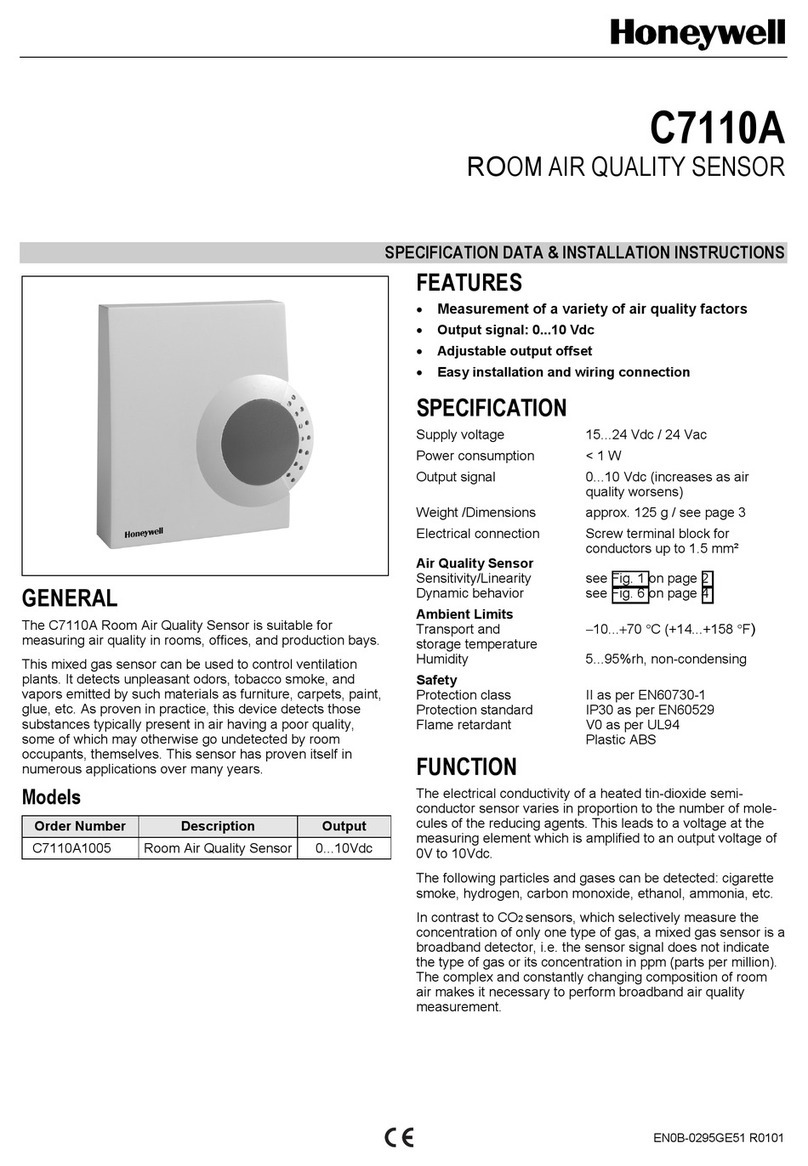

C7110A1010 ROOM AIR QUALITY SENSOR

EN0B-0644GE51 R1109A 2

FUNCTION

The device contains a heated tin dioxide semiconductor

sensor, the electrical conductivity of which varies in proportion

to the concentration of reducing agents in the ambient air.

This leads to a voltage at the measuring element which is

amplified to an output voltage of 0 to 10 Vdc.

The following particles and gases can be detected: cigarette

smoke, hydrogen, carbon monoxide, ethanol, ammonia, etc.

In contrast to CO2 sensors, which selectively measure the

concentration of only one type of gas, the C7110A1010 is a

mixed gas sensor and as such functions as a broadband

detector, i.e. the sensor signal does not indicate the type of

gas or its concentration in ppm (parts per million). The

complex and constantly changing composition of room air

makes it necessary to perform broadband air quality

measurement using such a broadband detector.

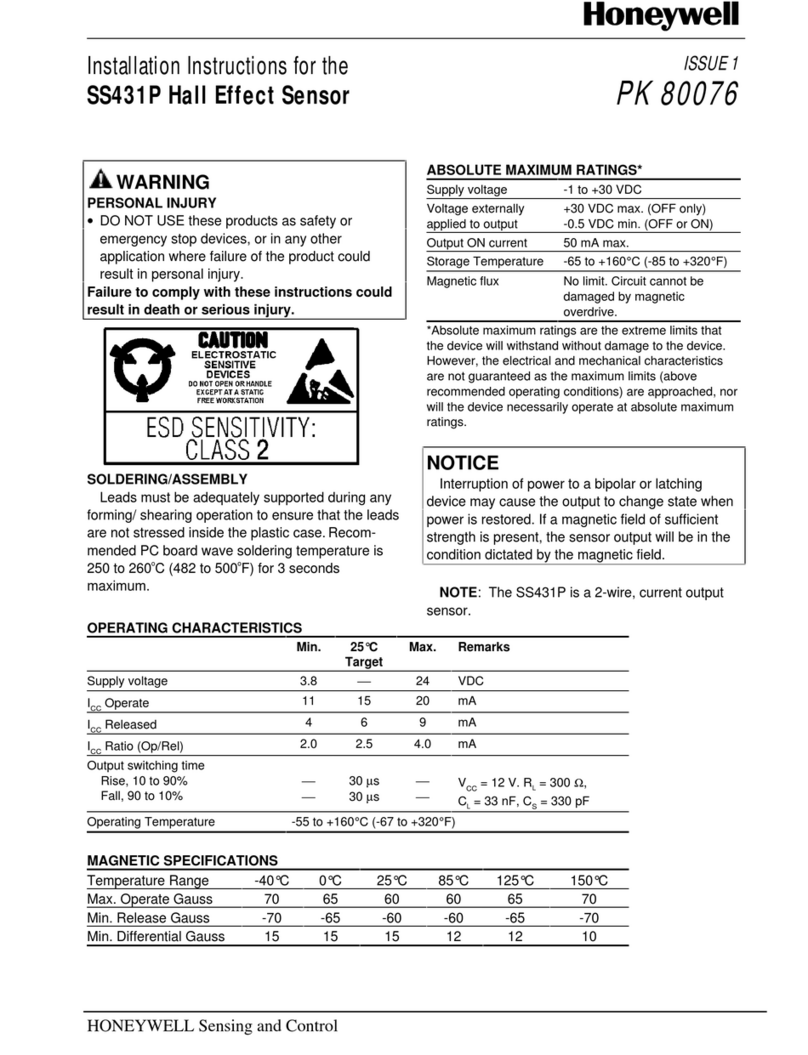

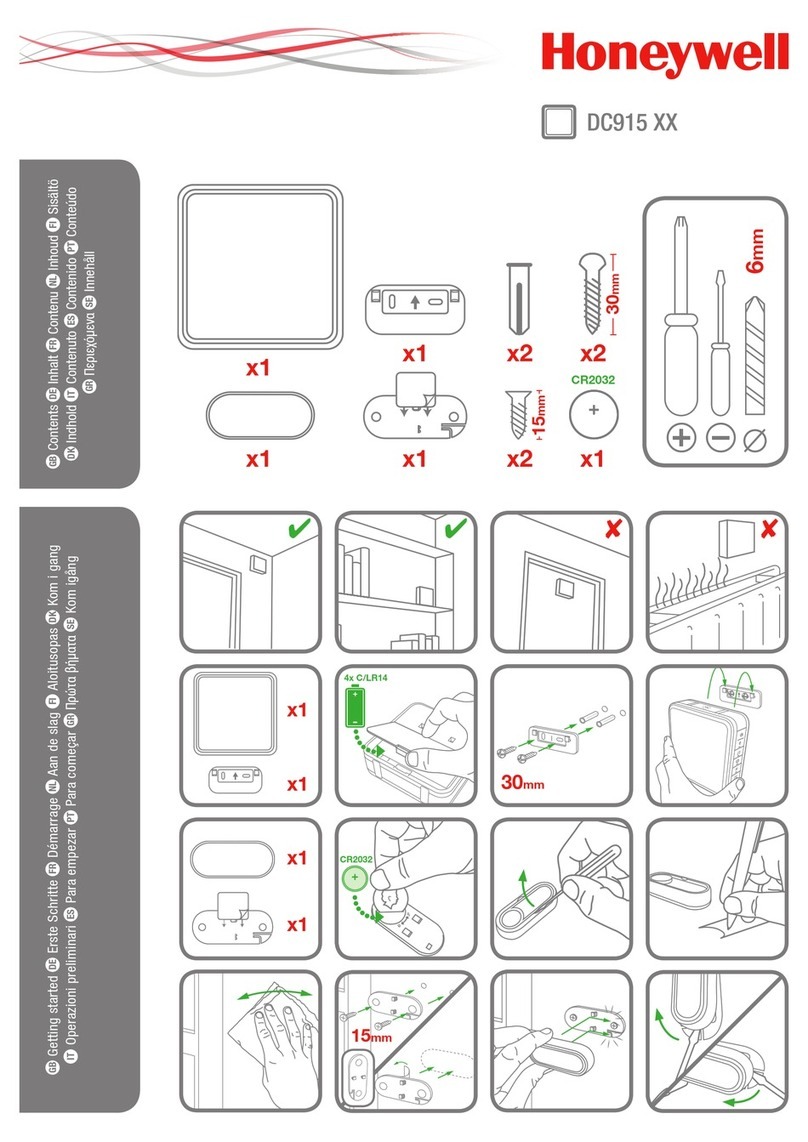

METHANE

CO

ETHANOL

HYDROGEN

INCREASING GAS CONCENTRATION

ISOBUTANE

INCREASING OUTPUT VOLTAGE

Fig. 1. Output voltage as a function of gas concentration

INSTALLATION

Wiring

All wiring must comply with local electrical codes and

ordinances or as specified on installation wiring diagrams.

Wall module wiring can be sized from 16 to 22 AWG (1.5 to

0.34 mm2), depending on the application. The maximum

length of wire from a device to a wall module is 1000 ft (305

m). Twisted pair wire is recommended for wire runs longer

than 100 ft (30.5 m).

Keep wiring at least one ft (305 mm) away from large

inductive loads such as motors, line starters, lighting ballast,

and large power distribution panels.

Run wall module wiring separately from 50 Vac or greater

power wiring.

CAUTION

Low Voltage Equipment.

Risk of equipment damage.

The 24 Vac power source for this product must be a

safety isolating transformer. To conform to Class III

restrictions, transformers must not be larger than

100 VA. A transformer that is CE certified and meets

the Low Voltage Device (LVD) requirements must be

used in Europe for all installations of this product.

Positioning

To avoid falsifying the measuring results, the device should

be installed at sites at which typical air quality prevails.

Direct exposure to sunlight and drafts should be avoided.

If the device is mounted on a standard flush box, the end of

the installation tube in the flush box must be sealed so to

avoid any draft in the tube falsifying the measuring result.

Maintain a mounting clearance of approx. 4 in. (10 cm) to the

right-hand side of the module in order to allow free airflow to

the air quality sensor.

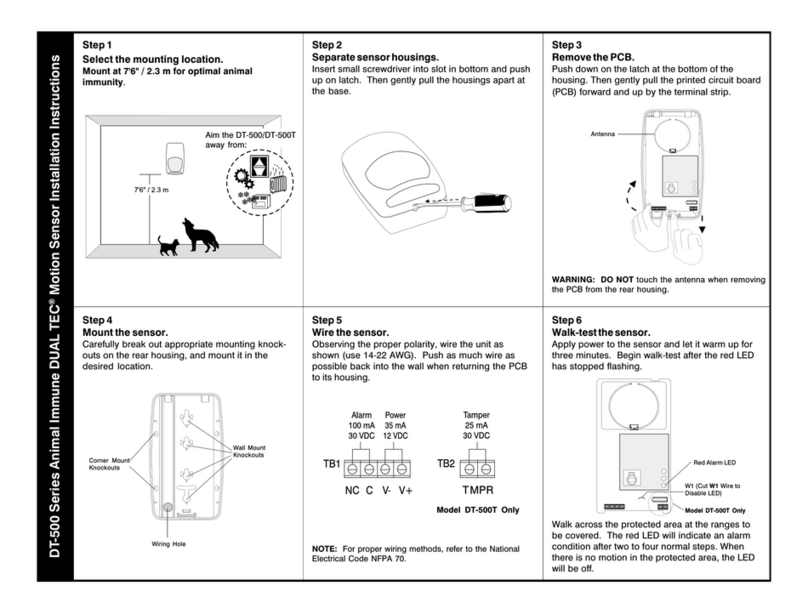

Mounting

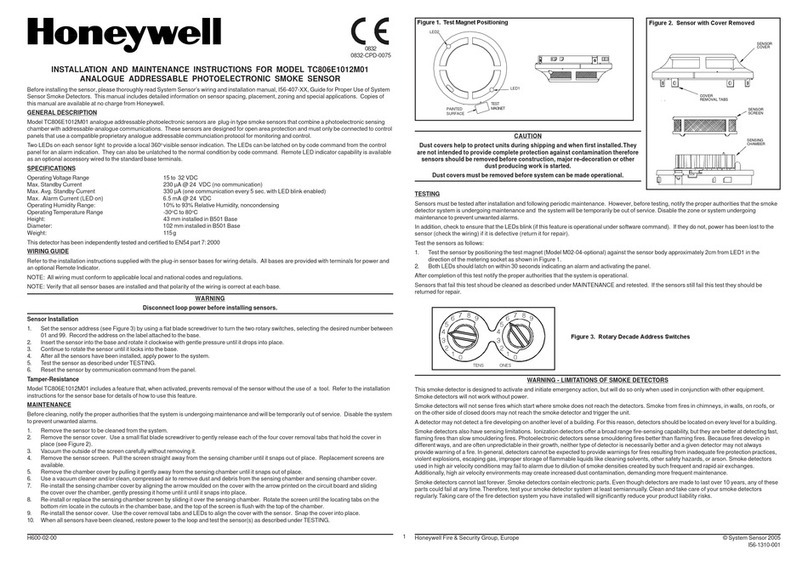

1. The cover of the air quality sensor is fixed by a tab on

the underside of the unit; to disassemble the cover

and the sub-base, see Fig. 2. To access all of the

mounting holes, pull off the perforated cover, bend

down slightly the tab to release the printed circuit

board, and leverage the printed circuit board out (see

Fig. 3).

1

2

LIFT

PRESS

Fig. 2. Cover disassembly

2. a) Mount the sensor onto the wall outlet box,

or

b) bore wall holes as specified in Fig. 3 and mount

the wall module with appropriate screws.