ENERGY SUPPORT CORPORATION DTF-102 User manual

Instruction Manual

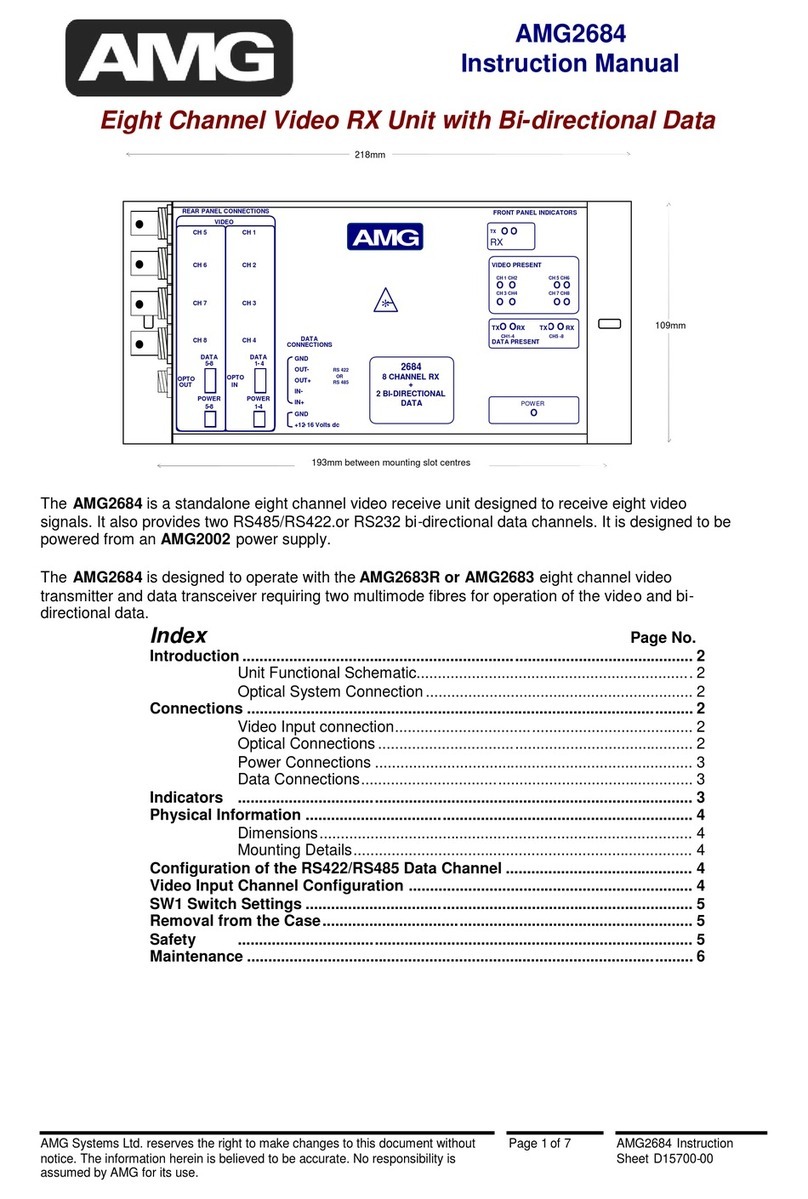

DTF-102 Receiver

Type:DTF-102

No.-3243E R2

【Product】

・ DTF-102 Receiver :KX-621038-XXXXXX

I

Preface

This manual is written for those who handle DTF-102 type receiver. Be sure to read this manual before

using the product to ensure proper and safe operation of the product.

In particular, be sure to read "For Your Safety" and use the product correctly. And keep it in a place

where anyone using this product can view it at any time.

The contents of this manual are subject to change without notice for improvement.

Please refer to the latest instruction manual when using.

If you find any unclear points, errors, omissions, etc. regarding the contents of this manual, please

contact us or our distributors.

Product Applications

Consult with us in advance regarding use for the following purposes.

Radiation-related equipment

Nuclear applications

Medical use

Uses that have a large impact on important property or rights

Other uses related to life and body

Scope of Liability and Warranty

[ Warranty Period ]

1 year after delivery

*If a separate warranty period is stipulated in a document such as a delivery specification, the

contract shall take precedence.

[ Warranty Conditions ]

During the warranty period, if a failure occurs due to our responsibility, we will provide a substitute or

replacement part or repair the delivered product free of charge.

However, the following cases are not covered by the warranty.

*If a separate warranty period is stipulated in a document such as a delivery specification, the

contract shall take precedence.

When used in environments other than those specified in this manual

Failure to follow the instructions in this manual or use in a manner other than that described in this

manual

In case of failure due to incorrect operation

If the product is repaired, processed, remodeled, or disassembled by anyone other than us or

someone authorized by us

When used in combination with parts other than our company

In the event of a disaster beyond our responsibility, such as a natural disaster

In case of damage, breakage, or failure due to dropping or transportation after purchase

Failure due to corrosion, rust, etc. Deterioration of appearance.

Consumable parts

II

[Warranty Scope]

The scope of warranty is limited to our products.

Regardless of the warranty period, our company does not take any responsibility for the following.

Indirect damage due to failure of our products or unforeseen defects by our company (Loss of profit,

opportunity loss, compensation for damage or failure to products other than those supplied by us,

compensation for other operations, compensation for accidents, etc.).

III

About This Instruction Manual

Deliver this manual to the final user.

The contents of this manual are subject to change without notice for improvement.

Unauthorized reproduction or duplication of part or all of the contents of this manual is strictly

prohibited.

If you find any unclear points, errors, omissions, etc. regarding the contents of this manual, please

contact us or our distributors.

About Related document

Related documents are below.

TF-10 Type Probe Transmitter Instruction Manual No.-3071-*

TF-Ⅲ Type Probe Transmitter Instruction Manual No.-3064-*, 3144-*, 3231-*, 3223-*

TF-Ⅳ Type Probe Transmitter Instruction Manual No.-3066-*, 3068-*

Description in This Manual

Notation of the Figure

The figures in this manual may be emphasized, simplified, or partially omitted for convenience of

explanation. Pictures such as screens may differ from the actual display. In addition, the contents

described may be "display examples".

Trademarks

Company names and brand names are either registered trademarks or trademarks of the respective

companies. (R), (TM) symbols may be omitted in this manual.

Original language

This is the English translation of an original Japanese document.

Disposal of the Product

When disposing of the product, comply with local regulations.

This interprets the necessary points for correct operation and notifies the important points for

handling the product.

Note

This indicates the part where to refer for information.

Refer

This indicates reference information.

Tip

IV

For Your Safety

Warning messages given here are for safe and correct use of the product and for prevention of harm or

damage. These are important safety note, so be sure to read it carefully before use and be sure to

observe it.

The meanings of the symbols are as follows.

DANGER This indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This is to be limited to the most extreme situations.

WARNING This indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION This indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

V

When deciding on the "Installation Location"

DANGER

Explosion or Fire

This product is not explosion-proof. Do not use in an explosive gas

atmosphere.

When using a standard gas cylinder, install or store the standard gas

cylinder in a location with an ambient temperature of 40°C or less and

out of direct sunlight.

CAUTION

Injury, Malfunction or Damage

Install in a location that satisfies the installation location conditions

described in "Table 3-1 Installation location".

When "Installing" or "Transporting"

CAUTION

Fall, Damage or Injury

Installation work correctly according to the instruction manual.

Tighten screws with the appropriate tightening torque. Insufficient

tightening may cause damage or drop. Also, if it is tightened too much, it

may not be possible to remove it.

When "Wiring"

WARNING

Fire, Electric shocks, Malfunction

Wiring work should be done by a person with appropriate technical

training and experience.

Use the power supply at the rated voltage.

Be sure to turn OFF the main power supply before performing wiring

connection work or wiring check.

Connect grounding.

Do not apply an excessive load to the cables and cord, such as bending

and stretching them repeatedly, putting a heavy thing on them.

Use appropriate wiring material according to the rating of the device.

VI

When "Starting measurement" or "Maintenance work"

WARNING

Fire, Electric shocks, Malfunction

Be sure to turn OFF the main power supply before performing wiring

connection work or wiring check.

Before turning ON the power, make sure that the power wiring is

properly connected.

If the fuse blows, check the cause and replace it with one of the same

capacity and type. Also, when replacing the fuse, be sure to turn OFF

the main power supply before starting work.

Be sure to use parts specified by our company for replacement parts

and consumables.

Other

CAUTION

Fire, Electric shocks, Injury or Damage

In the event of a failure that cannot be determined by looking at the

instruction manual, be sure to contact our company or the agency

where you purchased the product, and request repairs if necessary.

VII

Product Handling Information

If this product is used in a manner not specified by us, it may impair the protective functions and

performance provided by this product. It is strictly prohibited to modify the product by the customer.

Observe the following precautions.

General

Use in a manner not specified in this manual may impair the protection provided by this product.

Do not disassemble the parts other than those specified in this manual.

Do not modify by the customer.

Do not use accessories other than this product.

Even if the temperature is within the range of the ambient temperature specification of this product,

the life of the product may be shortened if it is used in a constantly high ambient temperature

environment.

This product is intended for industrial environments. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate measures.

Precautions during construction

Install the product in a location where the required space can be secured. If space is not secured,

daily inspections and maintenance will not be possible, leading to equipment stoppages and

product damage.

Notes on settings

When using the product for the first time or after replacing the sensor, always setting the sensor

parameters to receiver. The parameter settings to be used, see the inspection report.

VIII

Table of Contents

1

Type:DTF-102

Product Name:DTF-102 Receiver

Table of Contents

Preface .................................................................................................................. I

For Your Safety .................................................................................................. IV

Product Handling Information.......................................................................... VII

1 Overview ......................................................................................................... 5

1.1 About This Product ................................................................................................................ 5

1.2 Products and Accessories ..................................................................................................... 5

1.3 Temporary Storage ............................................................................................................... 5

2 Part Names ...................................................................................................... 6

2.1 Receiver ................................................................................................................................ 6

3 Installation ...................................................................................................... 8

3.1 System Configuration Example ............................................................................................. 8

3.1.1 System Configuration Example 1 ................................................................................................... 8

3.1.2 System Configuration Example 2 ................................................................................................... 9

3.1.3 System Configuration Example 3 ................................................................................................... 9

3.2 Place Conditions for Installation .......................................................................................... 10

3.3 Installing the Receiver ......................................................................................................... 11

3.3.1 Panel Mount ................................................................................................................................. 11

3.3.2 Wall Mount ................................................................................................................................... 11

3.3.3 Stand Mount ................................................................................................................................ 12

3.4 Connecting Wires ................................................................................................................ 13

3.4.1 Connecting to Terminal Block ....................................................................................................... 13

3.4.2 Wiring Connection Example ......................................................................................................... 14

3.4.3 Wiring Method When Replacing from DTF-101 Receiver .............................................................. 15

3.4.4 Wiring Confirmation Sheet When Replacing from DTF-101 Receiver ........................................... 16

4 Measurements .............................................................................................. 19

4.1 Necessary Steps before Starting ......................................................................................... 19

4.1.1 Setting Items of Sensor Parameters ............................................................................................. 19

4.2 Starting and Stopping Measurement ................................................................................... 20

4.3 Key Operation ..................................................................................................................... 21

4.3.1 Explanation of Keys ..................................................................................................................... 21

4.3.2 Display Transition ........................................................................................................................ 22

4.3.3 Display by Operating State ........................................................................................................... 23

4.3.4 Data Settings Overview ................................................................................................................ 24

4.3.5 Data Setting/Checking Method ..................................................................................................... 24

Table of Contents

2

5 Calibration ..................................................................................................... 25

5.1 About Calibration ................................................................................................................ 25

5.2 Calibration Point and Calibration Type ................................................................................ 25

5.2.1 Calibration Point Type ................................................................................................................. 25

5.2.2 Calibration method Type .............................................................................................................. 26

5.3 Manual Calibration .............................................................................................................. 27

5.3.1 Manual Calibration (Air Point) ...................................................................................................... 27

5.3.2 Manual Calibration (Air Point & Other Points) .............................................................................. 28

5.4 Semi Auto / Auto Calibration ............................................................................................... 30

5.4.1 Semi Auto / Auto Calibration (Air Point) - advance setting – ......................................................... 30

5.4.2 Semi Auto Calibration (Air-Point) - Key Operation or Contact Input - ............................................ 31

5.4.3 Auto Calibration (Air-point)........................................................................................................... 32

5.4.4 Semi Auto/Auto Calibration (Air Point & Other Points) - advance setting - .................................... 33

5.4.5 Semi Auto Calibration (Air Point & Other Points) - Key Operation or Contact Input - ..... 34

5.4.6 Auto Calibration (Air Point & Other Points) ................................................................................... 35

5.4.7 Calibration Stop Operation ........................................................................................................... 35

6 Purging .......................................................................................................... 36

6.1 About Purging ..................................................................................................................... 36

6.2 Purge Method Type ............................................................................................................. 36

6.3 Semi Auto Purge / Auto Purge ............................................................................................ 37

6.3.1 Semi Auto Purge / Auto Purge - advance setting - ....................................................................... 37

6.3.2 Semi Auto Purge - Key Operation or Contact Input - .................................................................... 38

6.3.3 Auto Purge .................................................................................................................................. 39

6.3.4 Purge Stop Operation .................................................................................................................. 39

6.4 Reset of Cycle Timer and Countdown ................................................................................. 40

6.4.1 Reset Method of Cycle Timer ....................................................................................................... 40

6.4.2 Cycle Timer Countdown ............................................................................................................... 41

7 Other Settings/Functions.............................................................................. 42

7.1 Analog Output ..................................................................................................................... 42

7.1.1 Analog Output Specifications ....................................................................................................... 42

7.1.2 Setting, Checking and Switching of Output Range ....................................................................... 42

7.1.3 Output Hold Function ................................................................................................................... 43

7.1.4 Simulated Output ......................................................................................................................... 44

7.1.5 Adjustment of Analog Output ....................................................................................................... 44

7.2 Contact Output .................................................................................................................... 45

7.2.1 Contact Outputs Specifications .................................................................................................... 45

7.2.2 Contact Outputs Items and Setting .............................................................................................. 45

7.3 Contact Input....................................................................................................................... 48

7.3.1 Contact Inputs Specifications ....................................................................................................... 48

7.3.2 Contact Inputs Items .................................................................................................................... 48

7.4 Sleep Mode ......................................................................................................................... 49

7.4.1 About Sleep Mode ....................................................................................................................... 49

7.4.2 Switch to Sleep Mode and Operation ........................................................................................... 49

Table of Contents

3

7.5 Other Functions ................................................................................................................... 50

7.5.1 Concentration Upper / Lower Alarm (Alarm H, Alarm L, Alarm H&L) ............................................. 50

7.5.2 Primary Delay Calculation Function .............................................................................................. 50

7.5.3 Moving Average Function ............................................................................................................. 50

7.5.4 Protection Function of Set Value .................................................................................................. 50

7.6 CH Data Table .................................................................................................................... 51

8 Maintenance .................................................................................................. 54

8.1 Daily / Periodic Inspection ................................................................................................... 54

8.2 Consumable Parts and Spare Parts .................................................................................... 54

9 Troubleshooting ........................................................................................... 55

9.1 Phenomena and Countermeasures ..................................................................................... 55

9.2 Error Code Table ................................................................................................................. 56

9.2.1 Oxygen Sensor Failed .................................................................................................................. 57

10 Technical Data .............................................................................................. 58

10.1 Specifications ...................................................................................................................... 58

Table of Contents

4

1 Overview

5

1 Overview

1.1 About This Product

This product is a control device that drives and controls the oxygen sensor in an oxygen analyzer that

uses a limiting current type zirconia oxygen sensor, and is responsible for concentration calculation

and output. It is used in combination with our oxygen sensor (transmitter).

Since the oxygen sensor of this analyzer does not require pretreatment of the measurement gas, it is

smaller and has a faster response speed than conventional sampling-type devices equipped with a

pretreatment device.

In addition, since calibration can be performed using only "instrumentation air" using compressed air,

which is commonly found in factories and ships, there is the advantage of not needing to install or

manage standard gas cylinders.

1.2 Products and Accessories

When you receive the product, open the package and check for any shipping damage.

Also, make sure that the delivered items and accessories are correct.

Table 1-1 Supply Parts List (one set)

Name No. Q'ty Remarks

Receiver KX-621038-XXXXXX 1

If Receiver is delivered in a unit case or mounted on an independent panel, refer to the supply parts list

of the delivery specifications.

Table 1-2 Option Parts List

Name No. Q'ty Remarks

Stand mounting bracket

KS-224193 1 For detail, see "3.3.3 Stand Mount".

1.3 Temporary Storage

When storing the product temporarily prior to installation, observe the following conditions.

Away from direct sunlight.

The ambient temperature is between -10℃ and 50℃, with little variation in temperature.

There is little humidity and dust.

The location is not exposed to rainfall.

There is little mechanical vibration.

There are no corrosive gases or dangerous gases.

2 Part Names

6

2 Part Names

2.1 Receiver

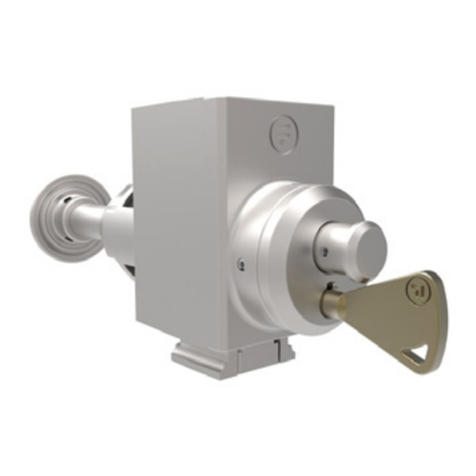

【Dimensions】

Front view

Bracket 1

Bracket 2

Right side view

Bottom view

Wiring hole 7-Φ27

With grommets

250 Knurled fastener

Door

Window

300

270

200

*Dimensional tolerances without individual tolerance indications are according to JEM 1459.

156

135

Mounting hole Φ10

2 Part Names

7

【Inside】

Display panel

(For detail, see below fig.)

Door

【

Display Panel

】

Terminal block

Power switch

Fuse

Power lamp

Lights when the power is on.

Operation key

Used for setting sensor parameters,

changing/checking various settings,

and releasing errors.

Display 1

"Oxygen concentration", "Setting data",

"Error code" and "Countdown" are displayed.

Display 2

"Output range", "CH No.", "States of Analyzer",

"Concentration upper limit alarm", "Concentration

lower limit alarm" are displayed.

%

lamp

Lights when the concentration

unit is %.

ppm lamp

Lights when the concentration unit

is ppm.

Display panel

3 Installation

8

3 Installation

This product is a device that controls Oxygen Sensor and calculates and outputs concentration.

In order to measure the oxygen concentration, connect our company's zirconia Oxygen Sensor and

use it by constructing piping related parts. A typical system configuration example is shown below.

3.1 System Configuration Example

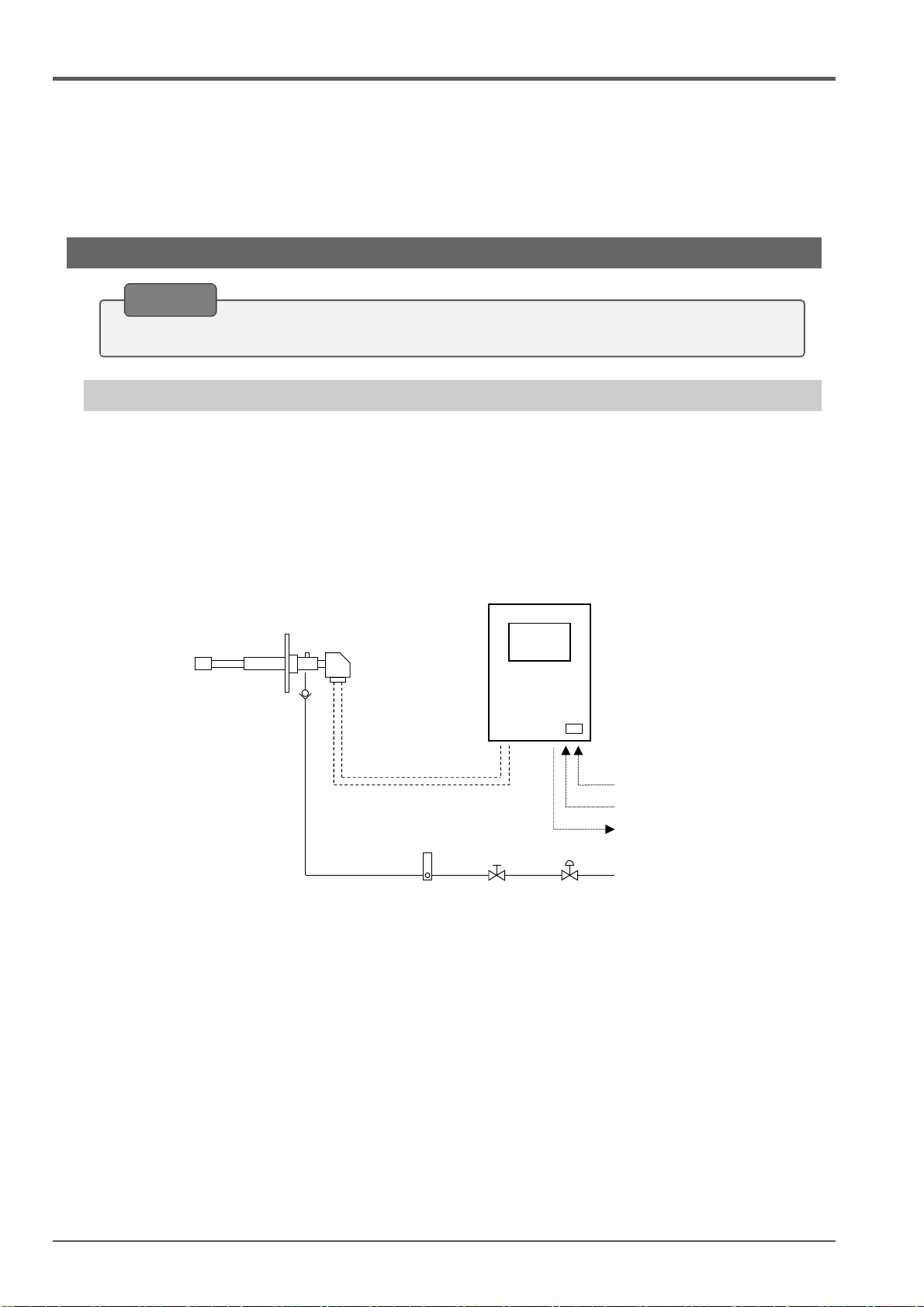

3.1.1 System Configuration Example 1

This system is an example of using "TF-10 Probe Transmitter" as an oxygen sensor to measure the

oxygen concentration in flue gas from a boiler, etc. Manually operated valves such as needle valve and

ball valve are used for calibration gas lines. At the time of calibration, after manually operating the

valve to supply the calibration gas, calibration is executed by key operation on the receiver.

Use instrument air or atmospheric gas for calibration. (Calibration using standard gas cylinders such

as zero gas and span gas is not required.)

Confirm the delivery specifications for scope of delivery and actual system configuration.

Note

TF-10 Probe Transmitter

DTF-102 Receiver

Power supply 100 to 240 VAC

Contact input

Analog output (DC4 to 20mA)

Contact output

Flow

meter

Needle

valve

Pressure

reducing valve

Check valve

Control/signal wires

for sensor

4 cores shielded×2

Calibration gas

(Instrument air or atmospheric gas)

Fig. 3-1 System Configuration Example 1

3 Installation

9

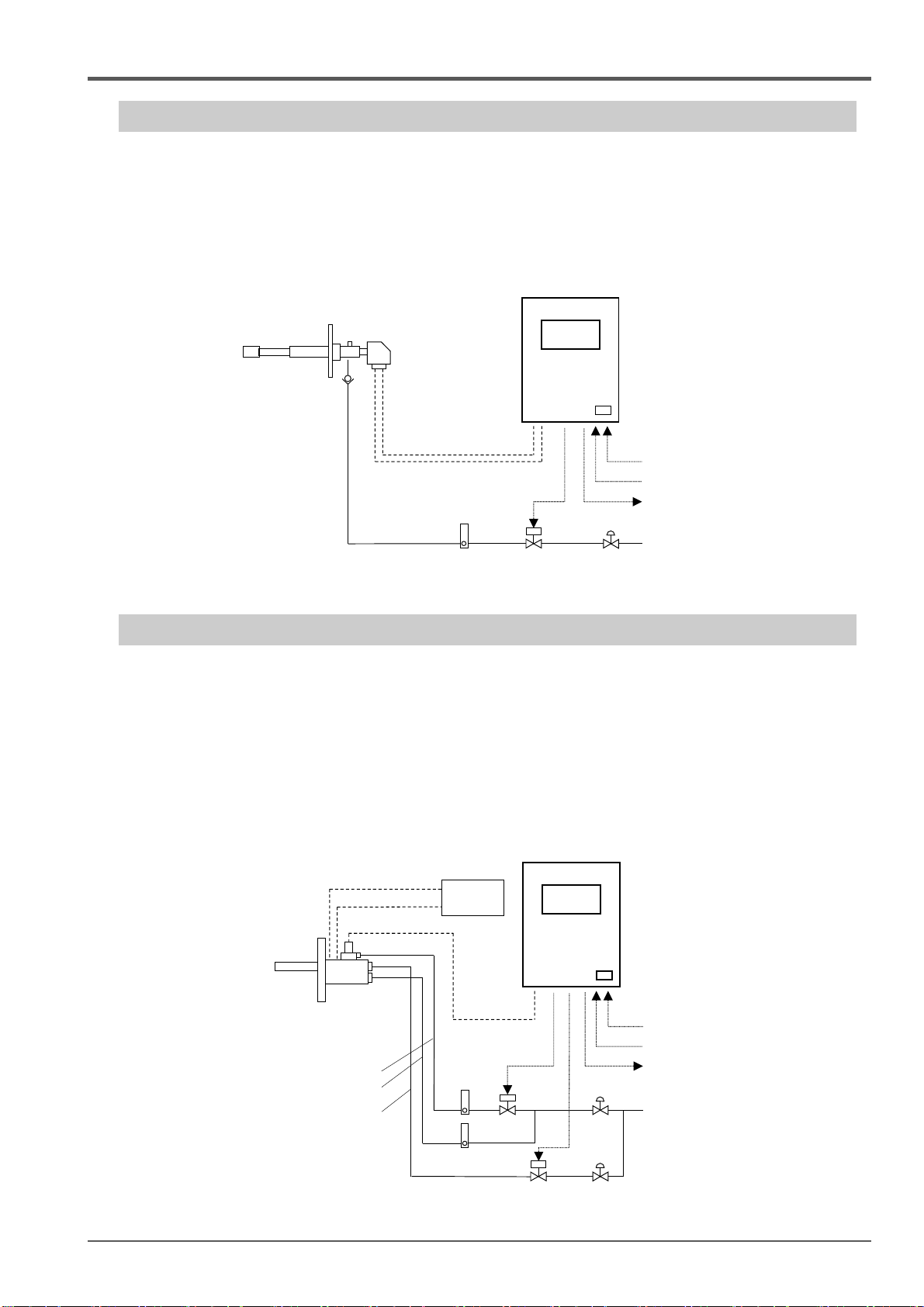

3.1.2 System Configuration Example 2

This system is an example of using "TF-10 Probe Transmitter" as an oxygen sensor to measure the

oxygen concentration in flue gas from a boiler, etc. A solenoid valve is installed in the calibration gas

line, and the contact output of the receiver is used to open and close the solenoid valve. Calibration

can be performed by methods such as "receiver key operation", "contact input", and "receiver internal

timer". Use instrument air or atmospheric gas for calibration. (Calibration using standard gas

cylinders such as zero gas and span gas is not required.)

3.1.3 System Configuration Example 3

This system uses a TF-III type probe transmitter as an oxygen sensor, to measure the oxygen

concentration in high-temperature flue gas in a heating furnace. In addition to calibration gas piping,

ejector air piping and purge air piping are used. Since the calibration gas and purge air are operated by

opening and closing the solenoid valve using the contact output of the receiver, calibration and purge

can be performed by methods such as "receiver key operation", "contact input", and "receiver internal

timer". Use instrument air gas for calibration. (Calibration using standard gas cylinders such as zero

gas and span gas is not required.) The TF-III type probe transmitter uses a separate power supply

and temperature control device for heating and keeping warm in order to prevent dew condensation in

the sampling section.

DTF-102 Receiver

K thermocouple

compensating lead

Heater power

Fig. 3-3 System Configuration Example 3

Fig. 3-2 System Configuration Example 2

TF-10 Probe Transmitter

Check valve

Control/signal wires

for sensor

4 cores shielded×2

Power supply 100 to 240 VAC

Contact input

Analog output (DC4 to 20mA)

Contact output

Flow

meter

Solenoid

valve

Pressure

reducing valve

Calibration gas

(Instrument air or atmospheric gas)

Contact output

Power supply 100 to 240 VAC

Contact input

Analog output (DC4 to 20mA)

Contact output

Flow

meter

Solenoid

valve

Pressure

reducing valve

Contact output

Instrument air

Control/signal wires

for sensor

8 cores shielded×1

TF-Ⅲ Probe Transmitter

Temperature

control device

Calibration gas piping

Ejector air piping

Purge air piping

DTF-102 Receiver

3 Installation

10

3.2 Place Conditions for Installation

When deciding on the "Installation Location"

DANGER

Explosion or Fire

This product is not explosion-proof. Do not use in an explosive gas

atmosphere.

When using a standard gas cylinder, install or store the standard gas

cylinder in a location with an ambient temperature of 40°C or less and

out of direct sunlight.

CAUTION

Injury, Malfunction or Damage

Install in a location that satisfies the installation location conditions

described in "Table 3-1 Installation location".

For safe, correct use of your oxygen analyzer, install the analyzer in a location with the following

conditions to provide the best possible installation conditions.

Not caused condensation by sudden temperature fluctuations.

Not directly exposed to much radiated heat.

Not significantly affected by electromagnetic fields.

Not exposed to much moisture and/or dust.

Little voltage fluctuation.

Little power frequency fluctuation.

Meeting the following conditions "Table 3-1 Installation Conditions":

Table 3-1 Installation Conditions

Item Spec.

Installation location Indoor

Ambient temperature -10℃ to +50℃

Ambient humidity 90%RH or less (Not condensation)

Environmental protection No waterproof structure

For the installation location conditions of the oxygen sensor (transmitter), check the instruction manual

of the oxygen sensor (transmitter) to be used.

Even if the temperature is within the range of the ambient temperature specification of this product,

the life of the product may be shortened if it is used in a constantly high ambient temperature

environment.

Install the product in a location where the required space can be secured. If space is not secured,

daily inspections and maintenance will not be possible, leading to equipment stoppages and product

damage.

This product is intended for industrial environments. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate measures.

Note

Popular Receiver manuals by other brands

Harman Kardon

Harman Kardon DPR 1005 Service manual

Explo IGNsystems GmbH

Explo IGNsystems GmbH RX2-1K Gas manual

Sony

Sony SAT-A2 Operating Instructions (primary... operating instructions

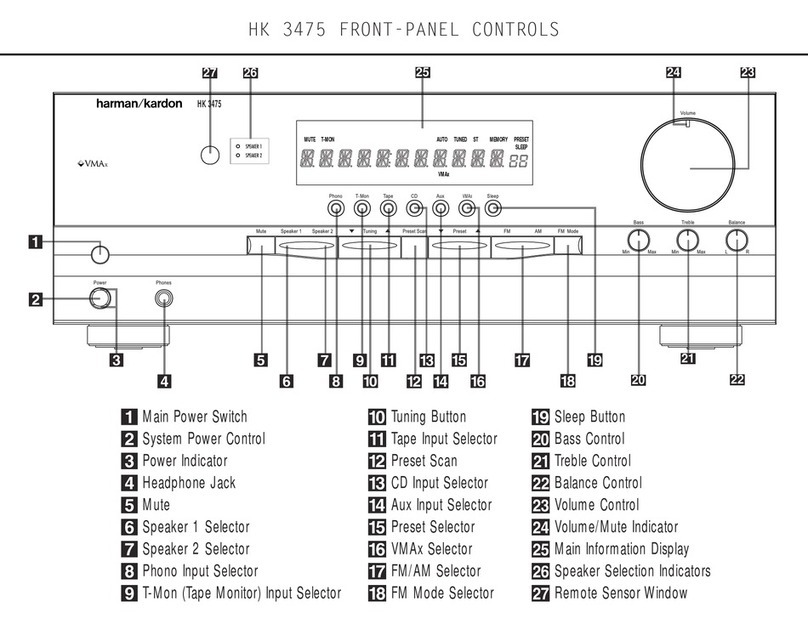

Harman Kardon

Harman Kardon HK3475 Product View

Extron electronics

Extron electronics FOXBOX Tx HDMI user guide

EasyDAB

EasyDAB V-DAB+ user manual