ENSIM SENSORS ELC 09 User manual

OPERATING

MANUEL

LEVEL SENSOR -

Conductivity Type

ELC

Model :

Model : 23-2022-008

Information in this manual is reviewed and completely reliable. Responsibility is not assumed due to any typing error.

Products in this manual are available only for information purpose and they may be changed without notice.

1

ELC 09 , ELC 09f , ELC 09m

ELC 10 , ELC 10m

ELC 11 , ELC 11m

ELC 12 , ELC 13 , ELC 14

ELC 20

ELC 20f

Models :

Table of Contents :

General Information...........................................................................................................................................................................2

Installation .........................................................................................................................................................................................5

Failure Detection..............................................................................................................................................................................8

Disassembly of Instrument ............................................................................................................................................................8

Service .............................................................................................................................................................................................8

Recalibration....................................................................................................................................................................................8

Repair................................................................................................................................................................................................8

Disposal ...........................................................................................................................................................................................8

Terms of Warranty ..........................................................................................................................................................................8

Terms of Return ................................................8

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Important Notes:

Used Symbols :

: Caution : Note : Disposal

Please read this manual carefully before installation of the level sensor. User is responsible for accidents and losses arising

from failure to comply with the warnings in this manual.

In the event that level sensor is broken, take measures in order to prevent accidents and losses which can occur in its system.

There is not any fuse and circuit breaker on the instrument; they should have been added to the system by the user.

This manual should be stored in an easily accessible place for subsequent use.

The manufacturer's liability cannot exceed the purchase price of the device according to the law.

Do not make any modification on the instrument and do not try to repair it. Reparation should be made by authorized service staff.

Do not operate the system before making assembly in compliance with the assembly chart related to the instrument.

Products which do not contain label and serial number are considered to be excluded from the warranty scope.

The instrument's useful life, determined and announced by the ministry, is 10 years.

2

1. General Information :

1.1. Material Acceptance

Check that there is no damage on the packages during the transportation immediately after the material acceptance. If packages are

damaged, open the packages immediately and check whether products are affected or not, if there is any damage, send your

complaint report to the transporter company and its photocopy to the address of our company.

1.2. Information about Areas of Use

ELC level switches are used for checking liquid level of tanks and boilers. As it does not have any movable part, it can be used in the

critical ambient and in the liquids with solid particle, low density and high viscosity.

lt is an economic and safe solution for air pressure tank applications, water level control of steam boilers and conductive tanks.

Ambient Conditions: Relative Humidity: 5-95 %RH Ambient temperature: 50C (It is not used under -5 C)

1.3. Working Principle

When liquid leved comes to the level of isolated electrode, current passage starts or stops between electrode and

liquid. Strengthened this AC current may be assesed with a relay cirruit.

1.4. Technical Specifications and Pictures:

All dimensions are given in mm.

Advantages :

* Economical

* Easy to install

* Used at high temperatured

ELC 09 ELC 09mELC 09f

L=50 mm (Std.)

L

HEX 24

M4

Ø6

R

Delrin

R

Ø6

L=175 mm (Std.)L=40 mm (Std.)

Ø10

HEX 24

Ø5

R

L

L

Technical Specifications :

Electrode Material

Isolation of Electrode

Connection Material

Max. Working Temp.

Max. Working Pressure

Mechanical Connection

Electrical Connection (R)

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

180 °C

10 bar

3/8" BSP / 1/2" BSP

Cable

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

160 °C

16 bar

3/8" BSP / 1/2" BSP

DIN 43650C

304 Stainless Steel

Opt.316 Stainless Steel

Makaron

304 Stainless Steel

60 °C

6 bar

3/8" BSP (Std)

Cable

ELC 20fELC 13 ELC 14

L=80 mm (Std.)

HEX24

L

Ø4

Ø8

R

Seramic

NBR

L= 150 mm (Std.)

L

Ø8

PTFE

R

60.7

L= 150 mm (Std.)

L

Ø8

PTFE

R

114

3

All dimensions are given in mm.

ELC 11 / ELC 11mELC 10 ELC 12ELC 10m

Ø8

PTFE

L

R

L= 150 mm (Std.)L= 150 mm (Std.)

L= 75 mm (ELC 11m )

L= 150 mm (Std.)

NBR

R

Polycarbonate

Ø5

L

L= 75 mm (Std.)

L

R

Ø5

NBR

PTFE

L

R

Ø8

Technical Specifications :

304 Stainless Steel

Opt.316 Stainless Steel

PP (Reinforced)

PP (Reinforced)

NBR

160 °C

10 bar

1/2" BSP(Std) 1/4" BSP(Std)

Cable

Electrode Material

Isolation of Electrode

Connection Material

Housing

Max. Working Temp.

Max. Working Pressure

Mechanical Connection (R)

Electrical Connection

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

Aluminum Injection IP 65

225 °C

16 bar

1/2" BSP(Std)

Cable

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

Delrin

225 °C

40 bar

1/2" BSP(Std)

PG 7

Electrode Material

Isolation of Electrode

Connection Material

Housing

Max. Working Temp.

Max. Working Pressure

Mechanical Connection (R)

Electrical Connection

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

-

220 °C

30 bar

3/8" BSP / 1/2" BSP (Std)

Cable

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

304 Stainless Steel

Opt.316 Stainless Steel

225 °C

16 bar

1/2" BSP (Std)

Cable

304 Stainless Steel

Opt.316 Stainless Steel

PTFE

304 Stainless Steel

Opt.316 Stainless Steel

Aluminium Enj

IP 66

225 °C

16 bar

1/2" BSP (Std)

Cable

ELC 20

R

PP

L

4

Technical Specifications :

LEVEL CONTROL RELAY

SK-P3

4 pcs. 5 A

Independent Relay

SK-P4

1 pc. 5 A Start - Stop Relay

2 pcs. 5 A Min. - Max. Relay

+

Electrode Material

Body Material

Max. Working Temp.

Max. Working Pressure

Mechanical Connection (R)

Electrical Connection

304 St.St.

Opt.316 St.St , Titanium

PP

85 °C

10 Bar

3/4 BSP Male Thread

2 m. Cable , PG 7

L=85 mm

(Stable)

Mark

Serial Number

Model Number

5

2. Installation :

2.1. General Notes

Installation of the instrument should be made only by authorized personnel.

Do not apply force to the instrument during the installation!

Do not use the level indicator with a greater pressure than recommended pressure.

Do not forget that instrument is precise, carry it carefully and prevent to be damaged.

It should be guaranteed that there are not any magnetic particles.

2.2. General Installation Stages

*Remove Level Sensor from the box carefully

*Check whether gasket is appropriate for fluid or not. If is not appropriate, contact with the producer.

*Then, apply below mentioned explanations according to structure of the design.

2.3. Special Notes

*Please ensure that there is no mechanical stress on the shaft following installation. Such case will cause slipping in thecharacteristic curve.

*Level Sensor must be placed upright or horizontal.

*In the operating conditions, Level Sensor may be hot according

to situation of fluid, in this case, do not touch the indicator, otherwise your skin is damaged.

2.4. Installation For Mechanical Connections

*Use appropriate O-Ring or gasket for tightness.

*Ensure that its surface is clean and smooth.

*Assemble the instrument manually.

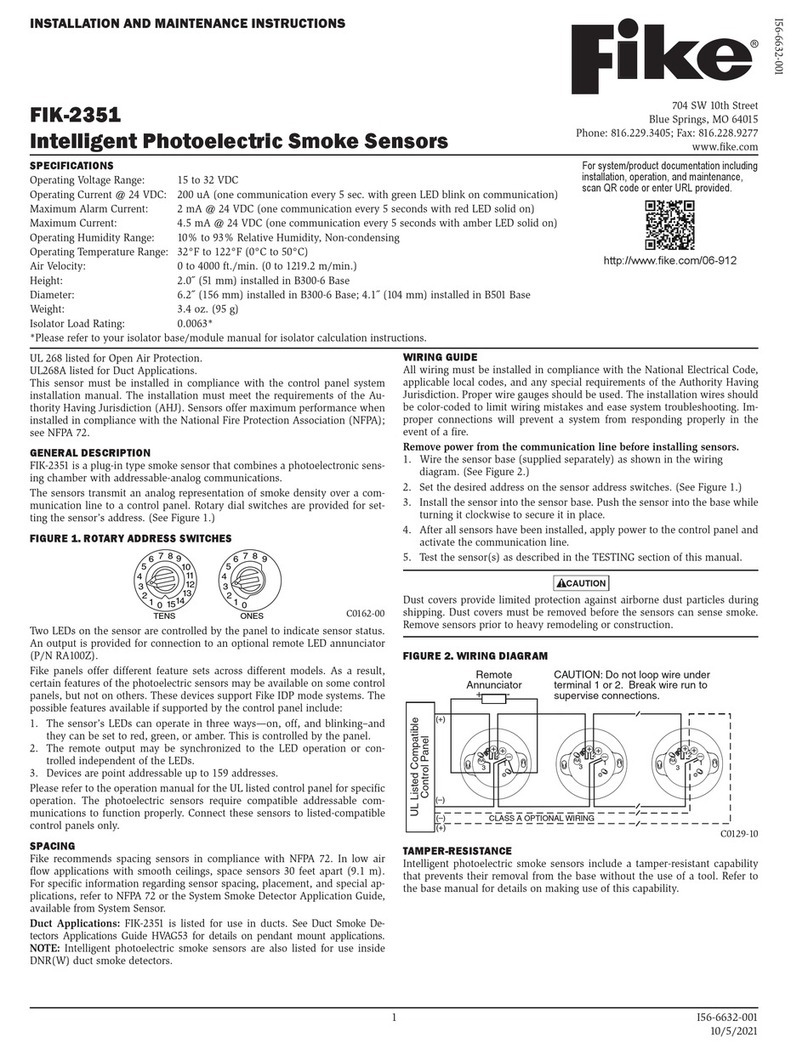

*Connect the contacts as shown in the figure.

(For G1/2" max. 20 Nm , For G2" max. 20 Nm)

2.5. Electrical Installation

Make the electrical connection of the instrument according to details on its label, table and cable figures in this manual

1.6. Target Group

This operating manual has been prepared for qualified technical personnel.

1.7. Security Notes

The following notes must be observed to avoid hazards to the operator and her/his surroundings.

Installation, use and maintenance of this device should only be done by people who have read the user manual and are knowledgeable about occupational safety!

Occupational safety rules, accident prevention regulations and national installation standards must be obeyed

The product should only be used within its specifications!

You can only mount the device when there is no pressure!

1.8. Package and package contents :

Please check whether you have taken delivery of below listed content completely or not and check

its conformity with criterions in your order:

* Level Sensor

* This operating manual

6

Order Form : Please consider sample models when coding!..

Small Boiler Type............................................09f

Small Type with Socket....................................09

Textile Type.................................................09m

Economic Type............................................10

Economic Mini Type.....................................10m

MODEL ELC

1

None....................................................................0

CERTIFICATE

2

High Temperature Type..........................................11

HighTemperature Type with Aluminum Housing...12

High Temperature Type With Stainless Steel Housing ....... 13

High Temperature IP 65........................................................14

Boiler Type.........................................................20f

Water Leakage Type.............................................................20

CONNECTION

3

CONNECTION MATERIAL

4

1/4"BSP .......................................................0002

3/8"BSP ........................................................0003

1/2"BSP ........................................................0004

3/4" BSP.............................................................0005

Special.....................................................................x

304 Stainless Steel..........................................001

316 Stainless Steel..........................................002

PP .......................................................................021

Special.....................................................................x

ELECTROD MATERIAL

5

None....................................................................0

HOUSING

6

ELECTRICAL CONNECTION

7

Polyamide Small Socketed P01........................51

PVC Cable (Max. 105 °C).................................81

Silicon Cable (Max. 200 °C)..................................82

With Cable.............................................................99

Special.....................................................................x

OPTIONAL

8

None................................................................../ 0

Aluminum Housing , B96x...................................853

Aluminum Housing , B22x...................................750

Special.....................................................................x

Level Control Device...................................../ SK-P3

Level Control Device...................................../ SK-P4

Special.................................................................../ x

SAMPLE :

304 Stainless Steel..........................................001

316 Stainless Steel..........................................002

Titanum...........................................................009

Special.....................................................................x

(EN10204-3-1) Material Certification ..........................1

ELC 09f - 0 - 0002 - 001 - 001 - 0 - 99 - 0

ELC 09f - 3/8 BSP Connection and Electrod - 304 Stainless Steel - Cable Output

2.6.

7

2.7.

Do not connect the switch in reverse.

Their characteristics may vary.

Vibration might be caused instability. When opening the upper part of the housing

not to break the connection plastic

please note.

Please keep away from magnetic materials

like iron board ; otherwise the

characteristics might be affected

Do not pull the cable strongly,

otherwise the characteristics

might be changed.

In case vapour splash cable

potting points,insulation

problem may cause.

Please do not dip cables

potting into liquids,otherwise

instulation problem may cause.

Do not fasten switch reversely ,

otherwise its characteristics

might be changed.

Fluids that can damage the material

keep away.

WARNING !!!

Please pay attention to following matters in order to operate your flow switch properly.

8

Breakdown

3. Failure Delection

Probable cause Failure detection \ Correction

If you find an error, try to eliminate it by using this table or send the instrument to our service address for repair.

The instrument should be repaired only by authorized service! Serial number shall be indicated to the authorized service center.

4. Disassembly of Instrument

Instrument should be disassembled while feeding and pressure is not available!

5. Service

6. Re-Calibration

During long period usage of level switch, there might be deviations on measurements. In those cases, recalibration is recomended. Re-calibration could be made by your

technical staff or you could send to manufacturer company. According to IEC 60017, ex proof devices must be go through detailed inspection every 3 year from purchase

date.Respobsibility of inspections are belong to the user ( IEC: International Electrotechnical Commission)

7. Repair Manufacturer Address

If irreparable breakdowns occur, the instrument should be sent to us for repair purpose. Before this, the instrument should be cleaned carefully and packaged

so as not to be broken. Furthermore, you should also add a detailed explanation which describes the breakdown while instrument is sent. If your instrument

contacts with harmful substances, decontamination report should be also sent additionally. In the event that instrument does not have any decontamination

report or our service department has doubts about instrument, repair process will not start until an acceptable report is sent.

8. Disposal

The instrument should be disposed according to 2002/96/EC and 2003/108/EC European Directives (waste electrical and electronic instruments).

Waste electrical and electronic equipment should not be mixed with domestic wastes!

If the instrument has contacted with harmful substances, special attention should be paid for its disposal!

9. Terms of Warranty

The instrument has warranty legally for 24 months after delivery date. Warranty demands are not accepted in case of inappropriate operation, damage on the

instrument or any modification on the instrument.

10. Terms of Return

In the return of materials, user should send an open list related to damage or problem, malfunction of the material to be returned or its operation in the different

modification, with the instrument. If it is required to return the material, used in the dangerous, corrosive or toxic fluid, in this case, used part should be cleaned

very carefully. Security of personnel should be ensured. All products to be returned should be sent to our company address, which

we have stated.

The instrument does not require maintenance. If it is desired, residue accumulated inside should be blown according to kind of fluid and instrument can be cleaned

with soft cleaning solutions. Measures should be taken during the disassembly.

If the instrument contacts with hazardous substances, necessary measures should be taken for decontamination!

Service -Manufacturer Company Name and Address:

LONCA MAK. SAN. TÝC. A.Þ. Ferhatpaþa Mah. Gazipaþa Cad. No: 104A Ataþehir - ÝSTANBUL - TÜRKÝYE

Probe Does Not Produce

Resistance Output

- Liquid might not be contacted.

- Plugs of the probe might be too relaxed.

- There migh be a break in process wire.

- Probe might be dissolved due to chemical substance.

- Liquid contact should be checked.

- Plugs should be checked.

- Process wire should be checked.

- Contact with the manufacturer.

High Resistance Output -Probes have short-circuited

- The wires used in process is not suitable

- Dirt has stacked on probes due to maintenance neglect

- The nut on probe thread have overly screwed

inside of housing

- Proper connection cable should be used.

- According to liquid, periodic maintenance

should be sustained.

-Pressure was applied above its value.

-Product was subjected to sudden pressure.

-Inform authorized service.

-Choose a model suitable for pressure.

Fluid is leaking

This manual suits for next models

11

Table of contents

Other ENSIM SENSORS Security Sensor manuals

Popular Security Sensor manuals by other brands

Larson Electronics

Larson Electronics SLEDB-110V-30C-XMS quick start guide

Xiaomi

Xiaomi Mijia PM 2.5 user manual

Vimar

Vimar Eikon 20181 manual

Indexa

Indexa FD01 Operating and safety instructions

Renkforce

Renkforce 751560 operating instructions

System Sensor

System Sensor 5151 Installation and maintenance instructions