21063-510 : Portable Fire Exnguisher, 6 Kg ABC Powder

File name Type of document Fire Exnguisher Model Date Rele. Check Rev. Pag.

21063-510_Technical manual

Use and Maintenance technical manual

21063-510 27/09/2022 M.R 0

REPRODUCTION IS PROHIBITED

5 di 8

2) Do not through the re exnguisher on to the direct ames.

3) This re exnguisher is a pressurized vessel and must not be pierced, dented or subjected to external damage.

4) Do not direct the jet on the people.

Ref.

Periodicity

Step Operaons

5.1 12 Months Ispecon Check internal pressure using an independent tool

5.2 5 Years Maintenance

Check the uidity of exnguishing agent.

Check the thread of the valve body

and if a non-compliance is detected, replace it.

5.3 10 Years

Hydrotest

Cylinder

Check the conservaon status and perform the hydraulic test

of the cylinder with suitable tool.

Is recommended the replacement of the dispensing valve

5.4 *20 Years Is recommended the replacement of the re exnguisher

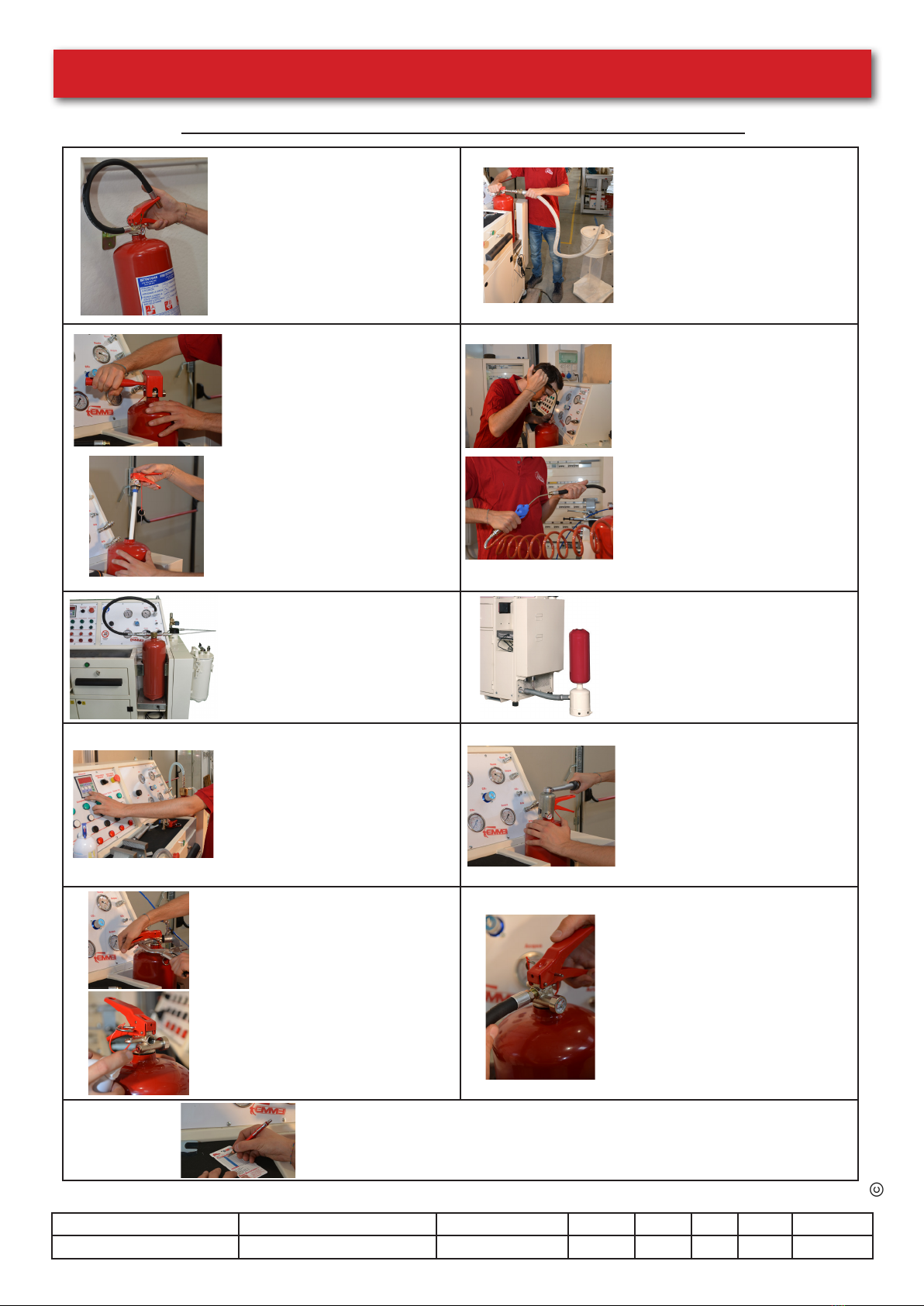

5.2) Maintenance Steps

1Remove the re exnguisher from the bracket and check the xing stability.

Check the marking label and replace it if damaged

2

Remove the hose and discharge the re exnguisher with suitable tool, comply at rules for a correct disposal

3

Remove the dispensing valve.

Check the uidity of exnguishing powder, that agglomerates are not present in the cylinder

(if powder is suitable, can be reused for recharge the re exnguisher)

4Check internally the cylinder that no shows corrosion signs.

For the hose, check the internal passage with compressed air

5Recharge the re exnguisher with exnguishing agent

6

Valve with

aluminum body

Check the thread of valve body with suitable tool and if damaged replace with a new valve.

For valves without safety device, replacement is recommended in any case.

Screw the valve with a ghtening torque as shown : min. 35 Nm - max 55 Nm

7Pressurize the re exnguisher with dehumidied air or nitrogen (15 bar at 20 °C) and check for leaks

8Reset the safety pin and secure it with safety seal, screw the hose

9Record the inspecon acvity on the maintenance tag and on the re protecon register

* If it located in parcular environments the ming can be reduced.

(it is recommended to reduce to 10 years)

N.B. : All the operaons must be calculated from the date of placing on the market.

For the hydraulic test refer to the date stamped on the tank.

5.1) Inspecon Steps

1Remove the re exnguisher from the bracket and check the xing stability

2Check the internal pressure with an independent tool

3Check the safety seal and the safety pin

4 Remove the hose and check the correct internal passage with compressed air

5Record the inspecon acvity on the maintenance tag and on the re protecon register

5) STEPS AND FREQUENCY RELATED TO MAINTENANCE OPERATIONS

(For stored pressure re exnguishers)

Note: The user have to complies to the naonal or internaonal rules, if they are more restricve of the below table

Table 2