Energy Wall U-ERV 600 Instruction manual

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

Gen 4, REV 0, 2/1/21

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ENERGY RECOVERY VENTILATORS

1ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

TABLE OF CONTENTS

Safety Information............................................................................................................................2

Warranty……………………………………………………………………………………………………………………………………...2

Installation…………………………..……………………………………………………………………………………………….……..3

Mechanical……………………………………………………………………………………………………………………….3

Required Tools…….…………………………………………………………………………………………………3

System Inspection.…………………………………………………………………………………………………3

Multi Unit Assembly...................................................................................................4

General Unit Specifications........................................................................................5

Rail Mount…………………………………………………………………………………….……………..…….…6

Horizontal Orientation.………………………………………………………………………………..6

Vertical Orientation.…………………………………………………………………………………….7

Curb Mount...………………………………………………………………………………………..…………..….8

Intakes...…………………………………….…………………………………………………………………….9-10

Ductwork..…………………………..…………………………………………………………………………11-13

Electrical..…………….…………………………………………………………………………………………………………14

Electrical Ratings......................................................................................................14

System Wiring……………………..………………………………………………………………………………15

Remote HMI……………………………………………………………………………………………………..…16

General Wiring Schematic.…………………………………………………………………………………..17

Operation………………………..…………………………………………………………………………………………………………18

Start – Up Procedure...........................................................................................................18

System Commissioning….........…………....………………………………………………...............…………..19

Menu Layout….……………………………………………………………………………………...........20-21

Menu Descriptions...........………………………………………………………………………………22-33

BACnet/Modbus....…………………………………………………………………………………….....34-41

Optional Features......………………………………………………………………………………………………………42

Economizer/Defrost…………………………………………………………………………………………….42

Auxiliary Damper......................................................................................................43

Auxiliary Heat...........................................................................................................43

Performance..…..………………………………………………………………………………………………………………..........44

Airflow……………………………………………………………………………………………………………………….44-47

Acoustic…………………………………………………………………………………………………………………………..48

Service & Maintenance....….………………………………………………………………………………………………………49

Troubleshooting……………………………………………………………………………………………………………...49

Fault List………………………………………………………………………………………………………………………...50

Filter Replacement.…………………………………………………………………………………………………...51-52

General Maintenance..…………………………………………………………………………………………………...53

2ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

WARRANTY

Parts and System Housing

•2 years from date of installation

•Repair or replace defective parts at no charge

•Replaced parts are warrantied for the remainder of applicable period

•Labor not included or other costs incurred for servicing, repairing, removing, installing,

shipping, or handling of either defective or replacement

Internal Core

• 5 Years from date of installation

• Defects due to improper workmanship and/or materials

SAFETY INFORMATION

CAUTION!

RISK OF INJURY

Each system contains high-speed moving components

that risk serious injury. Prior to opening any access

panel, disconnect all power supplies and verify there is

no voltage to the system. Ensure all moving fan parts

and damper have come to a stop. Do not operate the

system with any access panels removed.

WARNING!

ELECTRIC SHOCK HAZARD

Disconnect all electric power sources prior to working on equipment. Wear protective equipment per NFPA 70

before servicing the electrical cabinet. Failure to comply may result in serious injury or death. Before

commissioning or servicing the system, read through this entire document carefully and ensure all precautions are

taken. Verify system nameplate electrical requirements match utility power. Refer to electrical schematic prior to

wiring. Adhere to all local codes when servicing the system.

CAUTION!

HOT SURFACE TEMPERATURES

Certain electrical components such as the supply and

exhaust fan motors can reach temperatures that are

extremely hot during and soon after operation. Ensure

adequate time for these components to cool before

servicing the system. It is recommended to use proper

PPE when servicing any component within the system.

NOTE

Any damage caused by negligence or improper installation procedures and practices will void the system’s

warranty. Ensure compliance to all installation instructions and procedures outlined by the manufacturer.

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 3

ENERGY WALLTM

U-ERV/U-HRV

INSTALLATION

MECHANICAL - REQUIRED TOOLS

MECHANICAL –SYSTEM INSPECTION/SITE PREP

Upon system arrival:

1. Inspect system for any damage caused by shipping or inappropriate

storage.

2. If present, immediately record and report any damage to shipping carrier

3. Verify all necessary components are present and intact

4. Verify system is configured as ordered

5. Clear system of any debris

Prior to placing the system:

1. Ensure installation site is structurally sound and clear of any obstructions

2. Verify adequate service clearances

3. Position system in a way that reduces complex duct transitions

4. If mounting outdoors, verify system inlet is positioned in accordance with

local building codes

THIS DOCUMENT CONTAINS PROCEDURES FOR GENERATION 4

CONTROLS. PLEASE VISIT www.energywall.com/installation-

manuals/ FOR PREVIOUS GENERATION MANUALS.

4ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

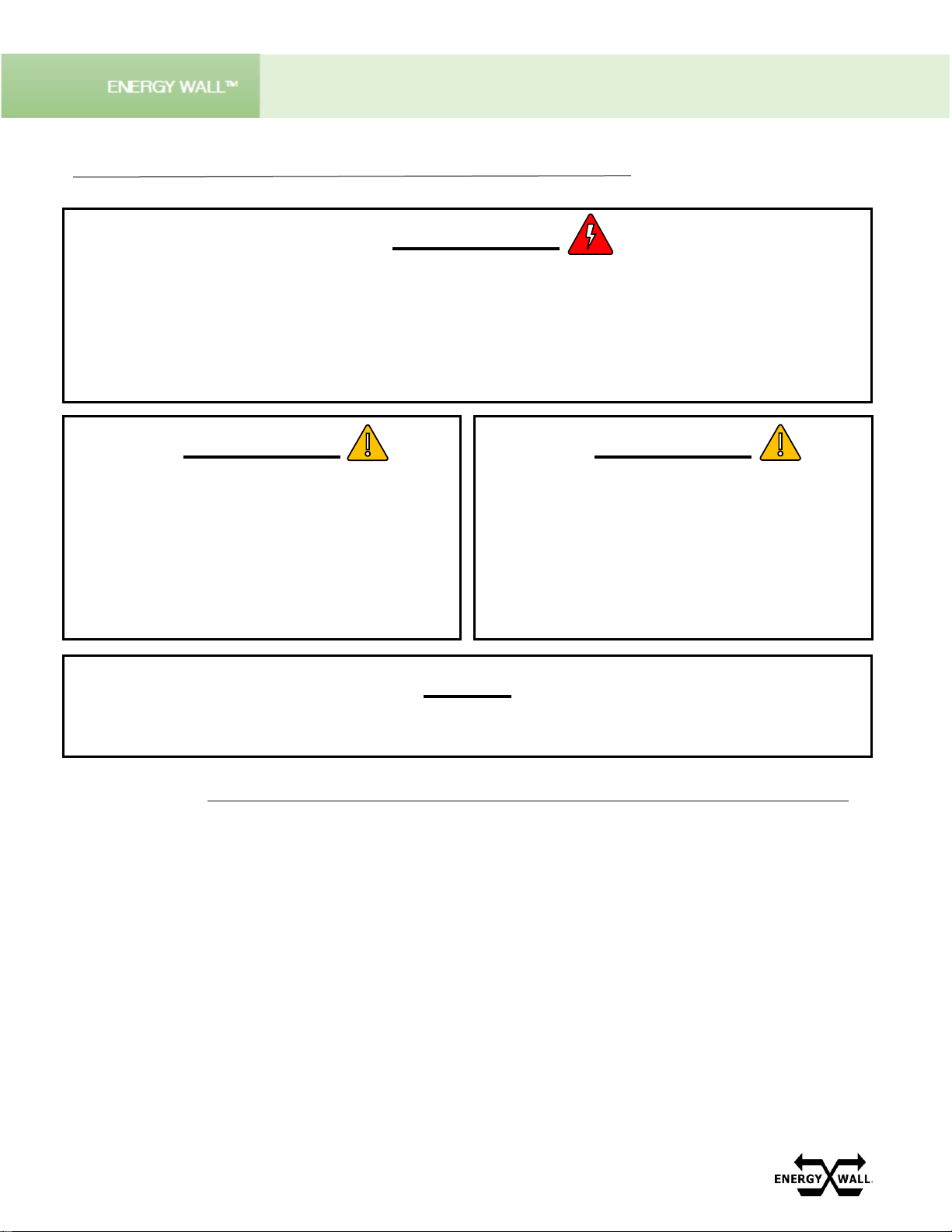

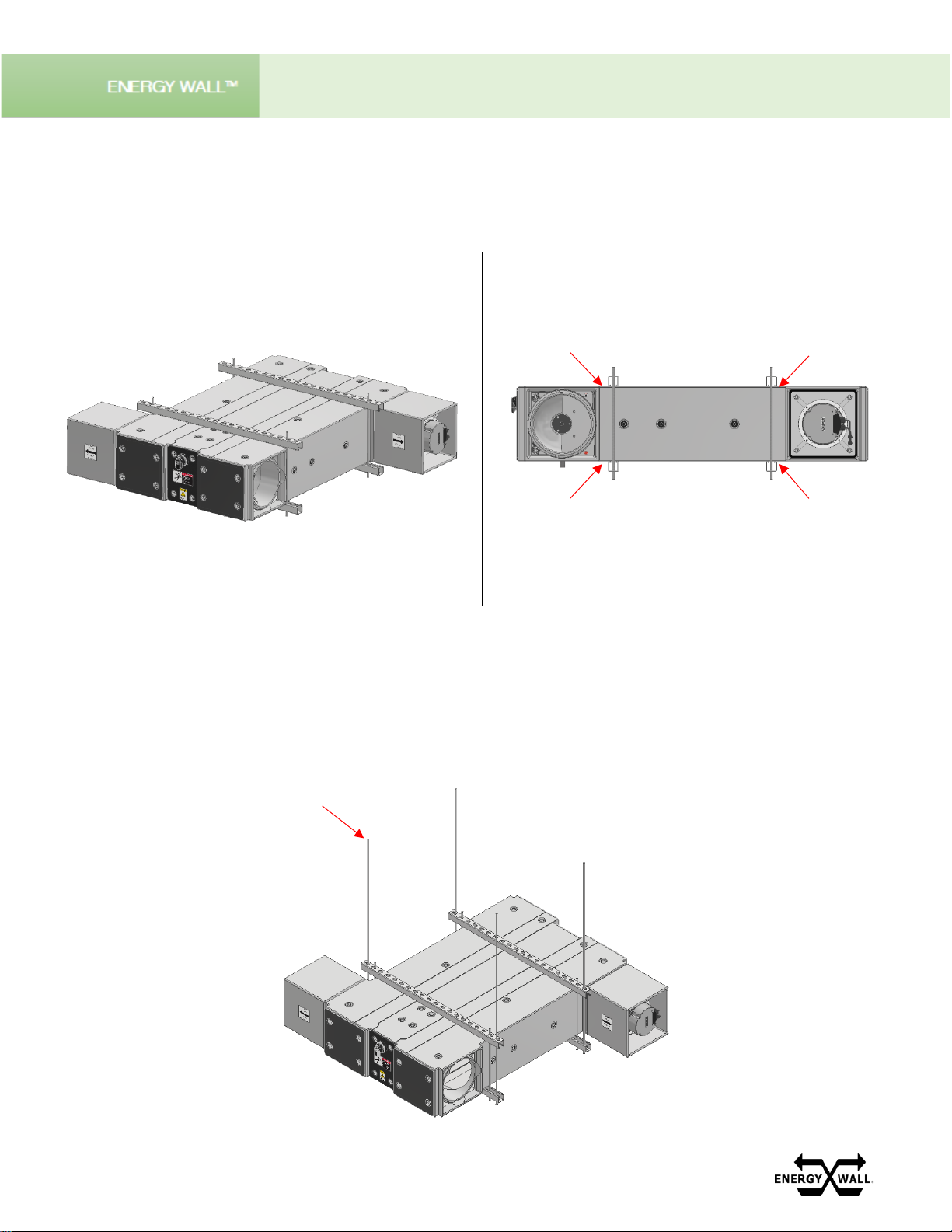

For systems larger than 600, units can be stacked to provide additional airflow and capacity. In

these scenarios, a secondary unit kit is provided with mounting hardware, wiring and gasketing.

INSTALLATION

MULTI-UNIT ASSEMBLY

Identify the primary unit with a disconnect handle as

shown below. All secondary units will not have a

disconnect handle.

PRIMARY

UNIT

SECONDARY

UNITS

Once the primary unit is positioned, ensure the

electrical cabinet wire plugs are removed using a

12mm Allen key (blue), perimeter gasketing is

installed at the locations as shown (red), and (4)

connecting bolts are installed in each quadrant (green).

Repeat on all units except the final unit in the system.

Prior to stacking the secondary unit with the primary,

ensure the secondary unit electrical cabinet wire plugs are

removed (blue

) and receiving plugs w/ a 7/16” dia. hole

are installed in each quadrant (green).

Stack the secondary unit to the primary unit as shown.

Tighten the connecting bolts with the hardware

provided and wire each unit per the electrical

schematics. Repeat as necessary to form the desired

system. The final unit will not have connecting bolts.

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 5

ENERGY WALLTM

U-ERV/U-HRV

INSTALLATION

GENERAL UNIT SPECIFICATIONS

6ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

Hang system assembly at desired height using minimum 3/8” dia. all-thread. When mounting the

system on a pad, 3/8” dia. all-thread can be substituted with vertical leg assemblies.

Ensure minimum 1.5” clearance between

Unistrut and system flanges to provide

adequate duct mounting clearance

Side View

INSTALLATION

MECHANICAL –HORIZONTAL RAIL MOUNT

Clamp system between 4 pieces of Unistrut as

shown below with minimum 3/8” dia. all-thread.

Be sure to leave an additional slot on each end to

hang the system.

DO NOT EXCEED 20 IN-LBS OF TORQUE WHEN

CLAMPING THE SYSTEM

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 7

ENERGY WALLTM

U-ERV/U-HRV

Clamp system between 4 pieces of Unistrut as

shown below with minimum 3/8” dia. all-thread.

Be sure to leave an additional slot on each end to

hang the system.

DO NOT EXCEED 20 IN-LBS OF TORQUE WHEN

CLAMPING THE SYSTEM

Ensure minimum 1.5” clearance between

Unistrut and system flanges to provide

adequate duct mounting clearance

Side View

Hang system assembly at desired height using minimum 3/8” dia. all-thread. When mounting the

system on a pad, 3/8” dia. all-thread can be substituted with vertical leg assemblies.

INSTALLATION

MECHANICAL –VERTICAL RAIL MOUNT

8ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

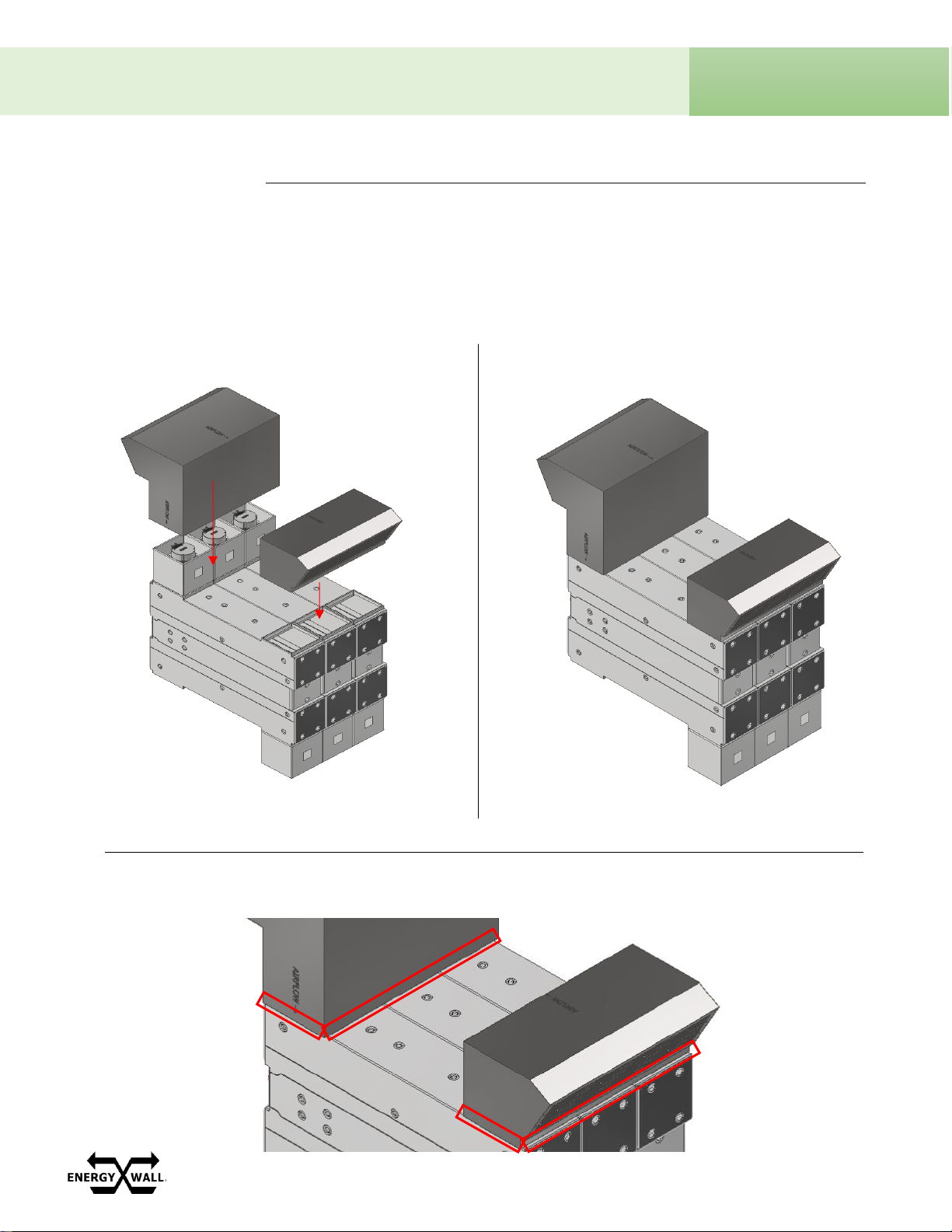

Once the curb is positioned and fastened in

place, apply the supplied gasket around each

flange as shown*

*1800 system shown for reference

Place the first unit on the curb, over the duct

flanges, as shown. In some instances, the fan

cubes will be mounted underneath the unit

as opposed to on top. This is acceptable.

Place the remaining units (if applicable). Fasten

the 4 connecting bolts inside each access panel

with the hardware provided as shown

Once the system is in place, secure it to the curb duct

flanges using #14 x 1.5” long self-drilling screws. A

minimum of 4 screws must be used per unit (i.e. an

1800 system requires at least 12 screws)

INSTALLATION

MECHANICAL –CURB MOUNT

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 9

ENERGY WALLTM

U-ERV/U-HRV

When mounted outdoors, an intake is required to eliminate water infiltration into the intake and exhaust ports

of the system. When an intake is required to be installed over a fan cube, it will have an acoustic liner. All

other intakes are unlined. Additional intake options with motorized dampers are available upon request.

Slide the intake hood over the fan cube (left) or

system flange (right) as shown below*

*1800 system shown for reference

Ensure the intake hood’s opening is flush with

the horizontal surface of the system as shown

Once the intake is in place, secure it to the system flanges using #14 x 1.25” long self-drilling screws on all 4

sides. A minimum of 2 screws must be used per unit (i.e. an 1800 system requires at least 6 screws per intake)

INSTALLATION

MECHANICAL –INTAKES, VERTICAL MOUNT

Acoustic

(lined)

Intake

Standard

(unlined)

Intake

10 ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

Slide the intake hood over the fan cube (right) or

system flange (left) as shown below*

*1800 system shown for reference

Ensure the intake hood’s opening is flush with

the vertical surface of the system as shown

Once the intake is in place, secure it to the

system flanges using #14 x 1.25” long self-

drilling screws on all 4 sides. A minimum of 2

screws must be used per unit (i.e. an 1800

system requires at least 6 screws per intake)

INSTALLATION

MECHANICAL –INTAKE, HORIZONTAL MOUNT

Acoustic

(lined)

Intake

Standard

(unlined)

Intake

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 11

ENERGY WALLTM

U-ERV/U-HRV

INSTALLATION

MECHANICAL –DUCTWORK

When designing and installing ductwork to each system, SMACNA guidelines and requirements

must be adhered to. Additionally:

•A single duct run can and should be used for each system.

•It is highly recommended to use insulated duct with a minimum of ¾” thick internal

insulation.

•Flexible duct connections should never be used and avoided at all costs.

•All transitions within the ductwork shall be gradual and all elbowsshall incorporate a radius

on internal and external corners.

•Turning vanes should be utilized whenever possible.

•NEVER USE THE SYSTEM TO SUPPORT DUCTWORK. All ductwork must have

its own support.

•Verify ductwork properly slides over the system flanges (fan cube when applicable). See

next page for recommended duct connection details.

•Minimum straight duct lengths prior to any elbow per the below table must be adhered to.

Additional length is recommended to mitigate sound within the space.

•When installing duct from curb hangers, ensure proper alignment of duct with system

inlet/discharge. Gasket must be used to seal the duct flanges with the underside of the

curb cap. Failure to gasket the ductwork flanges will result in airflow leakage and increases

the potential for condensation formation.

•Secure ductwork to system using #12 or #14 x 1.25” long self-drilling screws. DO NOT

USE LONGER THAN 1.25” SCREWS.

System Size

Recommended

Ductwork Size (IN)

Minimum Straight

Duct Length (IN)

600

12.13 x 12.13

35

1200

12.13 x 24.25

48

1800

12.13 x 36.38

60

2400

12.13 x 48.5

68

3000

12.13 x 60.63

78

3600

12 13 x 72.75

85

4200

12.13 x 84.88

90

4800

12.13 x 97

98

5400

12.13 x 109.13

103

6000

12.13 x 121.25

108

12 ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

INSTALLATION

MECHANICAL –DUCTWORK

It is highly recommended to A) section the duct that connects to the system with (2) 14” minimum duct

sections, or B) provide access panels within the sides of the duct to allow the system to be easily

serviced. An example of each duct connection recommendation for an 1800 system is shown below.

A*

*TO SERVICE A FAN WITHIN DUCT, REMOVE DUCT “2”, FOLLOWED BY DUCT “1”. ENSURE DUCT “3” IS

INDEPENDENTLY SUPPORTED AND DOES NOT RELY ON THE SYSTEM FOR SUPPORT.

B**

**A WATER-TIGHT ACCESS PANEL CAN BE INSTALLED IN THE LOCATION AND SIZE SPECIFIED WITHIN

THE DUCT TO SERVICE A FAN.

14” MIN

14”

6”

14”

6”

14” MIN

1

2

3

1

2

3

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 13

ENERGY WALLTM

U-ERV/U-HRV

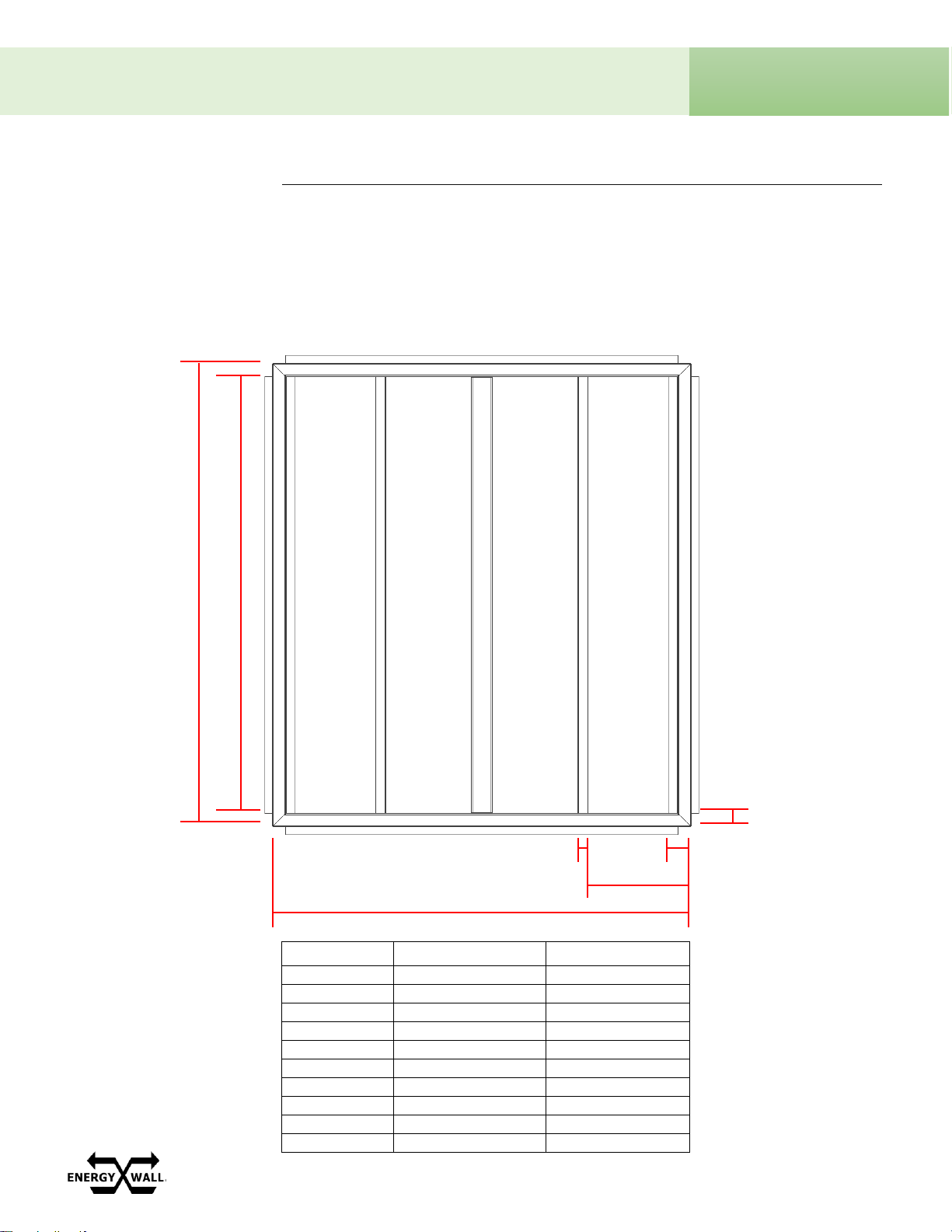

Refer to the table and image below for duct hanger locations within the curb (curb lid not shown).

System Size

A (IN)

B (IN)

600

17.5

13.75

1200

29.75

26

1800

42

38.25

2400

54.25

50.5

3000

66.5

62.75

3600

78.75

75

4200

91

87.25

4800

103.25

99.5

5400

115.5

111.75

6000

127.75

124

INSTALLATION

MECHANICAL –DUCT HANGERS

1.88”

A

B

60.13”

15.5”

3.25”

1.38”

14 ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

INSTALLATION

ELECTRICAL INFORMATION

The electrical ratings for each system size are listed below. Consult sales for additional voltage and

phase combinations.

SYSTEM ELECTRICAL RATINGS

System

Voltage

Frequency

Phase

FLA

MCA

MOP

600

208-277V

50/60

1

7.4

8.3

15

1200

208-277V

50/60

1

14.3

15.1

20

1800

208-277V

50/60

3

12.2

13.1

15

2400

208-277V

50/60

3

19.3

20.2

25

3000

208-277V

50/60

3

26.2

27

30

3600

208-277V

50/60

3

24.1

25

30

4200

208-277V

50/60

3

31.2

32.1

35

4800

208-277V

50/60

3

38.1

38.9

40

5400

208-277V

50/60

3

36

36.9

40

6000

208-277V

50/60

3

43.1

44

45

As standard, all supply and exhaust fans utilize a state-of-the-art electrically commutated motor

(ECM) to directly drive a mixed flow wheel. Fan specifications are listed below.

FAN DATA

System

Voltage

Frequency

Supply

Fan

Quantity

Exhaust

Fan

Quantity

Max

Supply

HP

Max

Exhaust

HP

Max

Fan

RPM

600

208-277V

50/60

1

1

0.9

0.9

6150

1200

208-277V

50/60

2

2

1.9

1.9

6150

1800

208-277V

50/60

3

3

2.8

2.8

6150

2400

208-277V

50/60

4

4

3.8

3.8

6150

3000

208-277V

50/60

5

5

4.7

4.7

6150

3600

208-277V

50/60

6

6

5.6

5.6

6150

4200

208-277V

50/60

7

7

6.6

6.6

6150

4800

208-277V

50/60

8

8

7.5

7.5

6150

5400

208-277V

50/60

9

9

8.5

8.5

6150

6000

208-277V

50/60

10

10

9.4

9.4

6150

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 15

ENERGY WALLTM

U-ERV/U-HRV

The system has (4) ¾” NPT threaded access ports that can be used for power and control wire

connections. (2) on the top and (2) on the bottom. High voltage wires and low voltage wires

should never run in the same conduit as each other, or parallel for long distances.

Top View Bottom View

To remove the threaded plug, a 12mm Allen wrench

is required. Once removed, a ¾” stress relief can be

used to secure the wire run to the system.

Connect power wires to the disconnect and terminal

blocks shown below in red, and control wires (if

applicable) to the terminal blocks and primary controller

shown below in blue. Detailed schematics will be

provided per job.

WARNING: BEFORE PROCEEDING, DISCONNECT POWER TO THE UNIT. WIRING

SHOULD ONLY BE PERFORMED BY AN EXPERIENCED, QUALIFIED ELECTRICIAN

Top View Bottom View

INSTALLATION

ELECTRICAL –SYSTEM WIRING

16 ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

For applications that require system control and menu navigation from the space, a remote human-machine

interface (HMI) can be used as shown below.

Typical HMI Wiring

The HMI can be mounted in a standard junction box

via the screw holes shown below. All hardware

required to physically mount the HMI is included.

INSTALLATION

ELECTRICAL –REMOTE HMI

UP

DOWN

ENTER

ESC/BACK

PROGRAM

FAULTS

ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365 17

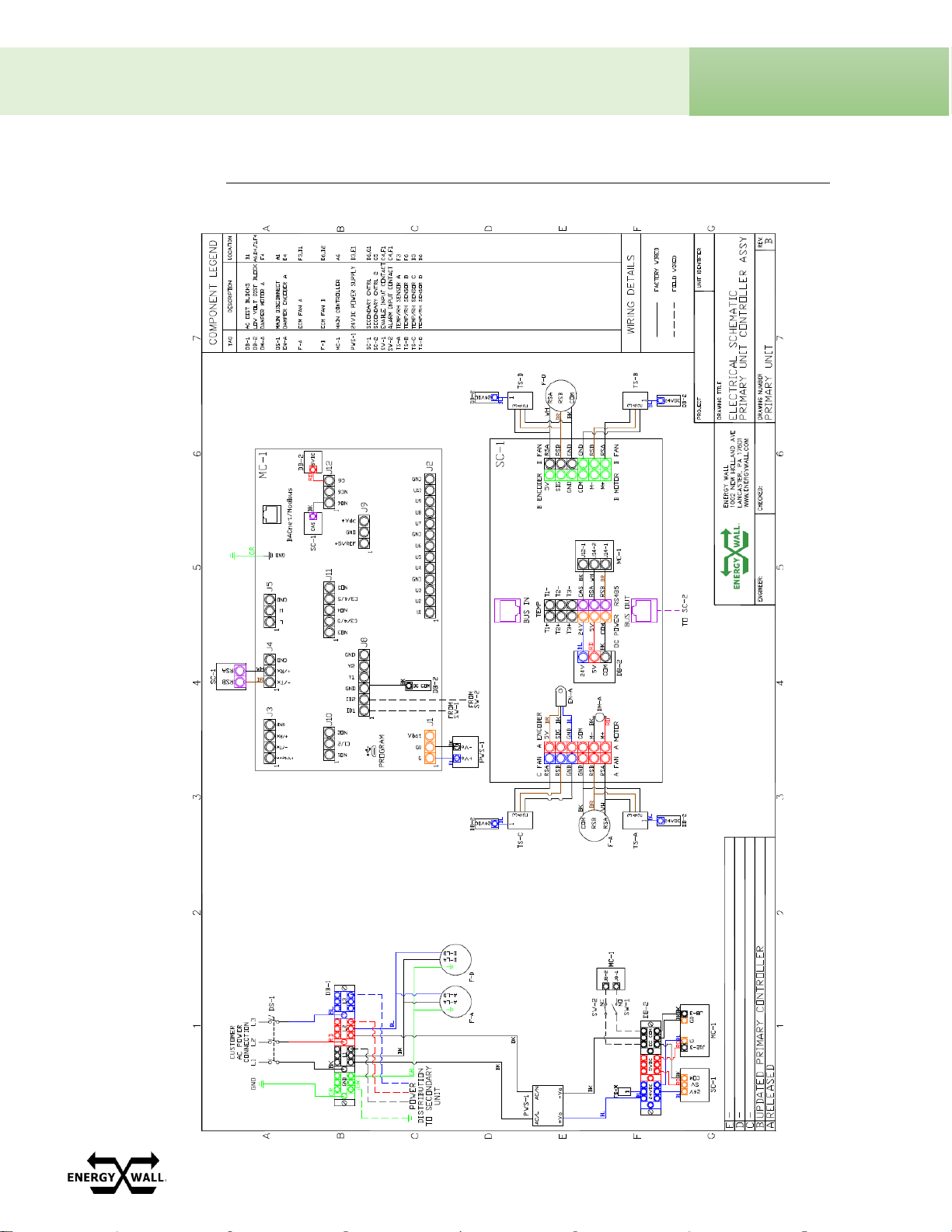

ENERGY WALLTM

U-ERV/U-HRV

INSTALLATION

ELECTRICAL –GENERAL WIRING SCHEMATIC

18 ENERGYWALL.COM INSTALLATION, OPERATION & MAINTENANCE MANUAL 717.814.5365

U-ERV/U-HRV

Prior to powering the unit, verify there areno loose parts or documentation within the system, or debris

in the airstreams.

1) Inspect all moving parts and verify they are free and clear of any obstructions.

2) Verify all hardware is tight.

3) Verify there are no loose wires.

4) Examine all duct connections and ensure there are no visible gaps that could cause airflow and

water leaks. If any are identified, seal as necessary.

5) Confirm all access panels are secured in place.

6) Once steps 1-5 have been completed, turn the disconnect to the “ON” position.

Most applications will be configured per job from the factory. If new software is required, or the

controller needs to be programmed, follow the “System Commissioning” instructions on page 14 of

this document.

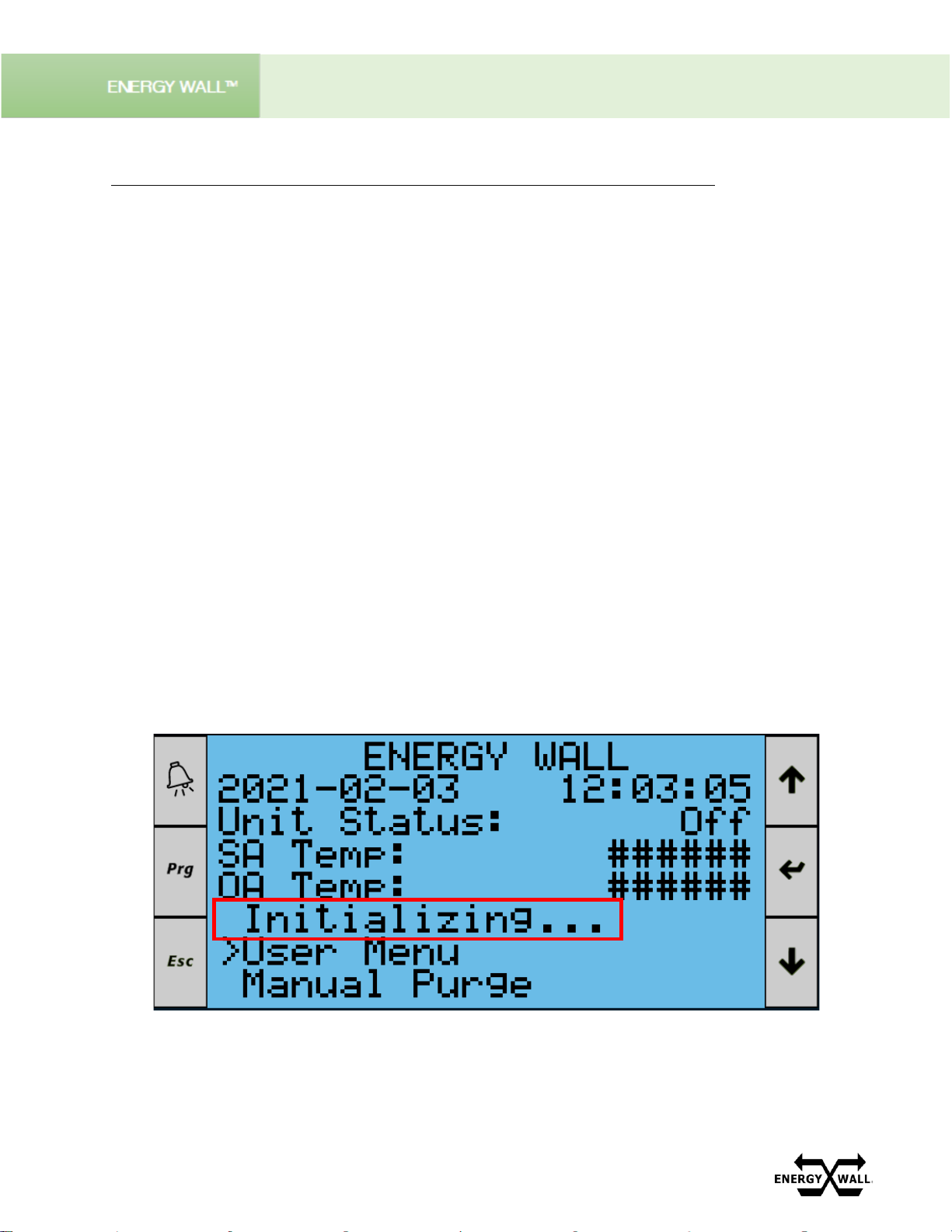

Once the system is powered, it will begin an initialization sequence to identify secondary units. The

initialization sequence can be identified on the remote HMI or main controller home screen as shown

below. This occurs every time the system is power cycled. Once completed, the “Initializing...” term

will no longer be displayed. The system is now ready to operate.

OPERATION

SYSTEM START-UP PROCEDURE

This manual suits for next models

18

Table of contents

Other Energy Wall Fan manuals

Popular Fan manuals by other brands

AccuraSEE

AccuraSEE MINI user manual

Vent-Axia

Vent-Axia Lo-Carbon Silhouette 100HT Installation and wiring instructions

Broan

Broan SKY Series Installation and user guide

Taurus Alpatec

Taurus Alpatec BOREAL 12 ELEGANCE manual

Monte Carlo Fan Company

Monte Carlo Fan Company 3MAVR60RZW Owner's guide and installation manual

Wonderlamp

Wonderlamp W-V000020 manual

Zehnder Rittling

Zehnder Rittling ComfoAir 550 Luxe Installer manual

Fantask

Fantask EP23485WH quick start guide

S&P

S&P HR100V Installation and wiring instructions

twin city

twin city HIB Installation, operation & maintenance manual

Vents

Vents VKMz 100 user manual

Broan

Broan Roomside / Flex Series instructions