EndurEnergy Systems ESP-BCU HL User manual

Rev. 1 – Aug 16th, 2023

ESP-BCU HL

User Manual

About this manual

This manual is meant for the Battery Control Unit: ESP-BCU HL. This product is designed

to enhance thecapacity ofenergy storagesystems. It is suitable for residential,commercial,

and small industrial applications. The ESP-BCU HL supports multiple communication

methods, including CAN, RS485, RS232, and Internet communication protocols.

Declaration

EndurEnergy declares that the ESP-BCU HL is compliant with the requirements of the RE

Directive 2014/53/EU.

Disclaimer

EndurEnergy cannot be responsible for system failure, damage, or injury resulting from

improper installation of their products. The information included in this manual is subject to

change without notice.

CONTENT

1Safety Introduction .........................................................................................................................................2

1.1 Important Safety Instructions.......................................................................................................2

1.2 Warnings in this Document............................................................................................................2

1.3 Battery Control Unit Handing Guide............................................................................................3

1.4 Response to Emergency Situations ............................................................................................3

1.4.1 Leaking Batteries ....................................................................................................................3

1.4.2 Fire .............................................................................................................................................. 4

1.4.3 Wet Unit...................................................................................................................................... 5

1.4.4 Damaged Battery Control Unit ........................................................................................... 5

1.5 Installers ............................................................................................................................................ 5

1.6 Disposing.............................................................................................................................................6

1.7 Contact Information .........................................................................................................................6

2Guidance for Disconnection During Shipment.......................................................................................6

3Product Introduction ......................................................................................................................................7

3.1 Technical Specifications .................................................................................................................7

3.2 Indicators and Ports........................................................................................................................ 8

3.2.1 Indicators .................................................................................................................................. 8

3.2.2 Ports and Communication Interface................................................................................. 8

3.3 System Layout ................................................................................................................................. 10

3.4 Feature................................................................................................................................................11

4Installation Prerequisites............................................................................................................................11

4.1 Installation Process ........................................................................................................................11

4.2 Installation Location ...................................................................................................................... 12

4.3 Tools.................................................................................................................................................... 12

4.4 Personal protective equipment (PPE)...................................................................................... 13

4.5 Storage............................................................................................................................................... 13

5Battery Installation.......................................................................................................................................14

5.1 Package Items .................................................................................................................................14

5.2 Mounting ............................................................................................................................................14

5.2.1 Rack Mounting (R6 / R12) ....................................................................................................14

5.2.2 Enclosure Mounting - (BU10/15/20/30)........................................................................... 17

5.3 Cable Connections of the Battery............................................................................................. 20

5.3.1 Battery Control Unit Grounding......................................................................................... 21

5.3.2 Communication Cables........................................................................................................ 21

5.4 Battery Control Unit DIP Switch Setting................................................................................. 26

6Commissioning ............................................................................................................................................. 28

7Shutting Down............................................................................................................................................... 29

8Firmware Update & Troubleshooting..................................................................................................... 29

2

1Safety Introduction

1.1 Important Safety Instructions

This manual contains crucial instructions for the ESP-BCU HL product. It is imperative

to follow this manual during installation and use of the product.

While this product is designed and tested to meet international safety requirements such

as IEC 62040, and IEC 62619, it is essential to take certain precautions when installing

and/or operating any electrical and electronic equipment.

To minimize the risk of personal injury and ensure the safe installation and operation of the

product, it is crucial to thoroughly read and adhere to all instructions, cautions, and

warnings provided in this manual.

WARNING

Failure to follow the instructions or warnings in this document can result in electrical

shock, serious injury, or death. Damage to the Battery Control Unit is also possible,

potentially rendering it inoperable.

ONLY qualified personnel should install the ESP-BCU HL.

1.2 Warnings in this Document

A warning indicates a potential hazard to equipment or personnel. It highlights procedures

or practices that, if not performed correctly, may result in damage to or destruction of the

equipment, other connected equipment, or personal injury.

Symbol

Description

Caution, risk of electric shock

Heavy enough may cause severe injure

Keep the battery away from open flame or ignition sources

Keep the battery away from children

Dispose of waste batteries according to local laws and regulations

Recycling

Read this manual before installation and operation

3

For safety reasons, it is the responsibility of installers to thoroughly review the contents of

this manual and familiarize themselves with all warnings prior to performing the installation.

1.3 Battery Control Unit Handing Guide

Please follow the guidelines below to ensure safe handling and usage of the battery control

unit:

⚫Use the battery control unit only as directed.

⚫If the battery control unit appears cracked, broken, damaged, or fails to operate,

immediately contact EndurEnergy hot line at 1-888-E2-ENDUR (1-888-323-6387).

⚫Do not attempt to open, disassemble, repair, tamper with, or modify the battery in any

way.

⚫The battery control unit is not suitable for users to handle independently.

⚫When transporting the battery control unit, handle it with care to protect the battery

control unit and its components from damage.

⚫Avoid subjecting the battery control unit to any strong force or impact.

⚫Do not insert foreign objects into any part of the battery control unit.

⚫Refrain from using cleaning solvents to clean the battery control unit.

⚫Never connect the battery control unit directly to a SELV (Separated Extra-Low

Voltage) circuit.

1.4 Response to Emergency Situations

While the ESP-BCU HL is equipped with multiple safety features to prevent hazards

caused by failures, it is important to note that EndurEnergy cannot guarantee absolute

safety in uncertain situations.

1.4.1 Leaking Batteries

The ESP-BCU HL includes an auxiliary battery to maintain operation in the absence of an

alternate power source. In case of electrolyte leakage from the auxiliary battery, it's

imperative to prevent any contact with the leaked liquid or gas. Electrolyte possesses

corrosive properties and can result in skin irritation and chemical burns. Should you come

into contact with the leaked substance, please take the following steps:

•Inhalation:

oEvacuate the contaminated area immediately.

oSeek medical attention without delay.

4

•Eye contact:

oRinse your eyes with flowing water for at least 15 minutes.

oSeek medical attention promptly.

•Skin contact:

oWash the affected area thoroughly with soap and water.

oSeek medical attention as soon as possible.

•Ingestion:

oIf the electrolyte is ingested, promptly induce vomiting.

oSeek immediate medical attention.

The previous instructions are provided to address potential risks associated with electrolyte

leakage. It is important to prioritize your safety and seek professional medical assistance

without delay in case of exposure to the leaked substance.

1.4.2 Fire

In the event of a fire, it is important to have an ABC or carbon dioxide extinguisher readily

fire.

available. Do not use water to extinguish the

WARNING

The auxiliary battery may catch fire when heated above 150°

If a fire breaks out where the battery control unit is installed, please follow these actions:

•Prioritize extinguishing the fire before the battery catches fire if it is safe to do so.

Use appropriate fire extinguishing methods and equipment according to the type

of fire (e.g., ABC or carbon dioxide extinguisher). Ensure your safety and consider

seeking professional assistance if necessary.

•If the battery control unit has already caught fire or if it is not safe to attempt

extinguishing the fire, prioritize the immediate evacuation of all individuals from the

area. Follow established emergency evacuation procedures and ensure everyone

moves to a safe location.Contact the appropriate emergency services to report the

fire.

5

Note: The above actions are intended to address fire situations where the battery is

involved. Always prioritize personal safety and adhere to established emergency

procedures.

WARNING

If the battery control unit catches fire, it will produce poisonous gases. Do not

approach.

1.4.3 Wet Unit

If the battery control unit becomes wet or submerged in water, do not attempt to access it.

Instead, please contact EndurEnergy Customer Service or reach out to your distributor for

immediate technical assistance.

1.4.4 Damaged Battery Control Unit

If you notice any damage to the battery control unit, please contact EndurEnergy customer

service or your distributor for assistance as soon as possible. It is crucial to handle a

damaged battery control unit with extreme caution, as it can be dangerous. A damaged

battery control unit is not suitable for use and may pose a risk to people and property. If

you suspect the battery control unit is damaged, promptly return it to EndurEnergy or your

distributor.

CAUTION

A damaged battery control unit may release electrolyte or flammable gas.

Additionally, please note that a damaged battery control unit can adversely affect

the functionality of connected batteries, potentially causing damage to them.

1.5 Installers

It is highly recommended that the installation of the ESP-BCU HL is carried out by a skilled

worker or electrician. A skilled worker is defined as an individual who has received proper

training and possesses the necessary qualifications as an electrician, or has acquired the

following skills and experience:

⚫Comprehensiveknowledgeofthefunctionalprinciplesandoperationofon-gridEnergy

Storage systems.

6

⚫Understanding of the potential dangers and risks associated with the installation and

use of electrical devices, as well as familiarity with acceptable mitigation methods.

⚫Proficiency in the installation of electrical devices.

⚫Familiarity with and adherence to the instructions provided in this manual, including

all safety precautions and best practices.

1.6 Disposing

When dealing with scrap battery(-ies), it is important to comply with local laws and

regulations regarding the recycling or disposal of batteries. Please ensure that you follow

the appropriate procedures as outlined by your local authorities for recycling or disposing

of Lithium Iron Phosphate batteries.

1.7 Contact Information

For technical assistance, please use the contacts provided. Please note that the phone

numbers are available for assistance during business hours on weekdays.

Customer careline

1-888-E2-ENDUR (1-888-323-6387)

Email

support@endurenergy.com

2Guidance for Disconnection During Shipment

⚫The ESP-BCU HL is not suitable for air transport.

⚫Cartons that have been crushed, punctured, or torn in such a way that the contents

are revealed shall be set aside inan isolated areaand inspected by a skilled person.

If the package is deemed to be non-shippable, the contents shall be promptly

collected, segregated, and either the consignor or consignee should be contacted.

⚫The AC circuit of the ESP-BCU HL has been disconnected and turned off prior to

shipping.

⚫We have conducted comprehensive tests to ensure that the equipment distributed

worldwide is safe for shipping. These products should be handled with care and

immediately inspected if visibly damaged. If the carton is visibly damaged, please

contact EndurEnergy customer service to confirm whether the battery control unit

can be used safely or not.

7

3Product Introduction

3.1 Technical Specifications

Product Model

ESP-BCU HL

Port Power

40 W

Power Supply

13-17 VDC / Backup battery

Nominal Discharge/Charge

Power

15 W

UPS Rated Capacity

15 Ah

UPS Nominal Current

2 A

UPS Power Supply

12 V

Communication Protocols

CAN / RS485 / Internet

Comunication Method

Protocol & Baud rate: Depend on Inverter

Protective Mode

Dual hardware protection

UPS working temperature

0-45 ⁰C

32-113 ⁰F

Port Temperature (Working)

-20-65 ⁰C

-4-149 ⁰F

Port Temperature (Storage)

-30-70 ⁰C

-22-158 ⁰F

WiFi Frequency Range

2400 MHz-2483 MHz

IP Rating

IP20

Protective Class

I

Max. Number of Parallel

Connections

4

Dimensions

442 x 300 x 89 mm

17.4 x 11.8 x 3.5 inch

Weight

5 kg

11..2 lb

Cooling Type

Natural cooling

Case Material

Steel

Color

White

Installation

Rack / Enclosure / Ground

Protections

Over-current/Over-voltage/Short circuit/ Under-

voltage/Over temperature

Hazardous Material

Classification

9

Warranty

10-Year

Lifespan

> 15 years

8

3.2 Indicators and Ports

3.2.1 Indicators

There are two LED indicators on the front of the battery control unit that show its operating

status.

Item

Designation

Definition

1

Run

Steady: The battery control unit is working

normally.

Blinking: Reset Button pressed, expecting Wi-Fi

connection from App.

2

Fault

There are failures or issues with the battery control

unit. See troubleshooting or contact EndurEnergy

Tech Support.

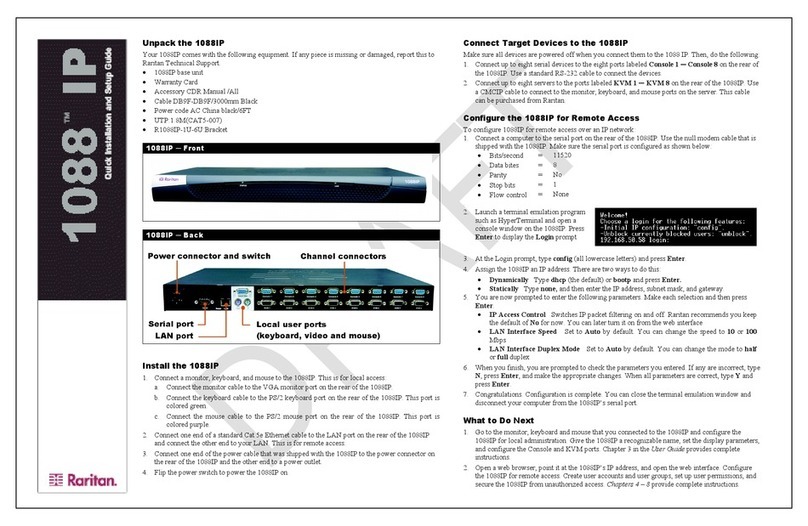

3.2.2 Ports and Communication Interface

Designation

Image

Number

Definition

Power Button

5

The power button on the Battery Control Unit (BCU) serves

to control the unit's operational status.

When the BCU is turned on, a green indicator light will

illuminate, signaling that the unit is active and operational.

Conversely, if the green light is not illuminated, it indicates

that the BCU is turned off and not currently functioning.

9

SW 1

1 and 2

This is a combination of two DIP switches: one rotary DIP

switch and one slide DIP switch. Both switches are used

according to the number of batteries, and the battery

clusters.

CAN/RS485

Switch

3

The DIP switch is used to select the communication mode

used between the BCU and the inverter, you can set it to

CAN or RS485. Please refer to the inverter's user manual

for detailed instructions.

•For CAN Communication, set SW1 to positions 1

and 2.

•For RS485 Communication, set SW1 to positions

3 and 4.

SW 2

6

Used for communication between the battery control unit

and the inverter, either through CAN Low or RS485B

communication. Please refer to the inverter's user manual

for detailed instructions.

SW 3

7

Used for communication between the battery control unit

and the inverter, either through CAN High or RS485A

communication. Please refer to the inverter's user manual

for detailed instructions.

PCS / EMS

8

Used for communication between the battery control unit

and the inverter:

•For CAN Communication, use the bottom port.

•For RS485 Communication, use the upper port.

Clusters

Communication

Port

9

Ethernet ports used for communication between the

battery control unit and the battery clusters.

Use one port for each battery cluster.

Reset

10

Used to reset the Wi-Fi or GPPS/GPS module

configuration.

AC Power

Switch

4

Control mechanism designed to manage the electrical

power supply to a device.

When the switch is in the "On" position, it enables the

flow of alternating current (AC) electricity to the battery

control unit.

10

Conversely, when the AC Power Switch is in the "Off"

position, it interrupts the flow of AC electricity to the

battery control unit.

AC Power

Socket

11

Power cable connection designed to deliver alternating

current (AC) electrical power to the battery control unit.

Connect this input to an AC outlet to provide energy to

the BCU. If not connected the internal battery will drain

and stop working after 3 hours.

Note: Dry contact terminals and RS232 are not used for the installation, configuration, or

connection of the battery clusters.

NOTICE

The battery control unit is designed to work on a close loop environment for

communicating with compatible inverter (check inverter compatibility list), for open loop

type of applications we do not ensure proper operation and not encourage it.

If you intend to use the battery control unit on an open loop application or not supported

inverter, call our technical support.

3.3 System Layout

11

3.4 Feature

This product is designed to enhance the capacity of energy storage systems. It is suitable

for residential, commercial, and small industrial applications. The ESP-BCU HL has the

following features:

•Support for Multi-Cluster Batteries: This unit enables seamless connectivity for

multi-cluster batteries, both in series and parallel configurations.

•Capacity for Single Cluster Batteries: The ESP-BCU HL has the capability to

support up to sixteen batteries in a single cluster, effortlessly connected in either

series or parallel configurations.

•Versatility for Multi-Cluster Batteries: Experience flexibility like never before as

this product empowers you to link up to eight-cluster batteries in configurations of

series or parallel, further expanding your energy storage options.

4Installation Prerequisites

4.1 Installation Process

The battery should be installed according to the following flowchart. The detailed

installation process is described in Section Battery Installation.

12

4.2 Installation Location

Ensure that the installation location meets the following conditions:

⚫The building is designed to withstand earthquakes as per the building code (when

applicable).

⚫It is far away from the sea to avoid saltwater and humidity.

⚫The floor is flat and level.

⚫There are no flammable or explosive materials nearby.

⚫The optimal ambient temperature is between 15°C and 30°C.

⚫The temperature and humidity remain at a constant level.

⚫There is minimal dust and dirt in the area.

⚫There are no corrosive gases present, including ammonia and acid vapor.

⚫The battery and racks are rated IP20, indicating that they are suitable for indoor

use, if required to be placed outside it will require an enclosure or cabinet.

If the ambient temperature is outside the operating range, the battery control unit will

protect itself by shutting down. The optimal operating temperature for the battery is 15°C

to 30°C. Frequent exposure to severe operating conditions would negatively affect the

performance and lifespan of the battery.

4.3 Tools

To install the battery control unit, the following tools are required:

Flat-head &

Phillips

Screwdriver

Torque wrench

Cable crimper

Wire clamp

Voltmeter

Measuring tape

Drill

Bubble Level

To ensure the safety of the operator and installer, please select and use suitable tools

and measuring instruments that are certified for precision and accuracy.

13

4.4 Personal protective equipment (PPE)

When handling the battery control unit, the following safety gear should be worn. Installers

must comply with the relevant requirements of UL1973, IEC 62040, and IEC 62619, or

applicable domestic legislation and other relevant international standards.

Insulated gloves

Safety goggles

Dielectric Safety shoes

4.5 Storage

If the battery control unit is not going to be installed immediately and needs to be stored

for a long period, please choose an appropriate location for storage. Follow these

instructions for storage:

⚫Do not stack more than four boxes.

⚫The recommended storage temperature for the battery control unit is in the range of -

20°C to 30°C.

⚫Avoid exposing the battery control unit to water.

⚫If the battery control unit needs to be stored for over 3 months, the auxiliary battery

will discharge at a minimum rate and the capacity may degrade depending on the

storage time.

⚫The boxes should be stored upright as shown in the following figure and should not

be stacked upside down.

14

5Battery Installation

5.1 Package Items

You will receive one packing carton containing the batteries. The items included are

summarized as follows:

1 x ESP-BCU HL

1 x User Manual

1 x Warranty Letter

1 x Communication Cable

1 x Grounding Wire

1 x Power Cord

Note: Product accessories are customized according to customer needs. This list

represents only the standard accessories. EndurEnergy does not provide cables for all

situations, for special projects ask sales team.

5.2 Mounting

The ESP-BCU HL is designed as a rack mount type battery control unit, this adds flexibility

on installation and modularity for different configurations.

5.2.1 Rack Mounting (R6 / R12)

1. Place the Rack in the location desired (refer to the details about the installation

location described in Chapter 4.2). The enclosure should be moved close to its

installation location inside its shipping container before it is unpacked. The

enclosure must be installed in a structurally sound area with a level floor that is

able to bear the weight of the rack + the weight of the battery control unit + the

intended number of batteries to be installed inside.

CAUTION

Our rack solutions are designed for indoor installations IP20/NEMA1.

If the battery control unit or batteries are intended to be used outdoors, a cabinet / enclosure

is required.

15

2. Adjust leveler feet (if included), lower each leveler unit it reaches the floor, make

sure each leveler contacts the floor solidly. After lowering each leveler, use the

carpenter's level / bubble level to confirm that the rack is level. Adjust levelers as

needed to get level.

3. In order to secure the rack to the building structure for stability, attach the provided

brackets to the wall or to the floor (depending on the rack model) using adequate

screws. Verify foundation for seismic installations.

16

4. Slide the battery control unit into the horizontal brackets of the rack. Ensure that

each battery control unit or batteries are vertically spaced out by 1/3 U (0.583” /

14.82 mm) to facilitate heat dissipation. Utilize M6 screws to securely fasten the

batteries in place onto cage nuts, with a maximum torque of 8.7 lb*ft. If the rack

does not feature cage nuts, employ suitable screws to affix the unit firmly into the

predrilled holes.

17

5.2.2 Enclosure Mounting - (BU10/15/20/30)

1. Place the enclosure in the location desired (refer to the details about the installation

location described in Chapter 4.2). The enclosure should be moved close to its

installation location inside its shipping container before it is unpacked. The enclosure

must be installed in a structurally sound area with a level floor that is able to bear the

weight of the enclosure + the weight of the battery control unit + the intended number

of batteries to be installed inside.

NOTICE

Our enclosure solutions are designed for outdoor installations rated IP55 / NEMA 3R.

18

2. In order to secure the enclosure to the building structure for stability, adjust the 2x wall

brackets by losing the screws, move the brackets to leave a gap of at least 0.5”

between the wall and the enclosure to allow airflow and door opening. Tighten the

screw brackets and attach both brackets to the wall with 2x adequate screws (M8 or

5/16”).

Table of contents

Popular Switch manuals by other brands

RONK

RONK VIGILANT Series Owners & installation manual

NETGEAR

NETGEAR GSM7248NA Administration guide

LevelOne

LevelOne Infinity IES-1081 user manual

IEI Technology

IEI Technology PUZZLE-A002 user manual

Enterasys

Enterasys SecureStack A2 A2H123-24 Hardware installation guide

Transition Networks

Transition Networks LANMaster T8-FL user guide