ENDEVCO 7310A User manual

IM7310A Rev A

April 7th, 2020

7310A

Angular Rate Sensor

IM7310A

Instruction manual

IM7310A Rev A 2

April 7th, 2020

SAFETY CONSIDERATIONS

Model 7310A Angular Rate Sensor Is declared to fully comply with EU Council Directives:

LowVoltage Directive, 2014/35/EU - Compliant

EMC Directive, 2014/30/EU - Compliant

RoHS Directive, 2011/65/EU and2015/863(RoHS3)- Compliant

The Product listed above is manufactured byEndevco, Inc. and is declared to comply with the noted Product Safety and

Environmental Standards when installed and operated in accordance with the Manufacturer’s instructions provided.

The product is declared to comply by design, testing and 3rd party evaluation (when necessary). The certification

program management, product safety testing, EMC testing and evaluations were provided by Endevco, Inc. or an

Outsourced 3rd Party Provider. RoHS compliance declared by evaluation of product and materials used and exemptions

granted to test instruments. The product is eligible to bear and display the CE mark. All safety and EMC standards

listed beloware the latest revision in force at the time and date tests and evaluations were conducted.

EMC standards

EN 55011, Class A conducted and radiated RF emissions

EN 61000-3-2 Harmonic currentemissions EN 61000-3-3 Voltage fluctuations and flicker

EN 61000-4-2 Electrostatic discharge immunity EN 61000-4-3 Radiated electromagnetic field immunity

EN 61000-4-4 Fast transient burst immunity EN 61000-4-6 Conducted RF immunity

EN 61000-4-11 Voltage dips, short interrupts and variations

Safetystandard

EN/IEC 61010-1; Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 1

This manual contains information and warnings that must be followed to ensure safety of personnel and the safe

operation of the product.

Warnings:

Switch off all power to equipment before connecting or disconnecting the product. Failure to do so may cause

damage to the product.

Any adjustment, maintenance or repair, other than detailed within this manual, must be carried out by trained service

personnel.

If it is suspected that the correct operation of the equipment is threatened, impaired or otherwise, it must be made

safe and free from further operation until the threat has been removed.

To return unwanted product for disposal, please contact your local Endevco representative.

IM7310A Rev A 3

April 7th, 2020

1.0 Table of Contents

1.0 Table of Contents..........................................................................................................................................................................3

2.0 Product Description ......................................................................................................................................................................4

3.0 Materials Required .......................................................................................................................................................................4

4.0 Pre-installation Check-up..............................................................................................................................................................4

5.0 Mounting ......................................................................................................................................................................................4

5.1. Mounting Surface.....................................................................................................................................................................5

5.2. Screw Mount ............................................................................................................................................................................5

5.3. Adhesive Mount .......................................................................................................................................................................6

5.4. Cable.........................................................................................................................................................................................6

5.5. Electrical Connection................................................................................................................................................................6

5.6. Triaxial Mount ..........................................................................................................................................................................6

5.7. 6DoF Mount..............................................................................................................................................................................7

6.0 Electrical Precautions....................................................................................................................................................................8

6.1. Excitation Voltage.....................................................................................................................................................................8

6.2. Signal Leads ..............................................................................................................................................................................8

6.3. Grounding.................................................................................................................................................................................8

6.4. Signal Conditioning...................................................................................................................................................................8

7.0 Recalibration.................................................................................................................................................................................9

8.0 Questions......................................................................................................................................................................................9

IM7310A Rev A 4

April 7th, 2020

2.0 Product Description

The ENDEVCO Model 7310A is an angular rate sensor that utilizes unique silicon MEMS gyroscope technologies with custom

electronics and packaging and provides reliable sensing performance even under excessive shock and vibration

environments. This angular rate sensor is designed specifically for automotive safety testing and other system designs

requiring accurate measurement of angular velocity. As is the practice with all instrumentation, certain electrical

precautions should be followed with pre-installation check-up, mounting and recalibration.

3.0 Materials Required

All the materials used in the mounting of the Model 7310A angular rate sensor are supplied with the unit in the shipping

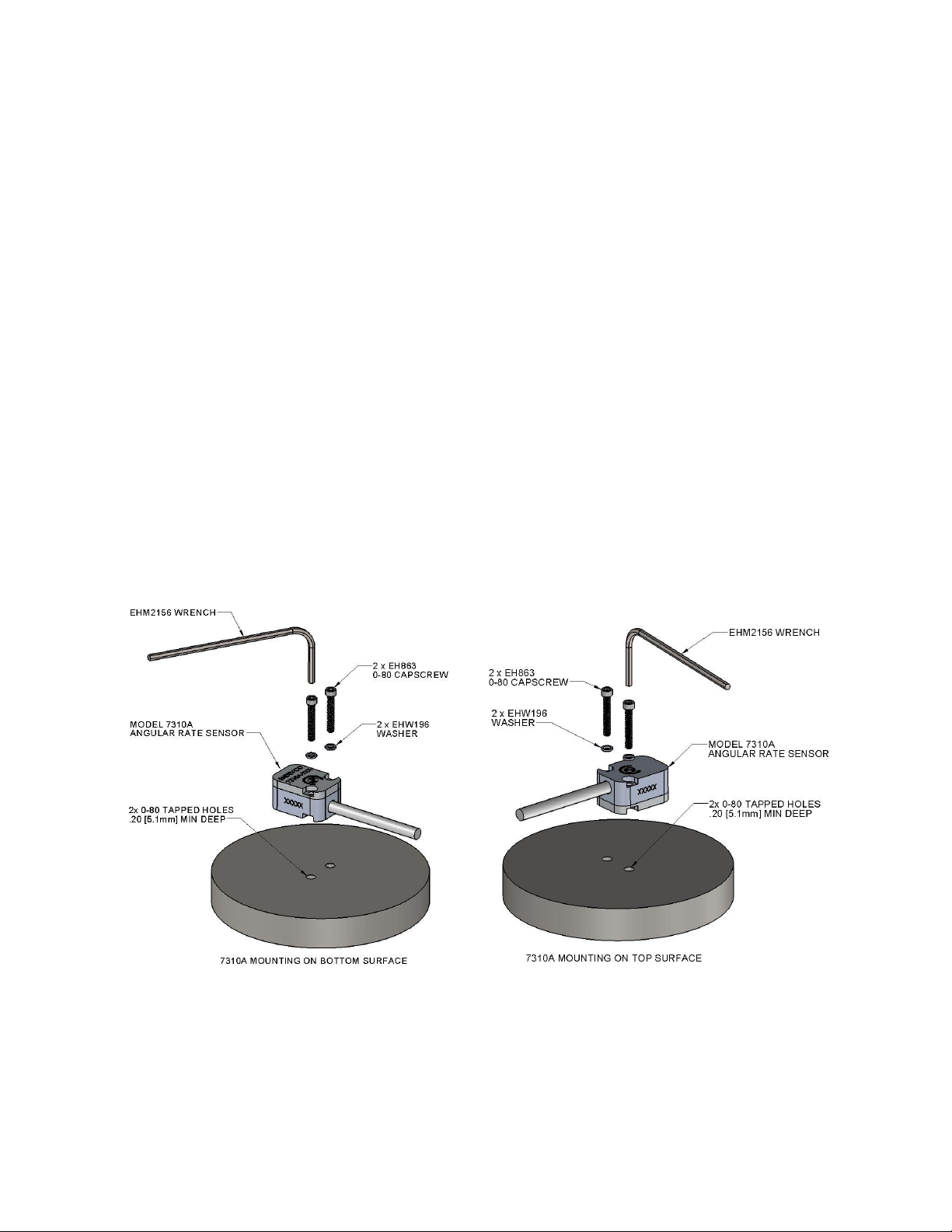

container. These materials, as shown in Figure 1, include:

(1) Allen wrench for 0-80 screws- Endevco P/N EHM2156 (1pc)

(2) 0-80 x 3/8 inch Socket Head Cap Screws- Endevco P/N EH863 (2pc)

(3) Size 0, Flat Washers- Endevco P/N EHW196 (2pc)

For triaxial angular rate measurements, or Six Degrees of Freedom (6DoF) measurements, the user should consider the

Model 7930 Triax & Six Degrees of Freedom Mounting Block which is available as an optional accessory.

4.0 Pre-installation Check-up

Before installation of the angular rate sensor, it should be checked to insure proper operation. A simple Output Voltage

test can be conducted with minimal test equipment. Place the unit on the flat surface of a vibration-free table top, apply

the specified excitation voltage to the angular rate sensor (see data sheet for proper wiring hook-up) and measure the

output with a voltage meter. Allow the unit to warm-up for one minute before the output voltage measurement.

The output voltage should be measured on the three tests listed in Table 1. The voltage of +OUT(Green) and –OUT(WHITE)

with respect to GND(Black) should fall in range of +2.3V ~ +2.6V, and the voltage of +OUT(Green) with respect to –

OUT(White) should be within -100mV ~ +100mV.

Table 1. Output Voltae test for sensor check-out

If this initial check does not give a proper reading, which indicates a possible malfunction, and the reason for the erroneous

reading cannot be found, please contact mailto:sales@endevco.com for troubleshooting or return.

5.0 Mounting

When mounting the Model 7310A angular rate sensor, it is best to utilize the proper techniques and tools listed to ensure

optimum performance. For triaxial angular rate measurements and 6DoF measurements, the Model 7930 Triaxial

Mounting Block is available - see paragraph 5.6 and 5.7 below.

Connection

Voltage

+OUT(Green) with respect to GND(Black)

+2.3V ~ +2.6V

-OUT(White) with respect to GND(Black)

+2.3V ~ +2.6V

+OUT(Green) with respect to –OUT(White)

-100mV ~ +100mV

IM7310A Rev A 5

April 7th, 2020

5.1. Mounting Surface

The mounting surface should be clean and free of burrs. Two #0-80 tapped holes, 0.2 inch minimum depth should be

spaced 0.3 inches (7.62 mm) apart. A 32 micro inch rms surface finish with flatness of 0.0001 inches is

recommended for the area that will contact the angular rate sensor. The rotational axis of the unit is perpendicular

to the mounting surface, so the angular alignment of the two mounting holes is not critical. The location of the

mounting holes is not critical either, the angular rate sensor can be mounted at the center or close to the edge of the

mounting surface of the rotational substrate.

5.2. Screw Mount

To screw mount Model 7310A to mounting surface, use the supplied mounting washers (EHX196, 18-8 CRES),

mounting screws (EH863, 0-80 x 3/8’’, alloy steel, black oxide finish) and Allen wrench (EHM2156, alloy steel, black

oxide finish) as shown in Figure 1.

Remove the unit from the shipping container. Place the unit on the mounting surface and align the mounting holes.

Slide the washers over the screws. Using the supplied wrench or a torque wrench, tighten the screws to 4 lbf-in (0.45

Nm). This is roughly equivalent to finger tight with the supplied wrench.

The Model 7310A angular rate sensor can be mounted on either the bottom surface of the sensor, as shown in Figure

1(a), or the top surface of the sensor, as shown in Figure 1(b). The rotation arrow mark printed on the top and

bottom surface of the angular rate sensor indicates the positive rotation direction. When mounted on bottom

surface, the angular rate sensor outputs a positive voltage in response to a clockwise rotation. When mounted on

top surface, the angular rate sensor outputs a positive voltage to an anti-clockwise rotation.

FIGURE 1 (Left) Screw Mount of Model 7310A Angular Rate Sensor (on sensor bottom)

(Right) Screw Mount of Model 7310A Angular Rate Sensor (on sensor top)

IM7310A Rev A 6

April 7th, 2020

5.3. Adhesive Mount

Model 7310A angular rate sensor can be mounted by adhesives too. Adhesion of epoxies to the hard anodized case is

excellent, but thermal mismatch to the mounting surface can degrade the joint and cause undulating surface. A

compliant adhesive, such as Dow Corning 3145 RTV, is recommended. Use care to maintain flatness of the unit

during curing to reduce angular rate measurement errors. To remove adhesive-mount sensor from the mounting

surface, apply acetone or other dissolving agent to the adhesive layer using a cotton tip, wait for epoxy to be partly

dissolved before gently removing the sensor by hand or tools. Do not apply excessive strain on the sensor body

during removal of the sensor, especially when the sensor is mounted on the top surface.

5.4. Cable

As practical, tie down the cable within 2 to 3 inches (4 to 6 cm) of the unit. Whipping of the cable during rotation,

vibration and shock will strain the cable unnecessarily at the unit. The cable jacket is silicone, so care should be taken

to avoid cutting or tearing the jacket. The cable is rated for 257°F (125°C) continuous service.

5.5. Electrical Connection

Connect the unit to the signal conditioner using the following lead designation:

Red - Excitation +

Green - Output +

White - Output -

Black - Ground (Excitation -)

Endevco Model 136 3-channel signal conditioner is an optional accessory and is recommended to be used with

Model 7310A.

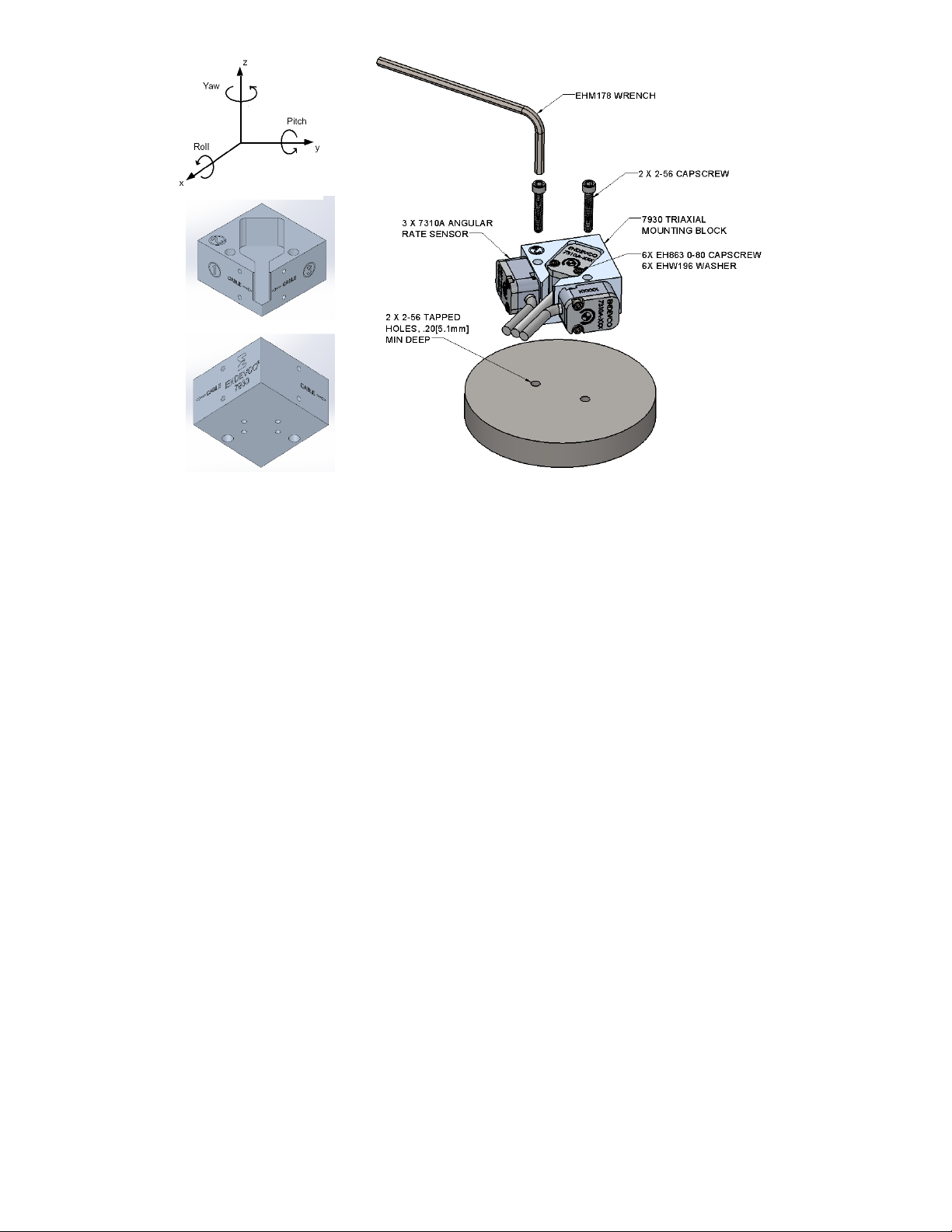

5.6. Triaxial Mount

For triaxial angular rate measurements, the Model 7930 Triax & Six Degrees of Freedom Mounting Block is attached

to the mounting surface with two 2-56 x 5/8 inch socket head cap screws as shown in Figure 2, with subsequent

attachment of the 3pc Model 7310A angular rate sensors per steps 5.2 through 5.5 above. To achieve optimum

mechanical coupling and accurate measurement of angular velocity, the three 7310A units should be mounted to the

three primary mounting surfaces marked of the 7930 block, corresponding to the three perpendicular axes of

rotation (Yaw, Pitch and Roll, top left of Figure 2). Same as the single unit installation in step 5.2, in triaxial

installation the 3pc 7310A units can be mounted on either the top or the bottom surface of the sensor depending on

the positive direction of rotation in the specific application. The Allen wrench (EHM178, alloy steel, black oxide finish)

and the 2pc 2-56 socket cap screws (EH572, 2-25 x 5/8’’, CRES) are supplied as mounting accessories in the shipping

container of the 7930 mounting block.

IM7310A Rev A 7

April 7th, 2020

FIGURE 2. (Top Left) Three Axes of Rotation. (Bottom Left) 7930 Triax & 6DoF Mounting Block

(Right) Installation of 3pc Model 7310A Angular Rate Sensor onto

Model 7930 Triax & 6 Degrees of Freedom Mounting Block

5.7. 6DoF Mount

The Model 7930 mounting block features Six Degree-of-Freedom (6DoF) measurement capability consisting of three

axes of linear acceleration and three axes of angular velocity. 6DoF measurement is important in applications such as

automotive safety testing, aerospace testing and other testing in harsh shock and vibration environments requiring

accurate measurement of a combination of linear and angular motions. For 6DoF measurement, 3pc Model 7310A

angular rate sensors and 3pc 7264 accelerometers are installed to the 7930 mounting block with 0-80 socket head

screws and washers per steps 5.2 to 5.5, as shown in Figure 3. Same as the triaxial installation in step 5.6, the three

angular rate sensors should be installed to the three primary mounting surfaces marked of the 7930 mounting

block, and they can be mounted on either the top or the bottom surface of the sensor depending on the positive

direction of rotation in the specific application. The three accelerometers are installed on the other three surfaces of

the mounting block, measuring linear accelerations along X/Y/Z axis as in the top left figure of Figure 2. The 7930

mounting block is installed to the mounting structure on surface of the block with two 2-56 x 5/8 inch socket head

cap screws. Please ensure the two 0-80 screws for mounting the angular rate sensor in slot of surface of the block

are tightened properly and they do not interfere with the mounting structure surface when the mounting block is

installed to the mounting structure. The EHM178 wrench and 2pc 2-56 socket cap screws are supplied as mounting

accessories in the shipping container of the 7930 mounting block.

Model 7930 mounting block is made of hard anodized aluminum. Drawings and 3D model of the 7930 mounting

block are available per request.

IM7310A Rev A 8

April 7th, 2020

FIGURE 3. (Left) Installation of 3pc Model 7310A Angular Rate Sensor and 3pc Model 7264

Accelerometer onto Model 7930 Triax & 6DoF Mounting Block

(Right) Bottom View of the 6DoF Installation

6.0 Electrical Precautions

6.1. Excitation Voltage

The Model 7310A angular rate sensor has an internal voltage regulator, so excitation from +5Vdc to +16Vdc is

adequate. A low noise power supply is recommended and care should be taken to minimize pickup on the cabling to

the accelerometer. The maximum current drain over the entire operating range is 6 mA. It’s recommended to use

Endevco Model 136 3-channel signal conditioner to provide power and signal processing functions to Model 7310A

angular rate sensor and Model 7264 accelerometer.

6.2. Signal Leads

The green and white signal leads are differential. The green lead has a varying output, while the white lead is fixed at

a reference voltage of approximately +2.5 Vdc. Although the output is high level, at ±2 Vdc, the usual precautions of

using twisted pair, shielded instrumentation cable should be taken to avoid noise pickup on the signal leads.

6.3. Grounding

The case of the model 7310A angular rate sensor is not attached to circuit ground, and the cable shield is not

attached to the case or to circuit ground. The recommended grounding scheme is to ground the cable shield at the

power supply ground and to no other point to avoid ground loops.

6.4. Signal Conditioning

The model 7310A angular rate sensor has a high level differential output of ±2 Vdc, biased at +2.5 Volts. The zero

rotation reading, or Zero Measurand Output (ZMO), is 0 volts ± 100 mV. When the angular rate sensor is subjected

to angular rate greater than the full range, the output of the unit will electrically clip, with a recovery time of < 10

µseconds.

IM7310A Rev A 9

April 7th, 2020

7.0 Recalibration

Sensitivity and Zero Measurand Output calibration should be performed at 6 to 12 month intervals, depending on usage.

Ordinarily, recalibration need be performed only at 12 month intervals if it is known that the angular rate sensor has not been

used beyond its rated specifications. If the unit is used under severe environments, it may be desirable to use shorter

calibration intervals.

Contact Endevco for local calibration facility information or return the 7310A unit to Endevco for recalibration. Endevco

maintains an angular rate recalibration service with A2LA traceability in the United States.

Dirty units may be wiped clean using a damp cloth and a solvent such as acetone.

8.0 Questions

If you have any questions regarding the use of this or any Endevco sensors, please contact mailto:sales@endevco.com or

go to our website https://endevco.com/ for information of Endevco Application Engineering in North America and your

local sales representatives.

Table of contents

Popular Accessories manuals by other brands

MK Electric

MK Electric K4019 Installation and commissioning instructions

Digi

Digi XBee Smart Plug Hardware setup guide

Sandstrom

Sandstrom S622UPP14 instruction manual

Spectrum Technologies

Spectrum Technologies WatchDog product manual

Honeywell

Honeywell C7110A1010 installation instructions

PCB Piezotronics

PCB Piezotronics IMI SENSORS HT640 B Series Installation and operating manual