ENDEVCO ISOTRON 4416C User manual

IM4416C, Page

1

®

Instruction Manual

4416C ISOTRON® Signal Conditioner

REV: A

IM4416C, Page

2

®

SAFETY CONSIDERATIONS

This equipment has been designed and tested in accordance with the following standards:

EN61326-1:2013 Electrical equipment for measurement, control and laboratory use –

Group1, Class B (Emissions)

EN61326-1:2013 Electrical equipment for measurement, control and laboratory use –

Industrial Environment (Immunity)

CFR 47, Class A Code of Federal Regulations: Pt 15, Subpart B

This equipment is not designed to be used in potentially explosive environments. It should not be

used in the presence of flammable liquids or gases.

This manual contains information and warnings that must be followed to ensure safety of personnel

and the safe operation of the equipment.

Warnings:

Switch off all power to equipment before making or breaking a connection. Failure to do so may

cause damage to the equipment.

Any adjustment, maintenance or repair, other than detailed within this manual, must be carried out

by trained service personnel.

If it is suspected that the correct operation of the equipment is threatened, impaired or otherwise,

it must be made safe and free from further operation until the threat has been removed.

RoHAS Compliant 2011/65/EU

Waste Electronic and Electronic Equipment Directive: 2012/19/EU

This product complies with the WEEE Directive (2012/19/EU) marking requirement. The affixed

product label (below) indicates that you must not dispose this electrical/electronic product in

domestic household waste.

To return unwanted product for disposal, please contact your local MSS Representative.

IM4416C, Page

3

®

Table of Contents

1.

BASIC INFORMATION 5

2.

DETAILED DESCRIPTION 5

2.1 Input 5

2.1.1 Connection 5

2.1.2 Status 5

2.2 Output 6

2.2.1 Connection 6

2.2.2 Gain 6

2.2.3 Filter 6

2.3 Power 6

2.3.1 Turn On 7

2.3.2 Low Battery Indicator 7

2.3.3 Battery Charge Indicator 7

3.

OPERATION 7

3.1 Transducer Connection 7

3.3 Gain Setting 8

3.4 Filter Selection 8

3.5 Battery Charging 8

4.

MAINTENANCE, CALIBRATION AND REPAIR 9

4.1.1 Equipment Required: 9

4.1.2 Instructions 9

4.2 Repair 10

4.3 Battery Replacement 10

4.3.1 Procedure 10

IM4416C, Page

4

®

5.

OPTIONS AND ACCESSORIES 13

5.1 Included Accessories 13

5.2 Options 13

6.

COMPLIANCE 13

IM4416C, Page

5

®

1. Basic Information

The Model 4416C ISOTRON® Signal Conditioner is a portable/desk top low-noise

signal Conditioner for use with integral electronics piezoelectric (IEPE) transducers

or piezoelectric (PE) transducers when used with a remote charge converter

(RCC). The unit provides the two wire constant current supply to the

transducer/remote charge converter and signal amplification/filtering. Signal

amplification (gain) is selectable as x1, x10 or x100 and the fixed frequency cut-

off filter is selectable as IN or OUT. The unit is powered from an internal Lithium

Ion (Li-ion) battery that can be recharged using the supplied charger. Led

indicators are used to show the status of the battery, gain range selected, filter in,

input status and battery charge.

Photo 1. Front Panel

2. Detailed Description

2.1 Input

2.1.1 Connection

The 4416C supports transducers with integral electronics, i.e. ISOTRON®

and IEPE and also Piezoelectric (PE) types with the use of a remote charge

converter (RCC). Input connector is a standard BNC located on the front

panel with one side connected to signal ground. Power to the

transducer/RCC is available at the input socket in the form of a constant

current of 4.7mA with a compliance voltage of 24V dc.

2.1.2 Status

An indicator on the front panel shows the status of the input – if a transducer

is connected and functioning correctly the indicator will be “green”. If a fault

condition exists, the indicator will be “Red”. A fault condition exists when

IM4416C, Page

6

®

either the input is open circuit, i.e. no transducer connected, or if the input

is short circuit, i.e. a cable fault. During turn on, both green and red

conditions are cycled before the steady state is reached.

2.2 Output

2.2.1 Connection

The output connector is a standard BNC located on the front panel with

one side connected to signal ground. The case of the unit is also connected

to signal ground. If a connection to earth is required it should be made

through via the output connector to associated instrumentation.

2.2.2 Gain

Three levels of amplification (gain) are provided and selectable on the front

panel. The selected gain level is shown by the associated indicator.

2.2.3 Filter

A low pass filter is provided in the form of a second order Sallen Key. With

the filter indicator on, the filter is selected IN.

2.3 Power

Power for the Conditioner comes from an internal Li-ion cell pack, and a

supplied external universal power adapter. The power adapter functions as

a charger for the internal battery, but also will power the Conditioner, while

the battery is being charged. Battery charge and discharge are managed

by internal circuitry to provide a safe and effective environment for the

battery to operate. It is recommended that the charger be disconnected

once charging has stopped to maximize battery life.

Photo 2. Rear Panel

Warning! Only use the power adapter supplied with the 4416C for charging

otherwise internal damage may occur!

IM4416C, Page

7

®

2.3.1 Turn On

The conditioner is turned on and off by a switch on the rear panel. To turn

on, press the “1” and to turn off, press “0”. When turned on the Conditioner

will cycle through the front panel indicators lighting the gain indicators in

turn and lighting the filter indicator.

2.3.2 Low Battery Indicator

The battery Low indicator is on the front panel and will be “Red” when the

battery reaches a pre-determined level. At this point it is recommended that

the charger be connected. If the charger is not connected at this point the

unit will continue to function until a second predetermined battery level is

reached. At this point all power is turned off and no further operation is

possible. The battery must be recharged before reuse, or connected to

the charger and used while charging.

2.3.3 Battery Charge Indicator

The battery charge indicator is mounted above the charger socket on the

rear panel. While charging is in progress the indicator will be “green”. When

charging is complete the indicator is extinguished.

3. Operation

For optimum performance, it is recommended that the unit be fully charged

before using it the first time. Note: Ensure the Conditioner is turned off

before making any connecting to the 4416C. Once connections have been

made, the unit can be turned on with the switch located on the rear panel.

The unit will then cycle the front panel gain and filter indicators to verify all

are working.

3.1 Transducer Connection

The transducer/RCC is connected to the Input socket. A constant current

supply powers the transducer /RCC. When powered on, the

transducer/RCC will set a bias voltage at the input of the 4416C of

approximately 12Vdc (dependent on the transducer). The 4416C monitors

the dc bias to be within a pre-set range of 8V to 16 VDC. If the bias is within

the range the status indicator is turned Green and the system is ready to

use. If the bias is out of range, the status indicator is turned Red – an alert

condition exists. (This does not mean a sensor is bad, just verify the bias

voltage is acceptable.) Note: Some transducers can take 1 – 2 minutes

before the bias settles into range, and some Low Frequency RCC’s can

take as long as 5 minutes to reach their operating point.

IM4416C, Page

8

®

3.2 Output Connection

Measuring Instrumentation, i.e. data acquisition, data logger etc., should

be connected to the output socket using coaxial cables. Load impedance

should be no lower than 100kΩ to meet all specifications. Ideally, the

4416C should be placed near the measuring instrumentation to minimize

the effect of cable capacitance loading.

3.3 Gain Setting

Depressing the “Gain” switch cycles through the gain ranges of x1, x10 and

x100. The gain range selected is shown by the indicator above the range

turning Green. The gain together with the transducer sensitivity determines

the acceleration range available from the system and the output sensitivity,

i.e. for an accelerometer with a sensitivity of 10mV/g pk, and the maximum

output of the 4416C being 10V pk:

Gain = 1 Range = 1000g Output sensitivity = 10mV/g

Gain = 10 Range = 100g Output sensitivity = 100mV/g

Gain = 100 Range = 10g Output sensitivity = 1000mV/g

3.4 Filter Selection

A second order low pass filter is selected by depressing the filter switch.

This toggles the filter in and out. With the indicator Green, the filter is

selected IN. The Standard filter provides attenuation of -5% at

approximately 10kHz, and -3dB at 30 kHz for gains of 1 and 10, or 18kHz

for gain of 100. The filter maybe used to reduce the effects of HF noise

and aliasing in data acquisition systems.

3.5 Battery Charging

Ensure that both the Charger and Conditioner are turned OFF before

connecting. Plug the Charger connector into the socket on the rear panel

of the Conditioner. Turn on the charger. Charging is accomplished in two

stages:

Stage 1 – Fast Charge Mode

“Fast Charge Mode”, covers both constant current and constant voltage

modes and charges the battery to approximately 85% of its capacity in

approximately 3 hours. Once 85% capacity has been achieved, the

charging will automatically switch into “Stage 2”.

Stage 2 – Trickle Charge Mode

“Trickle Charge Mode” will deliver sufficient charge to top up the battery to

100% of its capacity in approximately 45 minutes.

IM4416C, Page

9

®

Once 100% capacity has been achieved the charge indicator will

extinguish. In the event of a fault with the battery charging circuit, or the

battery pack itself, the charge indicator will be “Red”. In this event, please

contact your local representative to arrange for the repair of the

Conditioner. Note: For any repair, return the charger with the unit to insure

all components are performing properly – the charger could be the problem

source.

The charging times are approximate and will vary depending on initial

battery charge state and temperature. If the Conditioner is turned on while

being charged, the power from the charger will be shared between

operation and charging with the priority given to its operation.

To conserve battery life, it is recommended that once the battery is fully

charged, the charger is disconnected.

4. Maintenance, Calibration and Repair

If the unit is suspected of not working or malfunctioning it can be checked

by use of the following circuit. This circuit should also be used when

performing a calibration of the unit.

1.1 Check Out Procedure

4.1.1 Equipment Required:

Signal Generator, static free mat, DMM and Oscilloscope

4.1.2 Instructions

• Ensure the battery is fully charged.

• Connect the circuit above to the input of the 4416C.

• Set the signal generator for 70mV rms at a frequency of 100Hz.

• Turn on the 4416C and select a gain of 1. Allow 5 minutes to stabilize.

• Measure with the DMM across the 2.5kΩ resistor for a voltage of

approximately 12V dc.

• Verify on the oscilloscope that an undistorted sine wave of approximately

100mV pk is displayed.

IM4416C, Page

10

®

• Select a gain of 10. Verify the signal on the oscilloscope is undistorted and

approximately 1V pk in amplitude.

• Select a gain of 100. Verify the signal on the oscilloscope is undistorted

and approximately 10V pk in amplitude.

• To verify the output noise, replace the signal generator with a short circuit.

• If any of the above conditions are not met, the unit should be considered

faulty and requires repair.

4.2 Repair

In the event that the Conditioner requires repair please contact your local

Sales Representative or distributor who will advise on the returns

procedure. Note: Return the charger with the Conditioner whenever repair

is required. The charger could be the source of the problem.

4.3 Battery Replacement

Battery life is > 300 cycles, which under typical operating conditions should

exceed 3 years. Should the battery need to be replaced please contact

your local Sales Representative or distributor who will advise on the returns

procedure.

The internal battery of the Model 4416C is located centrally within the case.

Replacement of the battery requires minimal skill but the greatest of care.

The following describes how to replace the internal battery.

Parts Required: Replacement Battery – Part Number EHM2107

Tools Required: Torx T10 Driver, Small sharp implement

4.3.1 Procedure

a. Using the small sharp implement, gently pry out and remove the plastic

screw covers located on the front panel, shown removed on the left side

and at the red circle on the right side of the front panel in Photo 3 below.

Do not discard the plastic covers.

b. Remove the two screws securing the front panel using the T10 TORX

driver. Gently pull the front panel away from the body – there are short

connecting wires behind the panel. Note: The gasket remains with the

panel.

c. In a similar manner, remove the two screws securing the rear panel using

the T10 TORX driver. Gently pull the front panel away from the body – there

are short connecting wires behind the panel, shown in Photo 4. Do not

discard the covers. (The wire connections can be disconnected if

preferred, but less stress on the cables is better.)

d. Gently rotate the rear panel at an angle, allowing it to be flat, to easily pass

through the case by pushing from the rear, extracting the entire assembly

from the front. The entire assembly and battery will slide out with the circuit

IM4416C, Page

11

®

board. A gasket goes with each panel. Place the entire circuit board

assembly on a static free surface, to prevent potential static damage to

components. See Photo 5.

e. Unplug the battery from the socket on the circuit board. See photo 5.

f. Locate the new battery and connect it to the socket on the circuit board.

g. Gently ease the rear panel and one gasket first, into the case, followed by

the circuit board and battery into the case, compressing the battery foam.

Note: The circuit board is located in the lower channel in the case, just

below the two mounting screw holes. See Photo 6.

h. Replace and secure the rear panel.

i. Replace and secure the front panel.

j. Replace all plastic screw covers.

k. Place the unit on charge.

l. Dispose of the original battery responsibly or return it to MSS for disposal.

Photo 3

IM4416C, Page

12

®

Photo 4

Photo 5

IM4416C, Page

13

®

Photo 6

5. Options and Accessories

5.1 Included Accessories

QSG4416C Quick Start Guide included

IM4416C Instruction Manual (Download from Endevco.com

website)

EHM2107 Universal power supply, with adaptors for USA, UK,

EURO, Japan and Australia

5.2 Options

EJ21 10-32 to BNC adapter

EHM2106 Replacement Battery

EHM2107 Replacement Universal power adapter

6. Compliance

6.1 ROHS to 2011/65/EU;

6.2 CE to EN61326-1:2013; CFR47 Pt 15 B Class A.

Table of contents

Popular Media Converter manuals by other brands

Extron electronics

Extron electronics Two InpuT VIdeo Scaler IN1502 Brochure & specs

National Instruments

National Instruments GPIB-422CV user manual

Cross Technologies

Cross Technologies 3116-22-23 instruction manual

Transition Networks

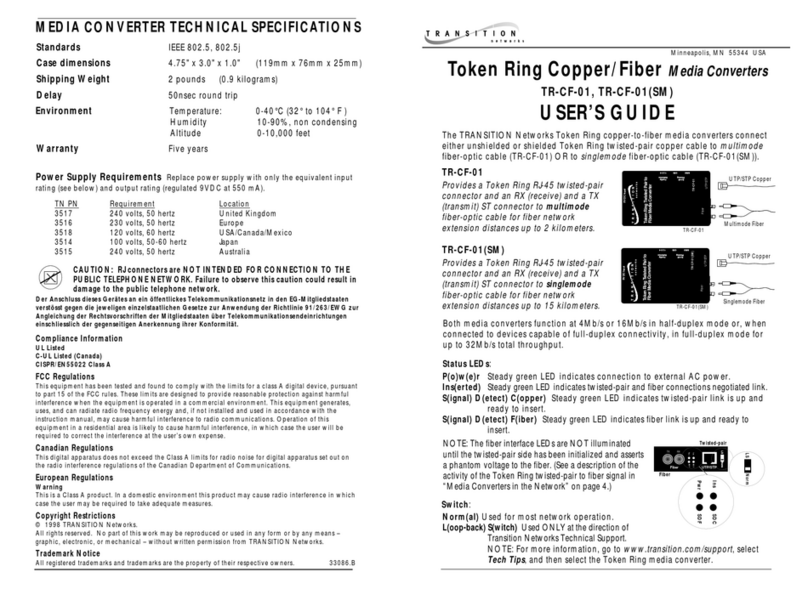

Transition Networks TR-CF-01 user guide

Atlona

Atlona AT-HDR-M2C installation guide

Z3 Technology

Z3 Technology Z3-HE4K-01-SW-02 User instructions