EMIS EMIS-BAR 103 User manual

www.emis-kip.ru

EB 100.000.00 OM

01.12.2020

V2.0.15-01

Pressure transmitters

EMIS-BAR

Operation manual

High accuracy

Accuracy does not

depend on process

parameters

Ex-proof application

LCD display

In-built self-check

EMIS CJSC

Russia, Chelyabinsk

EMIS-BAR

OPERATION MANUAL

2

1 DESCRIPTION AND OPERATION

4

1.1 Application

4

1.2 Specification

4

1.3 Explosion protection

11

1.4 Configuration and operation

14

1.5 Pressure transmitter adjustment

15

1.6 Operation via HART protocol

25

1.7 Error log

25

1.8 Supply scope

26

1.9 Marking and sealing

26

1.10 Package

27

2 APPLICATION

28

2.1 Operating features

28

2.2 Mounting requirements

29

2.3 Operation

30

2.4 Connection to HART

31

3 MAINTENANCE AND REPAIR

32

4 CALIBRATION

32

5 LIST OF POSSIBLE FAILURES

32

6 PERSONELL ACTIONS IN CASE OF ACCIDENT, CRITICAL FAILURE OR BREAKDOWN

34

7LIMIT STATE CRITERIA

34

8 STORAGE

34

9 TRANSPORTATION

34

10 RECYCLING

34

11 PRECIOUS MATERIALS CONTENT

34

Appendix A List of reference documents

35

Appendix B Connection schemes

36

Appendix C Order sheet EMIS-BAR pressure transmitters

38

Appendix D Mounting kit order sheet

52

Appendix EDimensions and connection sizes of pressure transmitters

57

Dimensions and connection sizes of flanges

71

Appendix FMounting kit

75

Appendix G Explosion protection scheme

81

Appendix H Installation on a bracket

83

Appendix I List of cable glands

85

EMIS-BAR

OPERATION MANUAL

3

Present Manual is used for studying the structure, operation, operating rules, maintenance and

calibration of the pressure transmitters EMIS-BAR.

This operation manual contains general technical parameters, directions for usage, calibration,

transportation and storage, and other information to ensure correct operation of the pressure transmit-

ter. The design of the transmitter is constantly being improved, so the device you purchased may

have minor differences from the description given in this document which do not affect the perfor-

mance, technical characteristics and usability.

Any use of the trade marks and present manual, partial or full, is prohibited without copyright

holder permission.

Manufacturer has the right to update the product and documents without prior notice if it does

not affect product performance.

Symbols and abbreviations

The following abbreviations are used in this document:

ADC - analog to digital converter;

DAC - digital to analog converter;

CPU - central processing unit;

LCD - liquid crystal display;

SCS - state calibration system;

CS - checksum;

SW - device software;

DDL - Device Description Language for HART. Is used to define and describe the device and

then read device data during digital communication;

DD - Device Description is a PC software written in DDL;

RFI - radio interference filter. Serve to eliminate the influence of electromagnetic interference

on the transmitter readings.

EMIS-BAR

OPERATION MANUAL

4

1DESCRIPTION AND OPERATION

1.1 Application

1.1.1 EMIS-BAR pressure transmitters (hereinafter "transmitters") are designed for continu-

ous measurement of pressure (gauge, vacuum, absolute, hydrostatic and differential (pressure differ-

ence)) and conversion of the measured pressure into a rated DC output signal 4-20 mA overlapped

with digital HART signal, as well as displaying the measured value on the display.

EMIS-BAR pressure transmitters can be used in automatic control, adjustment and operation

systems at various industries.

1.1.2 Transmitters can be operated and adjusted using an inbuilt keyboard or remotely using

HART-compatible device.

1.1.3 Transmitters with HART can transfer information about measuring value in digital form

via the 2-wire connection line along with 4-20 mA current signal. Digital signal can be received and

converted by any HART-compatible device. Digital output is used to connect transmitter with portable

HART communicator or PC via standard serial interface and additional HART modem. The following

operation can be executed: setup transmitter, select main parameters, read measured pressure, etc.

HART-protocol allows two master devices be connected to the system: HART-compatible PC and

portable HART communicator. Transmitter can receive and execute commands of each of the control

devices with different addresses and exchanging data in the time sharing mode.

Measured value is displayed in selected units on the transmitter indicator or HART communi-

cator in measuring mode.

1.1.4 Transmitter meets the requirements of the technical regulations: TR CU 020/2011, TR

CU 032/2013.

1.1.5 Transmitter can be used for both safe and explosive environments.

Ex-proof transmitters comply with the technical regulations TR CU 012/2011.

Ex-proof transmitter intended for use in explosive environment of premises and outdoor instal-

lations according to GOST IEC 60079-14 as given in the chapter 7.3 of the Russian Electrical Code

and other normative documents designed for explosive environments.

Transmitters of Exd and RV configurations have flameproof enclosure "d" under GOST IEC

60079-1-2011, ex-proof design and intended for use in explosive environments hazardous with gas

mixtures and vapours of I, IIB, IIC, IIIB иIIIC categories.

Transmitters of ЕхiaC, ExiaB and RO configurations have explosion protection "intrinsically

safe circuit "i" under GOST 31610.11-2014, with increased explosion protection and intended for use

in explosive environments hazardous with gas mixtures and vapours with oxygen of I, IIB, IIC, IIIB,

IIIC categories.

Transmitters of Exdia and RVia configurations have explosion protection "flameproof enclo-

sure "d" under GOST IEC 60079-1-2011 and "intrinsically safe circuit "i" under GOST 31610.11-

2014, intended for use in explosive environments hazardous with gas mixtures and vapours with oxy-

gen of IIC category. Exdia configuration has protection level "increased flame protection". RVia con-

figuration has protection level "flameproof".

1.1.6 Please specify transmitter symbolic designation when placing order. Use Annex C for

reference.

If transmitter is mentioned in the documents related to other products, the following shall be

specified:

- transmitter symbolic designation;

- technical parameters: TU 26.51.52-080-14145564-2018.

1.1.7 See Annex D for mounting kit order codes. Drawings and mounting kit are shown in the

Annex F.

1.2 Specification

1.2.1 Type of measurement pressure, transmitter model, order codes, full range of pressure meas-

urement, min 𝑃𝑢 𝑚𝑖𝑛 and max 𝑃𝑢 𝑚𝑎𝑥 limit of measurement are specified in the Table 1.2.

1.2.2 Measurement range and upper limit can be adjusted to required values from 𝑃𝑙 𝑚𝑖𝑛 to

𝑃𝑢 𝑚𝑎𝑥, as provided in the Tables 1 and 2.

EMIS-BAR

OPERATION MANUAL

5

1.2.3 Overload pressure for absolute pressure and gauge pressure transmitters is specified in

the Table 1.

1.2.4 Overload working pressure limit for differential and level pressure transmitters is speci-

fied in the Table 2.

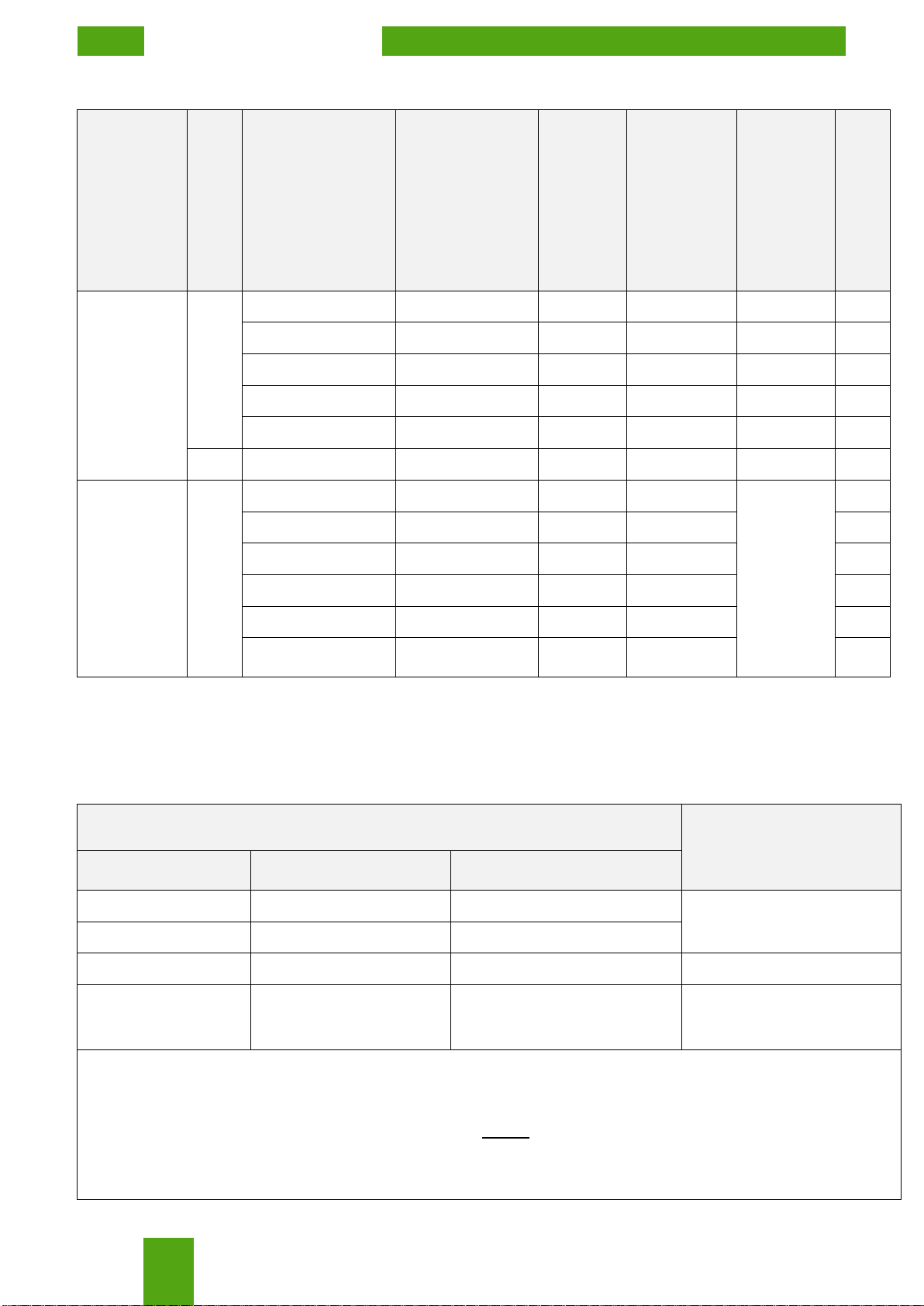

Table 1 –Measuring ranges of gauge and absolute pressure transmitters

Type of

measurement

pressure

Transmitter

model

Order code

Full

range

of measurement

Min upper level

𝑃𝑢 𝑚𝑖𝑛

Max upper level

of measurement

𝑃𝑢 𝑚𝑎𝑥

Overload

pressure, Mpa

Range

adjustment

Gauge

pressure

103

(-100…100) kPa

-100…100 kPa

5 kPa

100 kPa

0.6

1:20

(-100…400) kPa

-100…400 kPa

10 kPa

400 kPa

1

1:40

(-0.1…1.6) MPa

-0.1…1.6 MPa

16 kPa

1,6 MPa

3.2

1:100

(-0.1…6.3) MPa

-0.1…6.3 MPa

63 kPa

6,3 MPa

10

1:100

(-0.1…16) MPa

-0.1…16 MPa

160 kPa

16 MPa

25

1:100

(-0.1…40) MPa

-0.1…40 MPa

400 kPa

40 MPa

60

1:100

105

(-100…100) kPa

-100…100 kPa

5kPa

100 kPa

0.6

1:20

(-100…400) kPa

-100…400 kPa

10 kPa

400 kPa

1

1:40

(-0.1…1.6) MPa

-0.1…1.6 MPa

16 kPa

1,6 MPa

3.2

1:100

(-0.1…6.3) MPa

-0.1…6.3MPa

63 kPa

6.3 MPa

10

1:100

(-0.1…16) MPa

-0.1…16 MPa

160 kPa

16 MPa

25

1:100

113

(0…100) kPa

0…100 kPa

10 kPa

100 kPa

0.6

1:10

(0…400) kPa

0…400 kPa

40 kPa

400 kPa

1

1:10

(0…1.6) MPa

0…1.6 MPa

160 kPa

1.6 MPa

3.2

1:10

(0…6.3) MPa

0…6.3 MPa

630 kPa

6.3 MPa

10

1:10

173

174

(-100…100) kPa

-100…100 kPa

5 kPa

100 kPa

0.6

1:20

(-100…400) kPa

-100…400 kPa

20 kPa

400 kPa

1

1:20

(-0.1…1.6) MPa

-0.1…1.6 MPa

80 kPa

1.6 MPa

3.2

1:20

(-0.1…6.3) MPa

-0.1…6.3 MPa

320 kPa

6.3 MPa

10

1:20

(-0.1…16) MPa

-0.1…16 MPa

800 kPa

16 MPa

25

1:20

(-0.1…40) MPa

-0.1…40 MPa

2 MPa

40 MPa

60

1:20

Absolute

pressure

123

(0…25) kPa

0…25 kPa

0.83 kPa

25 kPa

0.6

1:30

(0…130) kPa

0…130 kPa

4.3 kPa

130 kPa

1

1:30

(0…500) kPa

0…500 kPa

16 kPa

500 kPa

3.2

1:30

(0…3) MPa

0…3 MPa

100 kPa

3 MPa

10

1:30

(0…16) MPa

0…16 MPa

600 kPa

16 MPa

25

1:25

(0…40) MPa

0…40 MPa

1.4 MPa

40 MPa

60

1:28

EMIS-BAR

OPERATION MANUAL

6

Table 1 continued

Type of

measurement

pressure

Model

Order code

Full

range

of measurement

Max upper level

of measurement

𝑃𝑢 𝑚𝑖𝑛

Max upper level

of measurement

𝑃𝑢 𝑚𝑎𝑥

Overload

pressure, Mpa

Range

adjustment

Absolute

pressure

133

(0…25) kPa

0…25 kPa

0.83 kPa

25 kPa

3.2

1:30

(0…130) kPa

0…130 kPa

4.3 kPa

130 kPa

3.2

1:30

(0…500) kPa

0…500 kPa

16 kPa

500 kPa

3.2

1:30

(0…3) MPa

0…3 MPa

100 kPa

3 MPa

16

1:30

(0…10) MPa

0…10 MPa

530 kPa

10 MPa

25

1:18

175

176

(0…25) kPa

0…25 kPa

5 kPa

25 kPa

0,6

1:5

(0…130) kPa

0…130 kPa

10 kPa

130 kPa

1

1:13

(0…500) kPa

0…500 kPa

25 kPa

500 kPa

3.2

1:20

(0…3) MPa

0…3 MPa

150 kPa

3 MPa

10

1:20

(0…16) MPa

0…16 MPa

600 kPa

16 MPa

25

1:26

(0…40) MPa

0…40 MPa

1.4 MPa

40 MPa

60

1:28

Table 2 –Measuring ranges of differential and hydrostatic pressure transmitters

Type of

measurement

pressure

Model

Order code

Full

measuring range

Max upper level

of measurement

𝑃𝑢 𝑚𝑖𝑛

Max upper level

of measurement

𝑃𝑢 𝑚𝑎𝑥

Overload working

pressure, MPa

Range adjustment

Differential

pressure

143

(-25…25)kPa

-25…25 kPa

1 kPa

25 kPa

16

1:25

(-60…60)kPa

-60…60 kPa

1 kPa

60 kPa

16

1:60

(-160…160)kPa

-160…160 kPa

1.6 kPa

160 kPa

16

1:100

(-500…500)kPa

-500…500 kPa

5kPa

500 kPa

16

1:100

(-0.5…3)MPa

-0.5…3 MPa

30 kPa

3 MPa

16

1:100

EMIS-BAR

OPERATION MANUAL

7

Table 2 continued

Type of

measurement

pressure

Model

Order code

Full

measuring range

Max upper level

of measurement

𝑃𝑢 𝑚𝑖𝑛

Max upper level

of measurement

𝑃𝑢 𝑚𝑎𝑥

Overload working

pressure, MPa

Range adjustment

Differential

pressure

183

184

185

186

187

188

(-25…25) kPa

-25…25 kPa

2.5 kPa

25 kPa

0.6

1:10

(-60…60) kPa

-60…60 kPa

3 kPa

60 kPa

1

1:20

(-160…160) kPa

-160…160 kPa

8 kPa

160 kPa

3.2

1:20

(-500…500) kPa

-500…500 kPa

25 kPa

500 kPa

10

1:20

(-0,5…3) MPa

-0.5…3 MPa

150 kPa

3 MPa

16

1:20

193

(-2…2) kPa

-2…2 kPa

0.1 kPa

2 kPa

0.2

1:20

Hydrostatic

pressure

163

164

(-10…10) kPa

-10…10 kPa

2 kPa

10 kPa

Depends

on flange

size

See Table.

C.3

1:5

(-25…25) kPa

-25…25 kPa

2.5 kPa

25 kPa

1:10

(-60…60) kPa

-60…60 kPa

2.5 kPa

60 kPa

1:24

(-160…160) kPa

-160…160 kPa

5.3 kPa

160 kPa

1:30

(-500…500) kPa

-500…500 kPa

16 kPa

500 kPa

1:30

(-0,5…3) MPa

-0,5…3 MPa

100kPa

3 MPa

1:30

1.2.5 The limits of the permissible basic reduced error 𝛾for models with an analog output

signal expressed as percentage of the upper limit or output signal measurement range do not exceed the

values shown in the Tables 3-4.

Table 3 - Limits of the permissible basic reduced error for transmitters with analog output sig-

nal

The limits of the permissible basic reduced error depending on the coefficient

of adjustment of the measuring range 𝛾,%

Application based on the

model

r≤10

10 < r ≤ 30

30 < r ≤ 100**

±0.04

±(0.004· r)

-

103, 105, 113, 123, 133,

143

±0.065

±(0.0065·r)

±(0.005·r+0.071)

±0.074

±(0.0074·r)

-

163, 164

±0.1; ±0.15; ±0.2;

±0.25; ±0.4; ±0.5;

±1.0

±(ɣ/10·r)

±(ɣ/10·r+0.071)

103, 105, 113, 123, 133,

143, 163, 164

Note

r - coefficient of adjustment of the measuring range of the pressure transmitter, calculated using the

formula: 𝑟=𝑃в 𝑚𝑎𝑥

𝛥𝑃

where ΔР=Рu -Рl–new measuring range of transmitter.

** r adjustment from 30 to 100 is possible only for models 103, 105 and 143.

EMIS-BAR

OPERATION MANUAL

8

Table 4 - Limits of the permissible basic reduced error γfor transmitters with analog output sig-

nal

The limits of the permissible basic reduced error depending on the

measuring range adjustment coefficient. 𝛾, %

Application based on the

model

r ≤ 5

5 < r ≤ 20

±0.086

±(0.071+0.0029·r)

193

±(0.09+0.01·r)

±(0.09+0.012·r)

173, 174

±0.15; ±0.2; ±0.25; ±0.4; ±0.5; ±1.0

±(0.09+ ɣ/10·r)

±0.15

±(0.09+0.012·r)

175, 176, 183, 184, 185,

186, 187, 188, 193

±0.2; ±0.25; ±0.4; ±0.5; ±1.0

±(0.09+ ɣ/10·r)

1.2.6 The limits of the permissible basic reduced error 𝛾for models with digital output signal

expressed as percentage of the upper limit or output signal measurement range do not exceed the val-

ues shown in the Table 5.

Table 5 - Limits of the permissible basic reduced error for transmitters with digital output signal

Limits of the permissible basic reduced error 𝛾, %

Application based on the

model

±0.04; ±0.065

103, 105, 113, 123, 133,

143

±0.074

163, 164

±0.1; ±0.15; ±0.2; ±0.25; ±0.4; ±0.5; ±1.0

103, 105, 113, 123, 133,

143, 163, 164, 173, 174

±0.086

193

±0.15; ±0.2; ±0.25; ±0.4; ±0.5; ±1.0

175, 176, 183, 184, 185,

186, 187, 188, 193

1.2.7 Output signal variability 𝛾Г, does not exceed absolute limit of the permissible basic re-

duced error |𝛾|.

1.2.8 Output signal ripple in the range from 0,06 to 5Hz does not exceed 0,7|𝛾|.

Analog signal ripple in the range from 5 to 106Hz shall not exceed 0,55% of the measuring

range. Analog signal ripple higher than 106Hz is not rated. Output signal ripple is rated at load re-

sistance of 250 Ohm (in the absence of communication with the transmitter via HART).

Note: signal ripple is rated at minimum averaging time of the measuring results.

1.2.9 Output signal is linear dependent or proportional to square root of the input measuring

value.

1.2.10 The nominal static characteristic of the transmitter with a linearly increasing depend-

ence of the analog output signal on the input measuring value corresponds to:

𝐼=𝐼н+𝐼в− 𝐼н

𝑃в−𝑃н×(𝑃−𝑃н)

(1)

where 𝐼–current value of the output signal, mA;

Р–measured value in stated units;

𝐼н= 4 mA, 𝐼в= 20 mA –upper and lower limits of the output signal, respectively.

𝑃в, 𝑃н- respectively, upper and lower limits of the output signal in stated units.

The nominal static characteristic of the transmitter with a linearly decreasing dependence of the

analog output signal on the input measuring value corresponds to:

𝐼=𝐼в−𝐼в− 𝐼н

𝑃в−𝑃н×(𝑃−𝑃н)

(2)

The nominal static characteristic of the transmitter with the function of converting the input

measured value according to the square root law corresponds to:

EMIS-BAR

OPERATION MANUAL

9

𝐼=𝐼н+(𝐼в− 𝐼н)×√𝑃−𝑃н

𝑃в−𝑃н

(3)

where 𝑃–input measured value - pressure difference in stated units.

1.2.11 General purpose industrial transmitter and ex-proof version with protection type "flame-

proof enclosure" shall be connected to 10.5 to 45VDC supply unit.

1.2.12 Ex-proof version with protection type "intrinsically safe electrical circuit "i" shall be con-

nected to 10.5 to 28VDC supply unit.

1.2.13 Electrical wiring diagrams are given in the Annex B.

1.2.14 Power consumption not exceed 1,0 V-A (0,65 V·A for versions ExiaC, ExiaB, RO, RVia

and Exdia).

1.2.15 The limits of the permissible load resistance (resistance of transmitter and communication

lines) depends on the stated transmitter supply voltage and should not go beyond the boundaries of the

working area shown in Figure 1 in the range from 𝑅𝑚𝑖𝑛 to 𝑅𝑚𝑎𝑥.

Fig.1 - Graph of dependence between the load resistor resistance and transmitter supply voltage

𝑅𝑚𝑎𝑥 are calculated as below:

𝑅𝑚𝑎𝑥 =𝑈−10,5

0,023

(4)

where U - transmitter supply power, V.

𝑅𝑚𝑖𝑛 =0 if HART signal is not available.

𝑅𝑚𝑖𝑛 =230 Ohm if using HART communication.

1.2.16 Transmitter has electronic damping of the output signal, which represents measuring re-

sults averaging time. Time range can be selected from the range: 0.1 s; 0.5 s; 1 s; 2.5 s; 5 s; 10 s; 20 s;

50 s; 100 s. Averaging time of measurement influence output signal detection time.

1.2.17 Response time of the transmitter shall not exceed 100ms.

1.2.18 Saturation current when measured value goes beyond the stated limits:

3.8 mA - measured value lower than stated lower limit;

20.5 mA - measured value higher than stated upper limit.

1.2.19 The transmitters are protected against reverse polarity of the supply voltage.

1.2.20 Ambient temperature range for general industrial transmitters, including LCD versions,

from -60° to +85°С. Ambient temperature range for ex-proof transmitters, including LCD versions, is

specified in the Table 9.

EMIS-BAR

OPERATION MANUAL

10

1.2.21 Additional reduced error ɣtcaused by ambient temperature changes within working

temperature range does not exceed the values given in the Table 6 for each 10°С.

Table 6 - Limits of additional reduced error ɣt

Additional reduced error to the measuring range caused by changes in

ambient temperature ɣt, %

Application based on the

model

with analog output

±(0.023·r+0.02)

103, 105, 113, 123, 133, 143

±(0.04·r+0.04)

163..188

±(0.046·r+0.04)

193

for versions with digital output signal

±0.043

103, 105, 113, 123, 133, 143

±0.08

163..188

±0.086

193

1.2.22 Medium temperature range from - 40° to +120°С for pressure transmitters models 103,

105, 113, 123, 133, 143, 163, 164, 193. For models 173...188 temperature range depends on the oper-

ating temperature of the liquid in capillaries ("Capillaries liquid" in the order line).

1.2.23 The transmitters are resistant to 95 ± 5% relative humidity at +35 ° C and lower temper-

atures with moisture condensation.

1.2.24 In terms of resistance to the effects of environmental factors, pressure transmitters can

be operated in boreal climates location class 1 under GOST 15150.

1.2.25 Transmitter is resistant to external magnetic field up to 400 A/m under GOST Р 50648 (IEC

1000-4-8-93).

1.2.26 Transmitter is resistant to industrial radio interference:

GOST R 51317.4.4 3rd test severity level.

GOST R 51317.4.3 3rd test severity level at 80-1000 MHz

GOST R 51317.4.2 4th test severity level.

GOST R 51317.4.6 2nd and 3rd test severity level with HART test operated under noises.

GOST R 50648 5th test severity level.

GOST R 50649 5th test severity level.

GOST R 50652 5th test severity level.

GOST R 51317.4.5 2nd test severity level "wire-to-wire" interference and 3rd test severity

level "wire-to-ground" interference. Interference resistance - A

1.2.27 The transmitters comply with the emission standards established for class B by

GOST R 51318.11.

1.2.28 Transmitter protection against dust and water comply with IP65, IP66, IP67, IP68 un-

der GOST14254, and depends on selected cable gland or plug adapter according to the Annex I.

1.2.29 Average service life is at least 30 years, provided proper maintenance and normal op-

erating conditions:

- environment temperature plus (23±10)ºС;

- relative humidity from 20 to 95%;

- atmospheric pressure from 84 to 105.7 kPa;

- power supply 24±0,5V DC;

- no external electrical and magnetic fields (except for earth) influence device operation;

- no vibration, shaking, bumps affecting the operation of the transmitter;

- non-corrosive medium.

EMIS-BAR

OPERATION MANUAL

11

1.2.30 Mean time before failure shall not be less than 150000 hours and depends on mainte-

nance as specified in the manual;

1.2.31 Transmitters are resistant to vibrations with frequency 10 to 2000Hz and acceleration

not exceeding 98m/s2, refers to G2 group under GOST R 52931-2008.

1.2.32 Pressure transmitters are earthquake resistant if exposed to earthquakes with an inten-

sity of 9 points on the MSK-64 scale.

1.2.33 Dimensions and connection size of pressure transmitter with mounting kit are show in

the Annex E.

1.2.34 Transmitters are equipped with protection unit (LP code as additional option) against

transient phenomena in communication lines caused by lightning, welding, the operation of powerful

electrical equipment and switching mechanisms.

1.2.35 Transmitters with LCD can be adjusted using inbuilt control functions.

1.2.36 Transmitters without LCD can be adjusted via HART compatible control unit.

1.2.37 Transmitter service life is 15 years provided that transmitter is made of corrosion re-

sistant materials.

1.2.38 For transmitters with remote diaphragm seal bending of capillary lines with a radius of

not less than 5 cm is allowed. The material of the capillaries is 316 stainless steel.

1.2.39 Transmitter body is equipped with ground clamp and marked with earth sign under

GOST 21130.

1.2.40 Transmitter parts materials which contact measuring medium are specified in the

Annex C.

1.2.41 Transmitter weight does not exceed the values specified in the Table 7.

Table 7 - Transmitter weight

Transmitter model

Weight, kg, not more than

103, 123,

1.6

113

1.8

105, 133, 143, 193

3.6

163, 164

3.6 without flanges

173, 174, 175, 176

1.6 without flanges

183, 184, 185, 186, 187, 188

3.6 without flanges

1.3 Explosion protection

1.3.1 Explosion protection "intrinsically safe circuit "i" under GOST 31610-11-2012 is pro-

vided by the following means:

- power supply shall be provided from intrinsically safe unit with output circuits of "ia" level and

electrical parameters complying with GOST 31610.11-2014 for intrinsically safe circuits of electrical

equipment operated in explosive environment;

- connection of external devices to digital, current outputs shall be provided via intrinsically safe

barriers with output circuits of "ia" level and electrical parameters complying with GOST 31610.11-

2014 for intrinsically safe electrical circuits of equipment operated in explosive environment.

- electrical load on active and passive elements of intrinsically circuits shall not exceed 2/3 of the

stated value;

- leakage path, clearance and insulation strength, electrical parameters of circuit boards and con-

nections comply with GOST 31610.11-2014;

- internal capacity and inductance of the electrical circuit do not accumulate energy, explosive

gas mixtures complying with explosive operating conditions;

- insulation of the circuit against the body and between the intrinsically safe circuit and the body

or grounded part of the transmitter withstands the testing voltage not less than 500V AC;

EMIS-BAR

OPERATION MANUAL

12

- current- carrying connections and electronic components are protected against environmental

exposure with IP67 (IP68) enclosure complying with GOST 14254.

For ЕхiaC, ExiaB, Exdia, RO, RVia versions input parameters of supply circuit and output signal

circuits are shown in the Table 8.

Table 8 - Supply circuit input parameters for ЕхiaC, ExiaB, Exdia, RO, RVia versions

Parameter

Parameter value for current circuit

Input voltage range Ui, V

12 to 28

Input current Ii, mA, not exceeding

100

Input power Pi, W, not exceeding

0.7

Internal capacity Ci, nF, not exceeding

30

Internal inductance Li, µH, not exceeding

0.6

1.3.2 Explosion protection "flameproof enclosure "d" under GOST IEC 60079-1-2011 is pro-

vided by the following means:

Electrical elements are covered with ex-proof enclosure to prevent from explosion pres-

sure and transfer of fire to the explosive environment.

flameproof enclosures comply with GOST IEC 60079-1-2011;

flameproof connections comply with GOST IEC 60079-1-2011;

tolerances and length of the planar and cylindrical explosion-proof joints comply with

the GOST IEC 60079-1-2011;

mechanical performance of enclosure complies with GOST 31610.0-2014 (IEC 60079-

0:2011);

warning signs on the cover: "Switch off before open in explosive environment".

Exd transmitters shall be equipped with Ex-proof cable glands and Ex-proof plugs complying

with "d" type of explosion protection for IIC sub-group, environment temperature for T6 version of

transmitter and ingress protection not lower than IP67 under GOST 14254-2015.

1.3.3 Transmitter protection against explosive dust is ensured by "flameproof enclosure "t"

complying with GOST IEC 60079-31-2013.

1.3.4 Ex-proof transmitters have an additional plate with the explosion protection marking in-

dicated in the Table 9.

Table 9 - Ex-proof marking

Ex-proof transmitters

Marking

Exd

1Ex d IIC T4 Gb X Ex tb IIIC 135°C Db

- 60 ≤ ta≤ + 85 °C

1Ex d IIC T5 Gb X Ex tb IIIC 100°C Db

- 60 ≤ ta≤ + 85 °C

1Ex d IIC T6 Gb X Ex tb IIIC 85°C Db

- 60 ≤ ta≤ + 70 °C

ExiaC

0Ex ia IIC T4 Ga X Ex ia IIIC 135°C Da

- 60 ≤ ta≤ + 85 0C

Ui≤ 28 В, li≤ 100 mA, Pi ≤ 0,7 W,

Ci= 30 nF, Li= 0,6 µH

0Ex ia IIC T5 Ga X Ex ia IIIC 100°C Da

- 60 ≤ ta≤ + 85 0C

Ui≤ 28 В, li≤ 100 mA, Pi ≤ 0,7 W,

Ci= 30 nF, Li= 0,6 µH

0Ex ia IIC T6 Ga X Ex ia IIIC 85°C Da

- 60 ≤ ta≤ +70 0C

Ui≤ 28 В, li≤ 100 mA, Pi ≤ 0,7 W,

Ci= 30 nF, Li= 0,6 µH

EMIS-BAR

OPERATION MANUAL

13

ExiaB

0Ex ia IIB T4 Ga X Ex ia IIIB 135°C Da

- 60 ≤ ta≤ + 85 0C

Ui≤ 28 В, li≤ 100 mA, Pi ≤ 0,7 W,

Ci= 30 nF, Li= 0,6 µH

0Ex ia IIB T5 Ga X Ex ia IIIB 95°C Da

- 60 ≤ ta≤ + 85 0C

Ui≤ 28 V, li≤ 100 mA, Pi ≤ 0,7 W, Ci= 30 nF, Li= 0,6 µH

0 Ex ia IIB T6 Ga X Ex ia IIIB 80°C Da

- 60 ≤ ta≤ + 70 0C

Ui≤ 28 V, li≤ 100 mA, Pi ≤ 0,7 W, Ci= 30 nF, Li= 0,6 µH

Exdia

1Ex d ia IIC T4 Gb X

- 60 ≤ ta≤ + 85 °C

Ui≤ 28 V, li≤ 100 mA, Pi ≤ 0,7 W, Ci= 30 nF, Li= 0,6 µH

1Ex d ia IIC T5 Gb X

- 60 ≤ ta≤ + 85 °C

Ui≤ 28 V, li≤ 100 mA, Pi ≤ 0,7 W, Ci= 30 nF, Li= 0,6 µH

-

1Ex d ia IIC T6 Gb X

- 60 ≤ ta≤ + 70 °C

Ui≤ 28 V, li≤ 100 mA, Pi ≤ 0,7 W, Ci= 30 nF, Li= 0,6 µH

RV

РВ Ex d I Mb X

- 60 ≤ ta≤ + 70 °C

RO

РО Ex ia I Ma X

- 60 ≤ ta≤ + 70 °C

RVia

РВ Ex d ia I Mb X

- 60 ≤ ta≤ + 70 °C

The body of RV, RO, RVia ex-proof transmitter versions operated in underground mines and

pits and its overground facilities hazardous with gas and dust are made of stainless steel.

ATTENTION:

during operation it is necessary to take measures of protection against excess temperature of the

transmitter elements due to heating from the measured medium above the value acceptable for the tem-

perature class T6 ... T4;

painted transmitters can present a risk of potential electrostatic charge. Wipe only with wet or

antistatic cloth;

close transmitter cover before switch it on;

the explosion protection is valid for the medium pressure below the maximum level permitted

for that type of transmitter.

EMIS-BAR

OPERATION MANUAL

14

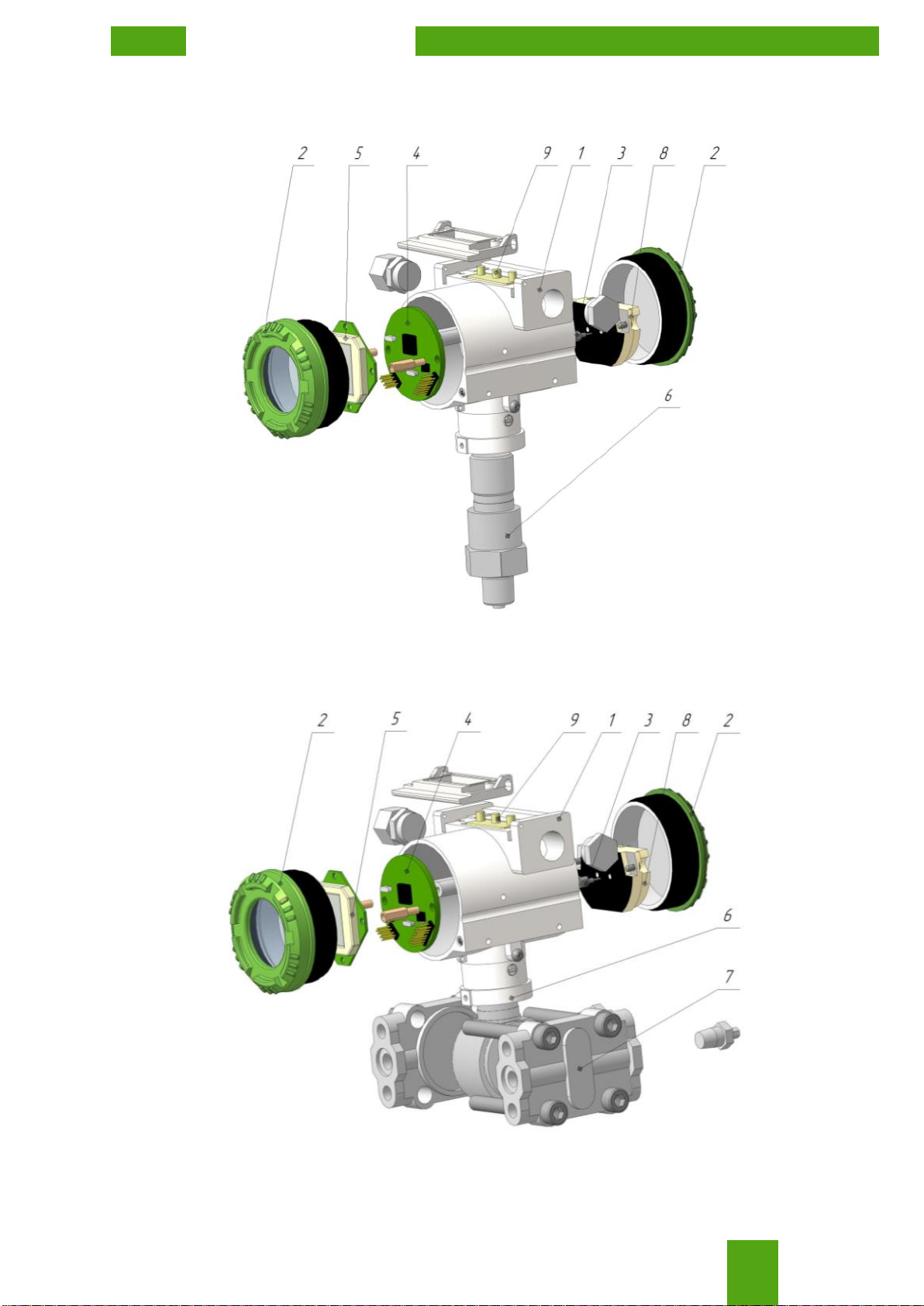

1.4 Configuration and operation

1.4.1 Transmitter structure is shown in the fig.2.

a) Transmitter with in-line mount connection

b) Transmitter with traditional mount connection

Fig.2 - Pressure transmitter structure

EMIS-BAR

OPERATION MANUAL

15

Pressure transmitter consists of pressure sensor and electronic unit (fig.2). Electronic unit is at-

tached to the threaded socket of the pressure sensor. Transmitter includes: electronic board (4), sealed

covers (2), LCD unit (5), RFI filters (3), terminal board (8), adjusting buttons (9).

The difference between the in-line mount and the traditional mount versions is in the design of

the pressure sensor (6). For in-line mount version, the pressure transmitter consists of a housing and a

socket, where the sensor and measuring diaphragm are located. For traditional mount version, the pres-

sure transmitter consists of the sensor with measuring diaphragms located at the positive side (high

pressure side) and the negative side (low pressure), flanges (7) and fasteners.

1.4.2 The transmitter work is based on a piezoresistive method of pressure measurement, which

is based on measuring the voltage difference across the resistances of the bridge circuit of an integrated

sensitive element made of single-crystal silicon under mechanical action. Sensor is fixed on the silicon

lining, which itself fixed on the measuring diaphragm. When the pressure of the working medium

changes, the geometry of the resistances of the Wheatstone bridge and the potential difference at its

outputs change. After double conversion of an analog-digital and digital-analog signal in the electronic

unit, amplification, filtering, modulation, the current signal at the output is proportional to the change in

the pressure of medium.

1.4.3 The structure allows to rotate transmitter for 270° around the common vertical axis, while

the rotation angle is limited to the design of the rotation assembly (fig.3).

After rotation is done, tighten the lock screw to avoid accidental rotation.

270º

Fig.3 - Transmitter rotation angle

1.4.4 LCD can be rotated for 360° with fixation at each 90° for convenient reading. To rotate

transmitter follow the steps below: unscrew two screws, pull up the display, rotate and put it back down,

screw two screws.

1.5 Pressure transmitter adjustment

1.5.1 To adjust the transmitter use the input buttons (fig. 4) located at the transmitter body.

The control unit is installed in the upper part of the housing and allows you to adjust the trans-

mitter in the hazardous area without violating the seal of the transmitter casing.

To access the buttons unscrew two screws in the upper side of the casing and fold back the plas-

tic cover. Use M button to navigate and «↑» and«↓» to change. To save changes in the nonvolatile de-

vice memory simultaneously press «↑» and «↓» buttons. After that Save will appear in the lower line of

the display.

Lock screw

EMIS-BAR

OPERATION MANUAL

16

Figure 4 - Input buttons

Follow the operating rules below:

To configure the device using the keyboard, unlock the input buttons.

The digital parameters of the device are always changed by successively increasing the value,

starting from the lowest digit of the displayed parameter Hold «↑» or «↓» to transfer to next digit. This is

used for rough adjustment within the wide range. For accurate adjustment release button «↑» or «↓»,then

press it again.

Any write commands via HART are disabled while the transmitter is being configured using

the buttons. Reading of measured parameters is allowed.

If more than two minutes have passed since the last press of the enter button, the entered set-

tings are automatically saved and the device enters the display mode.

1.5.2 LCD displays the following:

1 - measured pressure;

2 - selected units, parameter name in configuration mode, errors;

3 - quadratic dependence of the output signal;

4 - menu line and buttons lock mode;

5 - error symbol for "Under lower limit";

6 - measured pressure symbol;

7 - error symbol for "Over upper limit";

8 - communication indicator (blinking means that data are being transferred via HART).

Figure 5 - LCD display

Adjustable parameters are given in the Table 10.

Table 10 - Adjustable parameters

Parameter

Description

Adjustment

via

keyboard

via HART

Lower limit

Setup lower limit with reference pressure applied

(available for non-LCD versions).

+

+

Upper limit

Setup the upper limit of measurement with refer-

ence pressure applied (available for non-LCD ver-

sions).

+

+

Damping time

Setup damping time within stated limits.

+

+

Lower limit

Setup the lower limit without reference pressure.

+

+

EMIS-BAR

OPERATION MANUAL

17

Parameter

Description

Adjustment

via

keyboard

via HART

Upper limit of

measurement

Setup the upper limit without reference pressure.

+

+

Zero point

Setup zero value when no external pressure ap-

plied

+

+

Fixed value of

current

Setup fixed value of current 3,6; 4; 12; 20; 22;

22,8 mA.

+

+

Emergency current

value

Setup emergency current value according to NA-

MUR NE43 recommendations. Selection range:

3,6; 22,0; 22,8 mA.

+

+

Control lock

Keyboard lock and write protection.

+

+

Measuring units

Measuring units selection.

+

+

Pressure value

indication

Pressure indication mode: in stated units, as per-

centage of the measuring range, in current output

signal.

+

+

Output signal mode

Select output signal mode.

+

+

The point of applica-

tion of the quadratic

dependence of the

output signal

Setup quadratic dependence start point within 5 to

15% with step 0,1%.

+

+

Diagnostics function

Launch transmitter self-check.

-

+

Menu language

Available language options: Russian, English.

+

+

Inbuilt clock

Setup inbuilt clock.

-

+

Error log

See error log.

-

+

1.5.3 Menu structure is showed in the Table 11.

Table 11 - Menu structure

Menu

line

Parameter

Indication in Russian

Indication in English

-

Measured value normally displayed

01

Damping time

EMIS-BAR

OPERATION MANUAL

18

Table 11: continued

Menu

line

Parameter

Indication in Russian

Indication in English

02

Setup lower pressure limit in no-

pressure mode

03

Setup upper pressure limit in no-

pressure mode

04

Zero point adjustment

05

Fixed current value

06

Emergency current value

07

Control lock

EMIS-BAR

OPERATION MANUAL

19

Table 11: continued

Menu

line

Parameter

Parameter

Indication in Russian

Indication in English

08

Output signal

mode

Lineary-increasing

Lineary-decreasing

Linear until speci-

fied point, then

square

4mA until specified

point, then square

Linear kinked until

specified point,

then square

09

The point of application of the

quadratic dependence of the output

signal

EMIS-BAR

OPERATION MANUAL

20

Table 11: continued

Menu

line

Parameter

Indication in Russian

Indication in English

10

Pressure value

indication

Pressure

Output current

Percentage of

measuring range

11

Measuring units (Table 12)

12

Menu

language

Russian

English

1.5.4 Adjustment using buttons for LCD version:

01 - Damping time

Follow the steps below to select damping time:

Press "M" button to enter menu line 01 (Table 11).

Press «↑» and «↓» buttons to select required damping time.

Simultaneously press buttons «↑» and «↓»to save changes.

This manual suits for next models

18

Popular Transmitter manuals by other brands

Audio Limited

Audio Limited TX2040 user guide

GE Security

GE Security S700VT installation instructions

Becker

Becker Centronic EasyControl EC545 Assembly and operating instructions

WIKA

WIKA S-20 operating instructions

EnOcean

EnOcean PTM 200C user manual

Sennheiser

Sennheiser E W 300 IEM G2 Instructions for use