ENGCOM S40-S80 User manual

FOR ENGCON TILT MOUNTING S40–S80, S1–S3

– THE WIDEST RANGE ON THE MARKET

Increase your excavator’s efficiency and precision

Instruction manual

Tilt mounting S40–S80, S1–S3

English

2

Instruction manual

Congratulations for choosing engcon’s tilt mounting. This product has been developed

since 1985, and is highly adapted to its purpose. However, the quality of a product

depends on the maintenance it receives. To optimise the product’s safety, function and

lifespan, please read the information in this instruction manual carefully. The manual

describes the things you should check and the safety measures to observe.

We welcome you as a customer of engcon Nordic AB and look forward to a long, fruitful

collaboration. Do not hesitate to contact us for further information.

Kind regards,

Örjan Westerlund, CEO

engcon Nordic AB

3

Tilt mounting

CERTIFICATION OF CONFORMITY

According to AFS 1994:48, Appendix 2 A

Manufacturer’s name: engcon Nordic AB

Address: Box 111

Postal address: 833 22 STRÖMSUND

Country: SWEDEN

Phone: + 46 670 178 00

Fax: + 46 670 178 28

Email: [email protected]

hereby certifies that:

Machine specification

Type: Serial no.:

Upper mounting: Implement hitch:

Hydraulic diagram: Delivery date:

Miscellaneous:

was manufactured in accordance with Ordinance AFS 1994:48 of the Swedish Occupational Safety and

Health Administration (equivalent to EU Machine Directive 98/37/EG) with regulations on machines and

certain other technical devices, with special reference to the Ordinance’s Appendix 1 regarding basic

health and safety requirements for machine design and manufacture.

The following standards and regulatory directives have been applied and complied with:

• Machine Directive 98/37/EG

• Swedish standards SS-EN ISO 12100-1 and SS-EN ISO 12100-2

NB: This certification and engcon’s warrantees will immediately cease to be valid if the product is altered

or modified without engcon’s authorisation.

Title: CEO Name: Örjan Westerlund

Date: Signature:

4

Instruction manual

Type certificate for lifting hook

The below certificate regards tiltrotators/rotators supplied with a lifting hook.

5

Tilt mounting

Table of contents

1 Introduction 6

1.1 General 6

1.2 Identification and marking of tilt mounting 6

1.3 Decals and warning signs 6

1.4 System description and application areas 6

2 Safety regulations 7

2.1 General 7

2.2 Check list, safety 7

2.3 Warning decals 9

3 Technical data 10

3.1 Tilt mounting S40-S80 10

3.2 Tilt mounting S1-S3 11

4 Assembly and installation 12

4.1 Installation of tilt mounting 12

5 Handling 17

5.1 Connection of bucket (implement) 17

5.2 Disconnection of bucket (implement) 18

6 Maintenance 19

6.1 Daily maintenance 19

6.2 Lubrication instructions 19

6.2.1 Lubrication schedule TF S40 20

6.2.2 Lubrication schedule TF S45, TF S50, TF S60 21

6.2.3 Lubrication schedule TF S70, TF S80 22

6.2.4 Lubrication schedule TF S1, TF S2, TF S3 23

7 Exploded views 24

7.1 TF S40 24

7.2 TF S45, S50 26

7.3 TF S60 28

7.4 TF S70 30

7.5 TF S80 32

7.6 TF S1 34

7.7 TF S2 36

6

Instruction manual

1 Introduktion

1.1 General

This instruction manual provides relevant

information on installation, handling and

maintenance of the tilt mounting delivered

by engcon. The safety information in this

manual relates directly to the tilt mounting,

and does not regard the base machine.

In addition to this information, you should

carefully read the safety information

regarding the base machine and any other

equipment you will be using.

CAUTION

Do not attempt to install, use or perform

maintenance on the tilt mounting and

its accompanying equipment before

carefully reading all the information

regarding the tilt mounting, supplemen-

tary equipment and base machine.

Observe all safety instructions and

cautions carefully.

1.2 Identification and marking of

tilt mounting

Check that the information in “Certification

of conformity” corresponds to the information

on the tilt mounting (Figure 1), equipment

and documentation. In the event of devia-

tions, contact your supplier before starting

assembly.

Figure 1

1.3 Decals and warning signs

All the machine’s instructions and decals,

for instance warning signs, must be clearly

legible at all times. Contact your supplier to

order new instructions and decals.

1.4 System description and

application areas

Because of its functionality and the

number of implements on the market, the

tilt mounting has unlimited application

areas. However, please note that the tilt

mounting’s weight and the increased reach

may lead to reduced stability, causing risk

of damage and personal injury.

To avoid increased wear and abnormal

strain, engcon recommends that you avoid

using the tilt mounting in combination with

a hydraulic hammer.

Checkyourbasemachinemanufacturer’s

recommendations for calculating tipping

load, and make sure you include the

increased weight and reach caused by the

tilt mounting in these calculations.

7

Tilt mounting

2 Safety regulations

2.1 General

This instruction manual contains several

warning texts, which should be read care-

fully before assembling or using the tilt

mounting and its accompanying equip-

ment. The warning texts explain potential

risks and how to avoid them. If in any doubt,

contact your employer or the tilt mounting’s

supplier for further explanation of the

warning texts.

Remember: Sound judgment and

thorough knowledge of your machinery

reduces many unnecessary risks. Conse-

quently, operators should take the time to

learn correct use of the tilt mounting before

starting operation.

2.2 Safety check list

CAUTION

Do not attempt to install, use or per-

form maintenance on the tilt mounting

and its accompanying equipment before

carefully reading all the information

on the tilt mounting, its accompanying

equipment and the base machine.

Observe all safety information carefully.

CAUTION

Faulty installation can be dangerous.

If in any doubt about your knowledge or

the equipment, contact your dealer or

engcon Nordic AB.

CAUTION

Ensure that the hydraulic system is

decompressed before starting work on

the system. Risk of personal injury.

CAUTION

Never use your hands to check for

leaks in the hydraulic system. Hydraulic

oil can penetrate your skin under pres-

sure causing serious injury.

CAUTION

The mountings are safety features

and require regular inspection and

adaptation. Check carefully for cracks.

CAUTION

If in any doubt about your knowledge,

the equipment or the safety features,

contact your dealer or engcon Nordic

AB.

CAUTION

When mounting the tilt mounting

and implement hitches, check the

limits for tipping load to minimise risk of

accidents.

CAUTION

Implements connected to the tilt

mounting may only be used if correctly

locked into place. Always check that

the lock bolts have protruded according

to the specification for the relevant

implement hitch.

8

Instruction manual

CAUTION

Defective or faulty machinery and/or

equipment can cause harm to people,

property or the environment. Make

sure that the recommended servicing

and maintenance are performed on the

machine.

CAUTION

Exceeding the recommended maxi-

mum capacity for the tilt mounting can

damage the machine.

CAUTION

Do not attempt to upgrade the

equipment’s maximum capacity by

making modifications not approved by

the supplier.

CAUTION

Replace damaged and/or illegible

decals and warning signs before using

the machine. Risk of personal injury.

CAUTION

Short circuiting of electrical cabling

causes risk of personal injury. Insulate

the cable sockets.

CAUTION

Risk of burn injuries from hot hydraulic

oil.

CAUTION

Never operate the machine with the

implement lock switch in the activated

position except when connecting or

disconnecting a bucket or other imple-

ment.

CAUTION

Risk of catching in moving parts. Risk

of personal injury.

9

Tilt mounting

2.3 Warning decals

Take care when handling

long objects because of

the extra forces generated

by living weights and the

increased risk area.

Implement lock switch

deactivated.

NEVER stand or walk

beneath lifted implements.

Implement lock switch

activated.

Allow space for tilting and

laterally moving objects.

Risk area: 3 metres.

Manoeuvring of lock bolts.

Risk of catching in moving

parts.

Lock bolts in extended

locked position.

NEVER exceed the

machine’s approved tipping

load for the relevant arm.

Lock bolts in contracted

position.

Read the instruction

manual.

Figure 2

10

Instruction manual

3 Technical data

3.1 Tilt mounting S40-S80

Tilt mountingType

S40 S45/S50 S60 S70 S80

Width (A) [mm] 250 320 350 430 560

Width (B) [mm] 220 250 265 385 415

Width (C) [mm] 100 250 265 385 415

Build height (D) [mm] 220 310 340 580 630

Length (E) [mm] 360 540 550 770 900

Weight [kg]* 40 125 160 240 330

Min./Max. hydraulic flow [l/min] 15/35 30/60 40/70 50/80 50/100

Max. hydraulic pressure [MPa] 22 22 22 22 22

Tilt angle [°] 2x40 2x40 2x40 2x40 2x40

Tilt time** during hydraulic flow [s / l/min] 5 / 7.5 5 / 19 5 / 21 5 / 48 5 / 75

Base machine weight [t] 3-6 6-12 12-16 18-22 22-32

Table 1. *Depending on mounting. ** From tip to tip

D

A

BC E

11

Tilt mounting

3 Tekniska data

3.2 Tilt mounting S1-S3

Tilt mounting Type

S1 S2 S3

Width (A) [mm] 450 475 500

Width (B) [mm] 600 600 770

Build height (C) [mm] 370 485 510

Length (D) [mm] 830 875 875

Weight [kg]* 280 380 875

Min./Max. hydraulic flow [l/min] 15/35 30/60 40/70

Max. hydraulic pressure [MPa] 22 22 22

Tilt angle [°] 2x40 2x40 2x40

Tilt time** during hydraulic flow [s / l/min] 5 / 48 5 / 48 5 / 75

Base machine weight [t] 18-22 20-26 24-32

Table 1. *Depending on mounting. ** From tip to tip.

C

A

BD

12

Instruction manual

4 Assembly and installation

Check that the necessary supplementary documentation is available before starting

assembly. Your supplied tilt mounting and supplementary documentation are adapted

as far as possible to your base machine.

The below assembly and installation instructions only apply to direct mounting of the

tilt mounting. If the tilt mounting is mounted onto an implement hitch, you should use

the base machine’s manual for connection of implements.

4.1 Connecting the tilt mounting

Before starting assembly

1. Check the limits for tipping load. The tilt mounting’s

weight and the increased reach might make it necessary,

for instance, to reduce the bucket volume.

CAUTION

Check the limits for tipping load when connecting

the tilt mounting and implement hitches, to mini-

mise risk of accidents.

Faulty installation can be dangerous. If in any

doubt about your knowledge or the equipment,

contact your dealer or engcon Nordic AB.

Risk of catching in moving parts. Risk of personal

injury.

2. Place the base machine and tilt mounting on a flat,

non-slip surface. Make sure the tilt mounting is standing

straight and is aligned with the stick and dog bone (see

Figure 4).

3. During installation, use a ladder or other equipment that

does not cause risk of falling.

Figure 4

13

Tilt mounting

Figure 5

Assembly

1. Install the “O” rings (if using).

2. Position the dog bone so that it aligns with the

appropriate holes in the upper part of the tilt mounting.

3. Insert the supplied stub axle.

Figure 6

4. Mount the stub axle lock, making sure it locks

completely.

Figure 7

5. Position the stick so that it aligns with the appropriate

holes in the upper part of the tilt mounting.

6. Lower the stick carefully, making sure there are no

breaks.

7. Adjust the width with shims if necessary.

8. Insert the supplied stub axle.

9. Mount the stub axle lock, making sure it locks

completely. See Figure.

CAUTION

Faulty installation can be dangerous. If in any

doubt about your knowledge or the equipment,

contact your dealer or engcon Nordic AB.

14

Instruction manual

Bild 8

Electrical installation

1. Dismantle the relevant safety plates on the underside

of the base machine to facilitate installation.

CAUTION

Faulty installation can be dangerous. If in any

doubt about your knowledge or the equipment,

contact your dealer or engcon Nordic AB.

2. Mount the fastening plate on the lower part of the stick,

on the connector block for the hydraulics.

3. Connect the machine cable to the connector piece on

the fastening plate.

4. Connect the tilt mounting’s cable to the connector

piece on the fastening plate.

5. Fasten the machine cable along the hydraulic tube

for the hydraulic coupling using stripes (approximately

7 stripes per metre).

6. Run the machine cable along the whole stick and boom

into the cab through an appropriate cable grommet.

NB: When installing the cable, it should be placed in

a well-protected location. Take care that no damage is

caused to the cable. The cable’s length and position

should be adapted to the base machine’s built-in mobility

to avoid unnecessary stress or abrasion.

Figure 9

7. Install the implement lock switch (if included in the

control system) in a secure place.

8. Install the tilt mounting’s control unit in a location

that is protected and safe but easily accessible for

maintenance.

9. Install the push buttons (if included in the control

system) on the existing joysticks and run the cables

through the consoles and out behind the operator’s seat

(only applies to certain control systems, see enclosed

wiring diagram).

10. Connect all cable assemblies to the tilt mounting’s

control unit according to the enclosed wiring diagram.

CAUTION

Short circuiting in electrical cabling causes risk of

fire and personal injury. Insulate the cable sockets.

11. Connect the supply current to the control unit. A

suitable solution is a reserve fuse connected over the

ignition switch. If unsure about where to connect the

supply current, consult an authorised workshop or the

base machine’s dealer.

12. Replace the safety plates.

15

Tilt mounting

Figure 10

Installation of hydraulic tubes

When installing the tubes, make sure that their length

is correct. They should neither hang down too far or

stretch when the tilt mounting is angled. See Figure 10.

1. Mount the hydraulic tubes according to the enclosed

hydraulic diagram.

CAUTION

Ensure that the hydraulic system is decom-

pressed before starting work on the system.

Risk of personal injury.

NB: The maximum input pressure and input

flow must never be exceeded. This applies to all

control systems. See Technical Data, Point 3.

Final precautions

1. Stick the enclosed warning decal in the operator area

in a position that is clearly visible but does not disturb the

operator.

CAUTION

Replace damaged or illegible decals and

warning signs before using the machine. Risk of

personal injury.

2. Perform a functional inspection.

• Check that the tilt mounting works. Tilt and activate the

implement hitch.

• Check that the tubes and cables are not damaged by

crushing, cutting or stretching.

16

Instruction manual

Functional irregularity Measure

None of the functions work Check the supply current to the control unit

and the fuse.

Check that the pressure and the return line to

the tilt mounting are correctly connected.

Check that all cable assemblies are correctly

connected.

One function doesn’t work Check the cable assemblies and connections.

The implement lock doesn’t work Check that all cable assemblies are correctly

connected.

Check that the pressure and return line to the

tilt mounting correspond to the chosen oil flow

direction.

CAUTION

Switch off power when working on

the electrical system and remove rings,

watches etc. before starting work. Risk

of personal injury.

CAUTION

Ensure that the hydraulic system is

decompressed before starting work on

the system. Risk of personal injury.

17

Tilt mounting

5 Handling

The following instructions regard the general handling of

the tilt mounting.

5.1 Connection of bucket (implement)

The following instructions regard the general handling

of engcon’s adaptor bracket. For further information and

instructions, see separate instruction manual for the relevant

adaptor.

1. Push the quick hitch towards the bucket (implement)

(Figure 1)

2. Connect the quick hitch to the bucket (implement) (Figure

2)

3. Lift the tilt mounting so that the bucket (implement)

engages with the quick hitch (Figure 3)

4. Activate the implement lock switch (Figure 4)

5. Activate the hydraulics by pressing the pedal (if used for

the tilt mounting). If a pedal is not used, press a button for

extra hydraulics. The lock cylinder will be activated and a blue

indicator rod will show that the implement hitch is in the open

position. (Does not apply to universal hitch.)

6. Deactivate the implement lock switch. In other words, lock

the bucket (implement) when the bucket has engaged into its

rear mounting point.

7. Make sure that the lock bolts are protruding. For the engcon

RF implement hitch, the indicator rod should not protrude from

the hitch anymore (Figure 5). For other implement hitches,

make sure that the lock bolts are protruding as specified for

the relevant implement hitch.

CAUTION

The machine may never be operated with the

implement lock switch in the activated position except

when connecting or disconnecting a bucket or other

implement.

1

2

3

5

4

18

Instruction manual

5.2 Disconnection of bucket (implement)

Before disconnecting a bucket or implement, check the

underlying surface and surrounding area to rule out any risk of

tipping or other damage.

1. Position the bucket as shown in Figure 1, with the lock

bolts pointing away from the cab.

2. Activate the implement lock switch (Figure 2)

3. Activate the hydraulics by pressing the pedal (if a pedal

is used for tilt/rotation). If a pedal is not used, activate the

extra hydraulics. The lock cylinder will be activated and a blue

indicator rod will show that the implement hitch is in open

position. (Does not apply to universal hitch.) (Figure 3)

4. The lock bolts are now in the open position and the

bucket (implement) is loose. Carefully remove the tilt mounting

(Figure 4).

1

2

3

4

19

Tilt mounting

6 Maintenance

To avoid impairing the safety and lifespan

of the tilt mounting, daily maintenance

and lubrication must be performed as

specified.

6.1 Daily maintenance

Clean earth and stones from the tilt mounting.

Check:

• that the tilt mounting is not cracked or

damaged

• that the tilt mounting is correctly

attached to the machine and implement

CAUTION

Faulty installation can reduce safety. If

in any doubt regarding your knowledge

or the equipment, contact your supplier

or engcon Nordic AB.

Implements connected to the tilt

mounting may only be used if correctly

locked into place.

Risk of catching in moving parts. Risk of

personal injury.

• that warning decals are clearly displayed

and legible.

CAUTION

Replace damaged or illegible

decals and warning signs before using

the machine. Risk of personal injury.

• that the implement hitch is clean and

works correctly, and that there are no

gaps.

• that there is no hydraulic leakage.

Replace worn or damaged tubes.

CAUTION

Ensure that the hydraulic system is de-

compressed before starting work on the

system. Risk of personal injury. NB: The

maximum input pressure and maximum

input flow should be observed for all

control systems. See Technical Data,

Point 3.

Risk of burn injuries from hot hydraulic

oil.

Never use your hands to check

for leaks in the hydraulic system. The

hydraulic oil can penetrate your skin

under pressure causing serious injury.

6.2 Lubrication instructions

Lubricate the tilt mounting according to

the lubrication schedule.

Recommended grease:

As a lubricant, we recommend a lithium-

based grease with a viscosity (NLGI) of

2 or lower.

20

Instruction manual

6.2.1 Lubrication schedule TF S40

This manual suits for next models

1

Table of contents

Popular Rack & Stand manuals by other brands

sanus accents

sanus accents SAN22BB instruction manual

New Star Computer Products

New Star Computer Products FPMA-WTB050 instruction manual

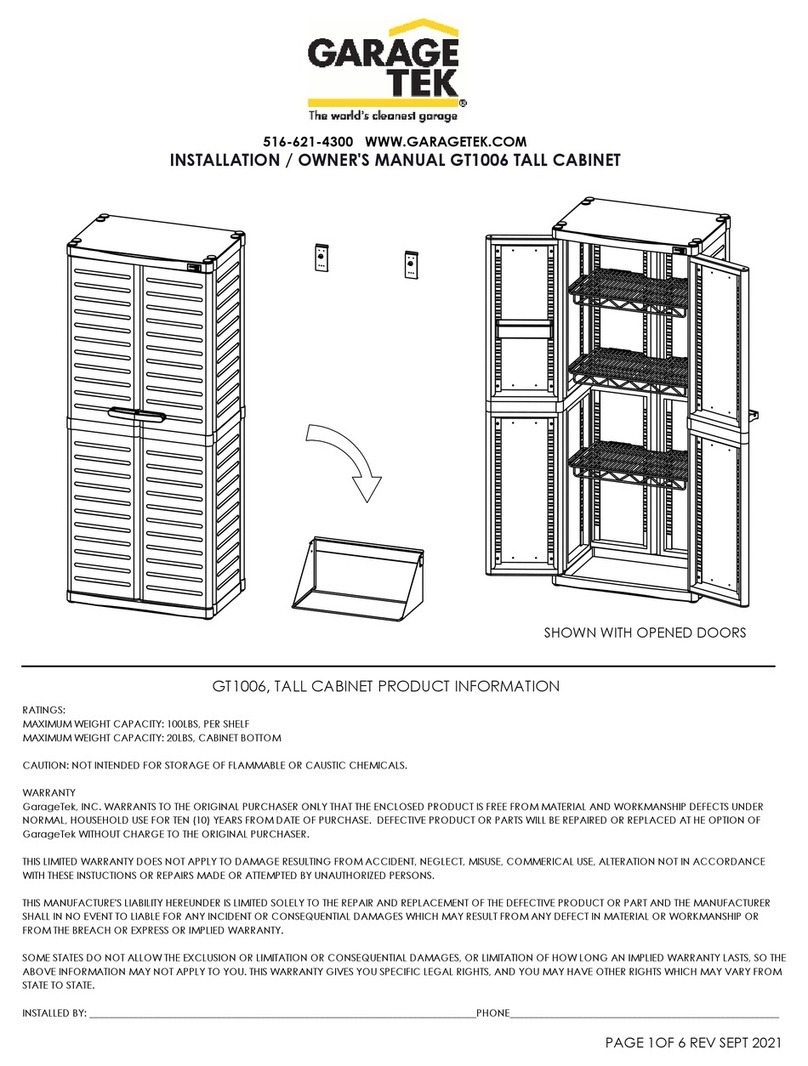

Garage Tek

Garage Tek GT1006 Installation & owner's manual

Wiremold

Wiremold 30TP-Series installation instructions

EuroLite

EuroLite ALU 3 user manual

HumanCentric

HumanCentric 101-2078 Quick installation manual