Installing the Indoor Unit Body to the Wall Hanging

Bracket

1. Pass the pipes through the wall sleeve and then hook the

indoor unit body on top of the wall hanging bracket.

2. For left-hand piping, bang the unit on top of the wall

hanging bracket and incline the unit using a tool such as a

screwdriver set between the middle area of the body and

bottom right of the wall hanging bracket. Connecting the

pipe can be done more easily if the unit is inclined.

3. F-LXthe bottom part of the unit to the wall hanging bracket

by pushing it carefully until the two bracket hooks fit into

the marked places at the base of the unit until it snaps into

place. Refer to Fig. 13.

NOTE:

Do not crush or kink the indoor piping. Avoid sharp bends

with a bend radius of less than 4 inches.

Do not over bend the same part of the pipe frequently.

•Do not remove the flare nut from the indoor unit pipe until

the piping is connected.

through a wall, seal the opening so that vibration is not transmit-

ted to structure. Leave some slack in refrigerant tubes between

structure and outdoor unit to absorb vibration.

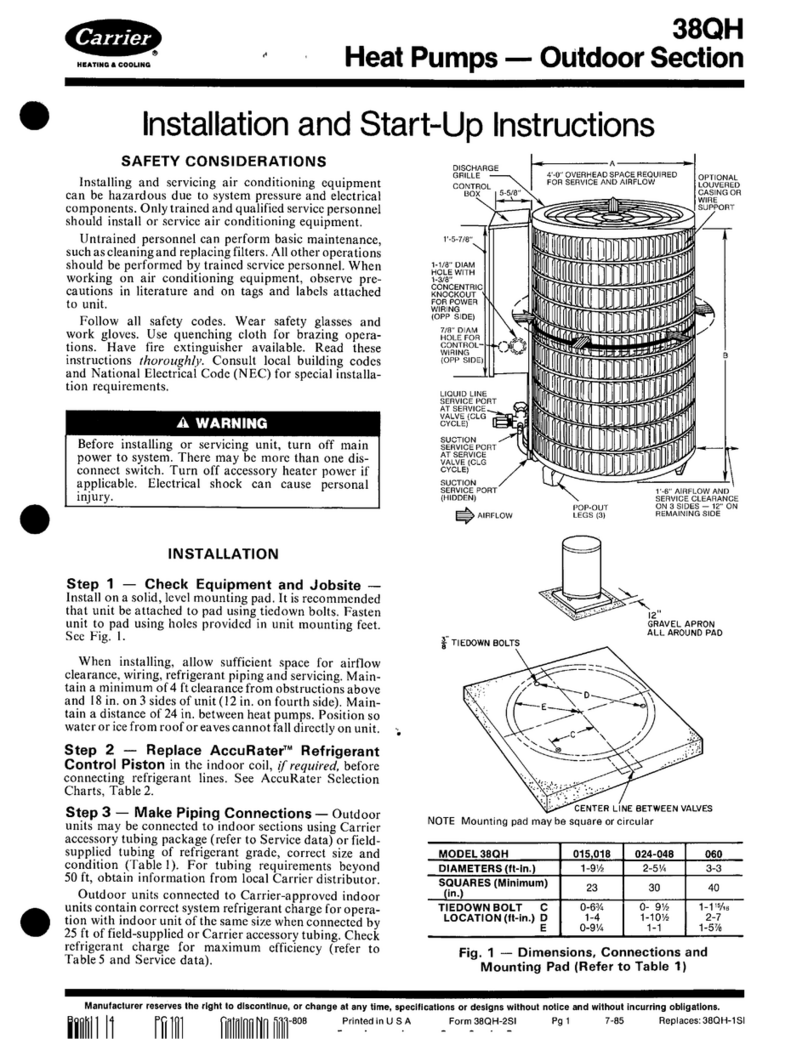

MAKE PIPING SWEAT CONNECTIONS -- Remove plas-

tic caps from liquid and suction service valves. Use refrigerant

grade tubing.

Position tube end downward and cut the tube to the request-

ed length. Remove the burrs with a reamer. See Fig. 14.

NOTE: Oil in the compressor is extremely susceptible to mois-

ture absorption. Keep ends of tubing sealed during installation.

Remove flare nuts from the unit connections and place them

on the tube end. Flare the tube with the flaring tool. The flare

end must not have any burrs or imperfections. The length of the

flared walls must be uniform. See Fig. 15.

Lubricate the tube end and thread of the flare fitting with

antifreeze oil. "tighten the fitting several turns, then tighten it

fully with two wrenches by applying the tightening torque indi-

cated in Table 4 and Fig. 16.

Hole

?

/

!

/

/

Insufficient tightening torque will cause gas leaks. Over-

tightening the fittings will damage the tube flaring and

cause gas leaks. Equipment damage and personal injury

may result.

NOTE: Unit is shipped with R-410A factory charge indicated

on nameplate.

AIR PURGING AND LEAK TEST -- Only use a vacuum

pump to purge air from the piping. Refer to Fig. 17.

IMPORTANT." Do not use the system compressor as a

vacuum pump.

IMPORTANT: Do not use the unit refrigerant gas to purge I

the connecting pipes. I

Retainer Retainer

Clip Clip

]LIfL _lrl.

Fig. 13- Wall Hanging Details

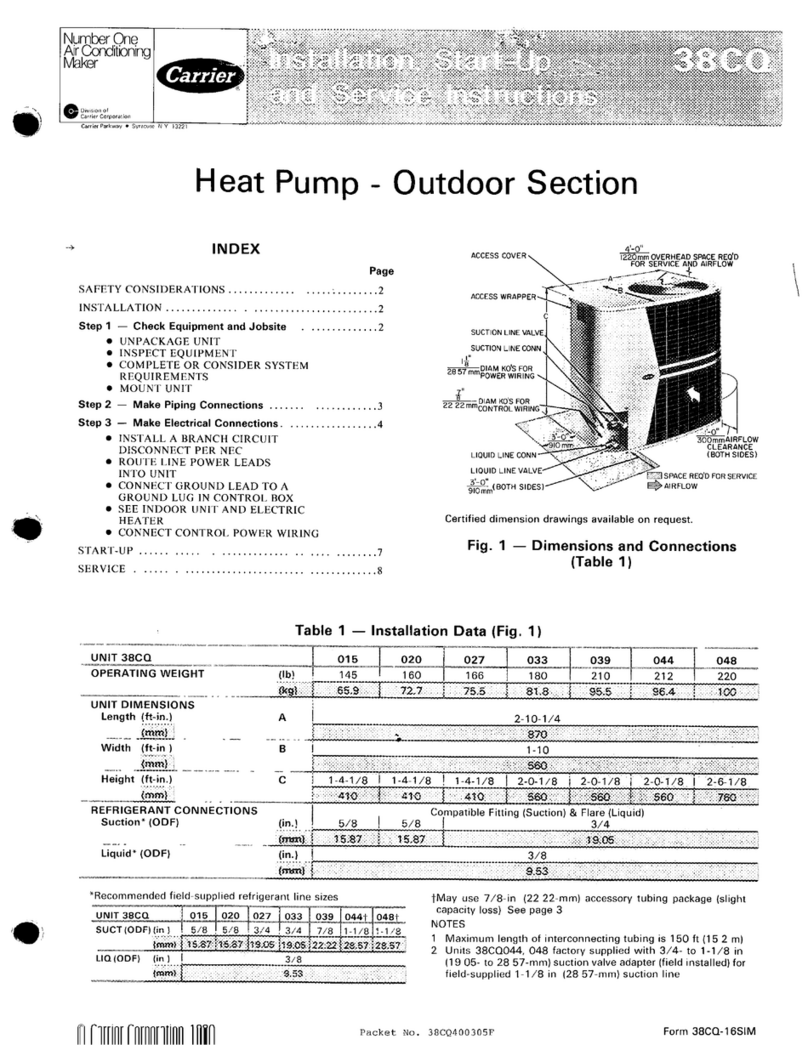

OUTDOOR UNITS- Outdoor units may be connected to

indoor units using field-supplied tubing of refrigerant grade

and condition. See Table 3A for correct line sizes. Do not use

less than 10 ft of interconnecting tubing.

DO NOT BURY MORE THAN 36 IN. OF REFRIGER-

ANT PIPE IN THE GROUND. If any section of pipe is

buried, there must be a 6-in. vertical rise to the valve

connections on the outdoor unit. If more than die

recommended length is buried, refrigerant may migrate to

cooler, buried section during extended periods of system

shutdown. This causes refrigerant slugging and could

possibly damage the compressor at start-up.

If either refrigerant tubing or indoor coil is exposed to

the atmosphere, the system must be evacuated following good

refrigeration practices.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes so they

do not damage insulation on vapor tube and do not transmit

vibration to structure. Also, when passing refrigerant tubes

Remove the caps from the valves. Create a vacuum with a

vacuum pump connected to the ser-(lce connection of the

suction shut-off valves completely shut until a 50 Pa vacuum

has been reached.

Open the mixed phase valve for 3 seconds, then quickly

shut it to check for possible leaks.

Replace caps and check for leaks using a leak detector

spe(lfiC for R-410A refrigerant.

After the leak test, fully open the three-way valves.

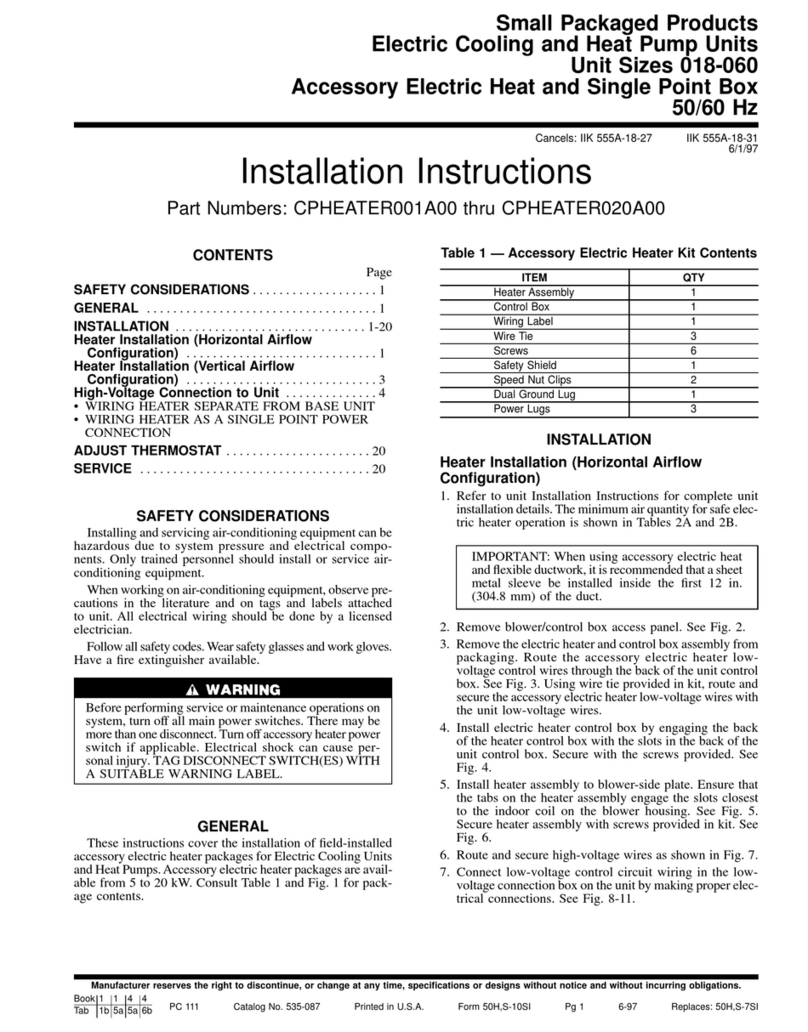

Table 4 -- Tightening Torque

VALVE SIZE FLARE NUT (in.-Ib)

1/4in. 159

s/sin. 372

112in. 487

Fig. 14- Removing Burrs