Enconnex EdgeRack 3P Series User manual

EdgeRack 3P Series

USER MANUAL

Legal Disclaimer

This publication has been compiled in good faith by Enconnex LLC. The

information presented in this manual is not warranted by Enconnex to be

authoritative, error-free, or complete. This publication is not meant to be a

substitute for a detailed operational and site-specific development plan.

Enconnex assumes no liability for damages, violations of codes, improper

installation, system failures, or any other problems that could arise based on

the use of this publication.

In no event shall Enconnex LLC, its officers, its directors, or its employees

be liable for any direct, indirect, consequential, punitive, special, or

incidental damages (including, without limitation, damages for loss of

business, contracts, revenue, data, information, or business interruption)

resulting from, arising from, or in connection with the use of, or inability to

use this publication or the content, even if Enconnex has been expressly

advised of the possibility of such damages.

Enconnex reserves the right to make changes or updates with respect to or

in the content of the publication or the format thereof at any time without

notice. Copyright, intellectual, and all other proprietary rights in the content

(including but not limited to software, audio, video, text, and photographs)

rest with Enconnex or its licensors. All rights in the content not expressly

granted herein are reserved. No rights of any kind are licensed or assigned

or shall otherwise pass to persons accessing this information.

Copyright by ENCONNEX Co. Ltd

This publication shall not be for resale in whole or in part. No organization or

individual shall extract and/or duplicate this document in any form without

written permission from Enconnex.

1

Notice

Enconnex is not responsible for damages to the unit or personal injury due

to noncompliance with operation requirements as outlined in this document.

●This User Manual must be strictly complied with at the time of

installation and throughout the life of the EdgeRack 3P and the

integrated cooling unit.

●Operation of the cooling unit equipment must be completed by

professionals who are familiar with this manual.

●Only technicians that have received professional training from

Enconnex may service the system.

●Power to the EdgeRack 3P must be shut off if internal maintenance of

the equipment is required.

●Warranty of the equipment is ensured only under the premise that the

contents included in this manual are complied with.

●Parameters included in this manual are only to be used as a reference.

Enconnex reserves the right to change the parameters without prior

notice.

●In case of a lost, damaged, or misplaced manual, a replacement copy

can be requested from the Enconnex website, www.enconnex.com.

●This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge unless they have been given supervision or

instruction concerning the use of the appliance by a person responsible

for their safety.

●Children should be supervised to ensure that they do not play with the

appliance.

●This appliance can be used by children aged 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or

instruction concerning the use of the appliance safely and understand

the hazards involved. Children shall not play with the appliance.

2

Cleaning and user maintenance shall not be performed by children

without supervision.

●If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent, or similarly qualified persons to avoid a hazard.

Enconnex LLC

Address: 4670 Aircenter Circle, Reno, NV 89502, USA

Website: www.enconnex.com

Customer service mailbox: [email protected]

Customer service number: +1 510 651 2205

3

Table of Contents

Legal Disclaimer 1

Copyright by ENCONNEX Co. Ltd 2

Notice 2

Table of Contents 4

1. General Safety Precautions 6

1.1. Overview 6

1.2. Local Rules and Regulations 6

1.3. Basic Installation Requirements 6

2. Product Overview 7

2.1. Appearance 7

2.2. Specifications 8

2.3. Components 8

2.4. Environmental requirements 11

2.4.1. Operating conditions 11

2.4.2. Storage Environment 11

2.5. Space 12

2.6. Weight capacity 14

3. Installation 15

3.1. Installation Instructions 15

3.1.1. Tools 15

3.1.2. Accessories 16

3.1.3. Self-Prepared Materials 16

3.2. Equipment transportation, unpacking, inspection 16

3.2.1. Transportation & Movement 16

3.2.2. Unpacking 20

3.3. Installation 21

3.3.1. Installing the cabinet 21

3.3.2. Installation of cooling accessories 23

3.3.3. Install the air duct 23

3.3.4. Connect the power cable 24

3.3.5. Network connection 24

3.4. Power-up and Shutdown Procedure 25

3.4.1. Inspection 25

3.4.2. Power-up procedure 25

3.4.3. Access control setting 27

3.4.4. Shutdown 28

4. Management System 30

4

4.1. Network Switch 30

4.2. Management system interface 30

4.2.1. Home page 31

4.2.2. Equipment-UPS 32

4.2.3. Equipment-Cooling 33

4.2.4. Equipment-Environment 34

4.2.5. Setting-Environment 34

4.2.6. Setting-Cooling 36

4.2.7. Log 36

4.2.8. Alarm 37

4.2.9. System 38

4.2.10. Remote access 38

5. Maintenance 39

5.1. Cooling system maintenance 39

5.2. UPS system maintenance 39

5.2.1. Check the UPS status 39

5.2.2. Replace the battery 40

5.3. Alarm reference 40

5.4. Troubleshooting 44

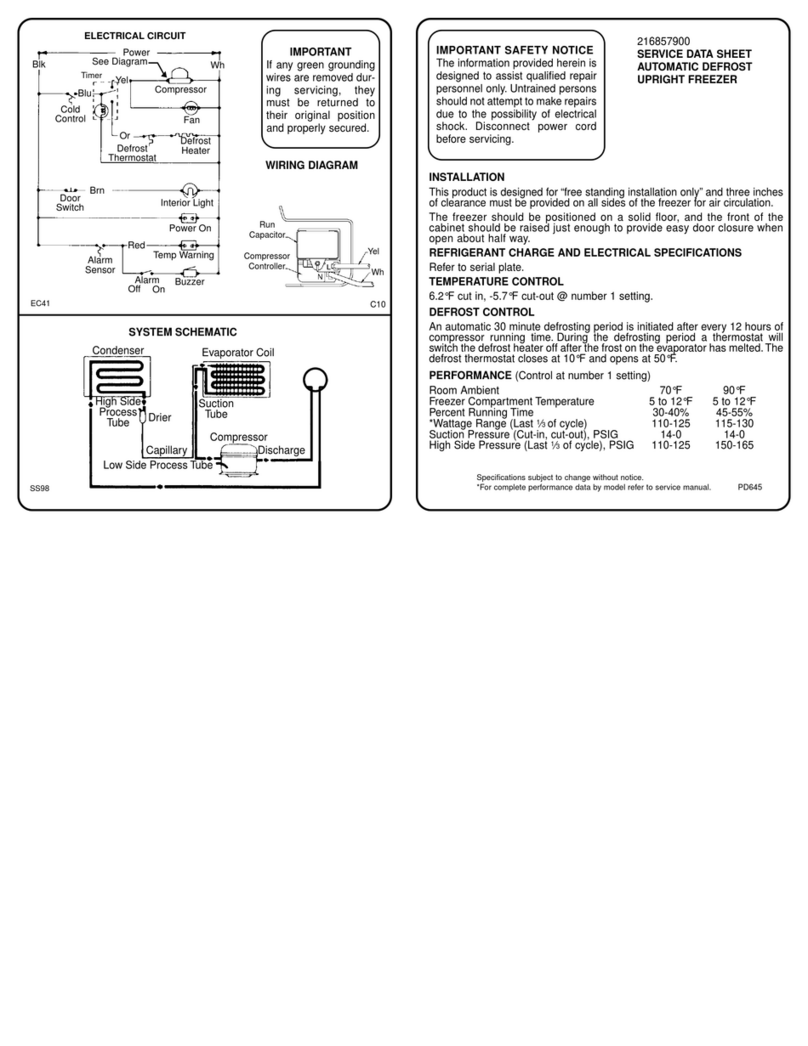

5.5. Electrical system layout 48

5

1. General Safety Precautions

1.1 Overview

Enconnex is not responsible for any of the following situations:

• Operation of equipment in adverse environments beyond the manual

instructions.

• Any installation and operation environment beyond regulations of any

relevant international standards.

• Altering of the product or changes in the software without prior

approval.

• Failure to follow the product and manual’s operational instructions and

safety warnings. See the end of this manual for further details.

• Equipment damage caused by natural disasters.

1.2 Local Rules and Regulations

Local rules and regulations should be followed during equipment operation.

Safety precautions in the manual serve as a supplementary guide to local

safety specifications.

1.3 Basic Installation Requirements

Personnel performing the EdgeRack 3P installation and maintenance must

receive authorized training.

• Equipment installation, operation, and maintenance can only be

conducted by qualified and trained people.

• Replacing and changing equipment or components (including software)

must be completed by professionals with Enconnex certification or

authorization.

• Operators should immediately report faults or errors which may cause

safety issues.

6

2. Product Overview

The EdgeRack 3P Series Secure Integrated Cabinet from Enconnex is a fully

integrated enclosure system that provides the power, cooling, management, and

security you need in a small footprint. Equipped with 3.5 kW of cooling, power

management, environmental sensors, remote monitoring, and intuitive controls, this

turn-key solution is 100% ready to be outfitted with whatever equipment you need for

your business to be successful. The EdgeRack 3P is ideal for areas where space is

limited and/or heat levels could be a concern and is a perfect solution for small to

medium offices, retail outlets, educational institutions, and remote edge computing

locations.

2.1. Appearance

Figure 2-1 Appearance of EdgeRack 3P

7

2.2. Specifications

Table 2-1 Specifications

Model

ECX-ER3P-42UXX

UPS

3 kVA

Input power

208~240 V 50/60 Hz

Usable IT space

26U

Rated Cooling capacity

3.5 kW

Dimension (W x D x H)

600 mm x 1100 mm x 2025 mm

Net weight

330 kg

2.3. Components

The Edge Rack 3P product mainly includes a cabinet structure, power distribution

module (PDM), UPS & Battery, cooling units, emergency ventilation system, monitoring

system, and LCD display. The system components are shown in Figure 2-2 and Table

2-2

Figure 2-2 Components

8

Table 2-2 EdgeRack 3P Main components

No.

Component Name

Part number

Functions

1

Cooling unit

ECX-EdgeRack

3P-001

The cooling unit provides clean

air for stable temperature and

humidity to critical load

equipment.

2

Temp & Humidity

sensor

ECX-EdgeRack

3P-002

Detects the temperature and

humidity of the cold air output.

3

Blanking panel

ECX-EdgeRack

3P-003

This allows for hot and cold

airflow isolation improving the

cool air utilization.

4

Integrated HMI screen

ECX-EdgeRack

3P-004

The touch-screen HMI

monitors, controls, and alarms

all the components, including

the UPS, cooling unit,

temperature and humidity

sensors, door switch, leak

detector, and other dry

contacts. All information can be

monitored remotely by the

network. For details, refer to

the monitoring system chapter.

5

Access control

ECX-EdgeRack

3P-005

This provides keypad and

fingerprint access to the

EdgeRack at the front and rear

doors.

6

Double-layered glass

door

ECX-EdgeRack

3P-006

Isolate the inside and outside

of the cabinet and protect the

equipment in the cabinet.

7

UPS

ECX-EdgeRack

3P-007

The UPS provides power

conditioning and switches to a

backup battery when mains

power is lost.

8

Battery

ECX-EdgeRack

3P-008

The battery provides backup

power through the UPS when

mains power is lost and

charges when mains is

restored.

9

Power distribution

module

ECX-EdgeRack

3P-009

Power distribution for critical

load equipment and EdgeRack

9

equipment.

10

Casters

ECX-EdgeRack

3P-010

The installed casters provide

for easy maneuverability.

11

Leveling feet

ECX-EdgeRack

3P-011

The feet are adjustable for

installation on slightly uneven

floors.

12

Water leakage sensor

ECX-EdgeRack

3P-012

This provides an alarm if a

water leak is detected at the

bottom of the EdgeRack.

13

Access control box

ECX-EdgeRack

3P-014

For access control

communication, control the

opening and closing of the

door.

14

Cable management

ECX-EdgeRack

3P-014

It is used for cable sorting and

fixing to make the cable tidier

and more standardized.

15

PDU

ECX-EdgeRack

3P-015

This provides integral power

distribution for user-installed

equipment.

16

Smoke sensor

ECX-EdgeRack

3P-016

The smoke sensor provides

alerts when activated.

17

Steel split doors

ECX-EdgeRack

3P-017

Isolate the inside and outside

of the cabinet and protect the

equipment in the cabinet.

18

Network switch

ECX-EdgeRack

3P-018

Installed for network

connection communication.

19

Mag-locks

ECX-EdgeRack

3P-019

The magnetic locks allow for

emergency ventilation in

over-heating conditions.

20

Cabinet side panel

ECX-EdgeRack

3P-020

Isolate the inside and outside

of the cabinet and protect the

equipment in the cabinet.

10

2.4. Environmental requirements

2.4.1. Operating conditions

The installation location for EdgeRack 3P should be easily accessed, away from

heat, direct sunlight, and corrosive gasses. Operating conditions are shown in

Table 2-3.

Table 2-3 Operating conditions

Items

Requirement

Temperature

18℃~45℃

Humidity

20%~80%

Altitude

Altitude < 1000 m, above 1000 m

derating capacity, power derating 6%

per kilometer

Rated voltage

208~240 V 50/60 Hz

Note

• During operation in high temperature and high humidity environments, there may be

condensation on the external surface of the front glass door. However, it is a normal

phenomenon and doesn’t affect the operations or usage.

• Derating is required for altitudes above 1000 m. For the UPS, the altitude should be

less than 1500 m. Derating is required for altitudes above 1500 m with reference to

local standards.

2.4.2. Storage Environment

Table 2-4 Storage Environment

Items

Requirement

Environment

Clean (no dust), good ventilation

Environment Temperature

-40℃~+60℃

Environment humidity

5%RH~95%RH without

condensation

11

2.5. Space

There must be sufficient space for installation, service, and maintenance of the

EdgeRack 3P unit. The figure below shows the area required on the front and rear

sides of the EdgeRack 3P unit.

A clearance of at least 2.6 ft (800 mm) is recommended on all sides of the installed

EdgeRack 3P. 2.6 ft (800 mm) is also recommended between adjacent EdgeRack

3P units. At least 400 mm space shall be reserved on the top of the unit.

Figure 2-3 Before opening the enclosure, the space required for the rear door

Edge Rack 3P model product space requirements inside the room where it is to be

installed are mentioned in the figure below.

12

Figure 2-4 Model space requirements

Figure 2-5: Top space requirements

13

2.6. Weight capacity

The EdgeRack 3P product is heavy equipment, and therefore, the weight-bearing

capacity of the computer room floor must be considered.

However, during installation, the weight-bearing capacity of the floor should also be

estimated based on the cabinet’s total weight, which also includes the installed

equipment.

Note

If the weight-bearing capacity cannot be estimated, consult the nearest ENCONNEX

office or the customer service/support center.

14

3. Installation

3.1. Installation Instructions

Please install the equipment in strict accordance with these requirements to

achieve the best operation and longest lifetime.

●Before installation, ensure that the installation environment complies with the

requirements and that the building is suitable for electrical wiring and air duct

construction.

●The installation shall strictly follow the design drawings with maintenance

space reserved.

Note

● Ensure the installation location is capable of supporting the total weight of a

fully-loaded EdgeRack.

● To ensure proper airflow, prepare to use blanking panels on the front in RU

spaces not occupied by IT equipment.

● It is recommended that the EdgeRack be installed in a room that does not have

employees working on a continual basis. The cooling runs at about 62 dBA.

3.1.1. Tools

Table 3-1 shows the usual tools used during the installation process.

Table 3-1 Install Tools

Name

Drawing

Name

Drawing

Level

Philips

screwdriver

Stepladder

Electric drill

Electric

Forklift

Hand forklift

15

3.1.2. Accessories

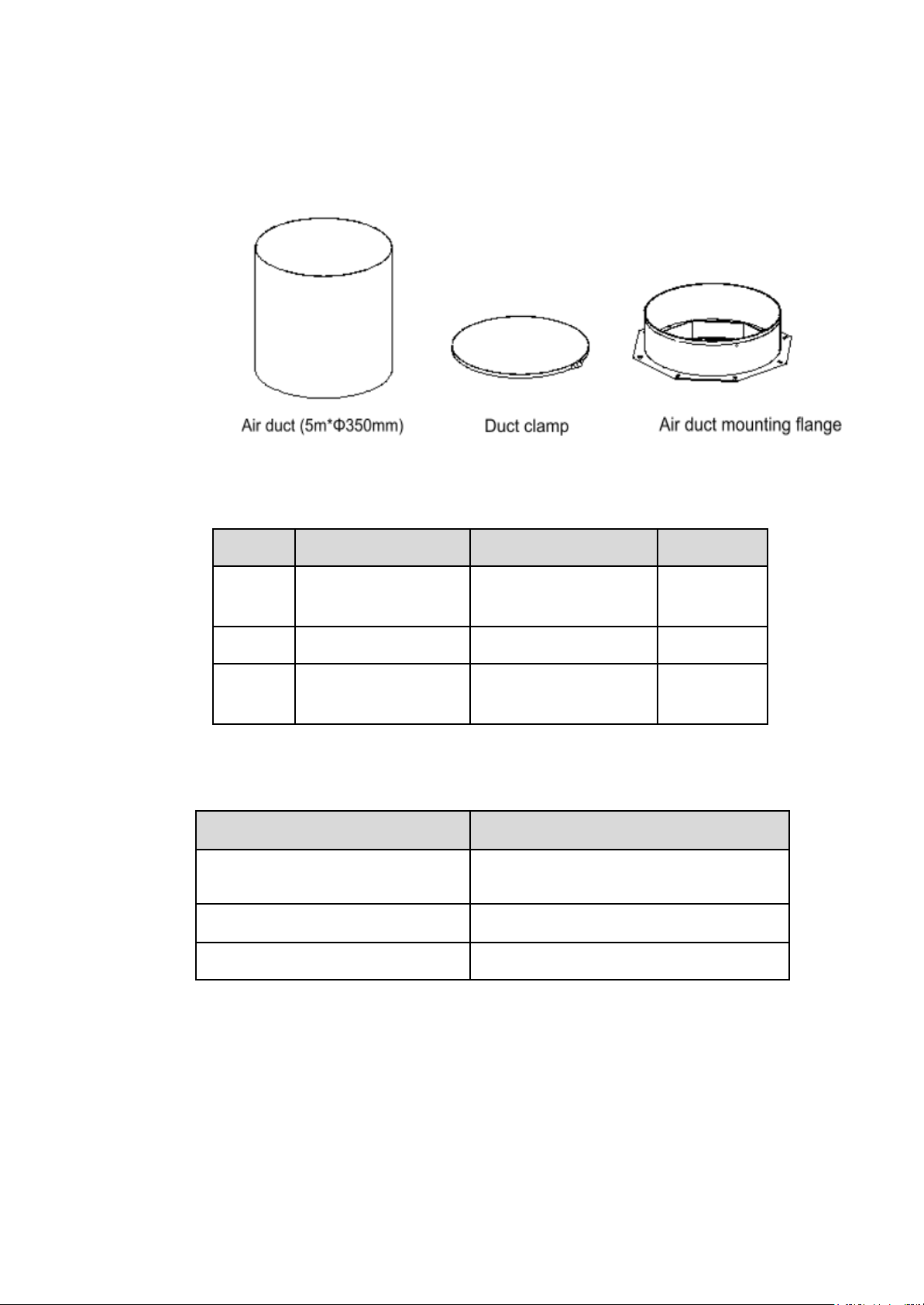

Figure 3-1 Accessories

Table 3-2 Accessories

No.

Product Name

Material

Quantity

1

Air duct

(5m x Φ350mm)

Nylon + Steel wire

1

2

Duct clamp

Metal

1

3

Air duct mounting

flange

Metal

1

3.1.3. Self-Prepared Materials

Please prepare the below materials before operating the unit.

Table 3-3 Self-Prepared Materials

Parts

Specifications

Plug

EU: 2 * IEC30916 (16A)

US: 2 * L6-20P (20A)

Power wire cable

4 mm2

Network cable

CAT6

3.2. Equipment transportation, unpacking, inspection

3.2.1. Transportation & Movement

The EdgeRack should be considered fragile and care must be taken during

transport, handling, and installation.

16

The appearance of the entire package, including all the components, is

shown in Figure 3-2.

Figure 3-2 Package inclusive of components

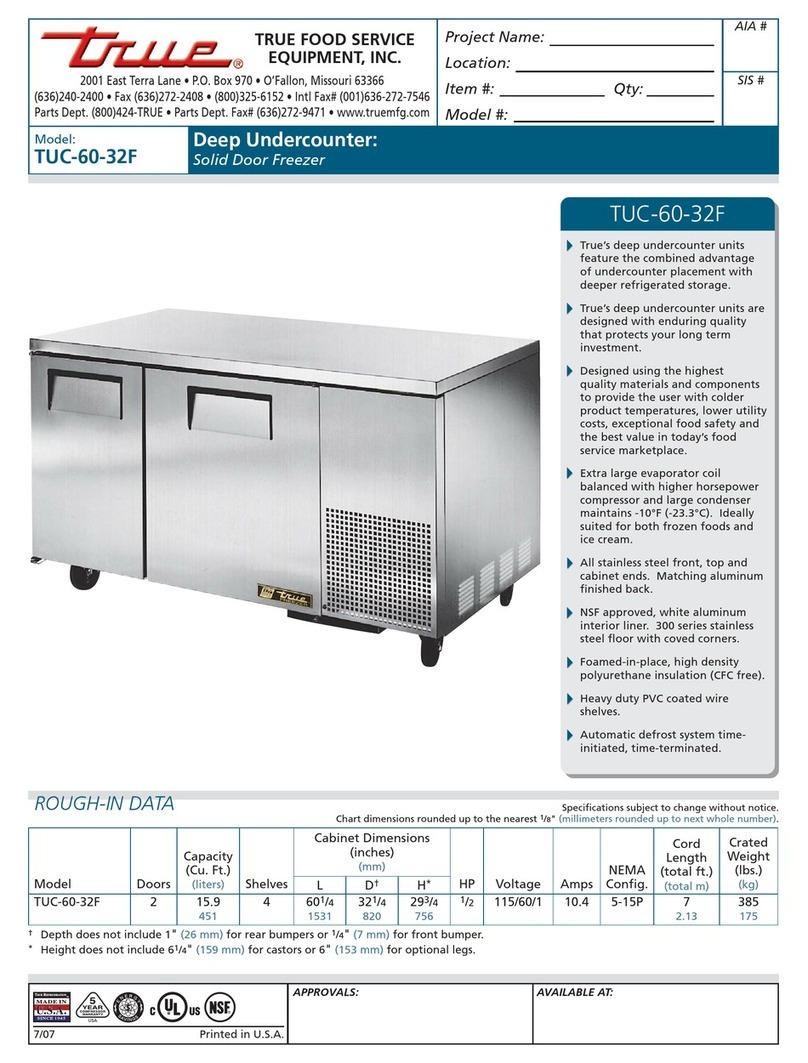

Table 3-4 Shipping Dimensions of the unit

Item

Package

Shipping Dimension (unit:

mm)

Shipping

Weight (unit:

kg)

W

D

H

EdgeRack 3P

Wooden

710

1210

2180

374

The EdgeRack 3P, including the cabinet, closed frames, and the cooling unit,

needs to be moved to the vicinity of the installation site. EdgeRack 3P, as a

piece of equipment with large components, is on the heavier side and needs to

be transported using equipment such as a hand pallet truck or electric forklift.

Figure 3-3 shows the schematic diagram of a hand pallet truck and an electric

forklift.

Figure 3-3 Hand Pallet Truck & an Electric Forklift

17

When using a hand pallet truck or an electric forklift truck, the tines of the hand

pallet or electric forklift must be aligned with the center of gravity to prevent the

package from toppling or falling over, as shown in Figure 3-4.

Figure 3-4 Forklift Direction

During transportation and installation, in order to avoid pipes from being

damaged and refrigerant from leaking, the equipment should not be

excessively jolted or tipped.

Warning: After transportation, like any refrigerant system, you must keep it in

its final location for some hours before starting up.

●Transportation inclination shall not exceed 15 °. Stay for 8 hours before

starting up.

18

Figure 3-5 Carrying obliquity

Note

●Ensure that the equipment stands upright. Do not place the equipment

outdoors.

●While using the forklift or the hand pallet truck, ensure that the fork arms

(if adjustable and flexible) open to the greatest extent, ensuring that the

fork arms can be placed under the pallet of the equipment in a precise

manner.

●Ensure that the length of the fork arms matches with the equipment.

●Use mechanical handling tools such as forklifts or pallet jacks during the

unloading and moving process. Place the unit in the middle to guarantee

symmetry. It is important to move slowly and carefully to prevent dents

and scratches to the equipment.

●Check the quantity and type for accessories according to the packing list.

In case of missing accessories or nonconformity of models, please keep

field records and immediately contact the Enconnex Customer Service

Center or representative.

●Be careful when moving the EdgeRack after it has been operating. The

condensation tray may contain water that must be drained out before

moving the EdgeRack. Take similar steps when moving the EdgeRack as

was taken during the initial installation.

19

This manual suits for next models

1

Table of contents

Popular Freezer manuals by other brands

True

True TUC-60-32F Specifications

Electrolux

Electrolux EU 6921 C Installation and instruction manual

Hotpoint

Hotpoint FZM80 Instructions for installation and use

Frigomat

Frigomat Ketty 05 Series Manual of use and maintenance

Fridgemaster

Fridgemaster MUZ4965 How to use

Electrolux

Electrolux ENT3FF18S user manual