ACU MANUAL

IOM-14 2 of 46 Feb 06 R4

TABLE OF CONTENTS

YOU HAVE RESPONSIBILITIES TOO ...................................................................................................................................3

INTRODUCTION ................................................................................................................................................................3

SAFETY PRECAUTIONS ......................................................................................................................................................3

WARRANTY .......................................................................................................................................................................4

PARTS................................................................................................................................................................................4

RECEIVING.........................................................................................................................................................................5

TEMPORARY STORAGE .....................................................................................................................................................5

INSTALLATION...................................................................................................................................................................5

CODES...............................................................................................................................................................................6

In Canada:.........................................................................................................................................................................6

In USA: ..............................................................................................................................................................................6

MINIMUM CLEARANCE FOR SERVICE AND TO COMBUSTIBLES IN INCHES (mm)............................................................6

QUALIFIED INSTALLER.......................................................................................................................................................7

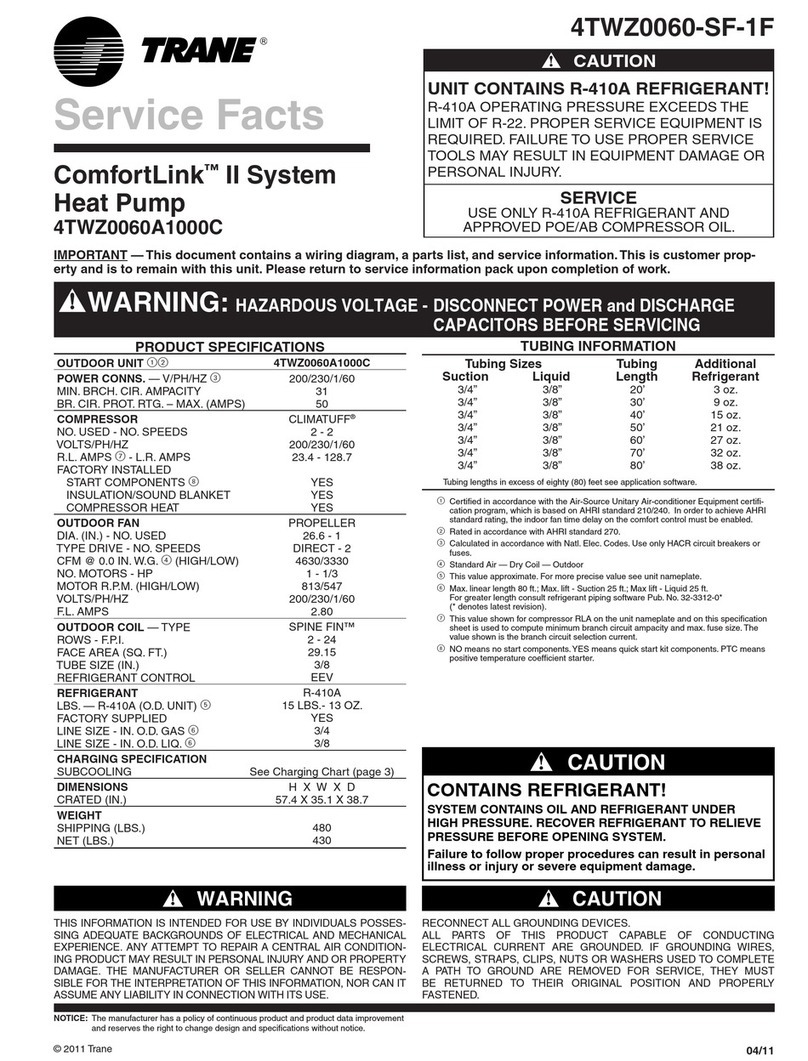

COMPONENT LOCATIONS.................................................................................................................................................7

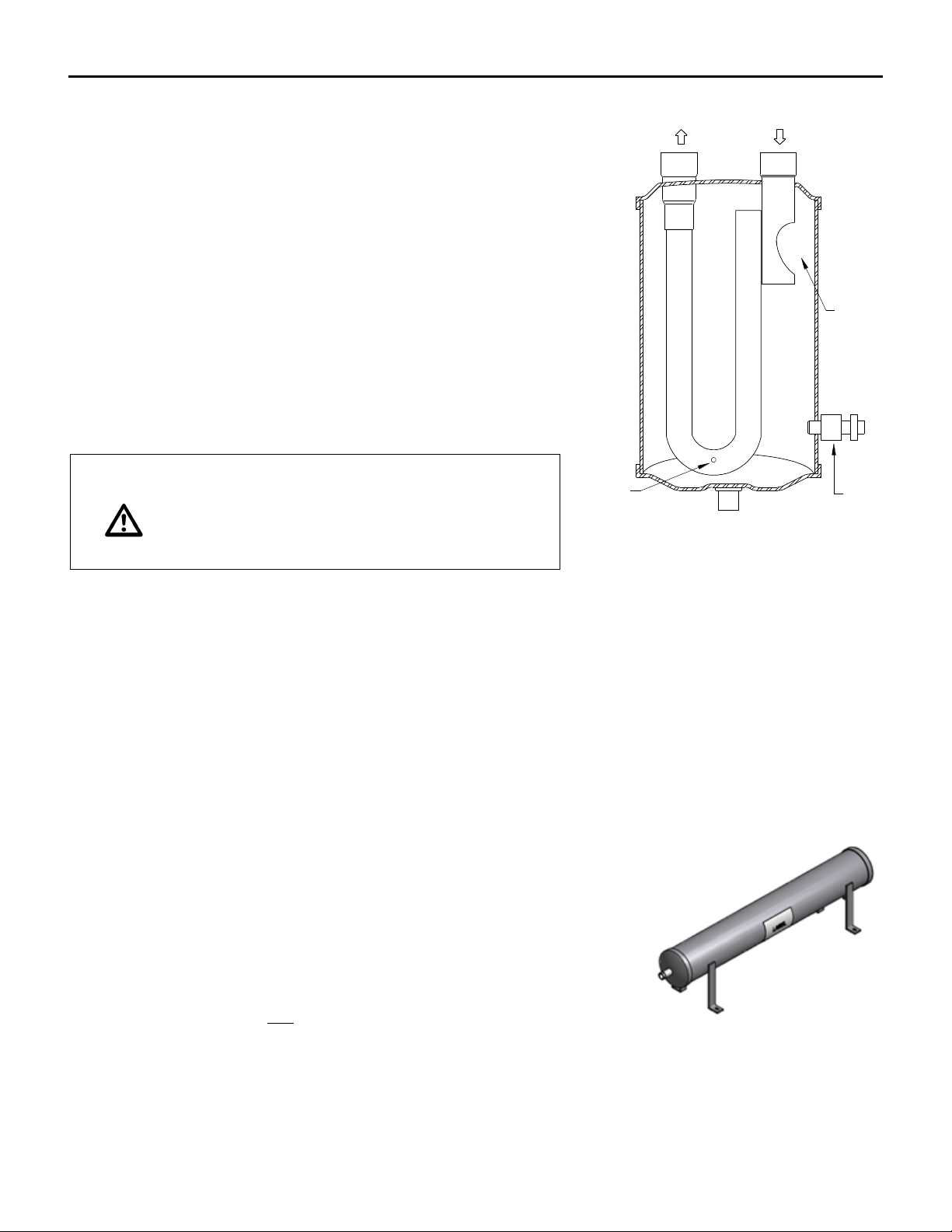

PIPING RECOMMENDATIONS...........................................................................................................................................8

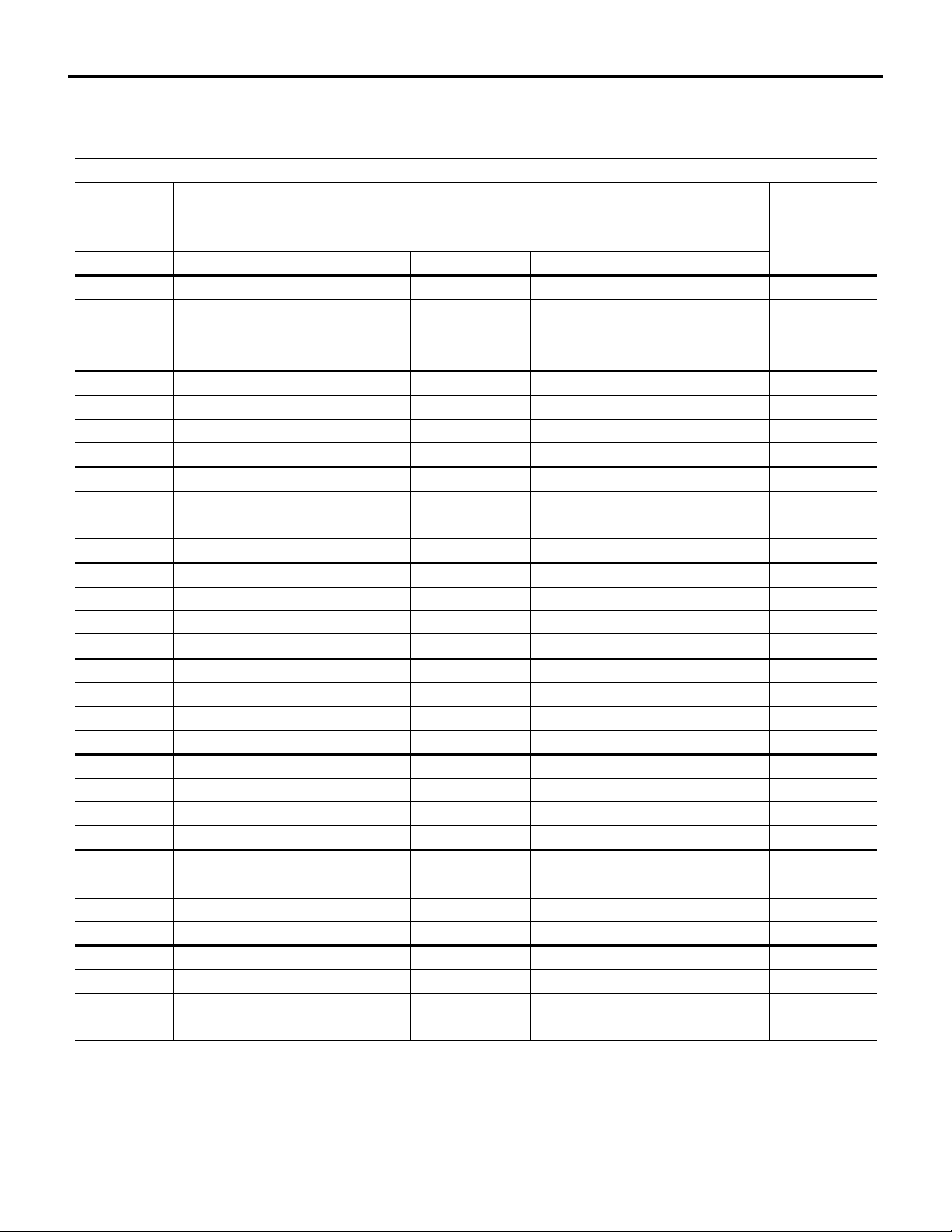

PIPE SELECTION PROCEDURE .........................................................................................................................................17

PIPING MATERIALS AND PROCEDURES ..........................................................................................................................23

CLEARANCE FOR CONDENSER AIR FLOW .......................................................................................................................25

LIFTING............................................................................................................................................................................26

MOUNTING.....................................................................................................................................................................26

SHIPPING MATERIALS.....................................................................................................................................................27

ASSEMBLY.......................................................................................................................................................................27

PIPING, ELECTRICAL OR CONTROL SERVICE CONNECTIONS...........................................................................................27

ELECTRICAL INSTALLATION.............................................................................................................................................28

BEFORE START-UP ..........................................................................................................................................................29

START-UP CHECK LIST.....................................................................................................................................................29

INITIAL START-UP............................................................................................................................................................33

CHARGING ......................................................................................................................................................................33

OPERATION.....................................................................................................................................................................34

SHUTDOWN PROCEDURE...............................................................................................................................................35

MAINTENANCE ...............................................................................................................................................................36

ELECTRICAL .....................................................................................................................................................................36

BELT ADJUSTMENT .........................................................................................................................................................36

BEARING SETSCREW TORQUES.......................................................................................................................................38

FILTERS............................................................................................................................................................................41

CONTROLS ......................................................................................................................................................................42

OUTDOOR AIR INTAKES, MIXING SECTIONS AND DAMPERS..........................................................................................42

REFRIGERATION..............................................................................................................................................................42

TROUBLESHOOTING CHART...........................................................................................................................................45

© Airtex Manufacturing Partnership. All rights reserved.