Enernet 130 User manual

Pub No. 13001-082207

ENERNET Corporation Copyright 2007

Model 130 User Guide

Communicating Thermostat Wireless RS485 Accessory

MODEL 13000 Application Guide

ENERNET CORPORATION IS NOT RESPONSIBLE FOR ANY

RADIO OR TV INTERFERENCE CAUSED BY UNAUTHORIZED

MODIFICATIONS TO THIS EQUIPMENT. SUCH

MODIFICATIONS COULD VOID THE USER’S AUTHORITY TO

OPERATE THE EQUIPMENT.

THIS EQUIPMENT COMPLIES WITH PART 15 OF THE FCC

RULES. OPERATION IS SUBJECT TO THE FOLLOWING TWO

CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE

THAT MAY CAUSE UNDESIRED OPERATION.

ENERNET CORPORATION PROVIDES THIS PUBLICATION “AS

IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

THIS MANUAL MAY CONTAIN TECHNICAL INACCURACIES

AND/OR TYPOGRAPHICAL ERRORS. CHANGES ARE

PERIODICALLY MADE TO THIS MANUAL, WHICH ARE

INCORPORATED IN LATER EDITIONS.

ENERNET CORPORATION MAY MAKE CHANGES AND

IMPROVEMENTS TO THE PRODUCT(S) AND/OR PROGRAMS

DESCRIBED IN THIS PUBLICATION AT ANY TIME WITHOUT

NOTICE.

IN NO EVENT WILL ENERNET CORPORATION BE LIABLE FOR

DAMAGES, INCLUDING LOST PROFITS, LOST SAVINGS OR

OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OF OR INABILITY TO USE SUCH

PRODUCT, EVEN IF ENERNET CORPORATION OR AN

APPROVED RESELLER HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY

ANY OTHER PARTY.

ENERNET

Corporation

307 Dewittshire Road, Syracuse, New York 13214

Phone: (315) 449-0839 Fax: (315) 449-3056

MODEL 13000 Application Guide

ANTENNA

The wireless RF equipment described in this document may be

supplied with one of two possible antenna configurations.

Stick-On 1/2-wave Dipole Antenna:

Antenna Factor P/N ANT-916-MHW-RPS

PCB Mounted 12-Inch CoaxialMonopole:

ENERNET P/N 060-012

EQUIPMENT MANUFACTURER (OEM)

The Original Equipment Manufacturer (OEM) must ensure that

FCC labeling requirements are met. This includes a clearly visible

label on the outside of the final product enclosure that displays the

following:

CONTAINS FCC ID: TGD13000

MODEL 13000 Application Guide

1

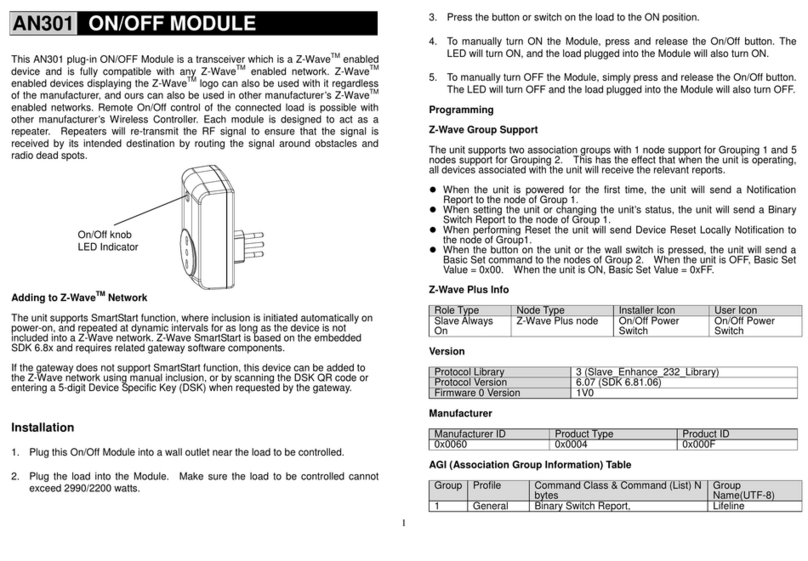

Figure 1: Aprilaire 8870 Thermostat —Model 130 Remote Communication Node

PB1

—

SERIAL LOOP BACK TEST

A valid 8870 thermostat command is sent ov er the

RS485 interface. A valid return data string is

expected.

?Green LED (D5) flash = PASS

?Red LED (D4) flash = FAILED.

PB2 —RF COMMUNICATION TEST

Initiates a 5-second communication test with the

model 130 Master transceiver it has been linked to. .

?Green LED (D5) flash = PASS

?Red LED (D4) flash = FAILED

PB3 —CONFIGURATION SETUP

Holding PB3 down for 3-seconds places unit into

configuration setup (see Configuration Setup section

for details).

PB2 + PB3 —INSTALLATION MODE

Simultaneously pressing PB2 & PB3 places the

model 130 Remote Communication Node (RCN) into

Installation Ready mode for a 5-

second period during

which time it can be linked to a Master Transceiver.

The Yellow LED (D3) and Green LED (D2) will

simultaneously light to indicate the RCN is in

Installation Ready mode.

PB1

PB3

PB2

D1D2

D3

D5D4

RED ( R )

BLK ( C )

YEL (A+)

BLUE (A-)

WH (B+)

GRN (B-)

J2

Power Supply

Network

Processor

ANT

Thermostat

24VAC Power

Crystal

Serial Interface

8870 Thermostat

Communication Terminals

RF

XCVR

RF Section

MODEL 13000 Application Guide

2

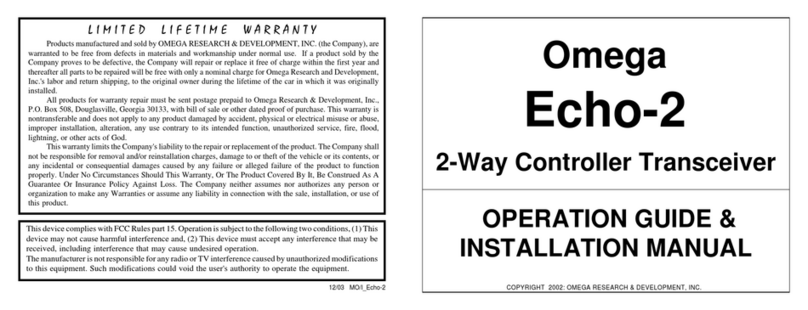

Figure 2: NI-700 —Model 130SMA Master Transceiver

PB1

—

SERIAL LOOP BACK TEST

A valid 8870 thermostat command is sent over the

RS485 interface. A valid return data string is

expected. Green LED (D5) flash indicates a pass.

Red LED (D4) indicates a failure.

Note that the Master Transceiver position is not

interfaced with an 8870 thermostat and will therefore

indicate a loop back test failure.

PB2 —LINK

Pressing PB2 when an RCN is in the Installation

Ready mode will link that RCN to the Master

Transceiver.

PB3 —CONFIGURATION SETUP

Holding PB3 down for 3-seconds places unit into

configuration setup (see Configuration Setup section

for instructions).

PB1

PB3

PB2

D1D2

D3

D5D4

RED ( + )

BLK ( -)

J2

Power Supply

Network

Processor

ANT

NI

-

700

12VDC PWR

Crystal

Serial Interface

NI

-

700

9-Pin Serial Port

ANTENNA

P/N: ANT-916-MHW-RPS

RF

XCVR

RF Section

MODEL 13000 Application Guide

3

INTRODUCTION

The model 130 series RF transceivers are designed to provide a

wireless, meshnetworkRS485/422 interfaceover an unlicensed

900MHz RF data channel. The application discussed in this

manual utilizes an NI-700 NetLinx Integrated Controller made by

AMX and the Aprilaire model 8870 Communicating Thermostat.

The Aprilaire 8870 thermostatsupports a hardwiredRS485/422

serial communication channel such as that provided byan NI-700

serial port. Through the NI-700, information can be receivedfrom

and commands can be sent to individually addressed thermostats.

As many as 64 thermostats can be connected on a single network.

The model 130 series RF transceiver provides a transparent

wirelesscommunication channel between an NI-700 and its

associated thermostats.

There are two physical configurations of the model 130 as well as

two operating configurations. Figure 1 above shows a model 130

Remote Communication Node or RCN, which is located with an 8870

thermostat. This configuration provides two power wires, four

RS485/422 serial communication wires and a 12” long coaxial

antenna. It should be powered by the same 24VAC as the

thermostat. (Black ‘C’wire MUST connect to the thermostat ‘C’

wire-Red ‘R’wire MUST connect to thermostat ‘R’wire.) Figure 2

depicts a model 130SMA Master Transceiver. In this physical

configuration, the four serial communication wires are replaced by

a 9-pin female serial connector. The antenna is replaced by the

SMA style threaded connector which mates to a remote antenna

connector.Operating configuration setup is covered later in this

manual.

MODEL 13000 Application Guide

4

OPERATING CONFIGURATION

Model 130 series RF transceivers can be configured to operate as

either a Master Transceiver or as a Remote Communication Node

(RCN) And, the mesh network / repeater function can be turned on

or off (factory default is off). Because of the physical configuration

differences in the two modelsit is unlikely to be necessary to alter

the Master Transceiver / RCN configuration.

Twoconfiguration property tablesare accessible by the user. The

first property table setsMode of Operation, The secondsetsthe

mesh network / repeater function on or off. The configuration

tables that followprovide operational descriptions and factory

default settings. Selections are indicated through the FLASH-

COUNT of LED’s D1and D2. (Refer to Figure 1 and 2 above.)

D2repeatedlyflashes 1 or2times to indicate the property table

that is active. D1flashes 1 or 2times to indicate thespecific

operational ‘property’ selected.

(Refer to Figure 1 or 2 for button and LED locations)

PB3 (Configuration Setup)will switch the unit into and out ofthe

configuration mode. Holding PB3 down for approximately 3-

seconds will take you into the configuration area. To leave the

configuration area, simply press and release PB3. PB2selects

configuration table 1 or2, which is indicated by D2FLASH-

COUNT.

PB1selects theconfiguration property as indicated by D1FLASH-

COUNT. Pressing PB3to leave the configuration area will save

changes made. To review or change the configuration, refer to the

configuration tables below for descriptionsand perform the

following:

1. Press and hold PB3 until LED indicator lamps D2 & D1 flash

alternately. (NOTE: At any time during the setup process PB3 can

be pressed again to return to normal operation.)

2. D2will flash once indicating Table 1, Operating Mode

configuration, followed by D1flashing 1 or 2times indicating the

specific configuration in Table 1 that is currently active. (NOTE:

D2 and D1 will flash repeatedly to indicate the Table and the

configuration.) Pressing PB1will advance the configuration option

by one. Press PB1until the FLASH-COUNT corresponds to the

desired configuration. (Refer to Table 1.)

3. Press PB2to advance to Table 2, Message Repeat

configuration. D2willflash2 times, followed by D1 flashing 1 or 2

times depending on how it is currently set. Press PB1until the

FLASH-COUNT corresponds to the desired configuration.

4. Press PB3 to return to normal node operation, saving any

configuration changes you’ve just made.

MODEL 13000 Application Guide

5

M A S T E R T R A N S C E I V E R / R C N C O N F I G U R A T I O N —T A B L E 1

D2D1

CONFIGURATION FLASH

COUNT FLASH

COUNT DESCRIPTION

1Remote Communication Node RCN*

(Factory Default) 11 Wires directly to an Aprilaire 8870 Communicating

Thermostat.

2Master Transceiver 12 Plugs on to one of the RS485/422 serial ports of an NI-700.

* Factory default setting.

R E P E A T E R ON / OFF C ONFI G URATI O N—T A B L E 2

D2D1

CONFIGURATION FLASH

COUNT FLASH

COUNT DESCRIPTION

1Mesh Repeater function OFF*

(Factory Default) 21 Does not repeat messages it hears from a Master

Transceiver or other RCN units. (Applies only to an RCN.)

2Mesh Repeater function ON 22 Repeats messages it hears from a Master Transceiver or

other RCN unit. (Applies onlyto an RCN.)

* Factory default setting.

MODEL 13000 Application Guide

6

INSTALLATION / LINKING

A Master Transceiver and Remote Communication Node will not

operate as a system until they are linked together through the

installation linking process. The linking process binds one or more

RCN units to a Master so that they will communicate with each

other as a control system. There is no practical limit to how many

RCN units can be linked to a Master. Once linked,Remote

Control Nodeswill only respond to the Master they are linked to.

Message traffic from other Master Transceiversand nodes will be

ignored. Master Transceivers and associated RCN unitswill not

interfere with or be affected by any other Masteror RCN in

adjacent apartments, hotel rooms or neighboring homes. Linking

information is stored in non-volatile memory —It is not necessary

to re-link a Master and RCN if power is lost.Upon restoration of

power the units will continue to communicate as before.

NOTE:

If multiple installation teams are performing the linking process at the same

time, coordinate theactivity to avoid the possibility of installers

simultaneously attempting to link RCN units.

For immediate visual confirmation of a successful link, it is recommended

that RCN’s and Master Transceivers are linked in close proximity to each

other.

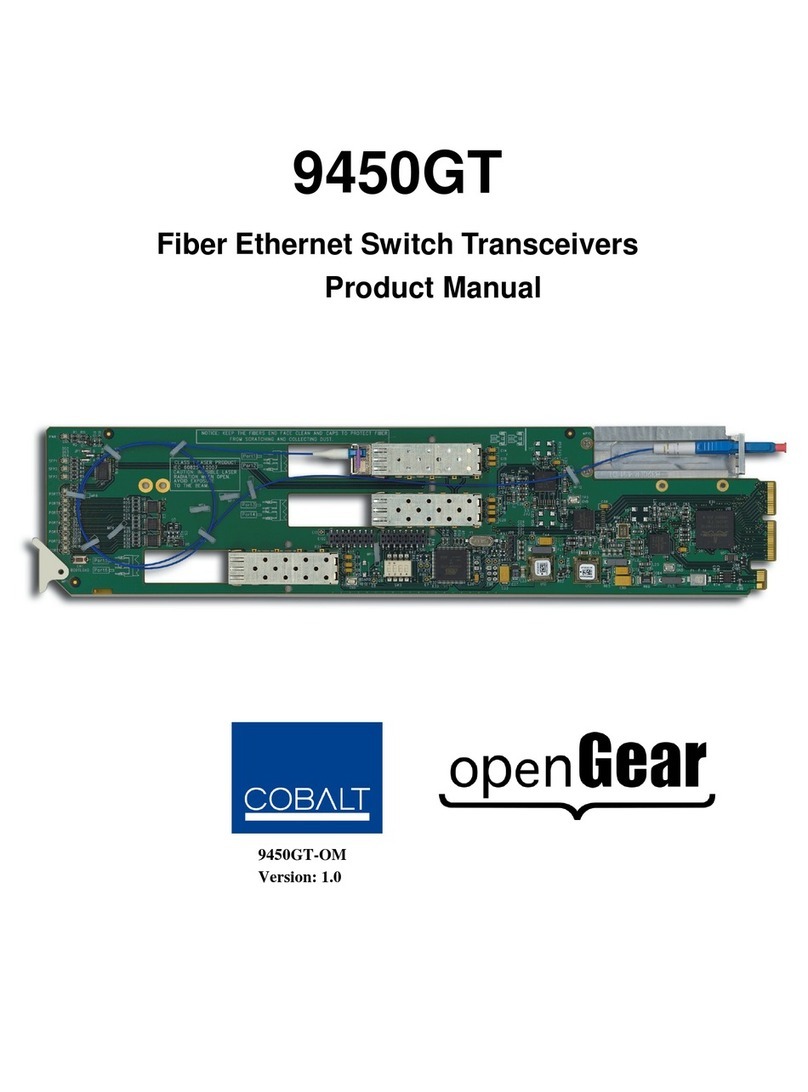

LINKING PROCESS

Start the linking process by simultaneously pressing PB2 and PB3

on the Remote Control Node you wish to associate with a given

Master Transceiver. LED’s D2 and D3 will light and stay on for

approximately 5-seconds after you have simultaneously pressed

both buttons indicating an installation link period window is open.

Simultaneously press PB2 and PB3 on any RCNcircuitboard to

initiate an installation period.

At any time during the link period window, press PB2 on the

Master Transceiver. A successful link is indicated by green LED

D4 flashon the RCN. Anunsuccessful link or installation period

timeout is indicated by red LED D5 flash.

PB1

PB3

PB2

D1

D2

D3

PB1

PB3

PB2

D1

D2

D3

MODEL 13000 Application Guide

7

RF COMMUNICATION TEST

After RCN units have been linked to a Master and installed on

thermostat bases, a communication test should be run to ensure a

reliable communication path exists between each RCN and its

Master Transceiver.

Initiate a 5-second communication test with the Master transceiver

by pressing PB2 on the RCN under test. After the 5-second test

period a PASS/FAIL indication is given:

?Green LED (D5) flash = PASS

?Red LED (D4) flash = FAILED

Each model 130 wireless RS485/422 RCN can be operated with

or without mesh (message repeating) functions turned on. Factory

default is repeater OFF. With the repeater function off, the Master

Transceiver must be able to directly communicate with each of its

RCN’s. While the repeater function allows the system to over

come RF range limitations, unnecessary repeats adds traffic to the

network. A better use of the function is to selectively enable it.

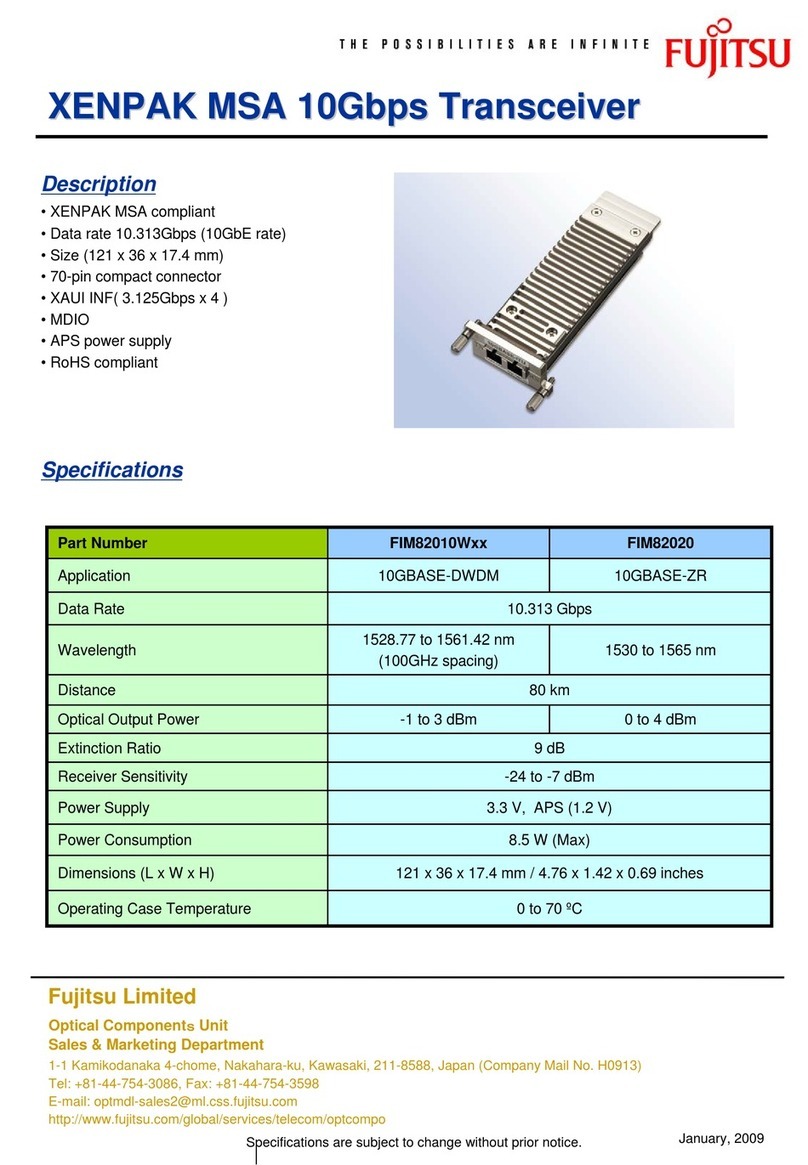

Figure 3 is an example of using the repeater function selectively.

In this example case, a Master Transceiver directly communicates

with RCN 1, 2 and 3. RCN 4 and 5 however are out of range.

RCN 3 is the closet RCN to 4 and 5. Its repeater function is

enabled, forming the bridge between the Master and RCN units 4

and 5.

Master

Transceiver

8870

RCN #1 8870

RCN #2

8870

RCN #5

8870

RCN #4

8870

RCN #3

(Repeater on)

NI

-

700

Figure 3: Mesh Repeater Example

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Table of contents