The air piping from the blower should have a minimum cross sectional area equal to blower discharge.

It is preferred that a higher size of pipeline should be used. For example, if rectangular opening of the

blower has got a discharge area equal to 100 mm dia a pipeline of 150 mm dia may be used. This is

to ensure that there is a minimum pressure drop in the pipeline.

The pressure drop between blower and the farthest burner should not exceed 50 mm water gauge.

There should be a minimum number of bends, elbows and valves in the pipeline to ensure that the

pressure drop is kept at the lowest.

No elbow or bend should be placed within four pipe diameters distance from the burner inlet in order

to ensure that the air enters the burner without any turbulence. The branch lines connected to the

burner should be of one size larger than the burner inlet and finally reducing its size near the burner.

Each burner should be fitted with a separate butterfly valve to control the air supply.

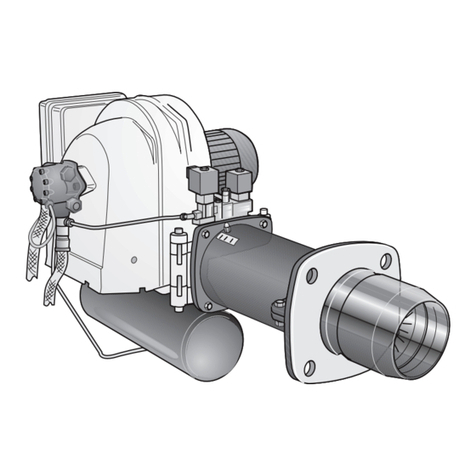

Atomising air connections should be given to the burner with the help of flexible hose pipe by giving

from the main air pipe, before butterfly valve, as indicated in the figure. The flow of atomising air should

not be controlled and it should always be full open.

(c) Oil connections

The size of the pipeline from the line heater or from the heating & pumping unit should be of adequate

size to avoid pressure drop and the size should be reduced nearer to the burner inlet. The oil should

be pumped to the burners through a composite heating pumping unit. Oil pressure near the burner

should be between 1 kg/cm² to 1.5 kg/cm².

ENCON ‘Film’ Burners are designed for furnace oil of viscosity of upto 200 seconds R.I. Furnace oil

of viscosity 1500 seconds R.I. at 380C. (presently available in the country) needs preheating to a

temperature of about 90-1000C, for getting the desired viscosity at burner tip.

A ‘Y’ strainer of 15 mesh should be used just before the burners. If there are two or more numbers of

burners near each other, a common ‘Y’ strainer can be used.

If the burner is to be used with heavy fuel oil requiring heating before atomisation, draining facilities

should be provided. This will help the draining of hot oil between the heater and burner, when the

furnace is not in use. Lights oils, such as LDO and HSD do not require such draining facility.

Micro valve should be fitted with each burner for the fine control of oil flow rate. ENCON micro valve

is designed for fitting directly on the burner oil inlet.

III. OPERATION

Important :

Keep doors & damper in open condition before firing burners, Ensure the furnace chamber is free of

combustible gases.

A. Starting of a new burner

a. Before lighting up the burner, the burner block is to be heated by open flame, such as, kerosene

soaked cloth introduced through the air opening of the burner. The preheating of burner block

should be continued for 10-15 minutes.

b. Start the heating & pumping unit and allow the oil to circulate within ring main till furnace oil attains

a temperature of 900C - 1000C.

c. Start the blower and allow air to pass through the burner.

d. After starting the air supply to the burners, open the micro valve and allow furnace oil supply to

the burners. The micro valve should be opened very steadly and slowly to the minimum desired

level. Normally, the steady flame will be achieved at position three of the micro valve, kerosene

soaked cloth should continue to the burn till the flame stabilises.

e. Allow the combustion to continue at the minimum level for about 5 minutes and then slightly

increase the flow of oil to the desired level, keeping the supply of air full open.

B. Shut down of the burner

a. Close the micro valve and stop the oil supply to the burner.

b. After about one minute, close the butterfly valve in the air line or stop the blower and close the

air ports of the burner.

Insert the shield to protect the burner choking due to cracking of fuel oil left over in the burner by

the furnace heat.

C. Restarting of burner

a. Remove the shield from the front of burner and keep the air sleeve open.

b. Start the blower and allow the air to enter the burner with butterfly valve fully open.

c. If the furnace is already hot (min. 7000C) open the micro valve slowly. The oil will automatically

ignite and stable flame will be established.

d. If the furnace is cold, follow the same procedure as mentioned above for starting the new burner.

IV. BURNER CLEANING

a. Remove the primary air connection.

b. Open the four bolts of spray gun holder (5).

c. Remove oil connection from the micro valve.

d. Take out the oil spray gun assembly consisting of inner tube, outer tube and spray gun holder.

e. Dismantle all the components, such as, lock nuts (7&9), inner tube (6), outer tube (8) and air

swirler (10).

f. The inner tube (6), outer tube (8) and air swirler (10) should be kept immersed in kerosene for

about 15 minutes.

g. Clean all these components with the help of soft cloth and remove all the carbon deposit.

h. Reassemble the oil spray gun assembly and ensure that the distance ‘X’ is maintained as desired

and tighten the lock nuts.

i. Ensure that asbestos rope packing is provided before tightening the collar cum lock nut (7) to avoid

any oil leakage.

j. Fix the oil spray gun assembly in the burner and tighten the bolts. Check that gasket in between

the oil spray gun holder and the air tube (4) is not damaged. Change the gasket if required.

k. Reconnect the primary air hose and the micro valve assembly. Ensure that the micro valve is

cleaned by flushing with kerosene before it is fitted.

ENCON THERMAL ENGINEERS (P) LTD. ENCON THERMAL ENGINEERS (P) LTD.