envea SM-4 User manual

Manual

Mercury Stack Monitor

SM-4

with integrated

Calibration Unit

MC-3000

Version 4.7

N:\Bedienungsanleitungen-Serviceanleitungen\SM-4\SM-4 + MC3000 E V4.7.doc

Manufacturer: ENVEA GmbH

Liebigstrasse 5

85757 Karlsfeld/Germany

[email protected]lobal

© 2022 by ENVEA GmbH, Karlsfeld (Germany

SM-4 page 2

General Safety Instructions

While operating the SM-4, parts of its interior are under high voltage and UV-beams

are produced inside the photometer. If safety regulations are ignored physical and/or

material damages could occur. Only qualified personnel should be allowed to

operate the SM-4. Following conditions for correct function of the SM-4 are to be

held: careful and correct storage, proficient operation and maintenance.

Do not operate instrument if it is damaged.

When connecting the SM-4 system to a power source please note the related

safety regulations.

The SM-4 should be operated from the type of power source indicated on the

rating plate.

Make sure that the power cords are not damaged.

Regulations for prevention of accidents are to be followed.

Before opening the SM-4 system disconnect it from the mains power supply.

Repairs and maintenance on the opened and powered instrument should only be

carried out by trained personnel.

Operate the SM-4 on a stable and dry surface. The interior of the SM-4 should

never get moist or wet. In case it happens, consult an expert.

The SM-4 is dedicated for the measurement of mercury concentration in stack

gases. Do regard the related dangers especially while operating with toxic gases.

Make sure that these parts of the instrument guiding the gas are not damaged

and that the gas is guided back to the source or into an appropriate absorber.

The SM-4 must not be used to measure explosive gases and must not be

operated in hazardous areas.

SM-4 page 3

Contents

1. GENERAL DESCRIPTION............................................................................................................................6

1.1 FIELDS OF APPLICATION.................................................................................................................................6

1.2 PRINCIPLE OF OPERATION..............................................................................................................................6

1.3 TYPICAL ARRANGEMENT...............................................................................................................................7

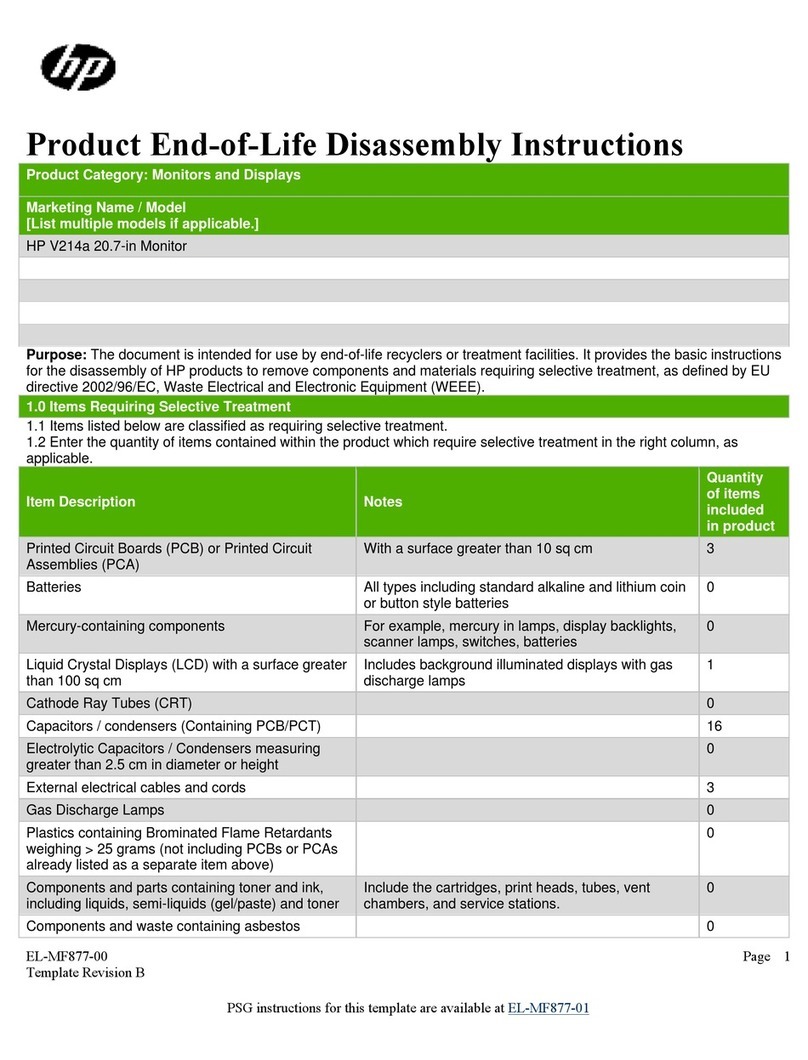

2. COMPONENTS OF THE SM-4 .....................................................................................................................8

2.1 GAS FLOW DIAGRAM................................................................................................................................8

2.2 SAMPLING PROBE..........................................................................................................................................9

2.2 SAMPLING PROBE..........................................................................................................................................9

2.3 PROBE CONTROLLER UNIT ..........................................................................................................................11

2.4 HEATED BUNDLE.........................................................................................................................................13

2.5 ANALYZER CABINET ...................................................................................................................................14

2.5.1 Mercury Detector.................................................................................................................................16

2.5.2 Calibration Gas Generator..............................................................................................................17

3. INSTALLATION............................................................................................................................................19

3.1 PLACE FOR INSTALLATION...........................................................................................................................19

3.2 INSTALLATION OF THE SAMPLING PROBE....................................................................................................20

3.3 ELECTRICAL CONNECTIONS.........................................................................................................................22

3.3.1 Power Supply of the Analyzer Cabinet ................................................................................................22

3.3.2 Heated Bundle Power Connection.......................................................................................................24

3.3.3 Power Supply of the Probe Controller Unit.........................................................................................25

3.3.4 Communication Connection of Probe Controller Unit to Analyzer Cabinet. ......................................27

3.3.5 Connection of Probe and Probe Controller.........................................................................................27

3.3.6 Signals: Analyzer cabinet Connector Strip X2 ....................................................................................28

3.3.7 Analog 4-20 mA Signal........................................................................................................................29

3.3.8 Status Signals.......................................................................................................................................29

3.3.9 External Cleaning Function.................................................................................................................29

3.3.10 Serial Data Output (RS 232)..............................................................................................................30

3.4 HOSE CONNECTIONS....................................................................................................................................31

3.4.1 Air Connection.....................................................................................................................................31

3.4.2 Outgoing Gas of the Analyzer Cabinet (Gas OUT) .............................................................................32

3.4.3 Connection of the Heated Bundle to the Analyzer Cabinet..................................................................32

3.4.4 Connection of the Heated Bundle to the Probe....................................................................................34

3.5 INSTALLATION OF THE PROBE......................................................................................................................36

3.6 CONNECTING THE CONVERTER WITH THE PROBE CONTROL UNIT...............................................................38

3.8 LEAKAGE TEST............................................................................................................................................39

3.9 SIGNAL OUTPUT ..........................................................................................................................................39

3.9.1 Analog Output Signal (4-20 mA) .........................................................................................................39

3.9.2 Status Signals.......................................................................................................................................39

4. SETTING THE SYSTEM INTO OPERATION..........................................................................................41

4.1 SWITCHING THE POWER ON .........................................................................................................................41

4.2 MAIN MENU ................................................................................................................................................42

4.3 START MEASURING .....................................................................................................................................42

4.3.1 Sampling..............................................................................................................................................42

4.3.2 Zeroing.................................................................................................................................................43

4.3.3 Heating ................................................................................................................................................43

4.3.4 First Trap Cooling...............................................................................................................................43

4.3.5 Trap Cleaning......................................................................................................................................43

4.3.6 Second Trap Cooling...........................................................................................................................43

4.4 PARAMETRIZATION......................................................................................................................................44

4.4.1 Sample Volume ....................................................................................................................................45

4.4.2 Measuring Range.................................................................................................................................45

4.4.3 Set System Check .................................................................................................................................46

SM-4 page 4

4.4.4 Set Calibration Device.........................................................................................................................48

4.4.5 Set Probe Purge Duration ...................................................................................................................48

4.4.6 Set External Cleaning..........................................................................................................................49

4.4.7 Set Orifice Cleaning Duration.............................................................................................................49

4.4.8 Set Fan Temperature ...........................................................................................................................50

4.4.9 Speciation (if this option is installed) ..................................................................................................50

4.5 CALIBRATION ..............................................................................................................................................51

4.5.1 Show actual calibration.......................................................................................................................51

4.5.2 Show all calibrations ...........................................................................................................................52

4.5.3 Perform new calibration......................................................................................................................52

4.6 DATA LOGGER.............................................................................................................................................53

4.6.1 Show Measurements ............................................................................................................................54

4.6.2 Show Error Records ............................................................................................................................54

5. SERVICE ........................................................................................................................................................55

5.1 SET DATE AND TIME....................................................................................................................................56

5.2 DEVICE DATA..............................................................................................................................................57

5.3 SHOW INSTRUMENT STATUS........................................................................................................................58

5.3.1 Show Analyzer Status...........................................................................................................................58

5.3.2 Show Probe Status...............................................................................................................................59

5.3.3 Status of the MC-3000.........................................................................................................................60

5.4 MANUAL TEST OF COMPONENTS.................................................................................................................60

5.4.1 Test Analyzer Components...................................................................................................................61

5.4.2 Test Probe Components.......................................................................................................................63

5.4.3 Test MC-3000 Components .................................................................................................................63

5.4.4 Leakage Check.....................................................................................................................................64

5.5 SET MEASURING CALIBRATION...................................................................................................................66

5.6 SET STATUS CONTACTS...............................................................................................................................66

5.7 SET OFFSETS................................................................................................................................................67

5.8 SEND SETTINGS TO RS232...........................................................................................................................67

5.9 SET LANGUAGE ...........................................................................................................................................67

6. CALIBRATION UNIT MC-3000 INTEGRATED IN SM-4 ......................................................................68

6.1 GENERAL INFORMATION FOR SAFE OPERATION ...........................................................................................68

6.2 OPERATION PRINCIPLE.................................................................................................................................69

6.3 SOFTWARE MC-3000 ..................................................................................................................................69

6.3.1 Device Data.........................................................................................................................................71

7. SERVICE AND MAINTENANCE ...............................................................................................................72

7.1 ROUTINE MAINTENANCE.............................................................................................................................72

7.2. SPARE PARTS/WEAR PARTS.......................................................................................................................72

7.2.1. UT-3000 Detector...............................................................................................................................73

7.2.2. Tubing inside the photometer .............................................................................................................75

7.3 LEAKAGE CHECK.........................................................................................................................................75

7.4 UFO-FILTER EXCHANGE..............................................................................................................................78

7.5 EXCHANGE OF THE CATALYTIC CONVERTER...............................................................................................79

7.6 CLEANING OF THE SAMPLE TUBE ................................................................................................................80

7.7 EXCHANGE OF THE GOLDTRAP....................................................................................................................80

7.8 EXCHANGE OF THE FILTERS AND OF THE ACTIVATED CHARCOAL IN THE PHOTOMETER..............................81

7.9 EXCHANGE OF THE DUST FILTER..................................................................................................................83

7.10 ERROR MESSAGES......................................................................................................................................85

7.11.1 Error message: HEATING FLOW! ...................................................................................................85

7.11.2 Error message: SAMPLING FLOW!.................................................................................................85

7.11.3. Error message: LAMP!.....................................................................................................................85

7.11.4. Error message: LOW INPUT PRESSURE! ......................................................................................85

7.11.5. Error message: TEMP PROBE!.......................................................................................................86

7.11.6 Error message GOLD TRAP!............................................................................................................86

SM-4 page 5

8. APPENDIX .....................................................................................................................................................87

8.1 DATA OUTPUT VIA RS232 SERIAL COMMUNICATION..................................................................................87

8.2 DISPLAY OVERVIEW....................................................................................................................................90

8.3 ELECTRIC FUSES ..........................................................................................................................................93

8.4. SAFETY DATA SHEET..................................................................................................................................94

SM-4 page 6

1. General description

1.1 Fields of application

The SM-4 is the ideal tool for continuous measurement of the mercury concentration in stack

gases from plants like power plants, waste incinerators, sewage sludge incinerators, cement

kilns or recycling furnaces. The SM-4 detects –as standard version- total mercury, i.e.

elemental mercury, ionic mercury, mercury compounds and particle bound mercury. As

option a speciation function is available, this allows separate measurements of elemental and

total mercury, which results in the amount of ionic mercury as the difference of both.

The outstanding features of the SM-4 are high availability, high sensitivity and virtually no

influence from the sample matrix.

1.2 Principle of Operation

The sample is continuously taken from the stack through a heated probe (180°C) by means of

an air-driven ejector pump. It passes through a heated sample filter and is then diluted with

air at a constant ratio. A partial stream of the diluted sample is treated in the thermo-catalytic

reactor where all mercury compounds are cracked and ionic mercury is reduced to the

elemental form. After this the sample travels through the heated sample line and enters the

detector inside the analyzer cabinet.

Basis for determination of the mercury concentration is the resonance absorption of the

mercury (Hg)-atoms at a wavelength of 253.7 nm (AAS, Atomic Absorption Spectroscopy).

A GoldTrap amalgamation system provides mercury pre-concentration and matrix separation.

SM-4 page 7

1.3 Typical Arrangement

The SM-4 measuring system consists of 4 modules:

1) The sampling system with probe, filter, dilution system and thermo catalytic converter

2) The probe controller

3) The heated sample bundle

4) The analyzer enclosure with bypass pump, detector, compressed air conditioning and

the calibrator

Ejector

Pump

Mass flow

controller

Optical Cell

GoldTrap

V1

Zero air

filter

Mercury Detector Sample

out

Sample Conditioning System

heated sample line

Critical

orifice

Ejector pump-

dilutor unit

Thermo-catalytic

reactor

Heated Probe

Dilution

air in

SM-4 Typical Arrangement

Dilution

air out

Elemental Mercury Calibration Gas Generator

Particle

filter

Calibration

valve

Sample in

Mass flow

controller

Mass flow

controller

Air in

Dilutor

saturation

chamber evaporation

chamber

Hg Hg

1

1. Probe with Sample

Conditioning System

4. Anqalyzer Enclosure

with Calibration Unit

3. Heated

Bundle

SM-4 page 8

2. Components of the SM-4

2.1 Gas Flow Diagram

SM-4 page 9

2.2 Sampling Probe

2.2 Sampling Probe

Figure: SM-4 Sampling Probe

The probe comprises two main parts:

(a) the Heated probe, containing inner tubing made of PFA (sample temperature up to

200 °C) or optionally made of SS316 tubing with glass inliner (sample temperature up

to 375 °C),

(b) the Converter Unit with sample dilution system and thermo-catalytic converter.

Both units can easily be disconnected. If the probe has been installed, the box

containing the dilution system and the thermo-catalytic converter can be removed

whilst the probe is remaining at the stack.

heated probe

converter

SM-4 page 10

Specifications Probe

Size and Weight: 14.2” (L) x 14.2” (W) x 26” (H), 79 lbs. (total weight including

mounting flange and heated probe); 62 lbs. (reactor unit only)

Materials: Main enclosure: resin coated aluminum

Structural parts (flange, probe cylinder walls): SS316

Sample wetted parts: ceramic, PFA, glass

Catalytic converter: Proprietary active material, temperature 400 °F (200 °C

Sample temperature: 400 °F max. (200 °C), up to 700 °F (375 °C) as an option

Installation: Mounting flange size: DIN 2527 DN65 PN6 (USA option: 4”

150 lbs.)

Operating temperature: -13 °F to 122 °F (-25 °C to 50 °C)

Power requirements: 230 VAC/50 Hz (USA option: 115 VAC/50/60 Hz) all power

supplied by Probe Controller Unit

Air requirements: Instrument air 6 bar –7 bar (90 psig –100 psig), ~12 l/min

Dilution ratio: 1:40 to 1:50 (1:100 as option for special applications)

Sample flow: 10-12 l/h

Figure: Dimensions of the probe with stinger

SM-4 page 11

2.3 Probe Controller Unit

PROBE CONTROLLER UNIT

The microprocessor driven Probe Controller Unit is mounted close to the sampling probe (1 -

10 feet). It controls the probe and probe temperature (dilution chamber temperature,

calibration valve, sample filter cleaning valve and orifice cleaning valve). The Probe

Controller Unit is easily connected to the sampling probe with two cables by heavy duty plug

connectors and to the analyzer unit with a protected cable. The cable glands are on the bottom

of the probe controller unit. They are all labeled. For the probe controller unit, a power

supply separate from the analyzer cabinet is needed.

Technische Spezifikation der Probensteuereinheit

Size and Weight: 17” (W) x 18” (H) x 26” (D), 30 lbs.

Operating temperature: -13 °F to 122 °F (-25 °C to 50 °C)

Power requirements: 115 VAC/50/60 Hz, 2600 VA

Controlled temperatures: T1: converter = ejector pump, critical orifice and catalyst

temperature

T2: vaporizer= vaporizer temperature (calibrator working with

ionic mercury)

T3: probe tube= heated probe tube temperature

Figure: Fiberglass reinforced polyester housing with temperature controllers and

interface box

SM-4 page 12

Figure: Dimensions of temperature controller box

Figure: Bottom view of the probe controller unit; all cable glands are labelled

SM-4 page 13

2.4 Heated Bundle

A heated tubing bundle is installed connecting the probe and the analyzer cabinet. The bundle

is electrically heated by a self-limiting heater element.

Specifications Heated Bundle

Media

Material

Diameter oD/iD

Colourcode

Calibration gas (elemental Hg)

FEP-Teflon

6/4

transparent

Calibration solution (for ionic Hg)

FEP-Teflon

6/4 with 1/16“/0.5

Inner tube

transparent

Clean air

FEP-Teflon

6/4

yellow

Sample

FEP-Teflon

6/3

red

Spare

FEP-Teflon

6/3

redblack

Vaporizer air (for elemental Hg)

FEP-Teflon

6/4

black

Dilution air

FEP-Teflon

6/4

blue

Dimensions: outer diameter 1.34“ (34 mm), length max. 100 feet (up to 600

feet as an option)

Power requirements: 230 VAC/ 50/60 Hz (option 115 VAC/ 50/60 Hz), 240 W for 30

m (100 feet) length

Operating temperature: -13 °F to 122 °F (-25 °C to 50 °C)

SM-4 page 14

2.5 Analyzer Cabinet

Figure: Measuring system with photometer and calibration gas generators for elemental and

ionic mercury.

SM-4 page 15

The analyzer cabinet is made of metal and has a transparent window on the front side. It

features four lifting eyes and four adjustable feet (see figure in chapter 3.1). The analyzer and

the automatic calibrator are mounted as 19” modules in a swing frame in the upper part,

whereas, the pressurized air conditioning and pressure regulators are mounted in the lower

part.

Technical specifications of the analyzer cabinet

Size and Weight: 63.6” (H) x 31.5” (W) x 23.6” (D), approx. 360 lbs. (total

weight including one automatic calibration unit)

Materials: resin coated aluminum

Detector: UT-3000 Mercury Ultratracer

Operating temperature: 41 °F to 104 °F (5 °C to 40 °C)

Power requirements: 115 VAC/50/60 Hz, 2500 VA (including power supply of 100

feet line bundle

Air requirements: instrument air 94.3 psi (6.5 bar)

Figure: Dimensions of the analyzer cabinet

SM-4 page 16

2.5.1 Mercury Detector

The SM-4 employs the UT-3000 Mercury Ultratracer as detector. A gold trap is used for

mercury enrichment and a UV-photometer for concentration measurement.

Specifications: mercury detector

Size and Weight: 17.7” (W) x 5.9” (H) x 13.8” (D), 26 lbs.

Detection principle: AAS Atomic Absorption Spectrometry with Gold

Amalgamation technique

Wavelength: 253.7 nm

UV source: electrodeless mercury discharge lamp, stabilized by reference

beam

Operating temperature: 41 °F to 104 °F (5 °C to 40 °C)

Power requirements: 230 VAC/50/60 Hz

Measuring range: 0.1 ng/m³ –30000 ng/m³, revealing an effective range before

sample dilution of 0.004 µg/m³ - 1200 µg/m³

Lower detection limit: 1 pg Hg

Sample flow: 40 l/h

Response time: 180 –360 sec (depending on range)

Interference SO2: below LDL

Interference NOx: below LDL

Figure: Photometer internal tubing

SM-4 page 17

Figure: Mercury Detector UT-3000 frontside (above) und backside (below)

2.5.2 Calibration Gas Generator

The system is equipped with an automatic calibration gas generator MC-3000 (Option).

Specifications MC-3000 Calibrator

Size and Weight: 450 (W) x 150 (H) x 350 (D) mm, 8.5 kg

Functional principle: evaporation of elemental mercury, condensation at

equilibrium and dilution

Range: depending on ambient temperature approx. from

15 µg/m3 to 200 µg/m3

Flow control: two thermoelectric mass flow controllers

Operating temperature: 41 °F to 104 °F (5 °C to 40 °C)

Power requirements: 230 VAC/50/60 Hz

Generated calibration

gas flow: 3 l/min to 9 l/min, depending on set concentration

SM-4 page 18

Figure: Mercury calibrator MC-3000 front view (above) and rear view (below)

SM-4 page 19

3. Installation

3.1 Place for installation

Advice: The mercury measuring system SM-4 is for indoor applications

only!

Der ideale

Ideally the place for installation for the SM-4 must be as close as possible to the sampling

point. This avoids long sample lines. The distance between sampling point and analyzer

should be between 3 feet and 100 feet, in special cases up to 300 feet. An unobstructed place

is of advantage for installation and service. The installation location must be free of strong

vibrations and strong electric fields.

The ambient temperature of the installation location for the analyzer cabinet should be in the

range between 32 °F and 100 °F (0 °C ... 38 °C).

The ambient temperature of the installation location for the sampling system and the

temperature controller module should be in the range between -13 °F and 110 °F (-25 °C ...

43 °C).

Caution: The maximal temperature of the sample gas should not exceed

400 °F (200 °C). For applications with higher sample gas temperatures a

special version is available.

Caution: The analyzer cabinet has to be fixed to the ground at the place

of installation. For this the analyzer cabinet has 4 screw holes on the

bottom.

Figure: Position of the

mounting screws for fixing

the analyzer cabinet to the

ground. Next to them are the

5 mm socket head screws of

the adjustable feet.

SM-4 page 20

3.2 Installation of the Sampling Probe

The location for installing the sampling probe has to be according to applicable regulatory

requirements for the setup of CEMs. The probe must not be installed upside down. The

maximal angle is shown in one of the following figures.

Figure: Space required for installation of the probe (view from side)

Table of contents

Other envea Monitor manuals