EnerSys Alpha GMT 125 Series User manual

GMT 125 Series™/ KLM 125 Series™

1RU Fuse Panel For Telecom Broadband

Technical Manual

Effective: March 2021

2C048-742-30 R04, Rev. B (03/2021)

The following sections contain important safety information that must be followed during the installation and maintenance

of the equipment. Read all of the instructions before installing or operating the equipment, and save this manual for future

reference.

There may be multiple warnings associated with the call out. Example:

ATTENTION provides specic regulatory/code requirements that may aect the placement of equipment and /or

installation procedures.

ATTENTION:

NOTICE provides additional information to help complete a specic task or procedure.

NOTICE:

ELECTRICAL HAZARD WARNING provides electrical safety information to PREVENT INJURY OR DEATH

to the technician or user.

WARNING! ELECTRICAL HAZARD

FUMES HAZARD WARNING provides fumes safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FUMES HAZARD

FIRE HAZARD WARNING provides ammability safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FIRE HAZARD

This WARNING provides safety information for both Electrical AND Fire Hazards

WARNING! ELECTRICAL & FIRE HAZARD

CAUTION provides safety information intended to PREVENT DAMAGE to material or equipment.

CAUTION!

GENERAL HAZARD WARNING provides safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! GENERAL HAZARD

Safety Notes

Alpha Technologies Services, Inc. considers customer safety and satisfaction its most important priority. To reduce the

risk of injury or death and to ensure continual safe operation of this product, certain information is presented dierently in

this manual. Alpha®tries to adhere to ANSI Z535 and encourages special attention and care to information presented in

the following manner:

3C048-742-30 R04, Rev. B (03/2021)

GMT 125 Series™/ KLM 125 Series™

1RU Fuse Panel For Telecom Broadband

Technical Manual

C048-742-30 R04, Rev. B

Eective: March 2021

©2021 by Alpha Technologies Services, Inc.

Disclaimer

Images contained in this manual are for illustrative purposes only. These images may not match your installation.

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If there are

questions regarding the safe operation of this powering system, please contact Alpha Technologies Services, Inc. or your

nearest Alpha representative.

Alpha® shall not be held liable for any damage or injury involving its enclosures, power supplies, generators, batteries or

other hardware if used or operated in any manner or subject to any condition not consistent with its intended purpose or is

installed or operated in an unapproved manner or improperly maintained.

Contact Information

Sales information and customer service in USA

(7AM to 5PM, Pacic Time): 1 800 322 5742

Complete Technical Support in USA

(7AM to 5PM, Pacic Time or 24/7 emergency support): 1 800 863 3364

Sales information and Technical Support in Canada: 1 888 462 7487

Website: www.alpha.com

4C048-742-30 R04, Rev. B (03/2021)

Table of Contents

1.0 Purpose and Applicability � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

1�1 Product Model � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2.0 Theory of Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1 Introduction� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1�1 GMT 125 Series� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1�2 KLM 125 Series � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�2 Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3.0 Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Package Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4.0 Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1 Installation Preparation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�1 Elevated Operating Ambient Temperature � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�2 Reduced Air Flow� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�3 Mechanical Loading� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�4 Circuit Overloading � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�5 Reliable Earthing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�6 Disconnect Device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�2 Mounting� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�1 Lacing Bar � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�2 Optional Rear Rack Support Kit� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

4�3 Chassis Ground � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�4 Input Connections� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

4�5 Output Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�5�1 Terminal Block Output Versions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�5�2 Connectorized Output Versions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

4�6 Installing Fuses� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

4�7 Alarm Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

4�8 Installation Checklist� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5.0 Operation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �15

5�1 Meter Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�1�1 Contrast Adjustment� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�1�2 Home Screen� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�1�3 Calibration and Settings� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�1�3�1 Reset Inventory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5.1.3.2 Bus Voltage Oset � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�1�3�3 Bus Voltage Gain � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5.1.3.4 Bus Current Oset � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�1�3�5 Bus Current Gain � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�1�3�6 Audible Alarm � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

6.0 Product Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �17

7.0 Models and Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �18

Appendix A: Mechanical Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

A�1 Front View � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

A�2 Rear View� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

A�3 Top View� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

A�4 Side View � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

5C048-742-30 R04, Rev. B (03/2021)

1.01.0 Purpose and ApplicabilityPurpose and Applicability

The purpose of this document is to detail the installation and operation instructions for the Alpha® GMT 125 Series™fuse

panel and KLM 125 Series™fuse panel�

1.11.1 Product ModelProduct Model

This document applies to the following models of the GMT 125 Series fuse panel and KLM 125 Series fuse panel

products:

Table 1. GMT 125 Series Fuse Panel Congurations

PART NUMBER DESCRIPTION INPUTS OUTPUTS MONITORING

C016-1871-10 GMT 125 Series Fuse Panel, -48VDC,

10A/10B GMT Fuse Positions

Dual-Input Terminal Block LED Indicators

C016-1875-10 GMT 125 Series Fuse Panel, -48VDC,

10A/10B GMT Fuse Positions

Dual-Input Terminal Block Meter Module

C016-1873-10 GMT 125 Series Fuse Panel, -48VDC,

10A/10B GMT Fuse Positions

Dual-Input Connectorized LED Indicators

C016-1877-10 GMT 125 Series Fuse Panel, -48VDC,

10A/10B GMT Fuse Positions

Dual-Input Connectorized Meter Module

Table 2. KLM 125 Series Fuse Panel Congurations

PART NUMBER DESCRIPTION INPUTS OUTPUTS MONITORING

C016-1846-10 KLM 125 Series Fuse Panel, -48VDC, 4A/4B

KLM Fuse Positions, 4A/4B GMT Fuse

Positions

Dual-Input Terminal Block LED Indicators

C016-1847-10 KLM 125 Series Fuse Panel, -48VDC, 4A/4B

KLM Fuse Positions, 4A/4B GMT Fuse

Positions

Dual-Input Terminal Block Meter Module

C016-1848-10 KLM 125 Series Fuse Panel, -48VDC, 4A/4B

KLM Fuse Positions, 4A/4B GMT Fuse

Positions

Dual-Input Connectorized LED Indicators

C016-1849-10 KLM 125 Series Fuse Panel, -48VDC, 4A/4B

KLM Fuse Positions, 4A/4B GMT Fuse

Positions

Dual-Input Connectorized Meter Module

2.02.0 Theory of OperationTheory of Operation

2.12.1 IntroductionIntroduction

2.1.12.1.1 GMT 125 SeriesGMT 125 Series

The GMT 125 Series product family consists of a dual-input 10A/10B GMT fuse position, 1RU panel with optional

connectorized outputs and meter module� GMT fuses are available for this panel in ratings starting with 1/64 ampere up

to 20 ampere rating�

2.1.22.1.2 KLM 125 SeriesKLM 125 Series

The KLM 125 Series product family consists of a dual-input 4A/4B GMT and 4A/4B KLM fuse position, 1RU panel with

optional connectorized outputs and meter module�

The bus rating is 125 amperes max per bus� GMT fuses are available for this panel in ratings starting with 1/64 ampere up

to 15 ampere rating� KLM fuses are available for this panel in ratings starting with 1 ampere up to 30 ampere rating�

6C048-742-30 R04, Rev. B (03/2021)

2.22.2 FeaturesFeatures

GMT 125 Series

yGMT fuse positions: 20; each available up to 20A max

KLM 125 Series

yGMT fuse positions: 8; each available up to 15A max

yKLM fuse positions: 8; each available up to 30A max

All Models

yRack mounting: 19 in� or 23 in� via reversible rack mount ears

yMounting oset: Front-ush, mid-mount forward, mid-mount rearward

yLED indicators (panels with standard bezel)

yAdvanced LCD display (panels with meter module)

yAlarm contacts: Form C dry contacts

yRear panel modular jack connections for alarm outputs

yFuse distribution output terminals: set screw terminals support 10-22 AWG wires terminated with a narrow ring or

spade lug (0�25 in� max width)

yOptional positive latching connectorized output connections

3.03.0 Unpacking and InspectionUnpacking and Inspection

The GMT 125 Series/KLM 125 Series fuse panel was carefully packaged at the factory to withstand the normal rigors

of shipping. However, you should carefully inspect the box and contents to conrm that no damage has occurred in

transit. Most shipping carriers require notication of shipping damage within twenty-four hours of delivery, and it is the

responsibility of the recipient to inspect the shipment immediately upon receipt�

3.13.1 Package ContentsPackage Contents

Included with your product are the following items:

yGMT 125 Series/KLM 125 Series fuse panel

yMounting hardware kit with necessary screws and washers

yCable lacing bar (models with connectorized outputs only)

7C048-742-30 R04, Rev. B (03/2021)

4.04.0 InstallationInstallation

4.14.1 Installation PreparationInstallation Preparation

When selecting an installation location, ensure that all of the

following conditions are met before proceeding�

4.1.14.1.1 Elevated Operating Ambient TemperatureElevated Operating Ambient Temperature

If you install the panel in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be

greater than room ambient� Therefore, take care to install the

equipment in an environment compatible with the maximum ambient

temperature (TMA) specied in Section 6.

4.1.24.1.2 Reduced Air FlowReduced Air Flow

Installation of the equipment in a rack should be such that the

amount of air ow required for safe operation of the equipment is not

compromised�

4.1.34.1.3 Mechanical LoadingMechanical Loading

Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical

loading�

4.1.44.1.4 Circuit OverloadingCircuit Overloading

Give consideration to the connection of the equipment to the

supply circuit and the eect that overloading of the circuits might

have on overcurrent protection and supply wiring� Use appropriate

consideration for equipment nameplate ratings when addressing this

concern�

4.1.54.1.5 Reliable EarthingReliable Earthing

Maintain reliable earthing of rack-mounted equipment� Pay particular

attention to supply connections other than direct connections to the

branch circuit (e�g�, use of power strips)�

4.1.64.1.6 Disconnect DeviceDisconnect Device

A readily accessible disconnect device must be incorporated in the

building installation wiring�

8C048-742-30 R04, Rev. B (03/2021)

4.24.2 MountingMounting

THIS PRODUCT MUST BE INSTALLED WITHIN A

RESTRICTED ACCESS LOCATION WHERE ACCESS IS

THROUGH THE USE OF A TOOL, LOCK AND KEY, OR

OTHER MEANS OF SECURITY, AND IS CONTROLLED BY

THE AUTHORITY RESPONSIBLE FOR THE LOCATION�

THIS PRODUCT MUST BE INSTALLED AND MAINTAINED

ONLY BY QUALIFIED TECHNICIANS�

NOTICE:

Step 1. Select the equipment rack location for installation of the fuse

panel� Orient the rack mount ears appropriately for either 19

in. or 23 in. rack and select either the front-ush mount, mid-

mount forward, or mid-mount rearward position to install the

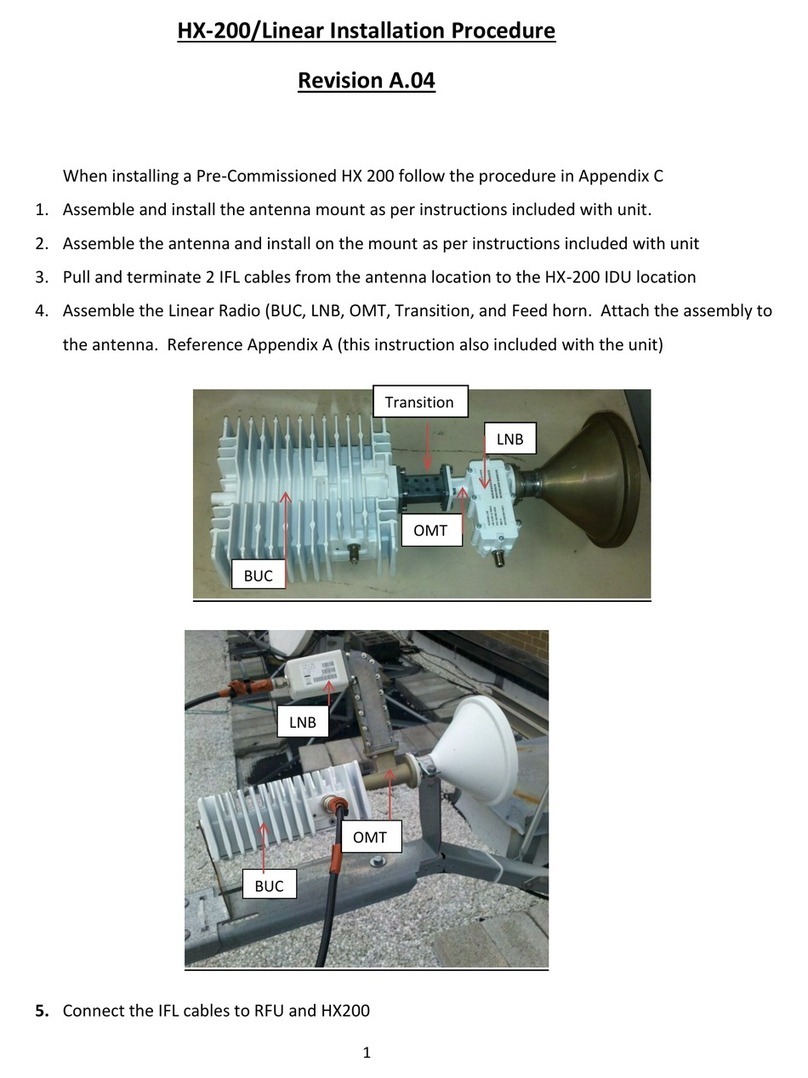

mounting ears (see Figure 1)�

Step 2. Attach the mounting ears with included 10-32 hardware (see

Figure 2)� Depending on the attachment point selected, the

panel will either be front-ush, mid-mount forward, or mid-

mount rearward in the rack�

Step 3. Secure panel to equipment rack by tightening the included

12-24 hardware into the mounting ears�

4.2.14.2.1 Lacing BarLacing Bar (Connectorized Output Models Only)(Connectorized Output Models Only)

GMT 125 Series/KLM 125 Series product models with connectorized

outputs include an output cable lacing bar for clean cable

management� This lacing bar does not come preinstalled from the

factory�

Step 1. Attach the output cable lacing bar by tightening the two 10-32

Phillips®head screws into the threaded holes located on the

rear of the panel (see Figure 3)�

Figure 1. Mounting ear positions

Figure 2. Mounting ears

(front-ush position shown)

Figure 3. Lacing bar

(connectorized models only)

9C048-742-30 R04, Rev. B (03/2021)

4.2.24.2.2 Optional Rear Rack Support KitOptional Rear Rack Support Kit

(C750-278-10 Kit; For Connectorized Output Models Only)(C750-278-10 Kit; For Connectorized Output Models Only)

An optional rear rack support kit is available for GMT 125 Series/

KLM 125 Series product models with connectorized output

congurations. This kit provides additional support to the rear

of the panel by attaching to the rear of the equipment rack� The

adjustable rails and lacing bar allow for exible and clean cable

management�

NOTE: This kit can not be used in combination with the standard

cable lacing bar that is included with connectorized fuse panels�

Step 1. Insert the cable lacing pole into the adjustment blocks,

then tighten the black phillips-head screws (see Figure 4)�

Step 2. Insert the two straight panel extension poles into the

bottom holes of the adjustment blocks (see Figure 5)�

Step 3. Insert the two rear rack mounting poles into the top holes

of the adjustment blocks (see Figure 6)�

Step 4. Secure the base of the two straight panel extension poles

from Step 2 to the threaded holes found on the rear of the

fuse panel chassis by tightening the hex-head hardware

(see Figure 7)�

Step 5. Secure the rear rack mount ears to the equipment rack by

tightening the 1/4 in� Phillips head screws (see Figure 8)�

Step 6. Secure the cable lacing bar into place by tightening the

thumbscrews found on the top of the adjustment blocks

(see Figure 9)�

Figure 4. Cable lacing bar

Figure 5. Panel extension poles

Figure 6. Rear rack mounting poles

Figure 7. Mount to chassis Figure 8. Rear rack mount ears Figure 9. Thumbscrew

10 C048-742-30 R04, Rev. B (03/2021)

4.34.3 Chassis GroundChassis Ground

DO NOT ENERGIZE THE PANEL BEFORE CHASSIS

GROUND IS CONNECTED�

CAUTION!

The chassis ground is located in the side of the panel� A two hole

lug landing position is provided� See table below for termination

information� A minimum of #6 AWG chassis ground cable is required�

IMPORTANT: Grounding hardware not included� A properly-sized

grounding conductor must be installed per NEC (250�122)�

Table 3. Chassis Ground Termination Specications

TERMINATION

TYPE

HOLE/

STUD SIZE

CENTER

TO CENTER

RECOMMENDED

TORQUE VALUE

Threaded Insert 1/4 in� 5/8 in� 5.83 ft∙lbs

Step 1. Secure the ground cable to the chassis by tightening 1/4 in�

hardware (see Figure 10)� Figure 10. Chassis Ground

11 C048-742-30 R04, Rev. B (03/2021)

4.44.4 Input ConnectionsInput Connections

WARNING! ELECTRICAL HAZARD

INPUTS MUST BE PROTECTED BY A LISTED CIRCUIT

BREAKER OR BRANCH RATED FUSE� THE CIRCUIT

BREAKER OR FUSE MUST BE RATED 125A MAX�

MULTIPLE POWER SOURCES ARE PRESENT,

ENSURE ALL INPUT POWER FEEDS ARE NOT

ENERGIZED BEFORE INSTALLING THEM� ELECTRICAL

INSTALLATION SHOULD ONLY BE PERFORMED BY

QUALIFIED PERSONNEL WITH PROPER TOOLS AND

PROTECTIVE SAFETY EQUIPMENT�

MAKE SURE THAT ALL FEEDER CABLES HAVE HEAT

SHRINK APPLIED PRIOR TO TERMINATION, AND THAT

NO-OXIDE COMPOUND IS APPLIED TO ALL COPPER-

TO-COPPER CONNECTIONS� REFER TO SECTION 7

FOR COMPRESSION LUG SPECIFICATIONS, TOOLING,

AND ORDERING INFORMATION�

NOTICE:

Table 4. Input Termination Specications

TERMINATION

TYPE

HOLE/

STUD SIZE

CENTER

TO CENTER

RECOMMENDED

TORQUE VALUE

Threaded Stud 1/4 in� 5/8 in� 4.17 ft∙lbs

Step 1. Remove the plastic input safety covers by pulling away from

panel (see Figure 11)�

Step 2. Install the return cables/lugs to the return input studs located

on the rear of the panel (see Figure 12)� Ensure all that

hardware is tightened�

Step 3. Install the hot input cables/lugs to the hot input studs located

on the rear of the panel (see Figure 13)� Ensure that all

hardware is tightened�

Step 4. Reinstall the input safety covers from Step 1�

WARNING! ELECTRICAL HAZARD

FAILURE TO REINSTALL THE INPUT SAFETY COVERS

WILL CREATE AN ELECTRICAL HAZARD�

Figure 11. Input Safety Covers

Figure 12. Return Input Landing

Figure 13. Hot Input Landing

12 C048-742-30 R04, Rev. B (03/2021)

4.54.5 Output ConnectionsOutput Connections

DO NOT PERFORM THIS STEP ON CIRCUITS

WITH FUSES INSTALLED� ENSURE NO POWER IS

PRESENT ON THE CIRCUIT BEING WIRED BEFORE

PROCEEDING� MAKE SURE THAT ALL CABLES HAVE

INSULATED TERMINALS OR HEAT SHRINK APPLIED

PRIOR TO TERMINATION, AND THAT NO-OXIDE

COMPOUND IS APPLIED TO ALL COPPER-TO-COPPER

CONNECTIONS�

CAUTION!

REFER TO SECTION 7 FOR TERMINAL

SPECIFICATION, TOOLING, AND ORDERING

INFORMATION�

NOTICE:

4.5.14.5.1 Terminal Block Output VersionsTerminal Block Output Versions

Table 5. Output Termination Specications

TERMINATION

TYPE

HOLE/

STUD

SIZE

CENTER

TO

CENTER

RECOMMENDED

TORQUE VALUE

Screw Terminal M3 (#6) 1/4 in� 5 in∙lbs

Refer to the front of the panel for the channel mapping card� On the

rear of the panel, locate the “stair-step” terminal block for the fused

outputs� Note that each output terminal is numbered from right to left

to correspond with the fuse holder on the front panel� The bottom

terminals in the terminal block are connected to the return bus bar

for each input bus� The top row of terminals are the fused outputs for

each fuse holder as numbered�

Step 1. Connect the wires to the equipment loads to be fed by the

panel fused outputs to these terminal block connections� The

RTN (+) wire connects to the bottom terminal (see Figure 14)

and the HOT (-) wire connects to the top terminal (see Figure

15) for each fuse position�

Step 2. Use appropriate crimp spade or ring lugs on the wires that will

be connected to the terminal block fused outputs� Ensure no

stray wire strands short out to adjacent terminals, and route

the wires in an organized fashion with cable ties or lacing

twine down the equipment rack to the equipment loads�

Step 3. Attach the included output safety cover by snapping it onto

the pre-tightened mounting screws (see Figure 16)�

WARNING! ELECTRICAL HAZARD

FAILURE TO REINSTALL THE INPUT SAFETY COVERS

WILL CREATE AN ELECTRICAL HAZARD�

Figure 14. RTN output wires

Figure 15. HOT output wires

Figure 16. Output safety cover

13 C048-742-30 R04, Rev. B (03/2021)

4.5.24.5.2 Connectorized Output VersionsConnectorized Output Versions

There are 20 positive latching DC connector positions for the output

circuits found on the GMT 125 Series fuse panel (10 per side) and

there are 16 positive latching DC connector positions for the output

circuits found on the KLM 125 Series fuse panel (8 per side)� Cable

whips are available in a variety of lengths and wire gauges (see

Section 7)� Refer to the front of the panel for the channel mapping

card for circuit mapping information�

Step 1. Insert the DC connectors into the outputs until they click� The

connectors are keyed to ensure correct polarity (see Figure

17)�

4.64.6 Installing FusesInstalling Fuses

USE BUSSMANN®GMT TYPE FUSES ONLY� FUSES

MUST CARRY A 450A INTERRUPT RATING�

NOTICE:

Step 1. Ensure that connected loads are in the o position, then insert

a fuse of sucient ampacity into the position to be fed. Turn

on the connected load�

4.74.7 Alarm InstallationAlarm Installation

WHEN DAISY CHAINING, THE ALARM MUST BE

MONITORED NORMALLY OPEN�

NOTICE:

The GMT 125 Series/KLM 125 Series fuse panel has Form-C dry

alarm contacts for remote alarm monitoring� If alarm monitoring is

required, (2) 8p8c (RJ-45) modular jacks are provided for alarm

connections� The (2) jacks support easy daisy chaining of panels�

The 8p8c modular jacks are located on the center rear of the panel�

Refer to mechanical drawings found in Appendix A for more details�

Step 1. Plug in a UTP cable with a TIA/EIA T568B termination into the

alarm jack (see Figure 18)� Refer to Table 6 for termination

pinout information�

Step 2. Connect the cable to the site alarm monitoring system�

Step 3. If daisy chaining is required, connect a UTP cable with TIA/

EIA T568B termination into the second jack and connect the

other end to the next panel in the chain� Repeat this process

until all panels are connected�

Table 6. Alarm Contact Pinout

PIN 1 PIN 2 PIN 3 PIN 4 PIN 5 PIN 6 PIN 7 PIN 8

Major

COM

Major

NC

Major

NO

Reserved Reserved Reserved Reserved Reserved

Figure 17. Connectorized output cables

Figure 18. Alarm jacks

14 C048-742-30 R04, Rev. B (03/2021)

4.84.8 Installation ChecklistInstallation Checklist

yRack mount ears congured for 19/23 in.

yEars mounted to panel and rack securely

yInput power cables/lug and return cables/lugs securely bolted/

connected to rear of panel

yHeat shrink installed on cables

yFused outputs wired with correct polarity, crimp lugs, wire lacing,

or cable tie routing to equipment loads

yOutput connections secured

yFuses sized as required for each load

yAll safety covers attached

15 C048-742-30 R04, Rev. B (03/2021)

5.05.0 OperationOperation

5.15.1 Meter ModuleMeter Module

The GMT 125 Series/KLM 125 Series fuse panel is available with an optional meter module for monitoring of voltage,

current, and alarms�

5.1.15.1.1 Contrast AdjustmentContrast Adjustment

The screen contrast can be adjusted by inserting a #00 screwdriver into the recessed contrast button

(view meter module illustration above for button locations)�

5.1.25.1.2 Home ScreenHome Screen

16 C048-742-30 R04, Rev. B (03/2021)

5.1.35.1.3 Calibration and SettingsCalibration and Settings

To enter the Calibration and Settings Menu, press the Select (Sel) button� To advance through each item on the menu,

press the Select (Sel) button� NOTE: Any changes are not saved until you have advanced back to the Home Screen�

5.1.3.15.1.3.1 Reset InventoryReset Inventory

For panels with KLM fuse positions, the meter module keeps track of KLM fuse inventory in order to report fuse status�

Any installed KLM fuses are detected and added to the inventory automatically� When a fuse is removed, however, the

inventory must be reset to clear the fuse fail alarm� Press the (+) button to reset the KLM fuse inventory� The meter will

return to the Home Screen immediately, skipping the calibration screens� Press Sel to advance to the next setting�

5.1.3.25.1.3.2 Bus Voltage OsetBus Voltage Oset

A and B bus voltage oset can be adjusted by pressing the (+) or (-) buttons. The measured bus voltage is shown in

hundredths of volts along with the applied oset. Press Sel to advance to the next setting.

5.1.3.35.1.3.3 Bus Voltage GainBus Voltage Gain

A and B bus voltage gain can be adjusted by pressing the (+) or (-) buttons� The measured voltage is shown in hundredths

of volts along with the applied gain� Press Sel to advance to the next setting�

5.1.3.45.1.3.4 Bus Current OsetBus Current Oset

A and B bus current oset can be adjusted by pressing the (+) or (-) buttons. The measured load is shown in tenths of

amps alng with the applied oset. Press Sel to advance to the next setting.

5.1.3.55.1.3.5 Bus Current GainBus Current Gain

A and B bus current gain can be adjusted by pressing the (+) or (-) buttons� The measured load is shown in tenths of

amps along with the applied gain� Press Sel to advance to the next setting�

5.1.3.65.1.3.6 Audible AlarmAudible Alarm

Audible alarm can be enabled (EN) or disabled (DIS) by pressing the (+) or (-) buttons� Press Sel to return to the Home

Screen� NOTE: The audible alarm is disabled by default�

17 C048-742-30 R04, Rev. B (03/2021)

6.06.0 Product SpecicationsProduct Specications

Table 7. GMT 125 Series Fuse Panel Specications

ALL MODELS

Type of Input Dual Input (A/B)

Circuits 10 (10A/10B)

Input Voltage (+/- 0%) -42 to -60V DC

Input Current 125A Max

Maximum Input Interruption Device 150A

Maximum Fuse Size 20A GMT

Maximum Per Circuit Current 20A

Maximum Continuous Load on 15-20A GMT Fuses 70% Fuse Rating

Maximum Continuous Load on <15A GMT Fuses 80% Fuse Rating

Max Operating Altitude 2000 m

Max Ambient Temperature 45º C

Width 17 in�

Height 1�75 in�

Depth (Not Including Lacing Bar Kits) 11 in�

Weight 8�5 lbs�

UL File Number E473904

UL Standard ANSI/UL 60950-1

Table 8. KLM 125 Series Fuse Panel Specications

ALL MODELS

Type of Input Dual Input (A/B)

Circuits 16 (8A/8B)

Input Voltage (+/- 0%) -42 to -60V DC

Input Current 125A Max

Maximum Input Interruption Device 150A

Maximum Fuse Size 30A KLM; 15A GMT

Maximum Per Circuit Current 30A KLM; 15A GMT

Maximum Continuous Load on 15-20A GMT Fuses 70% Fuse Rating

Maximum Continuous Load on <15A GMT Fuses 80% Fuse Rating

Max Operating Altitude 2000 m

Max Ambient Temperature 55º C

Width 17 in�

Height 1�75 in�

Depth (Not Including Lacing Bar Kits) 11�5 in�

Weight 8�5 lbs�

UL File Number E473904

UL Standard ANSI/UL 60950-1

18 C048-742-30 R04, Rev. B (03/2021)

7.07.0 Models and AccessoriesModels and Accessories

Table 9. GMT 125 Series Fuse Panel Model Congurations

DESCRIPTION PART NUMBER

GMT 125 Series Fuse Panel; 125A; 1RU; Dual Input; 10A/10B - 20A Max; LED Indicators;

Terminal Block Outputs

C016-1871-10

GMT 125 Series Fuse Panel; 125A; 1RU; Dual Input; 10A/10B - 20A Max; Meter Module;

Terminal Block Outputs

C016-1875-10

GMT 125 Series Fuse Panel; 125A; 1RU; Dual Input; 10A/10B - 20A Max; LED Indicators;

Connectorized Outputs

C016-1873-10

GMT 125 Series Fuse Panel; 125A; 1RU; Dual Input; 10A/10B - 20A Max; Meter Module;

Connectorized Outputs

C016-1877-10

Table 10. KLM 125 Series Fuse Panel Model Congurations

DESCRIPTION PART NUMBER

KLM 125 Series Fuse Panel; 125A; 1RU; Dual Input; 4A/4B KLM Fuses; 4A/4B GMT Fuses;

30A Max KLM Fuse; 15A Max GMT Fuse; LED Indicators; Terminal Block Outputs

C016-1846-10

KLM 125 Series Fuse Panel; 125A; 1RU; Dual Input; 4A/4B KLM Fuses; 4A/4B GMT Fuses;

30A Max KLM Fuse; 15A Max GMT Fuse; Meter Module; Terminal Block Outputs

C016-1847-10

KLM 125 Series Fuse Panel; 125A; 1RU; Dual Input; 4A/4B KLM Fuses; 4A/4B GMT Fuses;

30A Max KLM Fuse; 15A Max GMT Fuse; LED Indicators; Connectorized Outputs

C016-1848-10

KLM 125 Series Fuse Panel; 125A; 1RU; Dual Input; 4A/4B KLM Fuses; 4A/4B GMT Fuses;

30A Max KLM Fuse; 15A Max GMT Fuse; Meter Module; Connectorized Outputs

C016-1849-10

Table 11. Accesories

DESCRIPTION PART NUMBER

Rear Rack Mounting Kit; GMT 125 C750-278-10

Table 12. Supported Lugs for Input Connections

WIRE GAUGE

SUPPORTED

ALPHA PART

NUMBER

MANUFACTURER MANUFACTURER

PART NUMBER

CRIMP DIE REQUIRED

#2 AWG C538-173-10 BURNDY® YAV2CL2NT14FX Burndy U2CRT, W2CVT,

W2CRT, X2CRT

#2 AWG

(90 degree)

C538-275-10 BURNDY® YAV2CL2NT14FX90 Burndy U2CRT, W2CVT,

W2CRT, X2CRT

1/0 C538-260-10 BURNDY® YAZV252NT14FX Burndy U25RT, W25VT, W25RT,

X25RT

1/0

(90 degree)

C538-289-10 BURNDY® YAV25L2NT14FX90 Burndy U25RT, W25VT, W25RT,

X25RT

Table 13. Supported Lugs for Chassis Ground Connections

WIRE GAUGE

SUPPORTED

ALPHA PART

NUMBER

MANUFACTURER MANUFACTURER

PART NUMBER

CRIMP DIE REQUIRED

#6 AWG C538- 094-10 BURNDY® YAZV6C2TC14FX Burndy U5CRT, W5CRT,

W5CV T, X5CRT, Y1MRTC

Table 14. Supported GMT Fuses

DESCRIPTION PART NUMBER

GMT Fuse ¼A; 60VDC; violet ag C460- 014-10

GMT Fuse ½A; 60VDC; reg ag C460- 042-10

GMT Fuse 1A; 60VDC; gray ag C460- 013-10

GMT Fuse 2A; 60VDC; orange ag C460-026-10

GMT Fuse 3A; 60VDC; blue ag C460-027-10

GMT Fuse 4A; 60VDC; white/brown ag C460- 028-10

19 C048-742-30 R04, Rev. B (03/2021)

DESCRIPTION PART NUMBER

GMT Fuse 5A; 60VDC; green ag C460-009-10

GMT Fuse 7.5A; 60VDC; black/white ag C460- 012-10

GMT Fuse 10A; 60VDC; red/white ag C460-010-10

GMT Fuse 15A; 60VDC; red/blue ag C 46 0 - 011-10

GMT Fuse 20A; 60VDC; green/white ag C460 - 041-10*

*Not applicable for KLM 125 Series models

Table 15. Supported KLM Fuses

DESCRIPTION PART NUMBER

KLM Fuse 1A; 600VDC C460-089-10

KLM Fuse 2A; 600VDC C460- 088-10

KLM Fuse 3A; 600VDC C460-087-10

KLM Fuse 5A; 600VDC C460- 085 -10

KLM Fuse 7A; 600VDC C460-086-10

KLM Fuse 10A; 600VDC C460- 082-10

KLM Fuse 15A; 600VDC C460- 084-10

KLM Fuse 20A; 600VDC C460- 081-10

KLM Fuse 25A; 600VDC C460- 083-10

KLM Fuse 30A; 600VDC C460-080-10

Table 16. Connectorized Cable Assemblies (For Connectorized Models Only)

AWG LENGTH COLOR PART NUMBER

#10 7’ Red/Black C745 - 420 -10

Blue/Black C745 - 422-10

Red/Red Tracer C745-437-10

Blue/Blue Tracer C745-433-10

12’ Red/Black C745 -290 -10

Blue/Black C745 - 424 -10

Red/Red Tracer C745-438-10

Blue/Blue Tracer C745-434-10

#12 7’ Red/Black C745 - 421-10

Blue/Black C745-425-10

Red/Red Tracer C745-298 -10

Blue/Blue Tracer C745-299-10

12’ Red/Black C745 -293-10

Blue/Black C745 -294-10

Red/Red Tracer C745-197-10

Blue/Blue Tracer C745-198-10

#14 7’ Red/Black C745-436-10

Blue/Black C745 - 427-10

Red/Red Tracer C745-432-10

Blue/Blue Tracer C745-435-10

12’ Red/Black C745 -296 -10

Blue/Black C745 - 429 -10

Red/Red Tracer C745-227-10

Blue/Blue Tracer C745-228 -10

20 C048-742-30 R04, Rev. B (03/2021)

Table 17. Output Terminals (For Terminal Block Models Only)

WIRE GAUGE

SUPPORTED;

TERMINAL TYPE

ALPHA PART

NUMBER

MANUFACTURER MANUFACTURER

PART NUMBER

CRIMP DIE REQUIRED

#16-14 AWG; Ring

Terminal

C538-068-10 TE CONNECTIVITY®34158 TE Connectivity 58433-3 with

Die Assembly 58423-1

#10-12 AWG Ring

Terminal

C538-280-10 TE CONNECTIVITY®329697 TE Connectivity 169400 with

Die Assembly 169404

#16-14 AWG; Spade

Terminal

C538-038-10 TE CONNECTIVITY®52955 TE Connectivity 58433-3 with

Die Assembly 58423-1

#12-10 AWG; Spade

Terminal

C538-119-10 TE CONNECTIVITY®52961 TE Connectivity 58433-3 with

Die Assembly 58423-1

Other manuals for Alpha GMT 125 Series

1

This manual suits for next models

1

Table of contents