Energy Wall ERV-600 Instruction manual

Table of contents

Other Energy Wall Fan manuals

Popular Fan manuals by other brands

Johnson

Johnson Medina Instructions for use

Home Decorators Collection

Home Decorators Collection KENSGROVE YG493A-BN Use and care guide

Modern Forms

Modern Forms FR-W2202-62L-SB/MB installation instructions

Hitachi

Hitachi airCore 700 Operation installation maintenance manual

Klarstein

Klarstein VALDERAMA 10029347 manual

Westinghouse

Westinghouse ETL-ES-Comet-WH15 owner's manual

Salda

Salda VSA EKO Series Installation instruction

aerauliqa

aerauliqa Quasar Series installation manual

Monte Carlo Fan Company

Monte Carlo Fan Company AC-552 Owner's guide and installation manual

Gaggenau

Gaggenau AC270101 Instructions for installation and use

Daikin

Daikin AVV Installation and maintenance manual

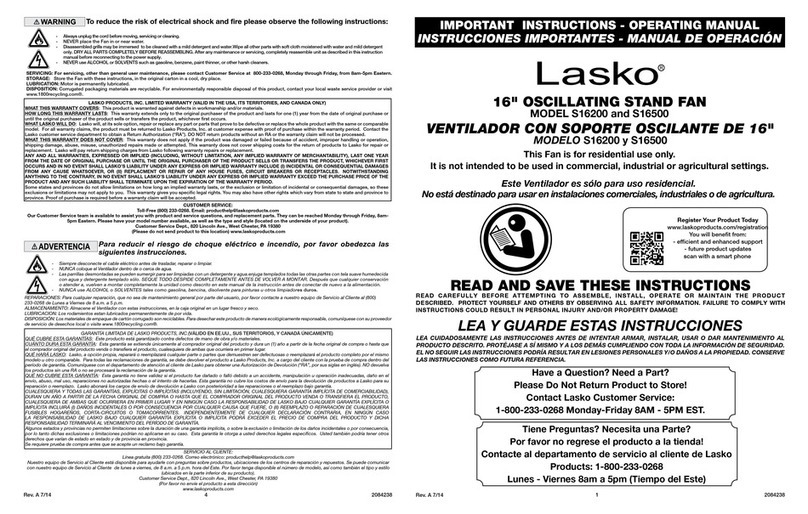

Lasko

Lasko S16200 instructions