmable relay

output 3

Programmable relay

output 4

Shielded wire

STP

Twisted pair

Main circuit

terminal

Control circuit

terminal

Communication interface

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 7 -

Applicable to models (>30kW) that have a built-in DC reactor but do not have a built-in brake unit.

200V级220VAC

50/60Hz

X0

X1

X2

X3

X4

X5

X6

XV

24(+24V)

XC

XC

V+

A0

A1

V-

PE

Modbus通讯接口

4C

4B

4A

3C

3B

3A

YC

Y1

Y0

0V

M1

M0

A+

B-

可编程多功能输入信号

模拟量输入0

(-10V~+10V或

0~20mA可选)

模拟量输入1

(-10V~+10V或

0~20mA可选)

可编程继电器输出3

可编程继电器输出4

可编程集电极开路输出1

多功能模拟量输出1

多功能模拟量输出0

可编程集电极开路输出0

三相电源

400V级380~460VAC R/L1

S/L2

T/L3

U/T1

V/T2

W/T3 M

0V

屏蔽线

屏蔽双绞线

双绞线

PE

主回路接线端子

控制回路接线端子

AS450通用矢量型变频器

UI

A0/SW4

UI

A1/SW3

拨动开关

P1

P2 PTC保护点

1A

1B

2A

2B 可编程继电器输出2

可编程继电器输出1

UI

M0/SW6

UI

M1/SW5

拨动开关

-

+

内置直

流电抗器

Figure 2.5 Schematic diagram for terminals wiring of AS180 inverter (30kW and above)

Note: Analog voltage and current optional signals can be input through A0/A1. Input simultaneously

through A0 and A1 can be input at the same time.

The inverter of this specification does not have a brake unit and provides terminals for an external

brake unit.

AS180 High Performance V/F

General Purpose Inverter

Built-in DC

reactor

Three-phase power supply

400V level 380~460VAC

200V level 200VAC

Programmable multi-function

input signal

Analog input 0

(-10V~+10V or

0~20mA optional)

Analog input 1

(-10V~+10V or

0~20mA optional)

Communication interface

Slide switch

Slide switch

Multi-function

analog output 0

Multi-function

analog output 1

PTC protection point

Programmable Open

Collector Output 0

Programmable Open

Collector Output 1

Programmable relay

output 4

Programmable relay

output 3

Programmable relay

output 2

Programmable relay

output 1

Shielded wire

STP

Twisted pair

Main circuit

terminal

Control circuit

terminal

Shanghai Sigriner STEP Electric Co., Ltd.

- 8 -

Main circuit terminals description

Table 2.2 Description of functions of the main circuit terminals

Terminal marks

Functions description

○+1

An external DC reactor can be connected, which has been

short connected in the factory

○+2

○+2

External braking resistor connection

B

○+2/○+

DC bus positive and negative output terminals, allowing for

connection of external brake unit or common DC bus

○-

R/L1

Main circuit AC power input, connected to a three-phase

input power supply

S/L2

T/L3

U/T1

Inverter output, connected to a three-phase asynchronous

motor

V/T2

W/T3

Grounding terminal, connected to the protective ground, the

grounding resistance at 400V level cannot be greater than

4Ω

Control circuit terminals description

Table 2.3 Control circuit terminals description

Nam

e

Terminal

marks

Signal name

Remarks

D i g i t a l i n p u t t e r m i n a l

X0

Multi-function input 0

(function code P30.00)

Contact input, the input signal is valid when the

contact is closed. The function can be selected

according to the parameters of the function group (code

P30 ).

Digital input circuit specifications are as follows:

Internal power

supply

+24VDC

Maximum load

current

100mA

X1

Multi-function input 1

(function code P30.01)

X2

Multi-function input 2

(function code P30.02)

X3

Multi-function input 3

(function code P30.03)

X4

Multi-function input 4

(function code P30.04)

X5

Multi-function input 5

(function code P30.05)

X6

Multi-function input 6

(function code P30.06)

24

Internal +24VDC power

output

XV

Input signal common port

XC

Internal 24V power supply 0V

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 9 -

Nam

e

Terminal

marks

Signal name

Remarks

Analo

g

input

termi

nal

A0

Multi-function analog input 0

(function code P32.01)

Voltage or current analog input, selected by toggling

switch (SW4, SW3):

Analog voltage input: -10V to +10V or 0 to 10V, Rin>34kΩ

Analog current input: 0~20mA or 4~20mA, Rin=120Ω

Can be used for analog signal input at a

given speed

A1

Multi-function analog input 1

(function code P32.07

(voltage)

V+

+10V power output

+10VDC power supply output for analog input,

maximum allowable current 20mA

V-

-10V power output

-10VDC power supply output for analog input, maximum

allowable current 20mA

0V

Analog input signal reference

ground

Analog input signal reference ground

R e la y o u t p u t te r min a l

1A

1B

Programmable relay output

(Function code P31.00)

Normally open contact

The programmable relay output function can be

selected according to the parameters of the function

code P31 group.

Contact specifications are as follows:

Project

Description

Rated capacity

5A/250VAC

5A/30VDC

Open/close

frequency 120

times / min

Failure rate P level

10mA/5V

Actuation time

below 10ms

2A

2B

Programmable relay output

(Function code P31.01)

Normally open contact

3A

3B

3C

Programmable relay output3

(Function code P31.02)

3A-3B:Normally open

contact

3B-3C:Normally closed

contact

The programmable relay output function can be

selected according to the parameters of the function

code P31 group.

Contact specifications are as follows:

Project

Description

Rated

capacity

Resistive, 4.5A 250VAC/30VDC

Sensitive, 0.4A 250VAC/30VDC

Open/close

frequency

120 times /

min

Failure rate P level

10mA/5V

Actuation

time

below 10ms

4A

4B

4C

Programmable relay output 4

(Function code P31.03)

4A-4B:Normally open

contact

4B-4C:Normally closed

contact

Trans

istor

set

open

outpu

t

termi

nal

Y0

Programmable set open

output 0

(Function code P31.04)

The programmable set open output function can be

selected according to the parameters of the function

code P31 group.

Drive capacity: no more than DC30V, 20mA

Y1

Programmable set open

output 1

(Function code P31.05)

YC

Programmable set open

output common port

Analo

g

outpu

t

termi

nal

M0

Programmable analog output

0

(Function code P33.00)

Voltage or current analog output, selected by toggling

switch (SW6, SW5):

Analog voltage output: -10V to +10V or 0 to 10V, RL≥1kΩ

Analog current output: 0 to 20 mA or 4 to 20 mA, RL ≤ 500

Ω

Can be used for monitor output

M1

Programmable analog output

1

(Function code P33.03)

0V

Analog output signal

reference ground

Analog output signal reference ground

Over

Temp

erature

Protec

tion

P1,P2

PTC function connection port

(Function code P30.07)

Matched temperature sensor model: PT1000

Over temperature protection point: 120 °C

State

indicator

(green) D35

ON: The temperature is normal

OFF: Over temperature protection

Shanghai Sigriner STEP Electric Co., Ltd.

- 10 -

Nam

e

Terminal

marks

Signal name

Remarks

Modbu

s

Com

muni

catio

n

Termin

al

A+

Modbus communication

signal +

Signal terminal for Modbus communication

Commun

ication

status

indicator

Yello

w

(TX)

D36

ON: The IO board is in the

state of sending data to the

bus

OFF: The IO board is in the

state of not sending data

Gre

en

(TX)

D37

ON: The IO board is in the

state of receiving data from

the bus

OFF: The IO board is in the

state of not receiving data

B-

Modbus communication

signal -

+5

Signal power supply +5

Communication signal isolated power supply 5V, 100mA

SC

Signal ground

MODBUS communication signal

ground

Grou

nd

termi

nal

AE

RC ground terminal

Grounding through the RC circuit, the shield can be

grounded through the RC circuit when the communication

cable is too long and the interference is large.

PE

Direct ground terminal

Direct grounding, suitable for situations with good

grounding conditions, analog, communication line shield

layer grounding

Note: The analog signal cable is a twisted pair shielded cable, and the shield layer is properly grounded.

And the distance to the power line is more than 5cm, preferably carry out cross-wiring with the power line,

trying not to keep it parallel to the power line, the shield layer can be connected to the inverter housing.

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 11 -

Chapter 3 Inverter Quick Commissioning

1. Inverter commissioning steps before power up

(1) Main circuit terminal wiring and confirmation:

1. The three-phase power input lines are connected to the inverter terminals R/L1, S/L2, and T/L3,

respectively.

2. The three-phase output terminals U/T1, V/T2 and W/T3 of the inverter are respectively connected

to the three-phase stator side windings of the motor.

3. The 30kW and below inverters come with a brake unit. The braking resistor is installed between

the B and ○+2 terminals. For >30kW inverters, to brake circuit, please connect an external brake

unit between the ○+and ○-terminals.

4. For 30 kW and below inverters, if DC reactors are required, please install them between the ○+1

and ○+2 terminals, while removing the short-connected piece between ○+1 and ○+2 terminals.

5. Then confirm if the above connections are secure.

U/T1

V/T2

W/T3

+1 +2

R/L1

S/L2

T/L3

-

B

+-

Figure 3.1 Main circuit terminal wiring diagram

(2). IO board control terminal wiring and confirmation:

1. When the external controller input switching value quantity signal is a dry node, confirm that

terminals 24 and XV are shorted.

Example: Multi-speed control terminal wiring

There are 16 kinds of multi-speed frequency available for selection. The external needs 4 switching

value input terminals for combination. For example, select X3, X4, X5 and X6 terminals. The specific

wiring is that four wires are externally controlled to be connected to X3, X4, X5 and X6, respectively,

and the other corresponding four wires connected to the XC terminal.

2. Switching value relay output terminal, 1A and 1B are normally open points, 1B and 1C are normally

closed points, and so on for other relays.

3. External voltage or current signal is optional for analog input, the external reference signal line is

connected to the OV terminal, and the signal line connected to A0 or A1 terminal (A1 is optional in

current type input);

use the

shielded wire

AS180

inverter IO

board

A0/A1

0V

PE

Analog

input

Upper

controller

Speed reference

0V

Figure 3.2 Analog input terminal wiring diagram

When the potentiometer is selected as the analog input, both terminals of the potentiometer are

connected to V+, and V- (or OV), and the potentiometer terminals are connected to A0 or A1.

Shanghai Sigriner STEP Electric Co., Ltd.

- 12 -

use the

shielded wire AS180 inverter IO

board

V+

A0/A1

V-/OV

PE

Analog voltage

input(-

10V~+10V)

potentio

meter

Figure 3.3 Analog (potentiometer) input terminal wiring diagram

4. Analog output terminal wiring:

use the

shielded wire Upper

controller

0V

PE

Analog

output

AS180 inverter

IO board

M0/M1

0V

V+

Figure 3.4 Analog output terminal wiring diagram

2. Inverter commissioning steps after power up

1. Confirm the rated power P96.00, the rated current P96.01, and the rated voltage P96.03 of the

inverter are the same as the actual parameters on the nameplate.

2. At first on-site commissioning, first perform factory reset. Parameter processing Init = 7 Select Y

to perform factory reset.

3. Monitor status to see if Udc is around 540V.

4. Confirm whether the controlled motor is an asynchronous motor. Parameters on the motor

nameplate include: rated power, rated voltage, rated current, rated frequency, rated speed,

number of motor poles and slip. Write these data into the corresponding parameters of the P20

group.

Slip calculation fs=(synchronous speed - rated speed)*number of motor pole pairs/60

For example, motor nameplate parameters: rated frequency 50Hz, 4 poles, rated speed 1470rpm,

the slip frequency is fs=(1500-1470)*2/60=1Hz.

3. Parameter settings:

1. List of commonly used parameters in commissioning:

Parameter no.

Name

Set value (remarks)

P10.00

Control mode selection

0: VF control 5: High performance VF control

P10.02

Command channel selection

Normal selection: 1

P10.03

Speed channel selection

Normal selection: 1 or 3 or 5 or 15

P11.00

Start mode selection

Default

P12.00

Stop mode selection

0: by inertia 1: slow down

P20.01

Motor 1 rated power

A parameter on motor nameplate

P20.02

Motor 1 rated current

A parameter on motor nameplate

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 13 -

Parameter no.

Name

Set value (remarks)

P20.03

Motor 1 rated frequency

A parameter on motor nameplate

P20.04

Motor 1 rated speed

A parameter on motor nameplate

P20.05

Motor 1 rated voltage

A parameter on motor nameplate

P20.06

Motor 1 pole number

A parameter on motor nameplate

P20.07

Motor 1 rated slip

Calculated according to parameters on motor

nameplate

P30.00

Input Di0 function

Default

P30.01

Input Di1 function

Default

P31.00

K1 function

Normal selection: 2 or 3

P31.01

K2 function

Normal selection: 3 or 2

P40.02

Acceleration time

Site request setting

P40.03

Deceleration time

Site request setting

2. If you select P10.03=1 digital for multi-speed setting, you need to set the parameters, such as

select X3, X4, X5, X6, terminal as multi-speed set signal

Parameter no.

Name

Set value

P30.03

Input Di3 function

3

P30.04

Input Di4 function

4

P30.05

Input Di5 function

5

P30.06

Input Di6 function

6

3. If you select P10.03=3 or 5 analog A0/A1 for target speed setting, you need to set the parameters.

Parameter no.

Name

Set value

P32.00

Input AI0 type

0:0~10V 1:-10~+10V 2:0~20mA 3:4~20mA

P32.02

Input AI0 lower limit

General default

P32.03

Input AI0 upper limit

General default

P32.06

Input AI1 type

0:0~10V 1:-10~+10V 2:0~20mA 3: 4~20mA

P32.08

Input AI1 lower limit

General default

P32.09

Input AI1 upper limit

General default

P32.11

Input AI1 limit range

General default value; when P32.06=2 or 3, this

value is set to 20.000mA

Note: When the analog input voltage value displayed on the operator is not equal to the input voltage value,

the A0 or A1 lower limits can be adjusted and upper limits increased, so that the actual voltage value is

equal to the displayed value.

Shanghai Sigriner STEP Electric Co., Ltd.

- 14 -

4. If you select P10.03=15 UP/DOWN for speed setting, you need to set the parameters, such as

selecting input terminal X1 as the UP signal and terminal X3 as the DOWN signal.

Parameter no.

Name

Set value

P30.01

Input Di1 function

31 or 38

P30.03

Input Di3 function

32 or 39

4. Special functions description

1. Selection of function below the lower limit frequency

Parameter no.

Name

Set value

P70.01

Lower frequency limit

Site request setting

P70.22

Selection below lower limit

frequency

0: Run according to the limit frequency 1: Stop

2: Set frequency is 0

Note: In some cases, the running command is always maintained. When the motor speed is lower than

a certain frequency, the inverter output voltage is zero. At this time, set P70.01=0.50Hz (if it is lower than

0.5Hz), P70.22 =1; that is, when the output frequency is lower than 0.5Hz, the inverter stops, and when

output frequency is above 0.5Hz, the inverter is started.

2. Analog input description

When the analog input function is selected as for target speed setting, 10V corresponds to the set speed

reference value P20.13 (maximum frequency of motor 1). For example, when P20.13=50.00Hz, if you

input 10V, set speed is 50Hz, if you input 5V, set speed is 25 Hz, and so on.

3. Analog output description

Analog output is 0~5V, corresponding to 0~100% rated value (such as rated speed, rated current, etc.), if

you want 0~100% rated value (such as rated speed, rated current, etc.), and the corresponding output is

0~10V, you can set the output P33.02 or P33.05.

4. Speed tracking start

To select this function, you need to set P11.00=2, and set the P11.14 parameter value.

Parameter no.

Name

Set value

P11.00

Start mode selection

2

P11.14

Maximum current during

tracking

Setting range 30~100%; set according to loading

conditions

5. Inverter test run process

1. Motor no-load test run

Check if the motor is in no-load state (disconnect from the machine)

For the first test run, the set frequency should not be too large, 5Hz is enough .

Check if the motor running direction is consistent with the set one?

Check if the motor acceleration and deceleration are smooth, with no abnormal sound

During test running, the actual current Irms is approximately 30% of the rated current of

motor

The output voltage value Uout is substantially linear with the current frequency value Vref

2. Motor loaded test run

Check if the motor is connected to mechanical equipment and confirm the safety of motor

and mechanical equipment

When loaded running starts, be ready to press the STOP button (if there is an abnormality)

Check if the load running direction is consistent with the set direction on the inverter?

Check if the motor acceleration and deceleration are smooth during running with load

Check if the actual motor current Irms is too large

Check if there is an abnormal sound or current oscillation when load frequency changes.

AS180 Series High Performance V/F General Purpose Inverter Operation Manual

- 15 -

6. Precautions

1. VF control refers to P10.00 = 0 control mode. If current oscillation occurs, try to adjust P61.06

and P61.07 parameters. See the table below for details.

Parameter no.

Name

Set value

P61.06

U/F control current loop

Max

Generally set to the default value; When P10.00=0

is active, current oscillation occurs, adjust this value

(change 0.2% for each time)

P61.07

U/F control current loop

Min

Generally set to default value; When P10.00=0 is

active, current oscillation occurs, adjust this value

(change 0.2% for each time)

2. High-performance VF control refers to P10.00 = 5 control mode. If the motor with heavy load

fails to start due to over-current, you can try to adjust the following parameters. See the table

below for details.

Parameter no.

Name

Set value

P71.35

SVC1 inertia coefficient

Generally set to default value; When P10.00=5 is

active, motor starts with heavy load, this value can

be increased; do not exceed 200% when setting

P71.36

SVC1 low speed torque

boosting

Generally set to default value; When P10.00=5 is

active, motor starts with heavy load, this value can

be increased; generally set to 150%~200%

3. If it is found that the motor noise is large at running, appropriately increase the PWM carrier

frequency value (P71.14 parameter) under the condition that the inverter does not report fault.

Other STEP Inverter manuals

Popular Inverter manuals by other brands

BlueHive

BlueHive 011-1945-0 instruction manual

SOLIS

SOLIS RHI-5G Series instruction manual

Mitsubishi Electric

Mitsubishi Electric 800 Series instruction manual

Toshiba

Toshiba PCT001Z-E instruction manual

Ryobi

Ryobi RG-1250I Owner's operating manual

Siemens

Siemens SINUMERIK 880 Installation operation & maintenance

Perfect power systems

Perfect power systems EXT Series Installation and operation manual

GivEnergy

GivEnergy Giv-AC3.0 user manual

Alpha Technologies

Alpha Technologies INVERTER 2000 user manual

Srne

Srne HF2420S40-75 user manual

SEW-Eurodrive

SEW-Eurodrive MOVIDRIVE system Compact operating instructions

Ego Paris

Ego Paris EM16 Assembly instructions